Peugeot Partner 2011 Owner's Manual - RHD (UK, Australia)

Manufacturer: PEUGEOT, Model Year: 2011, Model line: Partner, Model: Peugeot Partner 2011Pages: 200, PDF Size: 7.41 MB

Page 111 of 200

109

6

Fuel

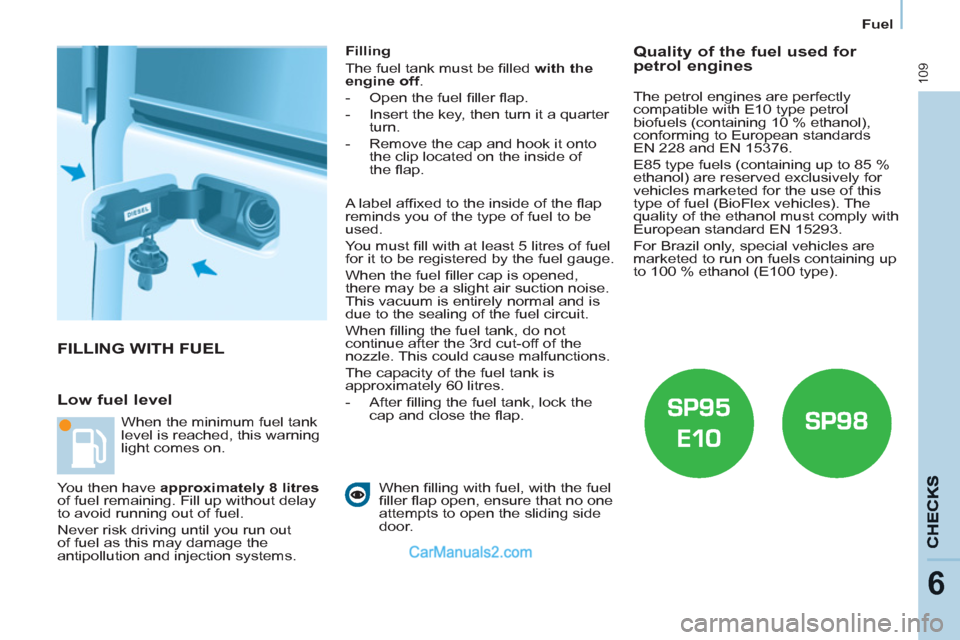

FILLING WITH FUEL

Low fuel level

Filling

The fuel tank must be fi lled with the

engine off

.

- Open the fuel fi ller fl ap.

- Insert the key, then turn it a quarter

turn.

- Remove the cap and hook it onto

the clip located on the inside of

the fl ap.

When fi lling with fuel, with the fuel

fi ller fl ap open, ensure that no one

attempts to open the sliding side

door. When the minimum fuel tank

level is reached, this warning

light comes on.

You then have approximately 8 litres

of fuel remaining. Fill up without delay

to avoid running out of fuel.

Never risk driving until you run out

of fuel as this may damage the

antipollution and injection systems.

Quality of the fuel used for

petrol engines

A label affi xed to the inside of the fl ap

reminds you of the type of fuel to be

used.

You must fi ll with at least 5 litres of fuel

for it to be registered by the fuel gauge.

When the fuel fi ller cap is opened,

there may be a slight air suction noise.

This vacuum is entirely normal and is

due to the sealing of the fuel circuit.

When fi lling the fuel tank, do not

continue after the 3 rd cut-off of the

nozzle. This could cause malfunctions.

The capacity of the fuel tank is

approximately 60 litres.

- After fi lling the fuel tank, lock the

cap and close the fl ap.

The petrol engines are perfectly

compatible with E10 type petrol

biofuels (containing 10 % ethanol),

conforming to European standards

EN 228 and EN 15376.

E85 type fuels (containing up to 85 %

ethanol) are reserved exclusively for

vehicles marketed for the use of this

type of fuel (BioFlex vehicles). The

quality of the ethanol must comply with

European standard EN 15293.

For Brazil only, special vehicles are

marketed to run on fuels containing up

to 100 % ethanol (E100 type).

Page 112 of 200

DIESEL

11 0

Fuel

FUEL CIRCUIT DISARMED

In a serious collision, a mechanism

automatically prevents fuel from

reaching the engine.

The fl ashing of this warning

light is accompanied by a

message on the display.

Check that there is no odour or

leakage of fuel outside the vehicle and

re-establish the fuel supply:

- switch off the ignition (STOP position),

- remove the key,

- put the key back in the ignition,

- switch on the ignition and start.

DIESEL REPRIMING PUMP

If you should run out of fuel, it is

necessary to re-prime the circuit:

- fi ll the fuel tank with at least

fi ve litres of diesel,

- squeeze and release the manual

re-priming pump, under the bonnet

under the protective cover,

- operate the starter until the engine

starts.

Refer to the "Under the bonnet"

section of chapter 6.

Quality of the fuel used for

Diesel engines

The Diesel engines are perfectly

compatible with biofuels which conform

to current and future European

standards (Diesel fuel which complies

with standard EN 590 mixed with a

biofuel which complies with standard

EN 14214) available at the pumps

(containing up to 7 % Fatty Acid Methyl

Ester).

The B30 biofuel can be used in certain

Diesel engines; however, this use

is subject to strict application of the

special servicing conditions. Consult a

PEUGEOT dealer.

The use of any other type of (bio)fuel

(vegetable or animal oils, pure or

diluted, domestic fuel...) is strictly

prohibited (risk of damage to the

engine and fuel system).

11 0

Page 113 of 200

111

QUICK HEL

P

7

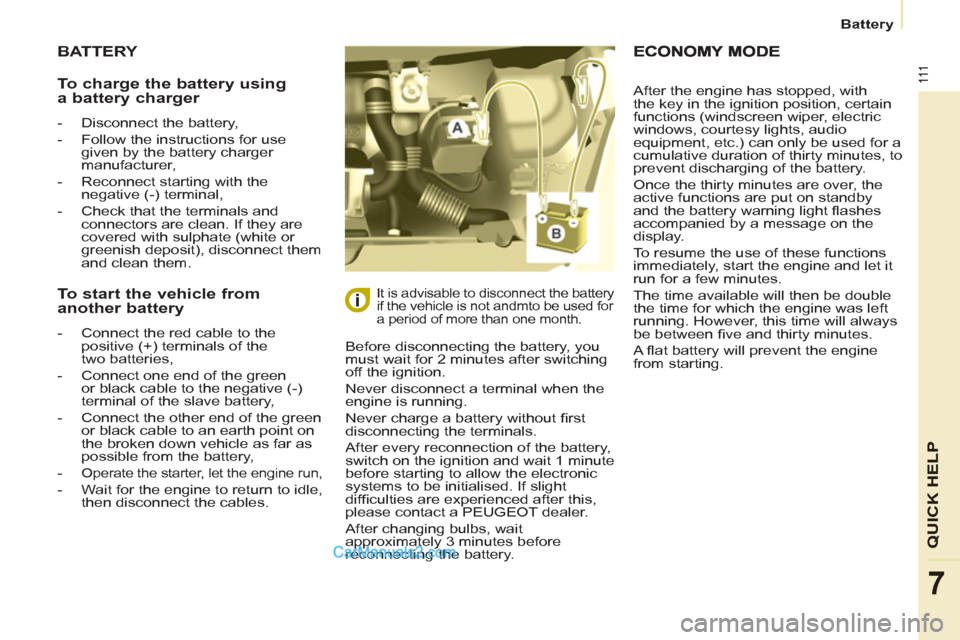

BATTERY

Before disconnecting the battery, you

must wait for 2 minutes after switching

off the ignition.

Never disconnect a terminal when the

engine is running.

Never charge a battery without fi rst

disconnecting the terminals.

After every reconnection of the battery,

switch on the ignition and wait 1 minute

before starting to allow the electronic

systems to be initialised. If slight

diffi culties are experienced after this,

please contact a PEUGEOT dealer.

After changing bulbs, wait

approximately 3 minutes before

reconnecting the battery.

It is advisable to disconnect the battery

if the vehicle is not andmto be used for

a period of more than one month.

To charge the battery using

a battery charger

- Disconnect the battery,

- Follow the instructions for use

given by the battery charger

manufacturer,

- Reconnect starting with the

negative (-) terminal,

- Check that the terminals and

connectors are clean. If they are

covered with sulphate (white or

greenish deposit), disconnect them

and clean them.

To start the vehicle from

another battery

- Connect the red cable to the

positive (+) terminals of the

two batteries,

- Connect one end of the green

or black cable to the negative (-)

terminal of the slave battery,

- Connect the other end of the green

or black cable to an earth point on

the broken down vehicle as far as

possible from the battery,

-

Operate the starter, let the engine run,

- Wait for the engine to return to idle,

then disconnect the cables. After the engine has stopped, with

the key in the ignition position, certain

functions (windscreen wiper, electric

windows, courtesy lights, audio

equipment, etc.) can only be used for a

cumulative duration of thirty minutes, to

prevent discharging of the battery.

Once the thirty minutes are over, the

active functions are put on standby

and the battery warning light fl ashes

accompanied by a message on the

display.

To resume the use of these functions

immediately, start the engine and let it

run for a few minutes.

The time available will then be double

the time for which the engine was left

running. However, this time will always

be between fi ve and thirty minutes.

A fl at battery will prevent the engine

from starting. Battery

Page 114 of 200

11 2

Changing a wheel

1. PARKING THE VEHICLE

- Tthe occupants must get out of the

vehicle and wait in a safe location.

- If possible, park the vehicle on

level, stable and non-slippery

ground.

- Apply the parking brake, switch

off the ignition and engage fi rst or

reverse gear.

- If available, place a chock under

the wheel diagonally opposite the

one to be changed.

If the vehicle is fi tted with a towbar,

it is sometimes necessary to raise

the vehicle slightly to make it easier

to remove the spare wheel from its

carrier.

On certain types of ground and/or

if considerable loads are being

transported, call a PEUGEOT dealer.

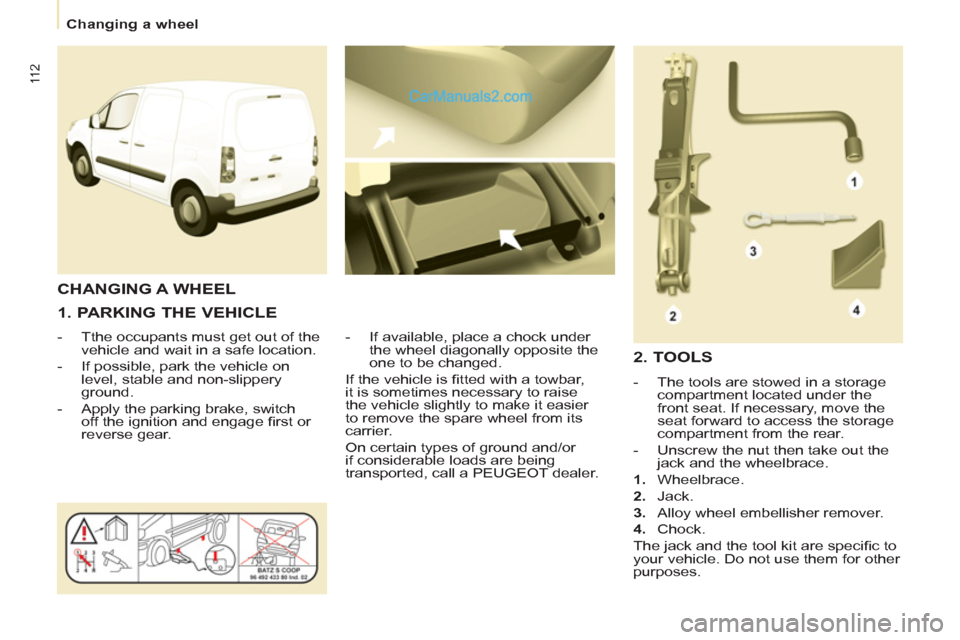

CHANGING A WHEEL

2. TOOLS

- The tools are stowed in a storage

compartment located under the

front seat. If necessary, move the

seat forward to access the storage

compartment from the rear.

- Unscrew the nut then take out the

jack and the wheelbrace.

1.

Wheelbrace.

2.

Jack.

3.

Alloy wheel embellisher remover.

4.

Chock.

The jack and the tool kit are specifi c to

your vehicle. Do not use them for other

purposes.

Page 115 of 200

11 3

QUICK HEL

P

7

Changing a wheel

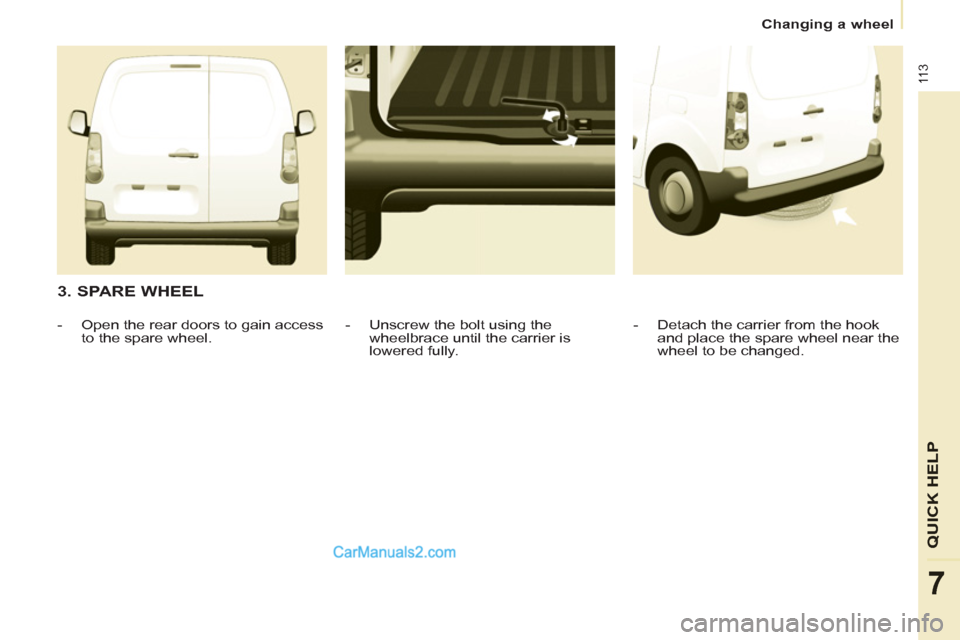

3. SPARE WHEEL

- Detach the carrier from the hook

and place the spare wheel near the

wheel to be changed.

- Unscrew the bolt using the

wheelbrace until the carrier is

lowered fully.

- Open the rear doors to gain access

to the spare wheel.

Page 116 of 200

11 4

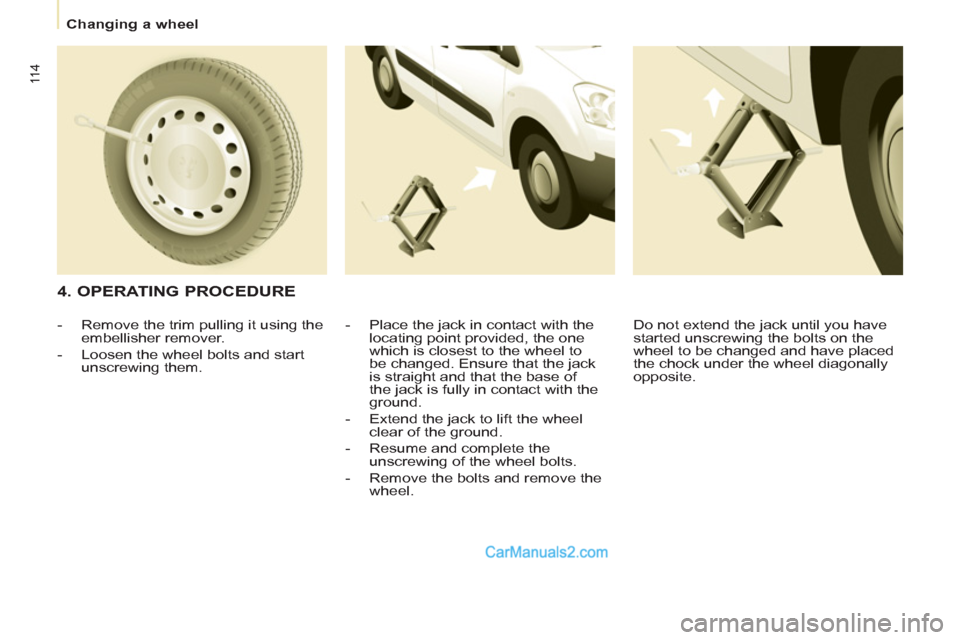

4. OPERATING PROCEDURE

- Place the jack in contact with the

locating point provided, the one

which is closest to the wheel to

be changed. Ensure that the jack

is straight and that the base of

the jack is fully in contact with the

ground.

- Extend the jack to lift the wheel

clear of the ground.

- Resume and complete the

unscrewing of the wheel bolts.

- Remove the bolts and remove the

wheel.

- Remove the trim pulling it using the

embellisher remover.

- Loosen the wheel bolts and start

unscrewing them. Do not extend the jack until you have

started unscrewing the bolts on the

wheel to be changed and have placed

the chock under the wheel diagonally

opposite.

Changing a wheel

Page 117 of 200

11 5

QUICK HEL

P

7

Changing a wheel

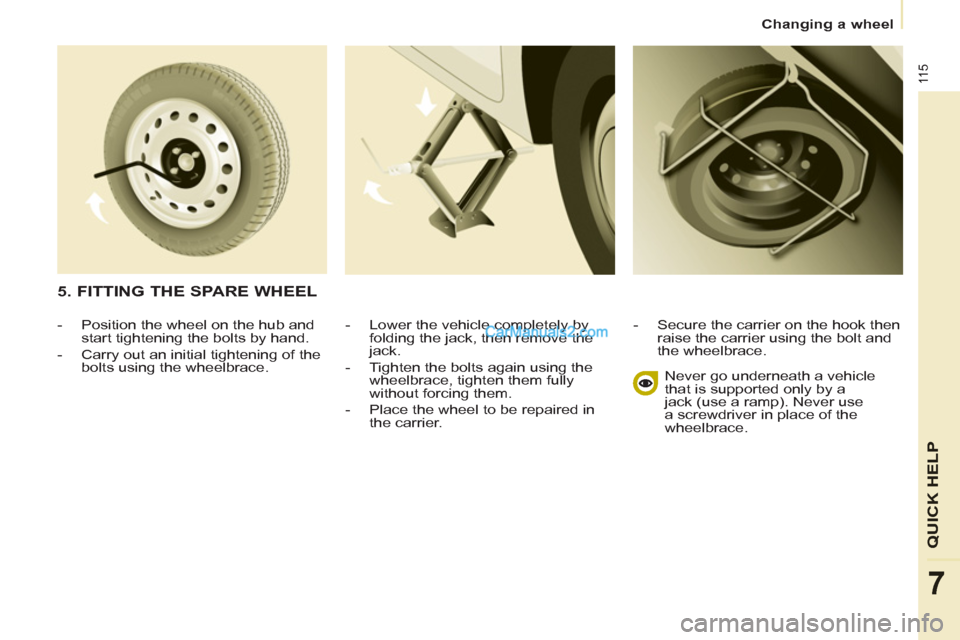

- Lower the vehicle completely by

folding the jack, then remove the

jack.

- Tighten the bolts again using the

wheelbrace, tighten them fully

without forcing them.

- Place the wheel to be repaired in

the carrier.

- Secure the carrier on the hook then

raise the carrier using the bolt and

the wheelbrace.

Never go underneath a vehicle

that is supported only by a

jack (use a ramp). Never use

a screwdriver in place of the

wheelbrace.

5. FITTING THE SPARE WHEEL

- Position the wheel on the hub and

start tightening the bolts by hand.

- Carry out an initial tightening of the

bolts using the wheelbrace.

Page 118 of 200

11 6

Snow screen

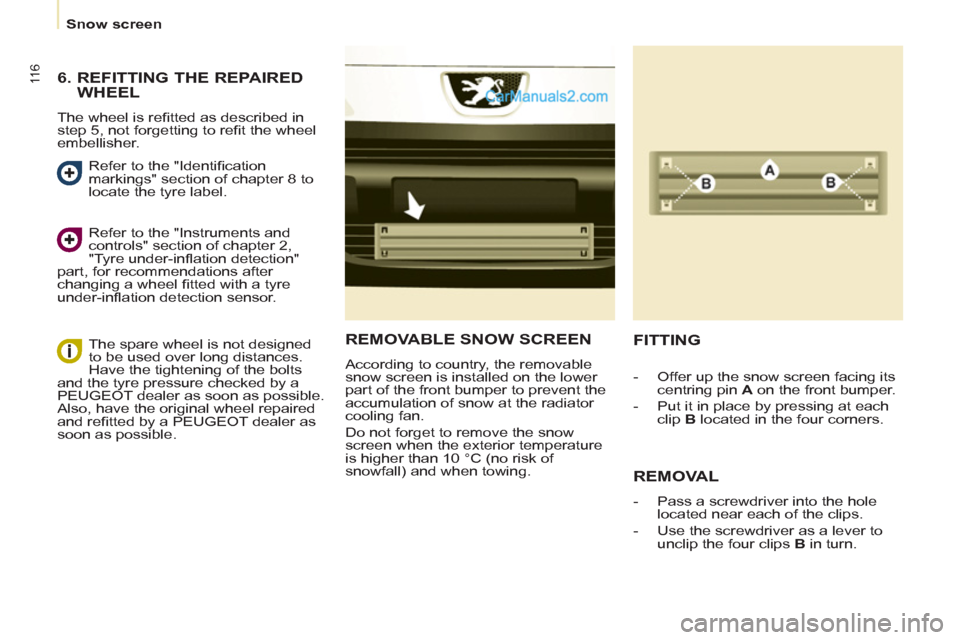

REMOVABLE SNOW SCREEN

According to country, the removable

snow screen is installed on the lower

part of the front bumper to prevent the

accumulation of snow at the radiator

cooling fan.

Do not forget to remove

the snow

screen when the exterior temperature

is higher than 10 °C (no

risk of

snowfall) and when towing.

FITTING

REMOVAL

- Pass a screwdriver into the hole

located near each of the clips.

- Use the screwdriver as a lever to

unclip the four clips B

in turn.

- Offer up the snow screen facing its

centring pin A

on the front bumper.

- Put it in place by pressing at each

clip B

located in the four corners.

6. REFITTING THE REPAIRED

WHEEL

The wheel is refi tted as described in

step 5, not forgetting to refi t the wheel

embellisher.

Refer to the "Identifi cation

markings" section of chapter 8 to

locate the tyre label.

Refer to the "Instruments and

controls" section of chapter 2,

"Tyre under-infl ation detection"

part, for recommendations after

changing a wheel fi tted with a tyre

under-infl ation detection sensor.

The spare wheel is not designed

to be used over long distances.

Have the tightening of the bolts

and the tyre pressure checked by a

PEUGEOT dealer as soon as possible.

Also, have the original wheel repaired

and refi tted by a PEUGEOT dealer as

soon as possible.

Page 119 of 200

11 7

QUICK HEL

P

7

Changing a bulb

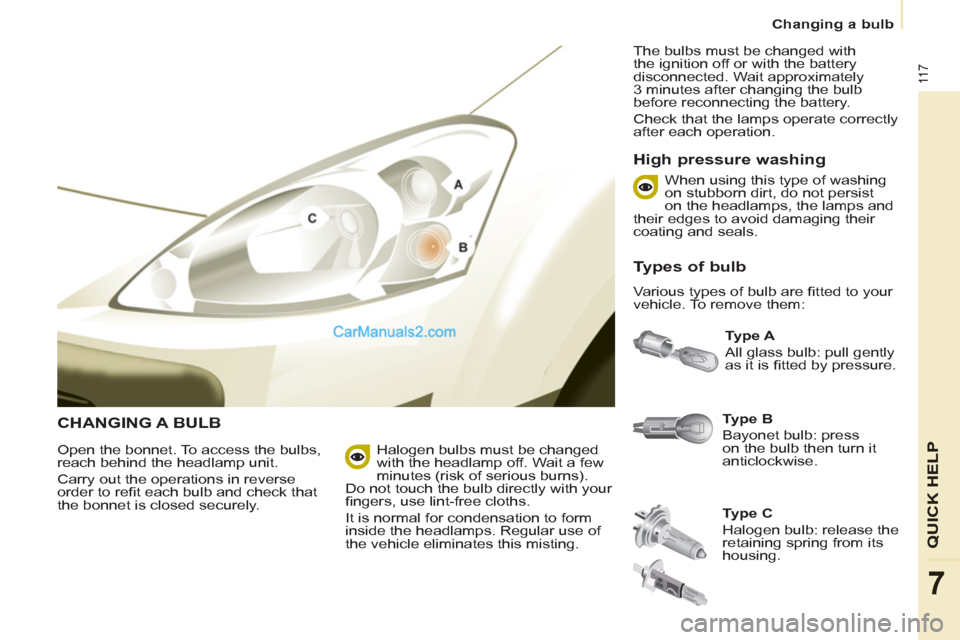

CHANGING A BULB

Type B

Bayonet bulb: press

on the bulb then turn it

anticlockwise.

Type A

All glass bulb: pull gently

as it is fi tted by pressure.

Open the bonnet. To access the bulbs,

reach behind the headlamp unit.

Carry out the operations in reverse

order to refi t each bulb and check that

the bonnet is closed securely.

Type C

Halogen bulb: release the

retaining spring from its

housing.

Halogen bulbs must be changed

with the headlamp off. Wait a few

minutes (risk of serious burns).

Do not touch the bulb directly with your

fi ngers, use lint-free cloths.

It is normal for condensation to form

inside the headlamps. Regular use of

the vehicle eliminates this misting. The bulbs must be changed with

the ignition off or with the battery

disconnected. Wait approximately

3 minutes after changing the bulb

before reconnecting the battery.

Check that the lamps operate correctly

after each operation.

High pressure washing

Types of bulb

Various types of bulb are fi tted to your

vehicle. To remove them: When using this type of washing

on stubborn dirt, do not persist

on the headlamps, the lamps and

their edges to avoid damaging their

coating and seals.

Page 120 of 200

11 8

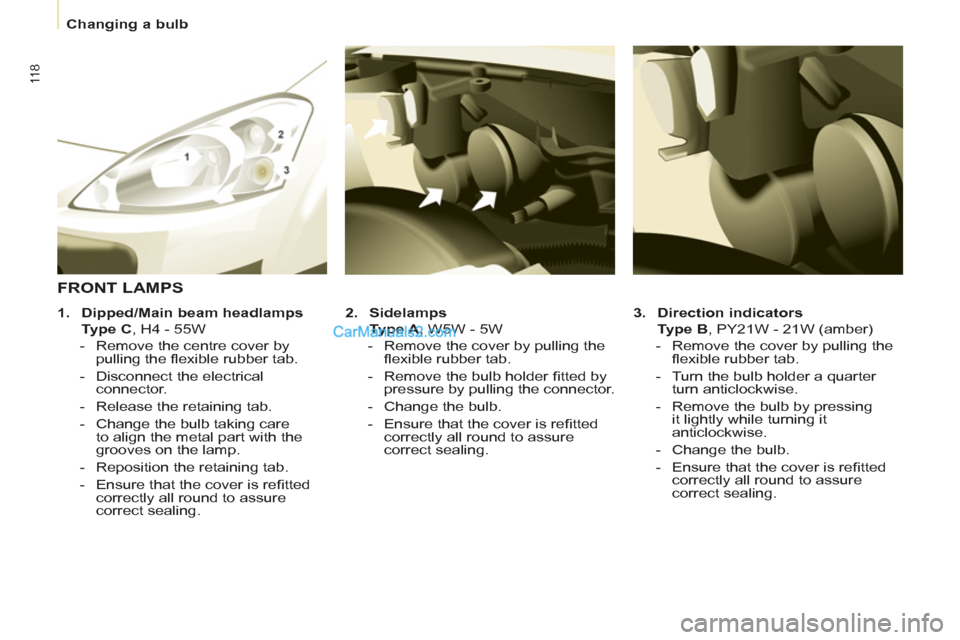

Changing a bulb

3.

Direction indicators

Type B

, PY21W - 21W (amber)

- Remove the cover by pulling the

fl exible rubber tab.

- Turn the bulb holder a quarter

turn anticlockwise.

- Remove the bulb by pressing

it lightly while turning it

anticlockwise.

- Change the bulb.

- Ensure that the cover is refi tted

correctly all round to assure

correct sealing.

2.

Sidelamps

Ty p e A

, W5W - 5W

- Remove the cover by pulling the

fl exible rubber tab.

- Remove the bulb holder fi tted by

pressure by pulling the connector.

- Change the bulb.

- Ensure that the cover is refi tted

correctly all round to assure

correct sealing.

FRONT LAMPS

1.

Dipped/Main beam headlamps

Type C

, H4 - 55W

- Remove the centre cover by

pulling the fl exible rubber tab.

- Disconnect the electrical

connector.

- Release the retaining tab.

- Change the bulb taking care

to align the metal part with the

grooves on the lamp.

- Reposition the retaining tab.

- Ensure that the cover is refi tted

correctly all round to assure

correct sealing.