PONTIAC FIERO 1988 Service Repair Manual

Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 1731 of 1825

5H-18 DOORS - F STYLE

REFER TO ADJUSTMENT INSTRUCTIONS FOR

1 1 MODELING CLAY

STRIKER

IMPRESSION LOCK

FORK

BOLT

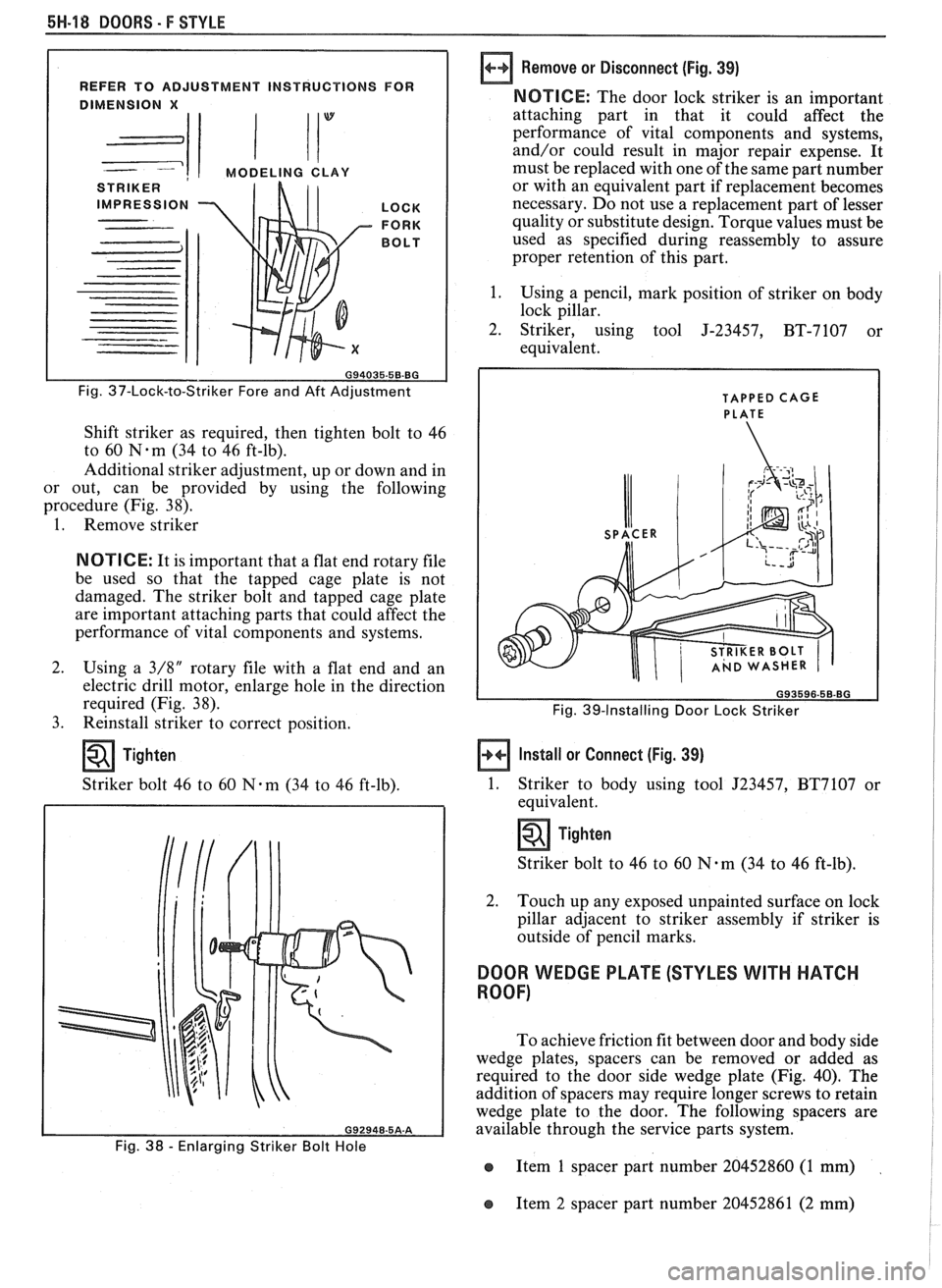

Fig. 37-Lock-to-Striker Fore and Aft Adjustment

Shift striker as required, then tighten bolt to 46

to 60

N-m (34 to 46 ft-lb).

Additional striker adjustment, up or down and in

or out, can be provided by using the following

procedure (Fig. 38).

1. Remove striker

NOTICE: It is important that a flat end rotary file

be used so that the tapped cage plate is not

damaged. The striker bolt and tapped cage plate

are important attaching parts that could affect the

performance of vital components and systems.

2. Using a

3/8" rotary file with a flat end and an

electric drill motor, enlarge hole in the direction

required (Fig. 38).

3. Reinstall striker to correct position.

Tighten

Striker bolt 46 to 60 N-m (34 to 46 ft-lb).

Fig. 38 - Enlarging Striker Bolt Hole

Remove or Disconnect (Fig. 39)

NOTICE: The door lock striker is an important

attaching part in that it could affect the

performance of vital components and systems,

and/or could result in major repair expense. It

must be replaced with one of the same part number

or with an equivalent part if replacement becomes

necessary. Do not use a replacement part of lesser

quality or substitute design. Torque values must be

used as specified during reassembly to assure

proper retention of this part.

1. Using a pencil, mark position of striker on body

lock pillar.

2. Striker, using tool J-23457,

BT-7107 or

equivalent.

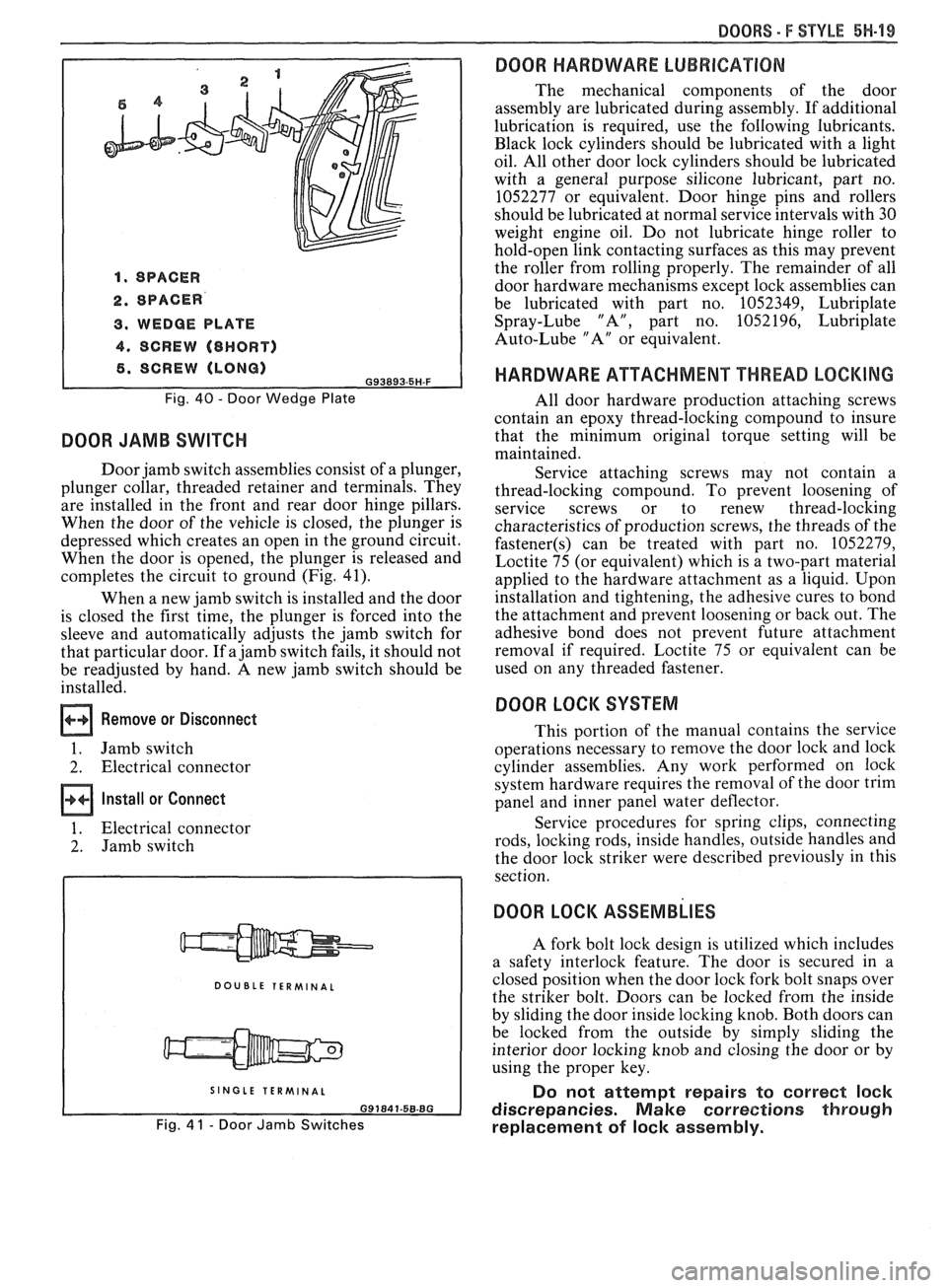

TAPPED CAGE

PLATE

Fig. 39-Installing Door Lock Striker

Install or Connect (Fig. 39)

1.

Striker to body using tool J23457, BT7107 or

equivalent.

Tighten

Striker bolt to 46 to 60 N-m (34 to 46 ft-lb).

2. Touch up any exposed unpainted surface on lock

pillar adjacent to striker assembly if striker is

outside of pencil marks.

DOOR WEDGE PLATE (STYLES WITH HATCH

ROOF)

To achieve friction fit between door and body side

wedge plates, spacers can be removed or added as

required to the door side wedge plate (Fig. 40). The

addition of spacers may require longer screws to retain

wedge plate to the door. The following spacers are

available through the service parts system.

e Item 1 spacer part number 20452860 (1 mm)

e Item 2 spacer part number 20452861 (2 mm)

Page 1732 of 1825

DOORS - F STYLE 5H-99

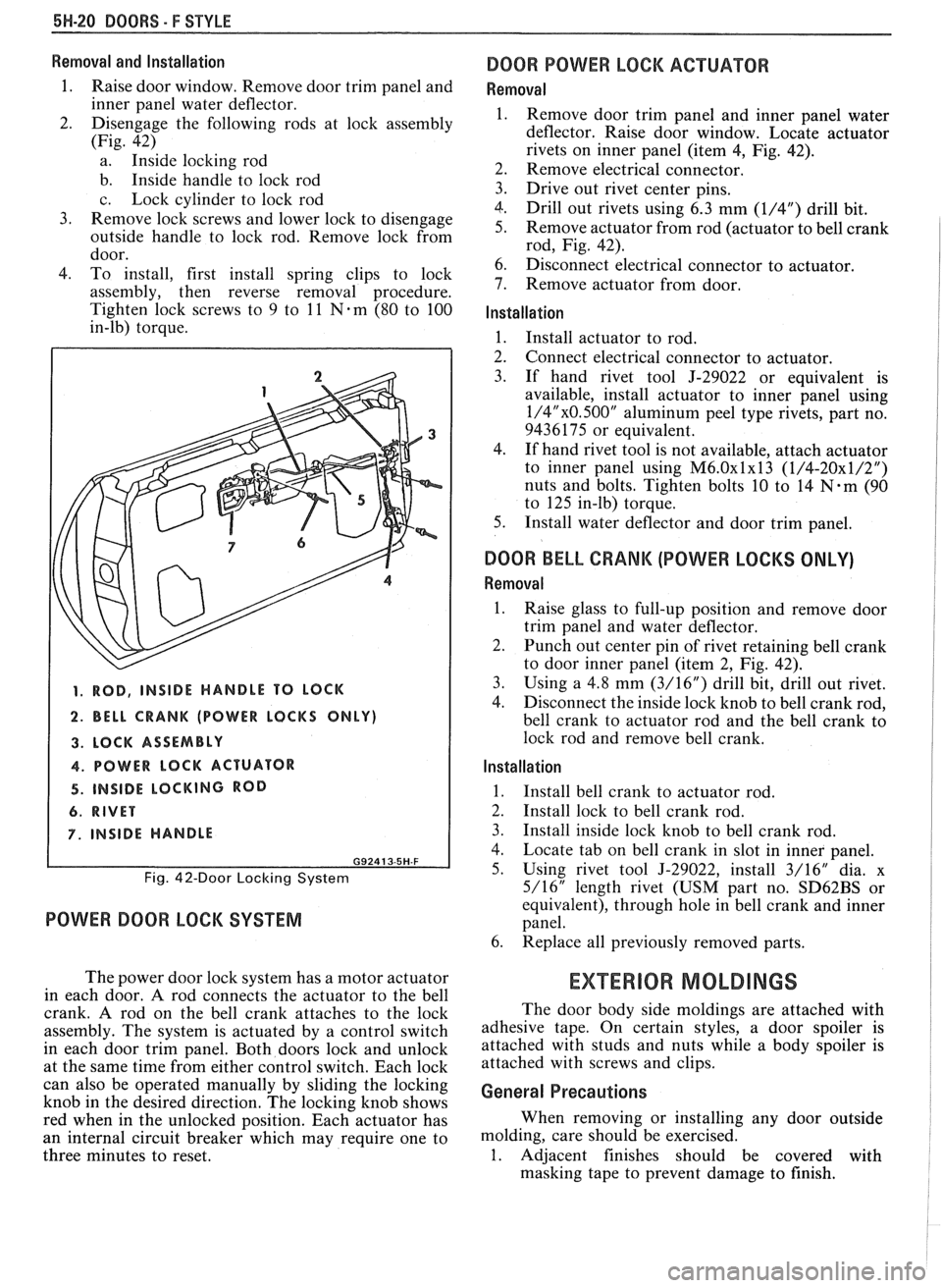

1. SPACER

2. SPACER

3. WEDGE PLATE

4. SCREW (8HORT)

6. SCREW (LONG) G93893.5H-F

Fig. 40 - Door Wedge Plate

DOOR JAMB SWITCH

Door jamb switch assemblies consist of a plunger,

plunger collar, threaded retainer and terminals. They

are installed in the front and rear door hinge pillars.

When the door of the vehicle is closed, the plunger is

depressed which creates an open in the ground circuit.

When the door is opened, the plunger is released and

completes the circuit to ground (Fig. 41).

When a new jamb switch is installed and the door

is closed the first time, the plunger is forced into the

sleeve and automatically adjusts the jamb switch for

that particular door. If a jamb switch fails, it should not

be readjusted by hand. A new jamb switch should be

installed.

Remove or Disconnect

1. Jamb switch

2. Electrical connector

Install or Connect

1. Electrical connector

2. Jamb switch

DOUBLE TERMINAL

I SINGLE TERMINAL I

Fig. 4 1 - Door Jamb Switches

DOOR HARDWARE LUBRICATION

The mechanical components of the door

assembly are lubricated during assembly. If additional

lubrication is required, use the following lubricants.

Black lock cylinders should be lubricated with a light

oil. All other door lock cylinders should be lubricated

with a general purpose silicone lubricant, part no.

1052277 or equivalent. Door hinge pins and rollers

should be lubricated at normal service intervals with 30

weight engine oil. Do not lubricate hinge roller to

hold-open link contacting surfaces as this may prevent

the roller from rolling properly. The remainder of all

door hardware mechanisms except lock assemblies can

be lubricated with part no. 1052349, Lubriplate

Spray-Lube "A", part no. 1052196, Lubriplate

Auto-Lube "A" or equivalent.

HARDWARE ATTACHMENT THREAD LOCKING

All door hardware production attaching screws

contain an epoxy thread-locking compound to insure

that the minimum original torque setting will be

maintained.

Service attaching screws may not contain a

thread-locking compound. To prevent loosening of

service screws or to renew thread-locking

characteristics of production screws, the threads of the

fastener(s) can be treated with part no. 1052279,

Loctite 75 (or equivalent) which is a two-part material

applied to the hardware attachment as a liquid. Upon

installation and tightening, the adhesive cures to bond

the attachment and prevent loosening or back out. The

adhesive bond does not prevent future attachment

removal if required. Loctite 75 or equivalent can be

used on any threaded fastener.

DOOR LOCK SYSTEM

This portion of the manual contains the service

operations necessary to remove the door lock and lock

cylinder assemblies. Any work performed on lock

system hardware requires the removal of the door trim

panel and inner panel water deflector.

Service procedures for spring clips, connecting

rods, locking rods, inside handles, outside handles and

the door lock striker were described previously in this

section.

DOOR LOCK ASSEMBLIES

A fork bolt lock design is utilized which includes

a safety interlock feature. The door is secured in a

closed position when the door lock fork bolt snaps over

the striker bolt. Doors can be locked from the inside

by sliding the door inside locking knob. Both doors can

be locked from the outside by simply sliding the

interior door locking knob and closing the door or by

using the proper key.

Do not attempt repairs to correct lock

discrepancies. Make corrections through

replacement of lock assembly.

Page 1733 of 1825

5H-20 DOORS - F STYLE

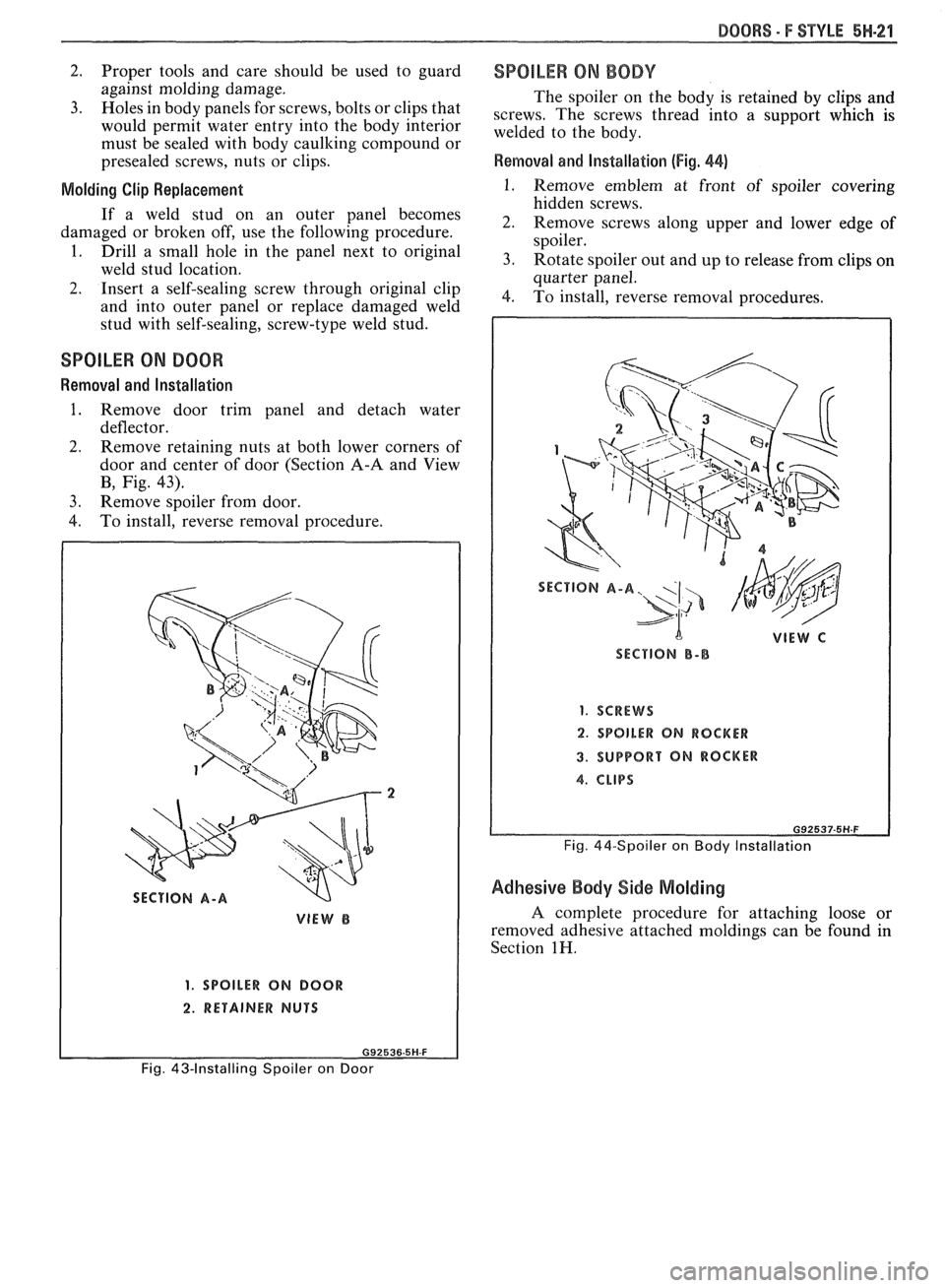

Removal and Installation

1.

Raise door window. Remove door trim panel and

inner panel water deflector.

2. Disengage the following rods at lock assembly

(Fig. 42)

a. Inside locking rod

b. Inside handle to lock rod

c. Lock cylinder to lock rod

3. Remove lock screws and lower lock to disengage

outside handle to lock rod. Remove lock from

door.

4. To install, first install spring clips to lock

assembly, then reverse removal procedure.

Tighten lock screws to 9 to

11 Nem (80 to 100

in-lb) torque.

1. ROD, INSIDE HANDLE TO LOCK

2. BELL CRANK (POWER LOCKS ONLY)

3. LOCK ASSEMBLY

4. POWER LOCK ACTUATOR

4. INSIDE LOCKING ROD

6. RIVET

7. INSIDE HANDLE

G92413-5H-F

Fig. 42-Door Locking System

POWER DOOR LOCK SYSTEM

The power door lock system has a motor actuator

in each door.

A rod connects the actuator to the bell

crank. A rod on the bell crank attaches to the lock

assembly. The system is actuated by a control switch

in each door trim panel. Both doors lock and unlock

at the same time from either control switch. Each lock

can also be operated manually by sliding the locking

knob in the desired direction. The locking knob shows

red when in the unlocked position. Each actuator has

an internal circuit breaker which may require one to

three minutes to reset.

DOOR POWER LOCK ACTUATOR

Removal

Remove door trim panel and inner panel water

deflector. Raise door window. Locate actuator

rivets on inner panel (item

4, Fig. 42).

Remove electrical connector.

Drive out rivet center pins.

Drill out rivets using 6.3 mm

(1/4") drill bit.

Remove actuator from rod (actuator to bell crank

rod, Fig. 42).

Disconnect electrical connector to actuator.

Remove actuator from door.

Installation

1. Install actuator to rod.

2. Connect electrical connector to actuator.

3. If hand rivet tool J-29022 or equivalent is

available, install actuator to inner panel using

1/4"x0.500" aluminum peel type rivets, part no.

9436175 or equivalent.

4. If hand rivet tool is not available, attach actuator

to inner panel using

M6.0~1~13 (1/4-20x1/2")

nuts and bolts. Tighten bolts 10 to 14 N-m (90

to 125 in-lb) torque.

5. Install water deflector and door trim panel.

DOOR BELL CRANK (POWER LOCKS ONLY)

Removal

1.

Raise glass to full-up position and remove door

trim panel and water deflector.

2. Punch out center pin of rivet retaining bell crank

to door inner panel (item 2, Fig. 42).

3. Using a

4.8 mm (3/16") drill bit, drill out rivet.

4. Disconnect the inside

lock knob to bell crank rod,

bell crank to actuator rod and the bell crank to

lock rod and remove bell crank.

Installation

1.

Install bell crank to actuator rod.

2. Install lock to bell crank rod.

3. Install inside lock knob to bell crank rod.

4. Locate tab on bell crank in slot in inner panel.

5. Using rivet tool J-29022, install 3/16" dia. x

5/16" length rivet (USM part no.

SD62BS or

equivalent), through hole in bell crank and inner

panel.

6. Replace all previously removed parts.

EXTERIOR MOLDINGS

The door body side moldings are attached with

adhesive tape. On certain styles, a door spoiler is

attached with studs and nuts while a body spoiler is

attached with screws and clips.

General Precautions

When removing or installing any door outside

molding, care should be exercised.

1. Adjacent finishes should be covered with

masking tape to prevent damage to finish.

Page 1734 of 1825

DOORS - F STYLE 5H-21

2. Proper tools and care should be used to guard SPOILER ON BODY against molding damage.

The spoiler on the body is retained by clips and

3.

~oles in body ~anels for screws, bolts or clips that screws, The screws thread into a support which is would permit water entry into the body interior welded to the body, must be sealed with bodv caulking. com~ound or " presealed screws, nuts or clips. Removal and Installation (Fig. 44)

Molding Clip Replacement 1. Remove emblem at front of spoiler covering

hidden screws.

If a stud On an Outer pane' becomes 2. Remove screws along upper and lower edge of damaged or broken off, use the following procedure.

spoiler.

1 Drill a small in the pane' next to 3. Rotate spoiler out and up to release from clips on weld stud location.

quarter panel.

2. Insert a self-sealing screw through original clip 4, To install, reverse removal procedures,

and into outer panel or replace damaged weld

stud with

self-sealing, screw-type weld stud.

SPOlLER ON DOOR

Removal and Installation

1. Remove door trim panel and detach water

deflector.

2. Remove retaining nuts at both lower corners of

door and center of door (Section

A-A and View

B, Fig. 43).

3. Remove spoiler from door.

4. To install, reverse removal procedure.

VIEW B

1. SPOILER ON BOOR

2. RETAINER NUTS

SECTION B-B

1. SCREWS

2. SPOILER ON ROCKER

3. SUPPORT ON ROCKER

Fig. 44-Spoiler on Body Installation

Adhesive Body Side Molding

A complete procedure for attaching loose or

removed adhesive attached moldings can be found in

Section

1H.

Fig. 43-Installing Spoiler on Door

Page 1735 of 1825

Page 1736 of 1825

REAR QUARTERS - F STYLE 8H-1

SECTION 6H

REAR QUARTERS

NOTICE: The anti-theft label found on some major sheet metal, engines, and transmissions must be masked

prior to painting, rustproofing, undercoating, etc. The mask

must be removed following the above operations.

Failure to keep the label clean and readable may result in liability for violation of Federal Vehicle Theft Prevention

Standard, and subject the vehicle owner to possible suspicion that the part was stolen.

CONTENTS

Quarter Trim .................................................... 6H- 1

Lower Trim Finishing Panel ....................... 6H- 1

Body Lock Pillar Trim Finishing

Panel

., ....................................................... 6H- 1

Upper Trim Finishing Panel Insert ............. 6H- 1

....................................................... Speakers 6H- 1

Lift Window Upper Finishing

Molding

..................................................... 6H-2

....................... Upper Trim Finishing Panel 6H-2

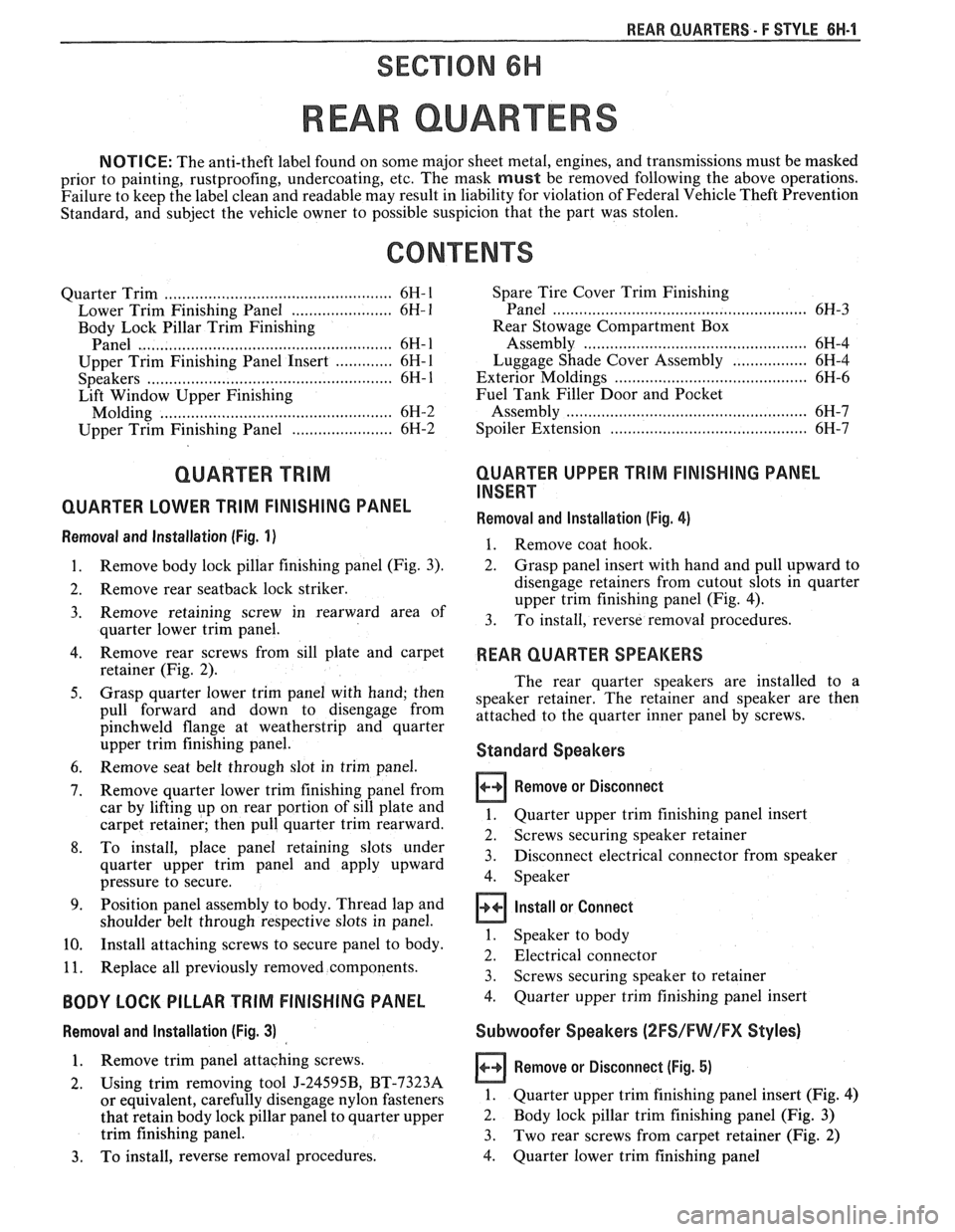

QUARTER TRlM

QUARTER LOWER TRlM FINISHING PANEL

Removal and Installation (Fig. 1)

Remove body lock pillar finishing panel (Fig. 3).

Remove rear

seatback lock striker.

Remove retaining screw in rearward area of

quarter lower trim panel.

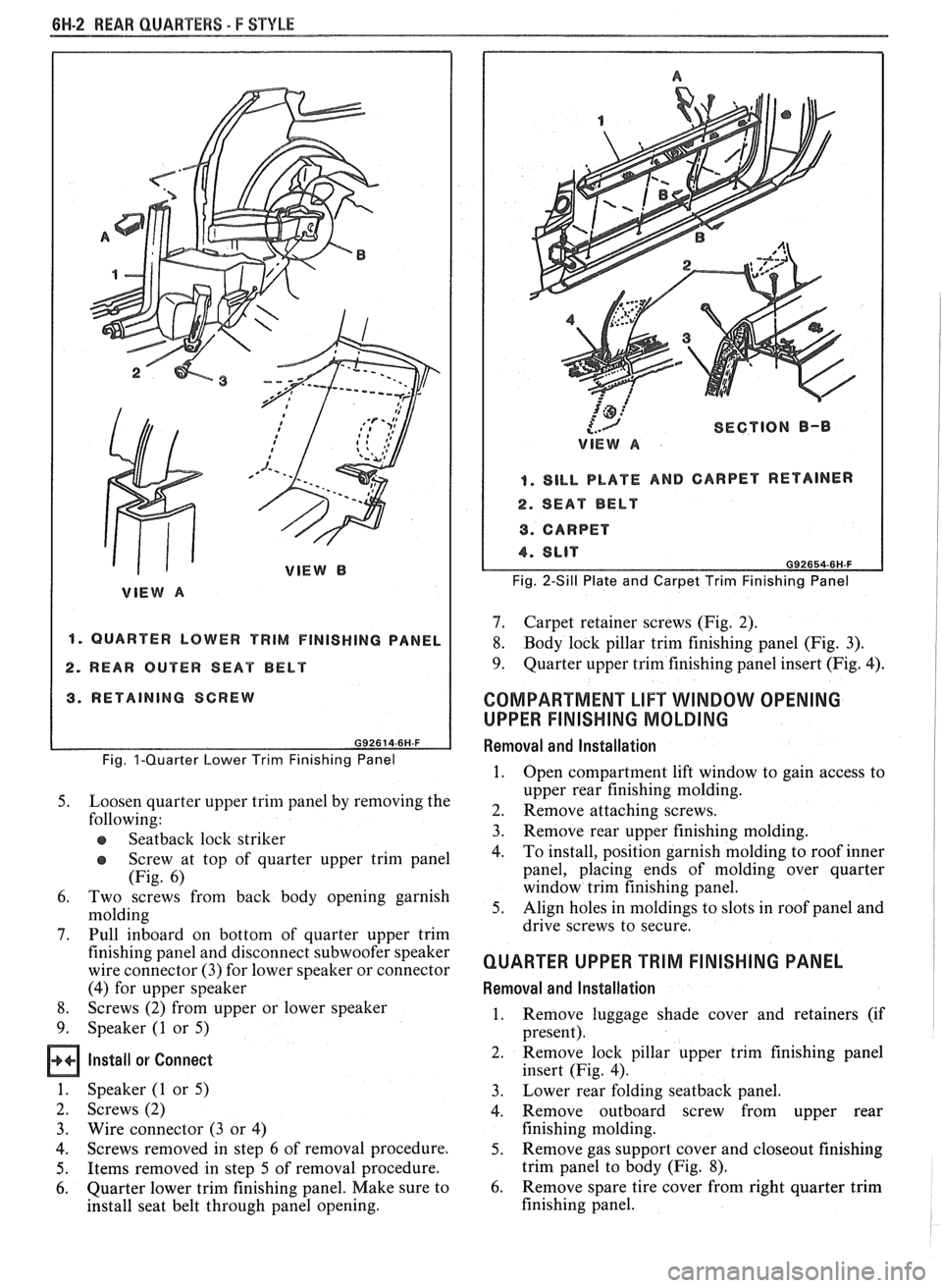

Remove rear screws from sill plate and carpet

retainer (Fig.

2).

Grasp quarter lower trim panel with hand; then

pull forward and down to disengage from

pinchweld flange at weatherstrip and quarter

upper trim finishing panel.

Remove seat belt through slot in trim panel.

Remove quarter lower trim finishing panel from

car by lifting up on rear portion of sill plate and

carpet retainer; then pull quarter trim rearward.

To install, place panel retaining slots under

quarter upper trim panel and apply upward

pressure to secure.

Position panel assembly to body. Thread lap and

shoulder belt through respective slots in panel.

Install attaching screws to secure panel to body.

Replace all previously removed components.

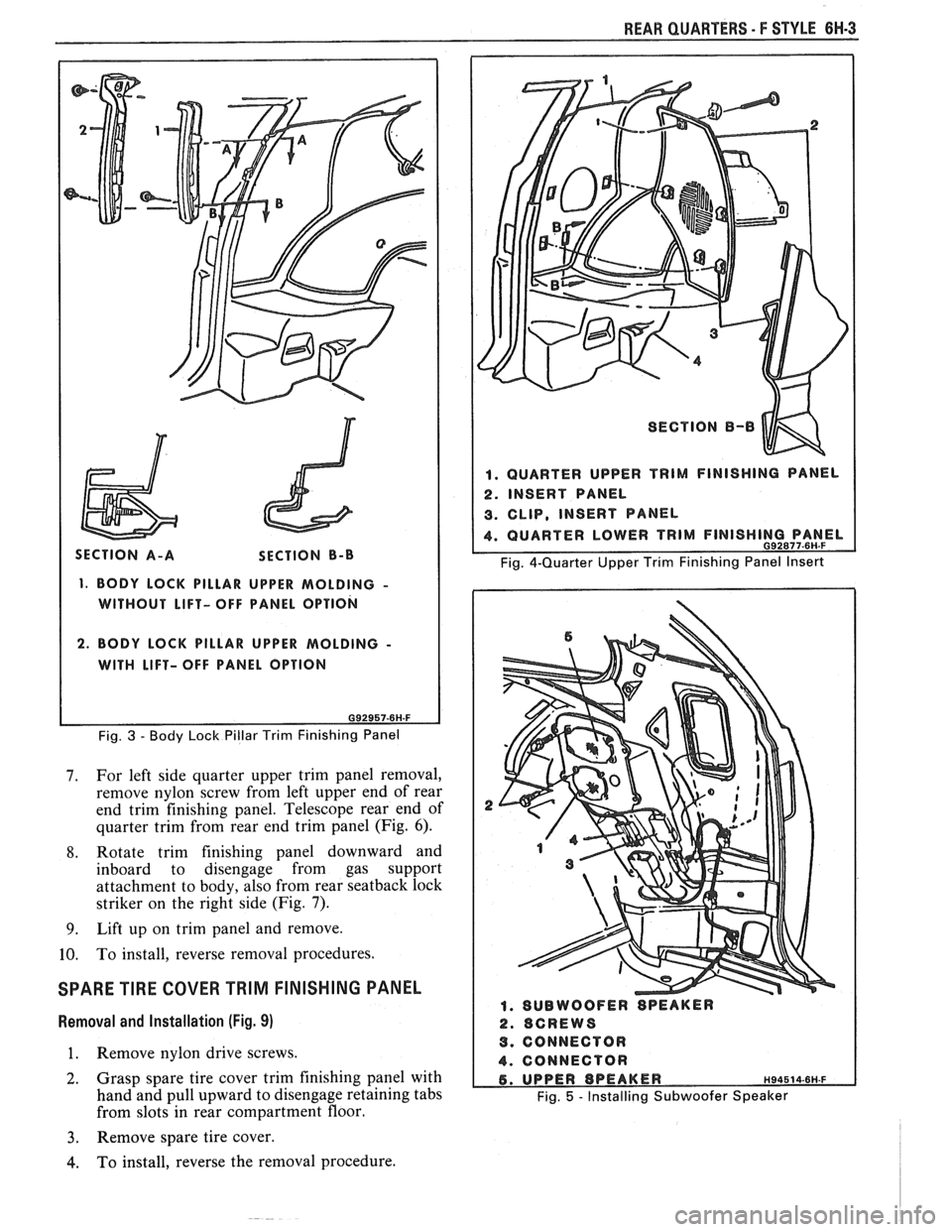

BODY LOCK PILLAR TRlM FINISHING PANEL

Removal and lnstallation (Fig. 3)

1. Remove trim panel attaching screws.

2. Using trim removing tool J-24595B, BT-7323A

or equivalent, carefully disengage nylon fasteners

that retain body lock pillar panel to quarter upper

trim finishing panel.

3. To install, reverse removal procedures. Spare

Tire Cover Trim Finishing

Panel

........................................................ 6H-3

Rear Stowage Compartment Box

Assembly

................................................... 6H-4

Luggage Shade Cover Assembly

................. 6H-4

Exterior Moldings

........................................... 6H-6

Fuel Tank Filler Door and Pocket

Assembly

....................................................... 6H-7

Spoiler Extension

............................ .. ........... 6H-7

QUARTER UPPER TRlM FINISHING PANEL

INSERT

Removal and Installation (Fig. 4)

1. Remove coat hook.

2. Grasp panel insert with hand and pull upward to

disengage retainers from cutout slots in quarter

upper trim finishing panel (Fig. 4).

3. To install, reverse removal procedures.

REAR QUARTER SPEAKERS

The rear quarter speakers are installed to a

speaker retainer. The retainer and speaker are then

attached to the quarter inner panel by screws.

Standard Speakers

Remove or Disconnect

1. Quarter upper trim finishing panel insert

2. Screws securing speaker retainer

3. Disconnect electrical

connector from speaker

4. Speaker

Install or Connect

1. Speaker to body

2. Electrical connector

3. Screws securing speaker to retainer

4. Quarter upper trim finishing panel insert

Subwoofer Speakers (2FS/FW/FX Styles)

Remove or Disconnect (Fig. 5)

1.

Quarter upper trim finishing panel insert (Fig. 4)

2. Body lock pillar trim finishing panel (Fig. 3)

3. Two rear screws from carpet retainer (Fig.

2)

4.

Quarter lower trim finishing panel

Page 1737 of 1825

661-2 REAR QUARTERS - F STYLE

"1 QUARTER LOWER TRIM FINISHING PANEL

2. REAR OUTER SEAT BELT

3. RETAINING SCREW

Fig. I-Quarter Lower Trim Finishing Panel

5. Loosen quarter upper trim panel by removing the

following:

e Seatback lock striker

@ Screw at top of quarter upper trim panel

(Fig. 6)

6. Two screws from back body opening garnish

molding

7. Pull inboard on bottom of quarter upper trim

finishing panel and disconnect subwoofer speaker

wire connector (3) for lower speaker or connector

(4) for upper speaker

8. Screws (2) from upper or lower speaker

9. Speaker (1 or 5)

Install or Connect

1. Speaker (1 or 5)

2. Screws (2)

3. Wire connector

(3 or 4)

4. Screws removed

in step 6 of removal procedure.

5. Items removed in step 5 of removal procedure.

6. Quarter lower trim finishing panel. Make sure to

install seat belt through panel opening.

'@ ,:'

{.-J SECTION B-I)

VIEW A

I. SILL PLATE AND CARPET RETAINER

4. SEAT BELT

9. CARPET

Fig. 2-Sill Plate and Carpet Trim Finishing Panel

7. Carpet retainer screws (Fig. 2).

8. Body lock pillar trim finishing panel (Fig. 3).

9. Quarter upper trim finishing panel insert (Fig. 4).

COMPARTMENT LIFT WINDOW OPENING

UPPER

FINISHING MOLDING

Removal and lnstallation

1. Open compartment lift window to gain access to

upper rear finishing molding.

2. Remove attaching screws.

3. Remove rear upper

finishing molding.

4. To

install, position garnish molding to roof inner

panel, placing ends of molding over quarter

window trim finishing panel.

5. Align holes in moldings to slots in roof panel and

drive screws to secure.

QUARTER UPPER TRIM FINISHING PANEL

Removal and Installation

1. Remove

luggage shade cover and retainers (if

present).

2. Remove

lock pillar upper trim finishing panel

insert (Fig. 4).

3. Lower

rear folding

seatback panel.

4. Remove outboard screw from upper rear

finishing molding.

5. Remove gas support cover and closeout finishing

trim panel to body (Fig.

8).

6. Remove spare tire cover from right quarter trim

finishing panel.

Page 1738 of 1825

REAR QUARTERS - F STYLE 6H-3

SECTION B-B

1. BODY LOCK PILLAR UPPER MOLDING -

WITHOUT LIFT- OFF PANEL OPTION

2. BODY LOCK PILLAR UPPER MOLDING -

WITH LIFT- OFF PANEL OPTION

Fig.

3 - Body Lock Pillar Trim Finishing Panel

7. For left side quarter upper trim panel removal,

remove nylon screw from left upper end of rear

end trim finishing panel. Telescope rear end of

quarter trim from rear end trim panel (Fig.

6).

8. Rotate trim finishing panel downward and

inboard to disengage from gas support

attachment to body, also from rear

seatback lock

striker on the right side (Fig.

7).

9. Lift up on trim panel and remove.

10. To install, reverse removal procedures.

SPARE TIRE COVER TRlM FINISHING PANEL

Removal and Installation (Fig. 9)

1. Remove nylon drive screws.

SECTION 8-8

a

1. QUARTER UPPER TRIM FINISHING PANEL

2. INSERT PANEL

3. CLIP, INSERT PANEL

4. QUARTER LOWER TRIM FINISHING G~zE~~-~H-F PANEL

Fig. 4-Quarter Upper Trim Finishing Panel Insert

1. SUBWOOFER PEAKER

1 2. SCREWS

9. CONNECTOR

I 4. CONNECTOR

2. Grasp spare tire cover trim finishing panel with

hand and pull upward to disengage retaining tabs

Fig. 5 - Installing Subwoofer Speaker

from slots in rear compartment floor.

3. Remove spare tire cover.

4. To install, reverse the removal procedure.

Page 1739 of 1825

BH-4 REAR QUARTERS - F STYLE

SECTION A-A

SECTION

B-B

I SECTION C-C I

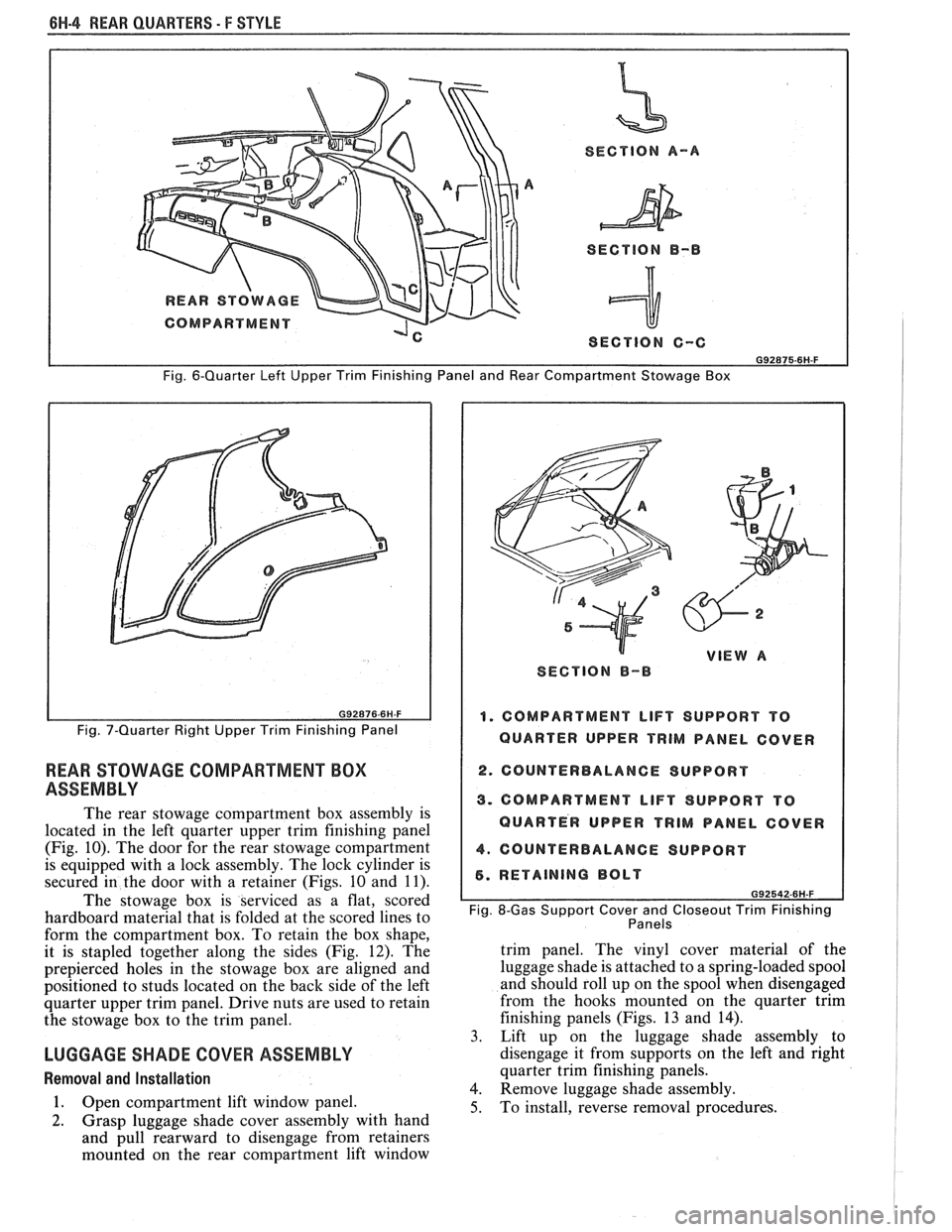

Fig. 6-Quarter Left Upper Trim Finishing Panel and Rear Compartment Stowage Box

Fig. 7-Quarter Right Upper Trim Finishing Panel

REAR STOWAGE COMPARTMENT BOX

ASSEMBLY

The rear stowage compartment box assembly is

located in the left quarter upper trim finishing panel

(Fig. 10). The door for the rear stowage compartment

is equipped with a lock assembly. The lock cylinder is

secured in the door with a retainer (Figs. 10 and 11).

The stowage box is serviced as a flat, scored

hardboard material that is folded at the scored lines to

form the compartment box. To retain the box shape,

it is stapled together along the sides (Fig. 12). The

prepierced holes in the stowage box are aligned and

positioned to studs located on the back side of the left

quarter upper trim panel. Drive nuts are used to retain

the stowage box to the trim panel.

LUGGAGE SHADE COVER ASSEMBLY

Removal and Installation

1. Open compartment lift window panel.

2. Grasp luggage shade cover assembly with hand

and pull rearward to disengage from retainers

mounted on the rear compartment lift window

W VIEW A

SECTION 8-B

1. COMPARTMENT LIFT SUPPORT TO

QUARTER UPPER

TRIM PANEL COVER

2. COUNTERBALANCE SUPPORT I

3. COMPARTMENT LIFT SUPPORT TO

QUARTER UPPER

TRIM PANEL COVER

4. COUNTERBALANCE SUPPORT I

5. RETAINING BOLT

Fig. 8-Gas Support Cover and Closeout Trim Finishing

Panels

trim panel. The vinyl cover material of the

luggage shade is attached to a spring-loaded spool

and should roll up on the spool when disengaged

from the hooks mounted on the quarter trim

finishing panels (Figs. 13 and

14).

3. Lift up on the luggage shade assembly to

disengage it from supports on the left and right

quarter trim finishing panels.

4. Remove luggage shade assembly.

5. To install, reverse removal procedures.

Page 1740 of 1825

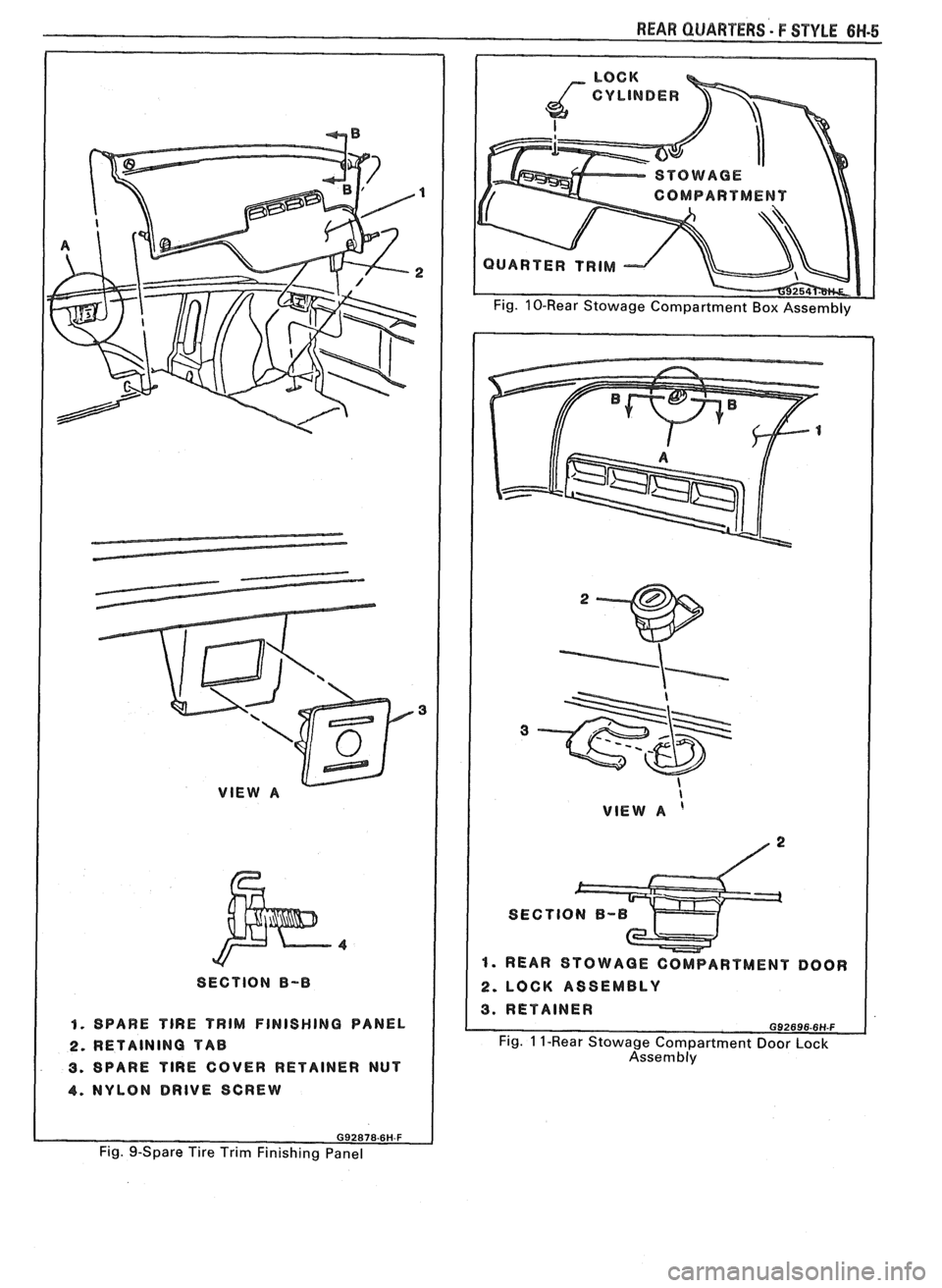

VlEW A

I

SECTION B-B

I 1. SPARE TlRE TRIM FINISHING PANEL

2. RETAINING TAB

3. SPARE TlRE COVER RETAINER NUT

4. NYLON DRIVE SCREW

REAR QUARTERS - F STYLE 6W-5

COMPART MENT

UARTER TRIM

I VlEW A ' I

I. REAR STOWAGE COMPARTMENT DOOR

2. LOCK ASSEMBLY

Fig. 1 I-Rear Stowage Compartment Door Lock

Assembly

Fig. 9-Spare Tire Trim Finishing Panel