PONTIAC FIERO 1988 Service Repair Manual

Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 1711 of 1825

4H-2 FRONT END - F STYLE

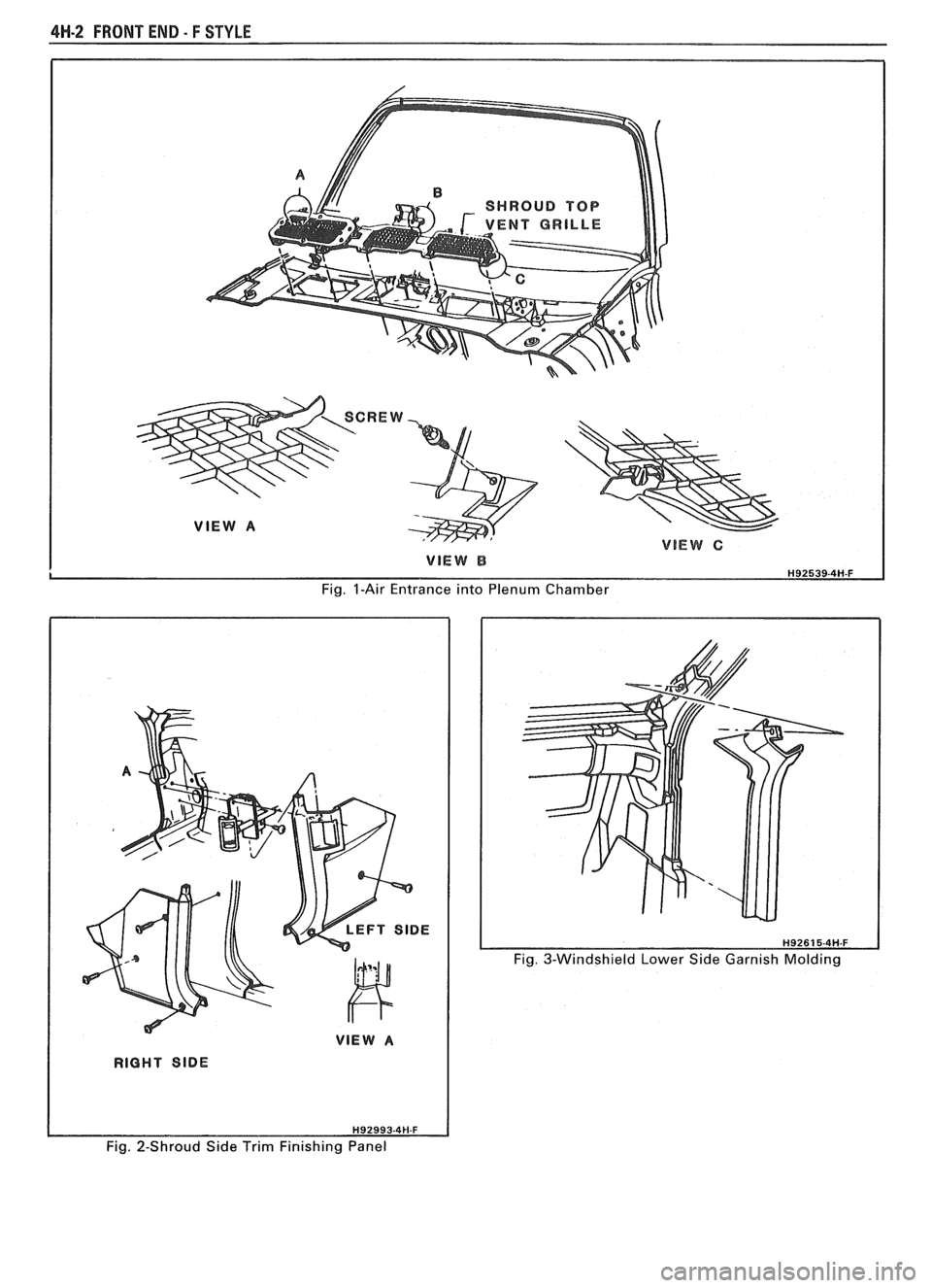

Fig. I-Air Entrance into Plenum Chamber

Fig. 3-Windshield Lower Side Garnish Molding

Fig. 2-Shroud Side Trim Finishing Panel

Page 1712 of 1825

FRONT END - F STYLE 4W-3

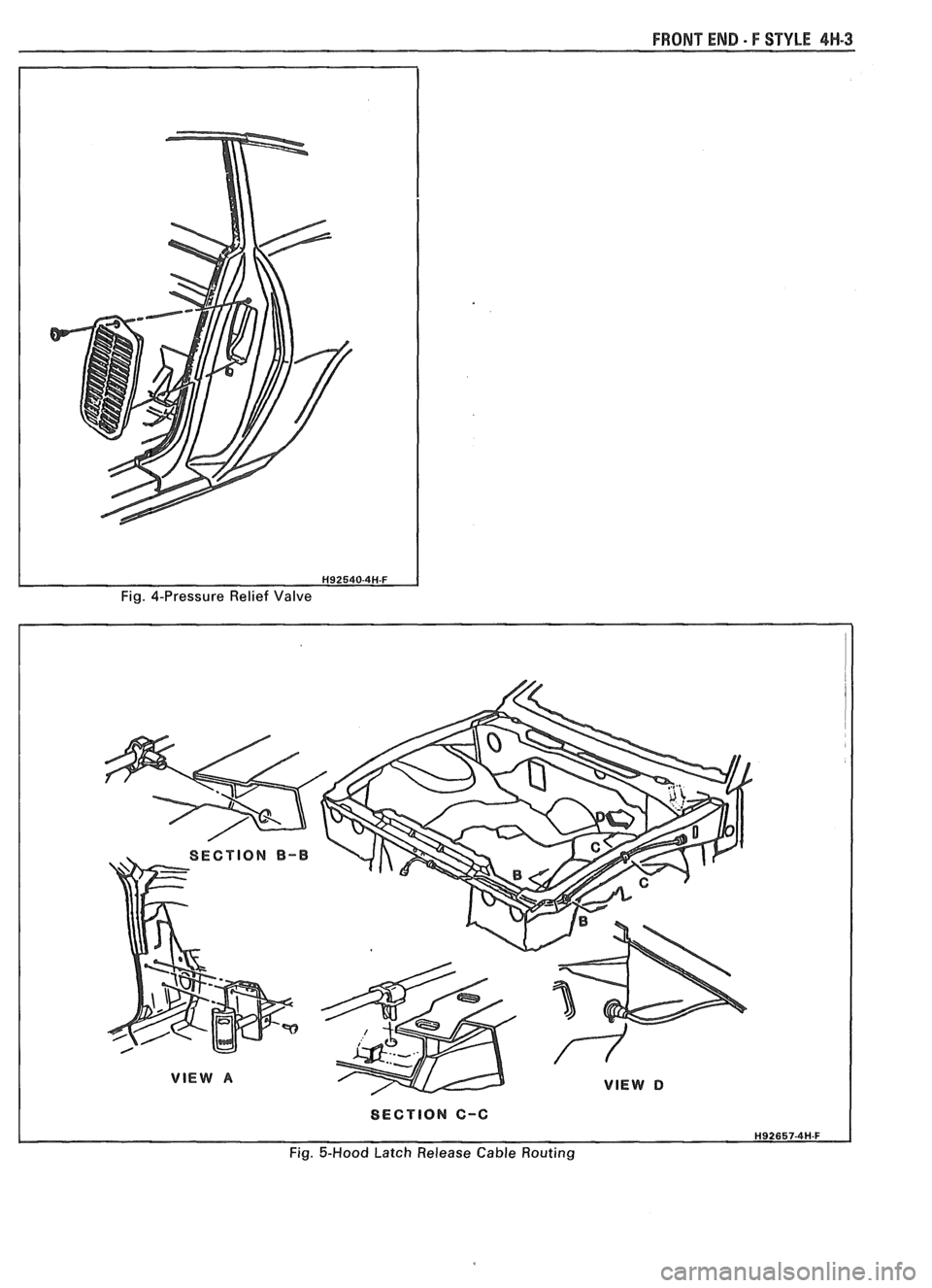

Fig. 4-Pressure Relief Valve

I SECTION C-C I

Fig. 5-Hood Latch Release Cable Routing

Page 1713 of 1825

Page 1714 of 1825

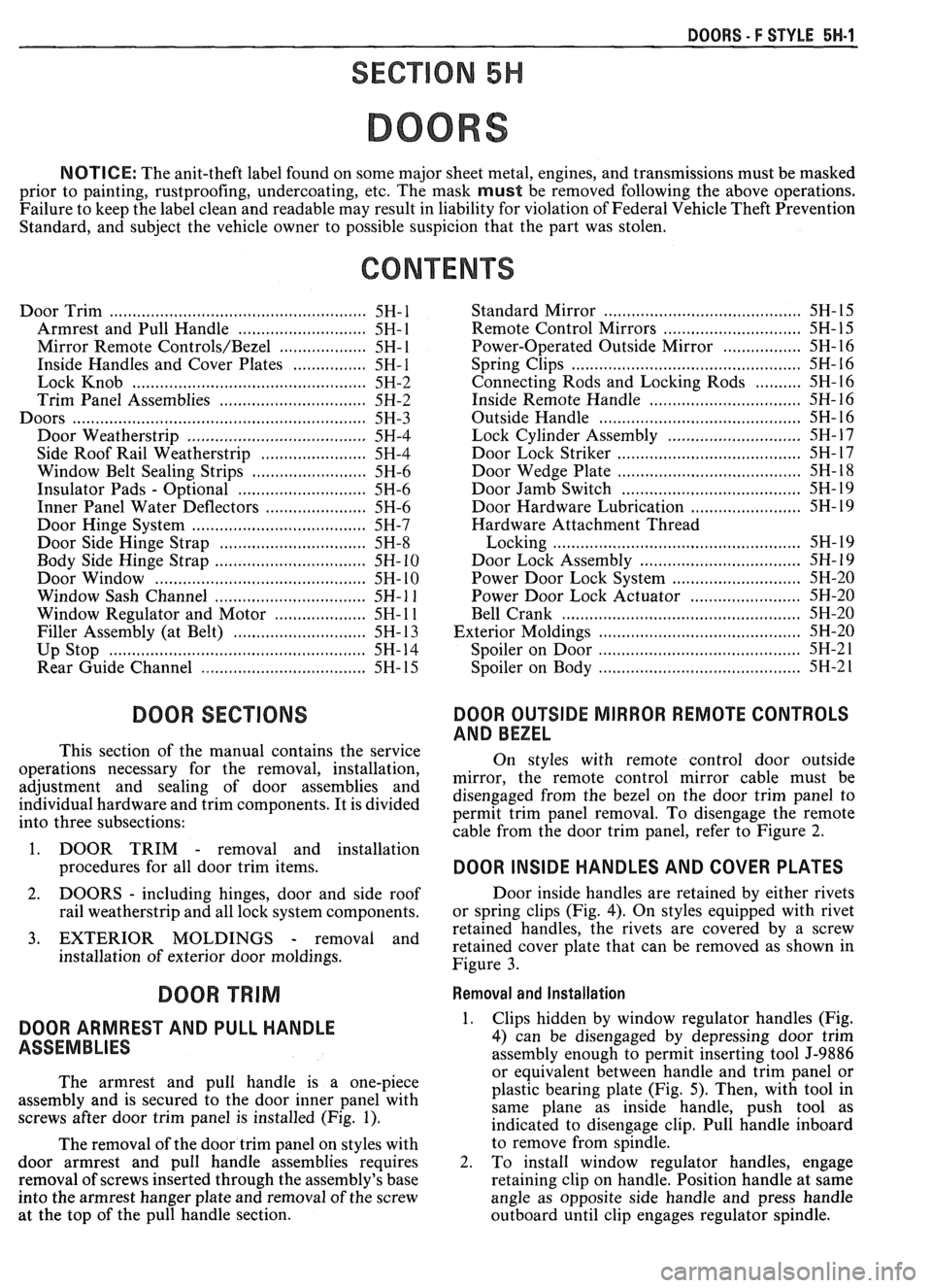

DOORS - F STYLE 5H-1

SEC"610N 5H

DOORS

NOTICE: The anit-theft label found on some major sheet metal, engines, and transmissions must be masked

prior to painting, rustproofing, undercoating, etc. The mask

must be removed following the above operations.

Failure to keep the label clean and readable may result in liability for violation of Federal Vehicle Theft Prevention

Standard, and subject the vehicle owner to possible suspicion that the part was stolen.

Door Trim

...................................................... 5H- 1

Armrest and Pull Handle .......................... 5H- 1

Mirror Remote Controls/Bezel ................... 5H- 1

Inside Handles and Cover Plates ................ 5H- 1

Lock Knob .................................... .... ........... 5H-2

Trim Panel Assemblies .............................. 5H-2

Doors ............................................................ 5H-3

Door Weatherstrip ....................................... 5H-4

Side Roof Rail Weatherstrip ....................... 5H-4

Window Belt Sealing Strips ......................... 5H-6

Insulator Pads - Optional ............................ 5H-6

Inner Panel Water Deflectors ...................... 5H-6

Door Hinge System .................................. .... 5H-7

Door Side Hinge Strap ............................... 5H-8

Body Side Hinge Strap ................................ 5H- 10

Door Window ..................... .. ................... 5H- 10

Window Sash Channel ................................. 5H- 1 1

Window Regulator and Motor .................... 5H- 1 1

Filler Assembly (at Belt) ......................... ... . 5H- 13

Up Stop ............................ .. ...................... 5H- 14

Rear Guide Channel .................................... 5H- 15

DOOR SECnONS

This section of the manual contains the service

operations necessary for the removal, installation,

adjustment and sealing of door assemblies and

individual hardware and trim components. It is divided

into three subsections:

1. DOOR TRIM

- removal and installation

procedures for all door trim items.

2. DOORS - including hinges, door and side roof

rail weatherstrip and all lock system components.

3. EXTERIOR MOLDINGS - removal and

installation of exterior door moldings. Standard Mirror

......................................... 5H- 15

........................... Remote

Control Mirrors 5H- 15

Power-Operated Outside Mirror ................. 5H-16

Spring Clips .................................................. 5H- 16

Connecting Rods and Locking Rods .......... 5H-16

Inside Remote Handle ................................ 5H- 16

......................................... Outside Handle 5H- 16

............................. Lock Cylinder Assembly 5H- 17

...................................... Door Lock Striker 5H- 17

....................................... Door Wedge Plate 5H- 18

....................................... Door Jamb Switch 5H- 19

........................ Door Hardware Lubrication 5H- 19

Hardware Attachment Thread

.................................................. Locking 5H- 19

................................... Door Lock Assembly 5H- 19

............................ Power Door Lock System 5H-20

........................ Power Door Lock Actuator 5H-20

............. .................................... Bell Crank ... 5H-20

.......................................... Exterior Moldings 5H-20

.......................................... Spoiler on Door 5H-21

.......................................... Spoiler on Body 5H-2 1

DOOR OUTSIDE MIRROR REMOTE CONTROLS

AND BEZEL

On styles with remote control door outside

mirror, the remote control mirror cable must be

disengaged from the bezel on the door trim panel to

permit trim panel removal. To disengage the remote

cable from the door trim panel, refer to Figure

2.

DOOR INSIDE HANDLES AND COVER PLATES

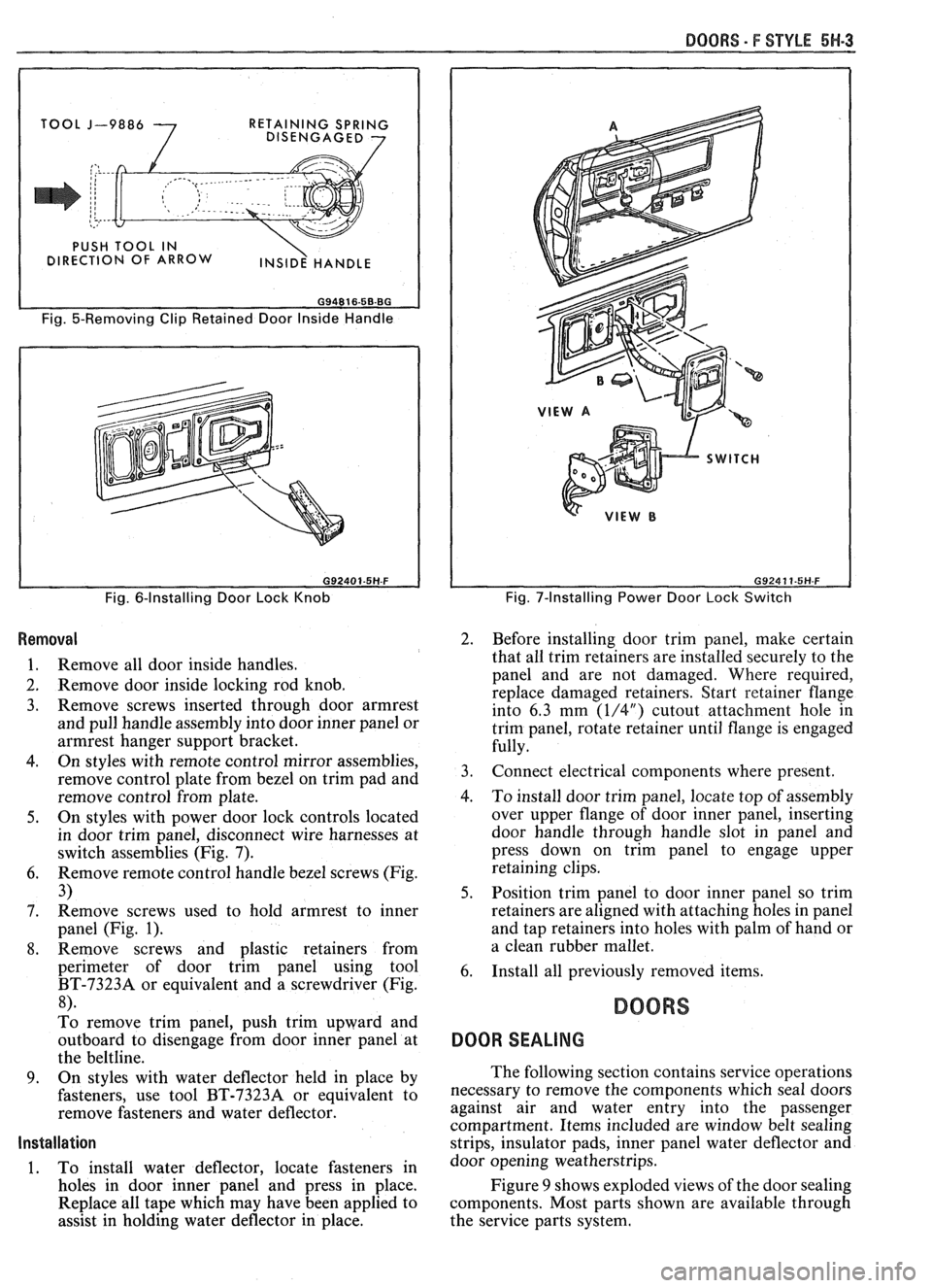

Door inside handles are retained by either rivets

or spring clips (Fig.

4). On styles equipped with rivet

retained handles, the rivets are covered by a screw

retained cover plate that can be removed as shown in

Figure

3.

DOOR TRIM Removal and Installation

DOOR ARMREST AND PULL HANDLE 1.

ASSEMBLIES

The armrest and pull handle is a one-piece

assembly and is secured to the door inner panel with

screws after door trim panel is installed (Fig. 1). Clips hidden

by window regulator handles (Fig,

4) can be disengaged by depressing door trim

assembly enough to permit inserting tool J-9886

or equivalent between handle and trim panel or

plastic bearing plate (Fig.

5). Then, with tool in

same plane as inside handle, push tool as

indicated to disengage clip. Pull handle inboard

The removal of the door trim panel on styles with to

remove from

s$n>le. -

door armrest and pull handle assemblies requires 2. To install window regulator handles, engage

removal of screws inserted through the assembly's base retaining clip on handle. Position handle at same

into the armrest hanger plate and removal of the screw angle as opposite side handle and press handle

at the top of the pull handle section.

outboard until clip engages regulator spindle.

Page 1715 of 1825

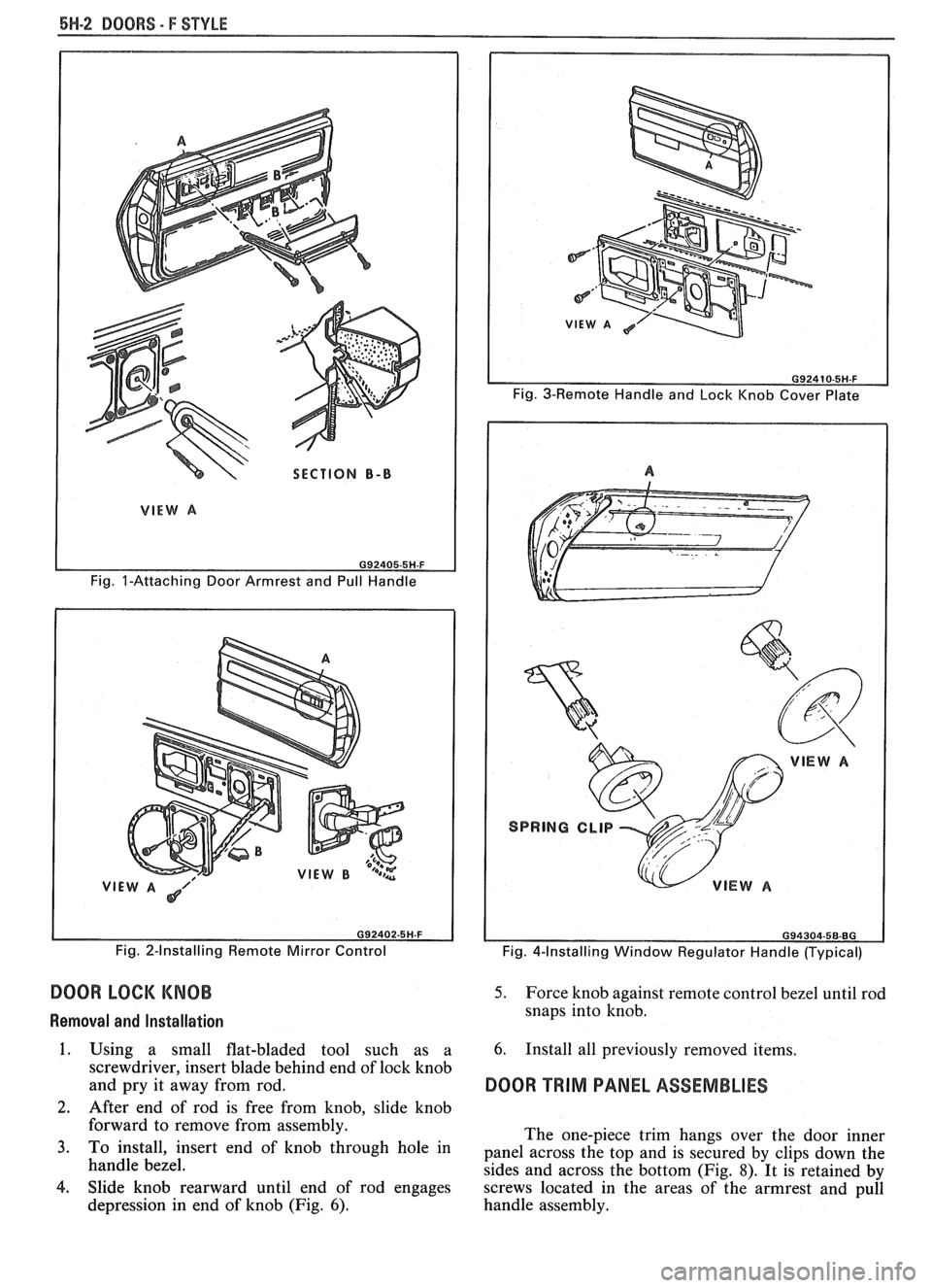

6H-2 DOORS - F STYLE

SECTION B-B

Fig. I-Attaching Door Armrest and Pull Handle

VIE Fig. 2-Installing Remote Mirror Control

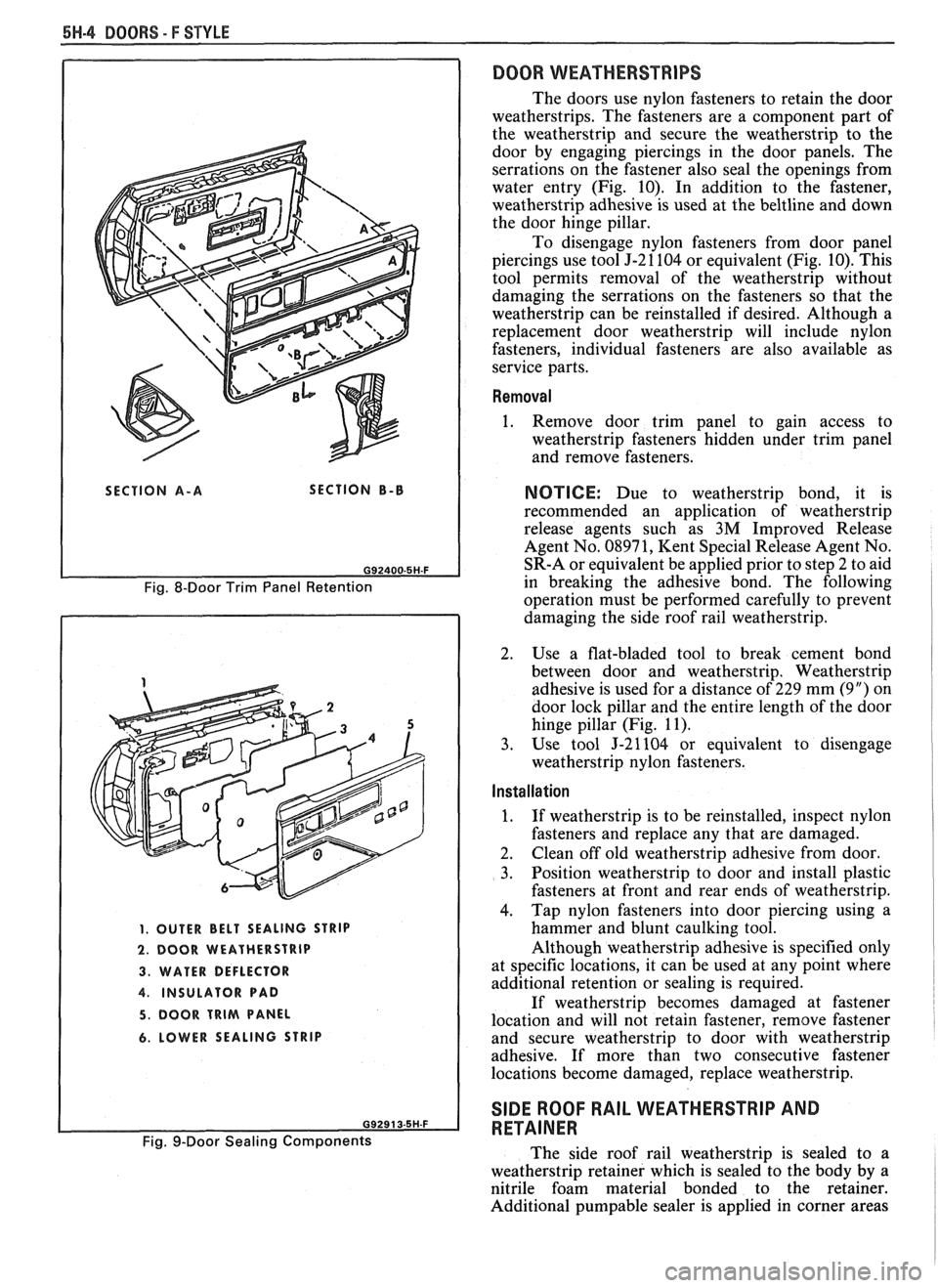

DOOR LOCK KNOB

Removal and Installation

1. Using a small flat-bladed tool such as a

screwdriver, insert blade behind end of lock knob

and pry it away from rod.

2. After end of rod is free from knob. slide knob

Fig. 3-Remote Handle and Lock Knob Cover Plate

Fig. 4-Installing Window Regulator Handle (Typical)

5. Force knob against remote control bezel until rod

snaps into knob.

6. Install all previously removed items.

DOOR TRIM PANEL ASSEMBLIES

forward to remove from assembly.

The one-piece trim hangs over the door inner

3. To install, insert end of knob through hole in panel across the top and is secured by clips down the

handle bezel.

sides and across the bottom (Fig.

8). It is retained by

4. Slide knob rearward until end of rod engages

screws located in the areas of the armrest and pull

depression in end of knob (Fig.

6). handle assembly.

Page 1716 of 1825

BOORS - F STYLE 5H-3

I

J-9886

7

RETAINING SPRING

DISENGAGED 7

Fig. 5-Removing Clip Retained Door Inside Handle

Fig. 6-Installing Door Lock Knob

Removal

1. Remove all door inside handles.

2. Remove door inside locking rod knob.

3. Remove screws inserted through door armrest

and pull handle assembly into door inner panel or

armrest hanger support bracket.

4. On styles with remote control mirror assemblies,

remove control plate from bezel on trim pad and

remove control from plate.

5. On styles with power door lock controls located

in door trim panel, disconnect wire harnesses at

switch assemblies (Fig. 7).

6. Remove remote control handle bezel screws (Fig.

3)

7. Remove

screws used to hold armrest to inner

panel (Fig.

1).

8. Remove screws and plastic retainers from

perimeter of door trim panel using tool

BT-73238 or equivalent and a screwdriver (Fig.

8).

To remove trim panel, push trim upward and

outboard to disengage from door inner panel at

the beltline.

9. On styles with water deflector held in place by

fasteners, use tool BT-7323A or equivalent to

remove fasteners and water deflector.

Installation

1. To install water deflector, locate fasteners in

holes in door inner panel and press in place.

Replace all tape which may have been applied to

assist in holding water deflector in place.

Fig. 7-Installing Power Door Lock Switch

2. Before installing door trim panel, make certain

that all trim retainers are installed securely to the

panel and are not damaged. Where required,

replace damaged retainers. Start retainer Range

into 6.3 mm

(1/4") cutout attachment hole in

trim panel, rotate retainer until flange is engaged

fully.

3. Connect electrical components where present.

4. To install door trim panel, locate top of assembly

over upper flange of door inner panel, inserting

door handle through handle slot in panel and

press down on trim panel to engage upper

retaining clips.

5. Position trim panel to door inner panel so trim

retainers are aligned with attaching holes in panel

and tap retainers into holes with palm of hand or

a clean rubber mallet.

6. Install all previously removed items.

BOORS

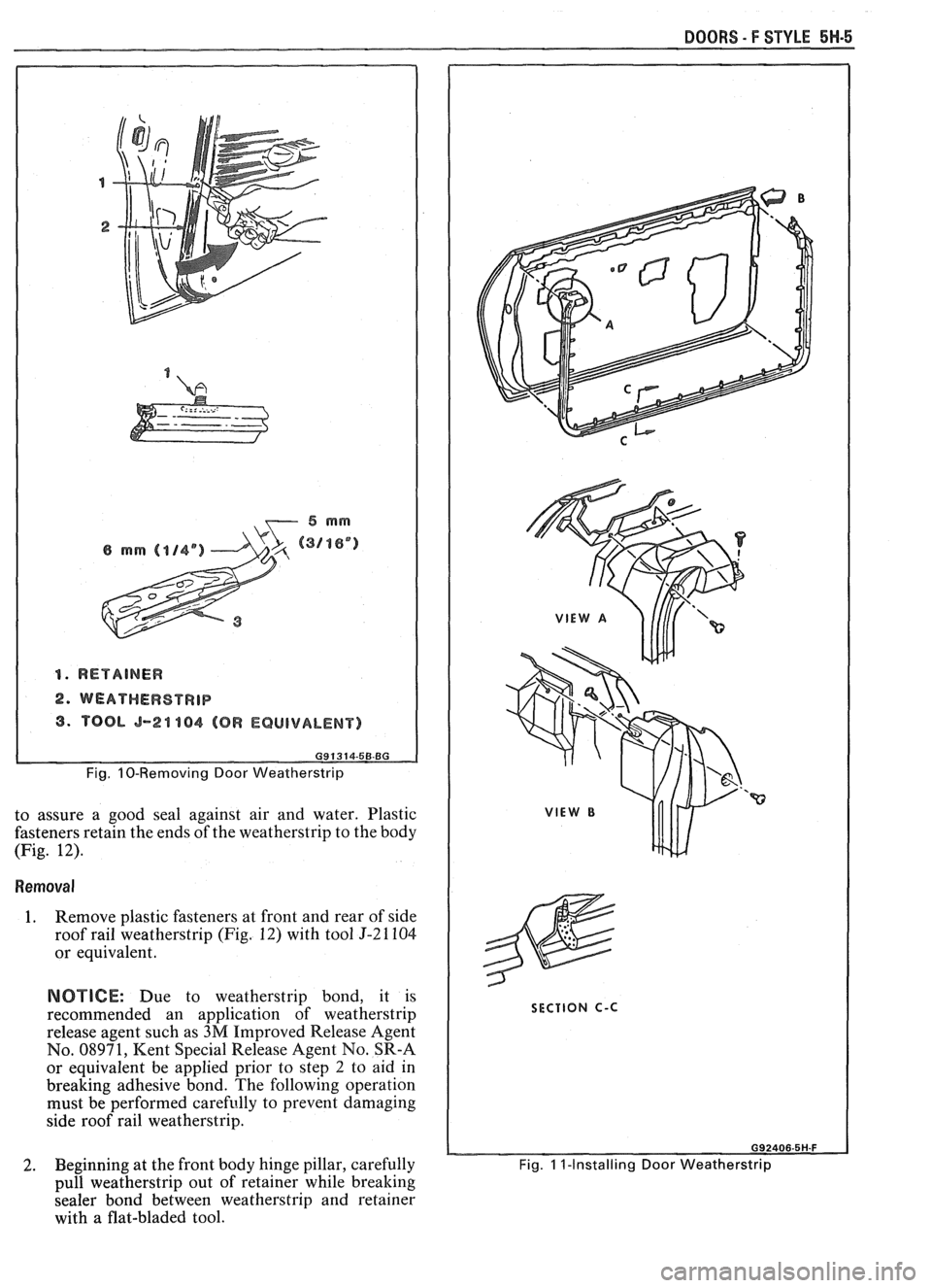

DOOR SEALING

The following section contains service operations

necessary to remove the components which seal doors

against air and water entry into the passenger

compartment. Items included are window belt sealing

strips, insulator pads, inner panel water deflector and

door opening weatherstrips.

Figure

9 shows exploded views of the door sealing

components. Most parts shown are available through

the service parts system.

Page 1717 of 1825

5H.4 DOORS - F STYLE

SECTION A-A SECTION B-B

Fig. 8-Door Trim Panel Retention

1. OUTER BELT SEALING STRIP

2. DOOR WEATHERSTRIP

3. WATER DEFLECTOR

4. INSULATOR PAD

5. DOOR TRIM PANEL

6. LOWER SEALING STRIP

Fig. 9-Door Sealing Components

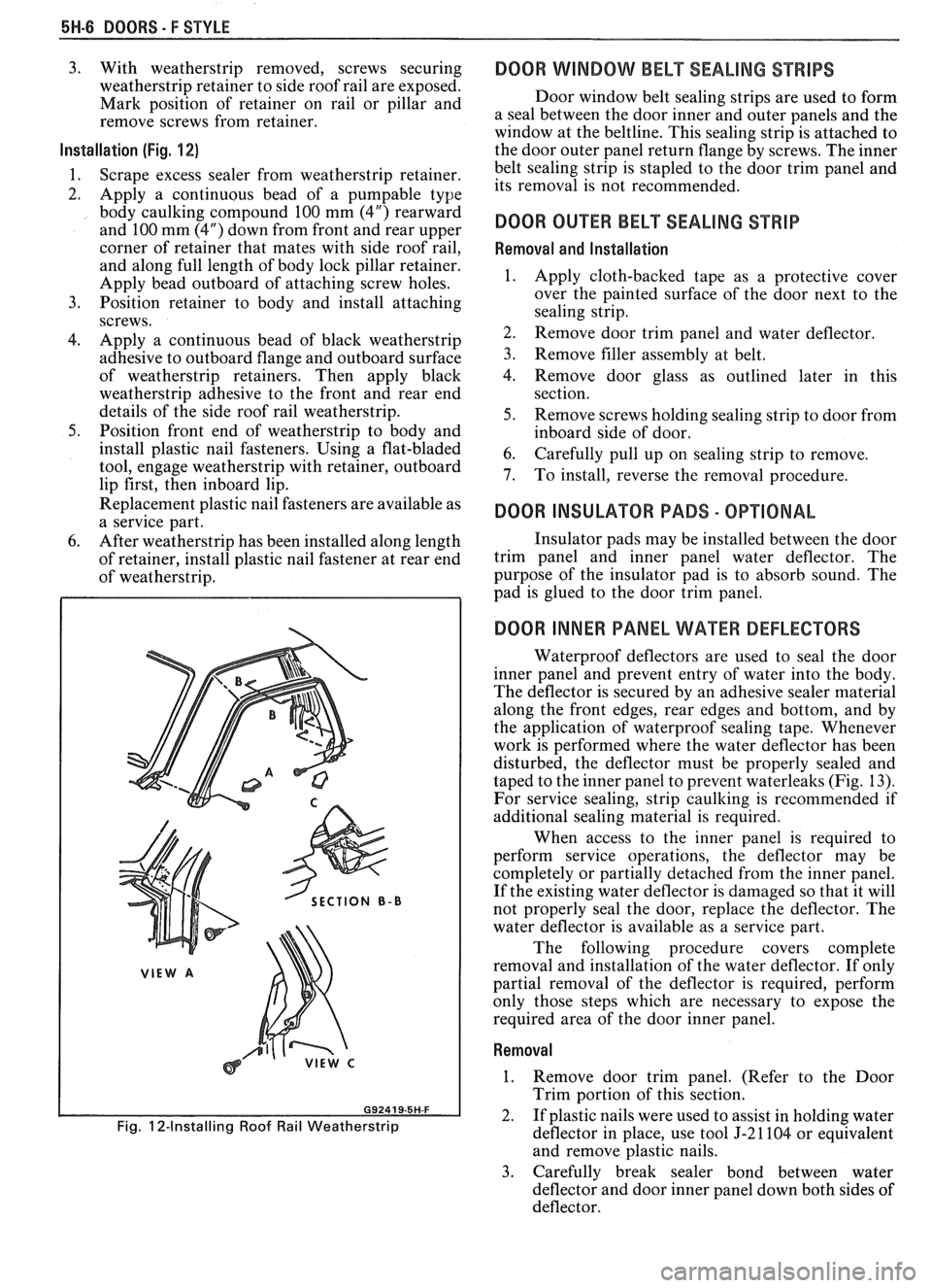

DOOR WEATHERSTRIPS

The doors use nylon fasteners to retain the door

weatherstrips. The fasteners are a component part of

the weatherstrip and secure the weatherstrip to the

door by engaging piercings in the door panels. The

serrations on the fastener also seal the openings from

water entry (Fig. 10). In addition to the fastener,

weatherstrip adhesive is used at the

beltline and down

the door hinge pillar.

To disengage nylon fasteners from door panel

piercings use tool J-21104 or equivalent (Fig. 10). This

tool permits removal of the weatherstrip without

damaging the serrations on the fasteners so that the

weatherstrip can be reinstalled if desired. Although a

replacement door weatherstrip will include nylon

fasteners, individual fasteners are also available as

service parts.

Removal

1. Remove door trim panel to gain access to

weatherstrip fasteners hidden under trim panel

and remove fasteners.

NOTICE: Due to weatherstrip bond, it is

recommended an application of weatherstrip

release agents such as

3M Improved Release

Agent No. 08971, Kent Special Release Agent No.

SR-A or equivalent be applied prior to step 2 to aid

in breaking the adhesive bond. The following

operation must be performed carefully to prevent

damaging the side roof rail weatherstrip.

2. Use a flat-bladed tool to break cement bond

between door and weatherstrip. Weatherstrip

adhesive is used for a distance of 229 mm (9") on

door lock pillar and the entire length of the door

hinge pillar (Fig. 11).

3. Use tool J-21104 or equivalent to disengage

weatherstrip nylon fasteners.

Installation I 1

1. If weatherstrip is to be reinstalled, inspect nylon

fasteners and replace any that are damaged.

2. Clean

off old weatherstrip adhesive from door.

3. Position weatherstrip to door and install plastic

fasteners at front and rear ends of weatherstrip.

4. Tap

nylon fasteners into door piercing using a

hammer and blunt caulking tool.

Although weatherstrip adhesive is specified only

at specific locations, it can be used at any point where

additional retention or sealing is required.

If weatherstrip becomes damaged at fastener

location and will not retain fastener, remove fastener

and secure weatherstrip to door with weatherstrip

adhesive. If more than two consecutive fastener

locations become damaged, replace weatherstrip.

SIDE ROOF RAIL WEATHERSTRIP AND

RETAINER

The side roof rail weatherstrip is sealed to a

weatherstrip retainer which is sealed to the body by a

nitrile foam material bonded to the retainer.

Additional

pumpable sealer is applied in corner areas

Page 1718 of 1825

DOORS - F STYLE 5H-5

1. RETAINER

2. WEATHEWSTRIP

3. TOOL 5-24 184 (OR EQUIVALENT)

Fig. 10-Removing Door Weatherstrip

to assure a good seal against air and water. Plastic

fasteners retain the ends of the weatherstrip to the body

(Fig. 12).

Removal I

1. Remove plastic fasteners at front and rear of side

roof rail weatherstrip (Fig.

12) with tool 5-21 104

or equivalent.

NOTICE: Due to weatherstrip bond, it is

recommended an application of weatherstrip

release agent such as

3M Improved Release Agent

No. 08971,

Kent Special Release Agent No. SR-A

or equivalent be applied prior to step

2 to aid in

breaking adhesive bond. The following operation

must be performed carefully to prevent damaging

side roof rail weatherstrip.

2. Beginning

at the front body hinge pillar, carefully

h

pull weatherstrip out of retainer while breaking

sealer bond between weatherstrip and retainer

with a flat-bladed tool.

SECTION C-C

Fig. 1 I-Installing Door Weatherstrip

Page 1719 of 1825

5W-8 BOORS - F STYLE

3. With weatherstrip removed, screws securing

weatherstrip retainer to side roof rail are exposed.

Mark position of retainer on rail or pillar and

remove screws from retainer.

Installation (Fig. 1 2)

1.

Scrape excess sealer from weatherstrip retainer.

2. Apply a continuous bead of a

pumpable type

body caulking compound 100 mm (4") rearward

and 100 mm (4") down from front and rear upper

corner of retainer that mates with side roof rail,

and along full length of body lock pillar retainer.

Apply bead outboard of attaching screw holes.

3. Position retainer to body and install attaching

screws.

4. Apply a continuous bead of black weatherstrip

adhesive to outboard flange and outboard surface

of weatherstrip retainers. Then apply black

weatherstrip adhesive to the front and rear end

details of the side roof rail weatherstrip.

5. Position front end of weatherstrip to body and

install plastic nail fasteners. Using a flat-bladed

tool, engage weatherstrip with retainer, outboard

lip first, then inboard lip.

Replacement plastic nail fasteners are available as

a service part.

6. After weatherstrip has been installed along length

of retainer, install plastic nail fastener at rear end

of weatherstrip.

SECTION B-B

Fig. 12-Installing Roof Rail Weatherstrip

DOOR WINDOW BELT SEALING STRIPS

Door window belt sealing strips are used to form

a seal between the door inner and outer panels and the

window at the beltline. This sealing strip is attached to

the door outer panel return flange by screws. The inner

belt sealing strip is stapled to the door trim panel and

its removal is not recommended.

DOOR OUER BELT SEALING STRIP

Removal and Installation

1.

Apply cloth-backed tape as a protective cover

over the painted surface of the door next to the

sealing strip.

2. Remove door trim panel and water deflector.

3. Remove filler assembly at belt.

4. Remove door glass as outlined later in this

section.

5. Remove screws holding sealing strip to door from

inboard side of door.

6. Carefully pull up on sealing strip to remove.

7. To install, reverse the removal procedure.

DOOR INSULAWR PADS - OPTIONAL

Insulator pads may be installed between the door

trim panel and inner panel water deflector. The

purpose of the insulator pad is to absorb sound. The

pad is glued to the door trim panel.

DOOR INNER PANEL WATER DEFLECTORS

Waterproof deflectors are used to seal the door

inner panel and prevent entry of water into the body.

The deflector is secured by an adhesive sealer material

along the front edges, rear edges and bottom, and by

the application of waterproof sealing tape. Whenever

work is performed where the water deflector has been

disturbed, the deflector must be properly sealed and

taped to the inner panel to prevent waterleaks (Fig. 13).

For service sealing, strip caulking is recommended if

additional sealing material

is required.

When access to the inner panel is required to

perform service operations, the deflector may be

completely or partially detached from the inner panel.

If the existing water deflector is damaged so that it will

not properly seal the door, replace the deflector. The

water deflector is available as a service part.

The following procedure covers complete

removal and installation of the water deflector. If only

partial removal of the deflector is required, perform

only those steps which are necessary to expose the

required area of the door inner panel.

Removal

1. Remove door trim panel. (Refer to the Door

Trim portion of this section.

2. If plastic nails were used to assist in holding water

deflector in place, use tool J-21104 or equivalent

and remove plastic nails.

3. Carefully break sealer bond between water

deflector and door inner panel down both sides of

deflector.

Page 1720 of 1825

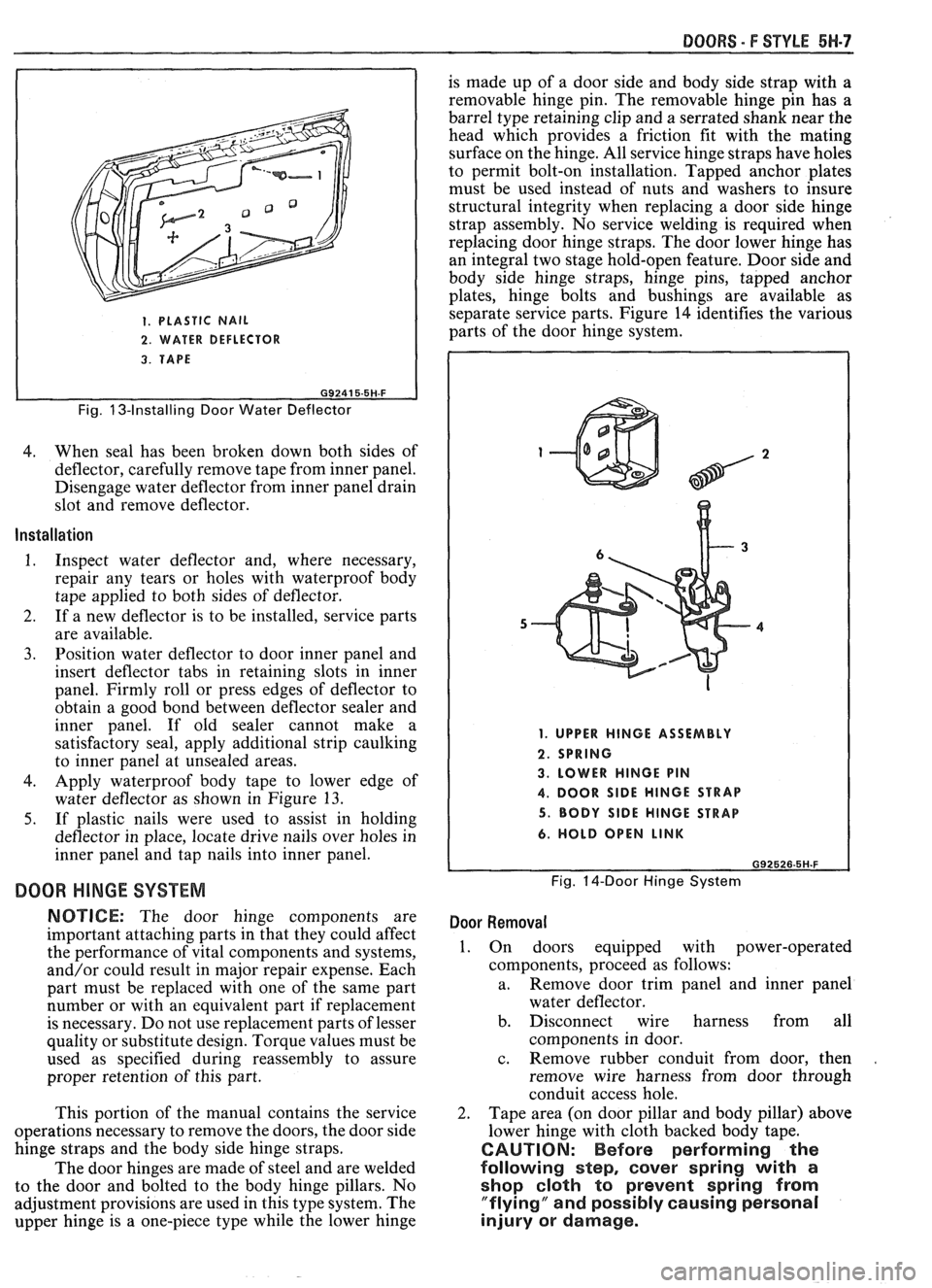

1. PLASTIC NAIL

2. WATER DEFLECTOR

DOORS - F STYLE 5H-7

is made up of a door side and body side strap with a

removable hinge pin. The removable hinge pin has

a

barrel type retaining clip and a serrated shank near the

head which provides a friction fit with the mating

surface on the hinge. All service hinge straps have holes

to permit bolt-on installation. Tapped anchor plates

must be used instead of nuts and washers to insure

structural integrity when replacing a door side hinge

strap assembly. No service welding is required when

replacing door hinge straps. The door lower hinge has

an integral two stage hold-open feature. Door side and

body side hinge straps, hinge pins, tapped anchor

plates, hinge bolts and bushings are available as

separate service parts. Figure 14 identifies the various

parts of the door hinge system.

3. TAPE

I

Fig. 13-Installing Door Water Deflector

4. When seal has been broken down both sides of

deflector, carefully remove tape from inner panel.

Disengage water deflector from inner panel drain

slot and remove deflector.

Installation

1. Inspect water deflector and, where necessary,

repair any tears or holes with waterproof body

tape applied to both sides of deflector.

2. If a new deflector is to be installed, service parts

are available.

3. Position water deflector to door inner panel and

insert deflector tabs in retaining slots in inner

panel. Firmly roll or press edges of deflector to

obtain a good bond between deflector sealer and

inner panel. If old sealer cannot make a

satisfactory seal, apply additional strip caulking

to inner panel at unsealed areas.

4. Apply waterproof body tape to lower edge of

water deflector as shown in Figure

13.

5. If plastic nails were used to assist in holding

deflector in place, locate drive nails over holes in

inner panel and tap nails into inner panel.

DOOR HINGE SYSTEM

NOTICE: The door hinge components are

important attaching parts in that they could affect

the performance of vital components and systems,

and/or could result in major repair expense. Each

part must be replaced with one of the same part

number or with an equivalent part if replacement

is necessary. Do not use replacement parts of lesser

quality or substitute design. Torque values must be

used as specified during reassembly to assure

proper retention of this part.

This portion of the manual contains the service

operations necessary to remove the doors, the door side

hinge straps and the body side hinge straps.

The door hinges are made of steel and are welded

to the door and bolted to the body hinge pillars. No

adjustment provisions are used in this type system. The

upper hinge is a one-piece type while the lower hinge

1. UPPER HINGE ASSEMBLY

2. SPRING

3. LOWER HINGE PIN

4. DOOR SlDE HINGE STRAP

5. BODY SlDE HINGE STRAP

6. HOLD OPEN LINK

Fig. 14-Door Hinge System

Door Removal

1. On doors equipped with power-operated

components, proceed as follows:

a. Remove

door trim panel and inner panel

water deflector.

b. Disconnect wire harness from all

components in door.

c. Remove rubber conduit from door, then

.

remove wire harness from door through

conduit access hole.

2. Tape area (on door pillar and body pillar) above

lower hinge with cloth backed body tape.

CAUTION: Before performing the

following step,

cover spring with a

shop cloth to prevent spring from

"flying" and possibly causing personal

injury or damage.