tires PONTIAC FIERO 1988 Service Owner's Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 148 of 1825

-

WHEEL. ALIGNMENT 3A-1

SECTION 3A

WHEEL AL GNMENT

NOTICE: These fasteners are important attaching Do not use a replacement part of lesser quality or

parts, in that they could affect the performance of substitute

design. Torque values must be used as

vital components and systems, and/or could result specified during reassembly to assure proper

in major repair expense. They must be replaced retention of these parts. For prevailing torque

with one of the same part number or with an

nut(s) and bolt(s), refer to the "Reuse of Prevailing

equivalent part if replacement becomes necessary. torque

Nut(s) and Bolt(s)" chart in Section 0.

General Description ...................... .. ...... 3A- 1 On-Car Service ........................ .. ........... 3A-2

Caster .................... .. ............................ 3A- 1 Caster and Camber Adjustment .................. 3A-2

..................................... Camber ................... .. .............................. 3A-I Toe-In Adjustment 3A-2

Toe.. ................................................. 3A- 1 Axle Housing Alignment ......................... .... 3A-4

Preliminary Checks Prior to Specifications ....................... ... ............... 3A-4

Adjusting Alignment ..................... ...... 3A- 1

GENERAL DESCRIPmIOMI

Wheel alignment refers to the angular they tend to roll parallel on the road when the car is

relationship between the wheels, the suspension moving.

attaching parts and the ground.

PRELIMINARY CHECKS PRIOR TO ADJUSTING

CASTER ALIGNMENT

Figure 1

Caster is the amount the top of the strut is tilted

forward or rearward from the vertical. When the strut

tilts rearward, the center is "positive"

(+). The

amount of tilt is measured in degrees from vertical.

CAMBER

Figure 1

Camber is the tilting of the wheels from the

vertical when viewed from the front of the car. When

the wheels tilt outward at the top, the camber is said

to be positive

(+). When the wheels tilt inward at the

top, the camber is said to be negative

(-). The amount

of tilt is measured in degrees from the vertical and this

measurement is called the camber angle.

TOE

Figure i

Toe is a measurement of how much the front of

the wheels are turned in or out from a straight-ahead

position. When the wheels are turned in, toe is

"positive"

(+). When the wheels are turned out, toe

is "negative"

(-). The actual amount of toe-in is

normally only a fraction of a degree. The purpose of a

toe specification is to ensure parallel rolling of the

wheels (excessive toe-in or toe-out may increase tire

wear). Toe also serves to offset the small deflections of

the wheel support system which occur when the car is

rolling forward. In other words, even when the wheels

are set to toe-in slightly when the car is standing still, Steering

and vibration complaints are not always

the result of improper alignment. Another possibility

is tire "lead" due to worn or improperly manufactured

tires. "Lead" is the deviation of the car from a straight

path on a level road without hand pressure on the

steering wheel. Section

3 of this manual contains a

procedure for determining the presence of a tire lead

problem.

Before making any adjustment affecting wheel

alignment, make the following checks to ensure correct

alignment readings and alignment adjustments:

1. Check all tires for proper inflation pressures and

approximately the same tread wear.

2. Hub and bearing assemblies for excessive wear;

correct if necessary.

3. Ball joints and tie rod ends; if they are excessively

lcose, correct them before adjusting.

4. Run-out of wheels and tires.

5. Car trim height; if out of limits and a correction

is to be made, do so before adjusting alignment.

Refer to Section

3 for trim height specifications.

6. Strut dampeners for proper operation.

7. Control arms for loose bushings.

8. Loose or missing stabilizer bar attachments.

Consideration must be given to excess loads, such

as tool boxes, sample cases, etc. If these items are

normally carried in the car, they should remain in the

car during alignment adjustments. Consideration

should also be given to the condition of the equipment

used to adjust alignment. Be sure to follow the

equipment manufacturer's instructions. Regardless

of

Page 195 of 1825

387-2 POWER STEERING

The effect of improperly adjusted worm thrust

bearings or an improperly adjusted over-center preload

could cause a handling stability complaint.

To properly adjust the power steering gear, the

assembly MUST be removed from the vehicle and

adjustments performed as outlined.

For removal of the power steering gear assembly

see "Power Steering Gear".

DRIVE BELT TENSION

All drive belt tension specifications can be found

in the Engine Cooling Section 6B.

When adjusting a power steering pump belt,

never pry against the pump reservoir or pull against the

filler neck. Two systems are used for belt adjustment.

On some

models, the pump is loosened from the

bracket and moved outward to increase the tension. On

other models, a half-inch square drive hole is located

in the bracket, and this hole is used to rotate the

pump-and-bracket assembly outward to increase belt

tension.

Place belt tension gage, J-23600 or equivalent

midway between the pulleys on drive belt being

checked.

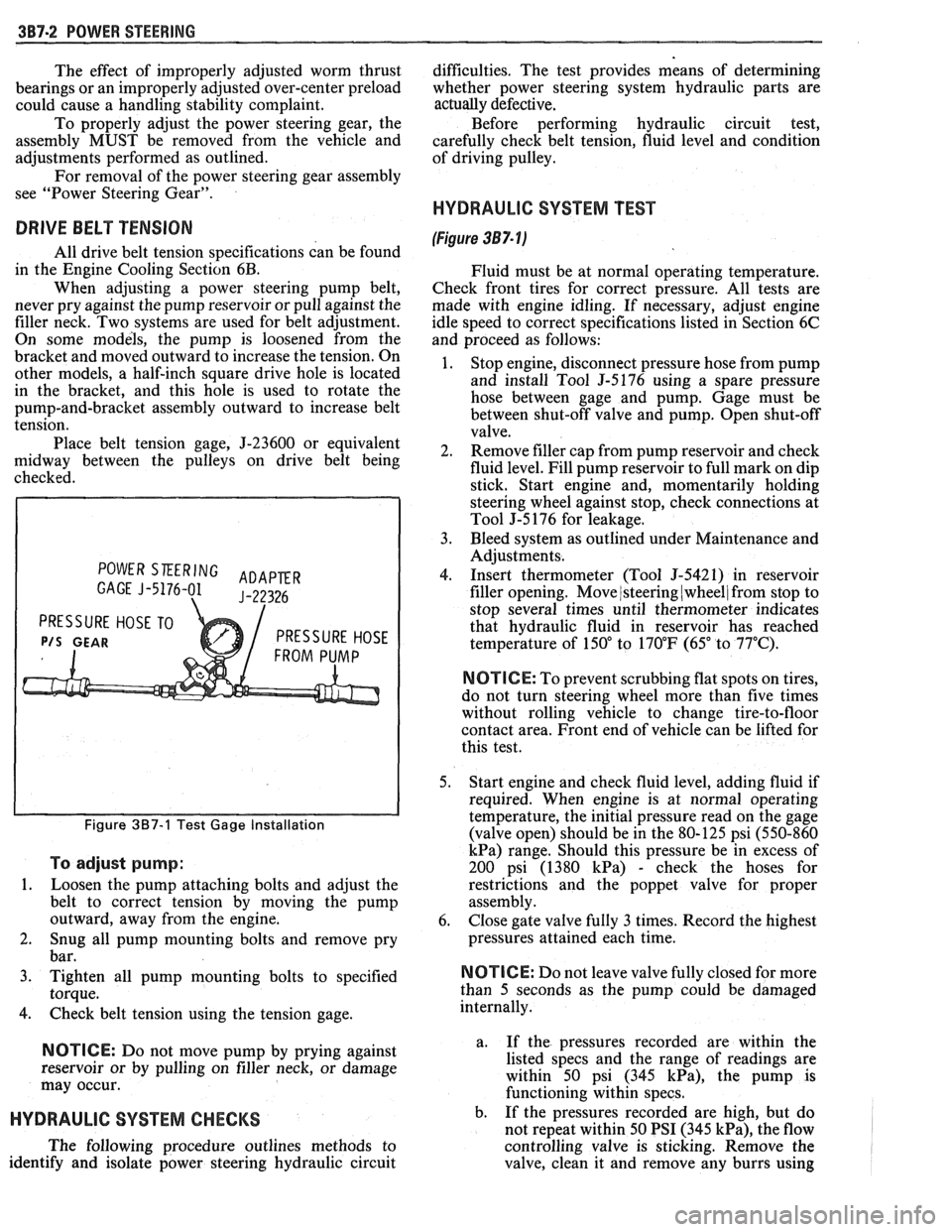

POWER SKERING ADAPER GAGE J-5176-01 J-22326

PRESSURE HOSE TO

P/S GEAR PRESSURE HOSE

Figure 387-1 Test Gage Installation

To adjust pump:

1.

Loosen the pump attaching bolts and adjust the

belt to correct tension by moving the pump

outward, away from the engine.

2. Snug all pump mounting bolts and remove pry

bar.

3. Tighten all pump mounting bolts to specified

torque.

4. Check belt tension using the tension gage.

NOTICE: Do not move pump by prying against

reservoir or by pulling on filler neck, or damage

may occur.

HYDRAULIC SYSTEM CHECKS

The following procedure outlines methods to

identify and isolate power steering hydraulic circuit difficulties.

The test provides means of determining

whether power steering system hydraulic parts are

actually

defective.

Before performing hydraulic circuit test,

carefully check belt tension, fluid level and condition

of driving pulley.

HYDRAULIC SYSTEM TEST

(Figure 387- lj

Fluid must be at normal operating temperature.

Check front tires for correct pressure. All tests are

made with engine idling. If necessary, adjust engine

idle speed to correct specifications listed in Section 6C

and proceed as follows:

1. Stop engine, disconnect pressure hose from pump

and install Tool

5-5176 using a spare pressure

hose between gage and pump. Gage must be

between shut-off valve and pump. Open shut-off

valve.

2. Remove filler cap from pump reservoir and check

fluid level. Fill pump reservoir to full mark on dip

stick. Start engine and, momentarily holding

steering wheel against stop, check connections at

Tool J-5 176 for leakage.

3. Bleed system as outlined under Maintenance and

Adjustments.

4. Insert thermometer (Tool J-5421) in reservoir

filler opening. Move

/steering (wheel/ from stop to

stop several times until thermometer indicates

that hydraulic fluid in reservoir has reached

temperature of

150" to 170°F (65" to 77°C).

N OTI G E: To prevent scrubbing flat spots on tires,

do not turn steering wheel more than five times

without rolling vehicle to change tire-to-floor

contact area. Front end of vehicle can be lifted for

this test.

5. Start engine and check fluid level, adding fluid if

required. When engine is at normal operating

temperature, the initial pressure read on the gage

(valve open) should be in the 80-125 psi (550-860

kPa) range. Should this pressure be in excess of

200 psi (1380

kPa) - check the hoses for

restrictions and the poppet valve for proper

assembly.

6. Close gate valve fully

3 times. Record the highest

pressures attained each time.

N OTI C E: Do not leave valve fully closed for more

than

5 seconds as the pump could be damaged

internally.

a. If

the pressures recorded are within the

listed specs and the range of readings are

within 50 psi (345

kPa), the pump is

functioning within specs.

b. If the pressures recorded are high, but do

not repeat within 50 PSI (345

kPa), the flow

controlling valve is sticking. Remove the

valve, clean it and remove any burrs using

Page 232 of 1825

TIRES AND WHEELS 3E-1

RES AND WHEELS

NOTICE: All wheel bolt and nut fasteners are important attaching parts in that they could affect the

performance of vital components and systems, and/or could result in major repair expense. They must be replaced

with one of the same part number or with an equivalent part if replacement becomes necessary. Do not use a

replacement part of lesser quality or substitute design. Torque values must be used as specified during reassembly

to assure proper retention of parts.

CONTENTS

Diagnosis ............................................... Section 3 Tire Repair ................................................... 3E-5

General Information .......................... ..... 3E-1 Waddle ........................................................ 3E-5

........ Replacement Tires ....................... ... 3E- 1 Measuring Wheel Runout ............................ 3E-6

P-Metric Tires ...................... .. ................... 3E-2 Spare Tire ...................................................... 3E-6 ................................................ Tire Placard 3E-2 Match Mounting ......................................... 3E-7

.......................................................... Wheels 3E-2 Balancing Tire and Wheel ............................ 3E-7

....................... Maintenance and Adjustments .............. 3E-2 General Balance Precautions 3E-7 ...................................... Wheel Repair .............................................. 3E-2 Off-Car Balancing 3E-8 .............................. Metric Wheel Nuts and Studs .................... .. 3E-3 On-Car Balancing .. ...... 3E-8

......................................... Inflation of Tires ........................................ 3E-3 Wheel Weights 3E-8 .................... Tire Rotation ........................... ...... . 3E-3 Correcting Non-Uniform Tires 3E-8 .......................... Tire Chain Usage ........................................ 3E-4 Aluminum Wheel Cleaning 3E-9 Aluminum Wheel Hub Cap ......................... 3E-9 Service Operations ..................................... 3E-4 Aluminum Wheel Porosity Repair .............. 3E-9 ......................... Wheel Removal .... .......... 3E-4 Aluminum Wheel Refinishing ...................... 3E-9 Tire Mounting and Dismounting ................. 3E-5 Wheel Nut Torque 3E-10 ......................................

GENERAL INFORMATION ~t is recommended that new tires be installed in

pairs on the same axle. If it is necessary to replace only

The tires and are one tire, it should be paired with the tire having the

designed to operate satisfactorily with loads up to and

most tread, to equalize braking traction. including the full rated load capacity when inflated to

Although they may appear different in tread

the recommended inflation pressures.

design, tires built by different manufacturers with

Correct tire pressures, wheel alignment and identical TPC specification numbers, can be

driving techniques have an important influence on tire

intermixed on the same car. life. Heavy cornering, excessive rapid acceleration, and

heavy braking will increase tire wear.

REPLACEMENT TIRES

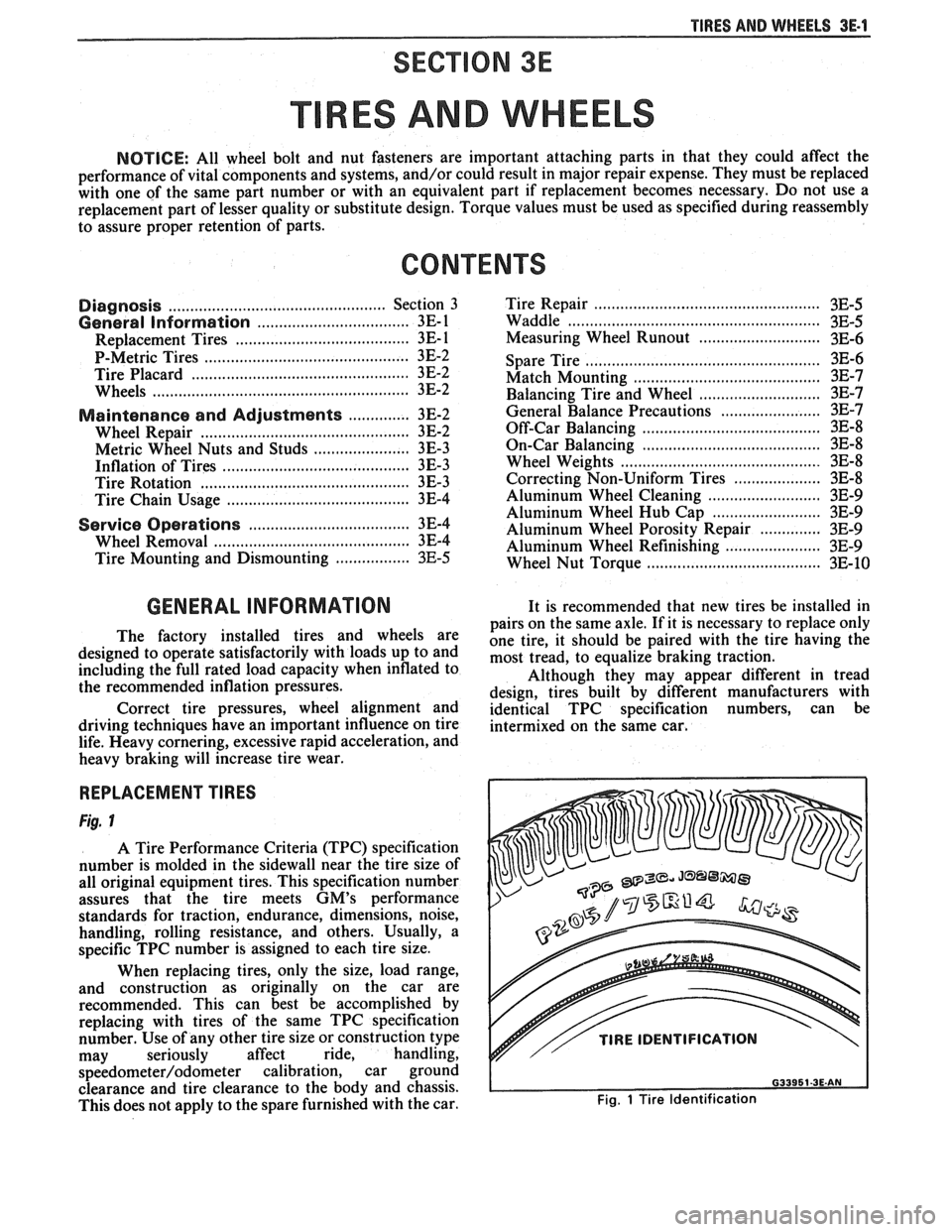

Fig. 1

A Tire Performance Criteria (TPC) specification

number is molded in the sidewall near the tire size of

all original equipment tires. This specification number

assures that the tire meets

GM's performance

standards for traction, endurance, dimensions, noise,

handling, rolling resistance, and others. Usually, a

specific TPC number is assigned to each tire size.

When replacing tires, only the size, load range,

and construction as originally on the car are

recommended. This can best be accomplished by

replacing with tires of the same TPC specification

number. Use of any other tire size or construction type

may seriously affect ride, handling,

speedometer/odometer calibration, car ground

clearance and tire clearance to the body and chassis.

This does not apply to the spare furnished with the car.

v// TIRE IDENTIFICATION

Fig. 1 Tire Identification

Page 233 of 1825

3E.2 TIRES AND WHEELS

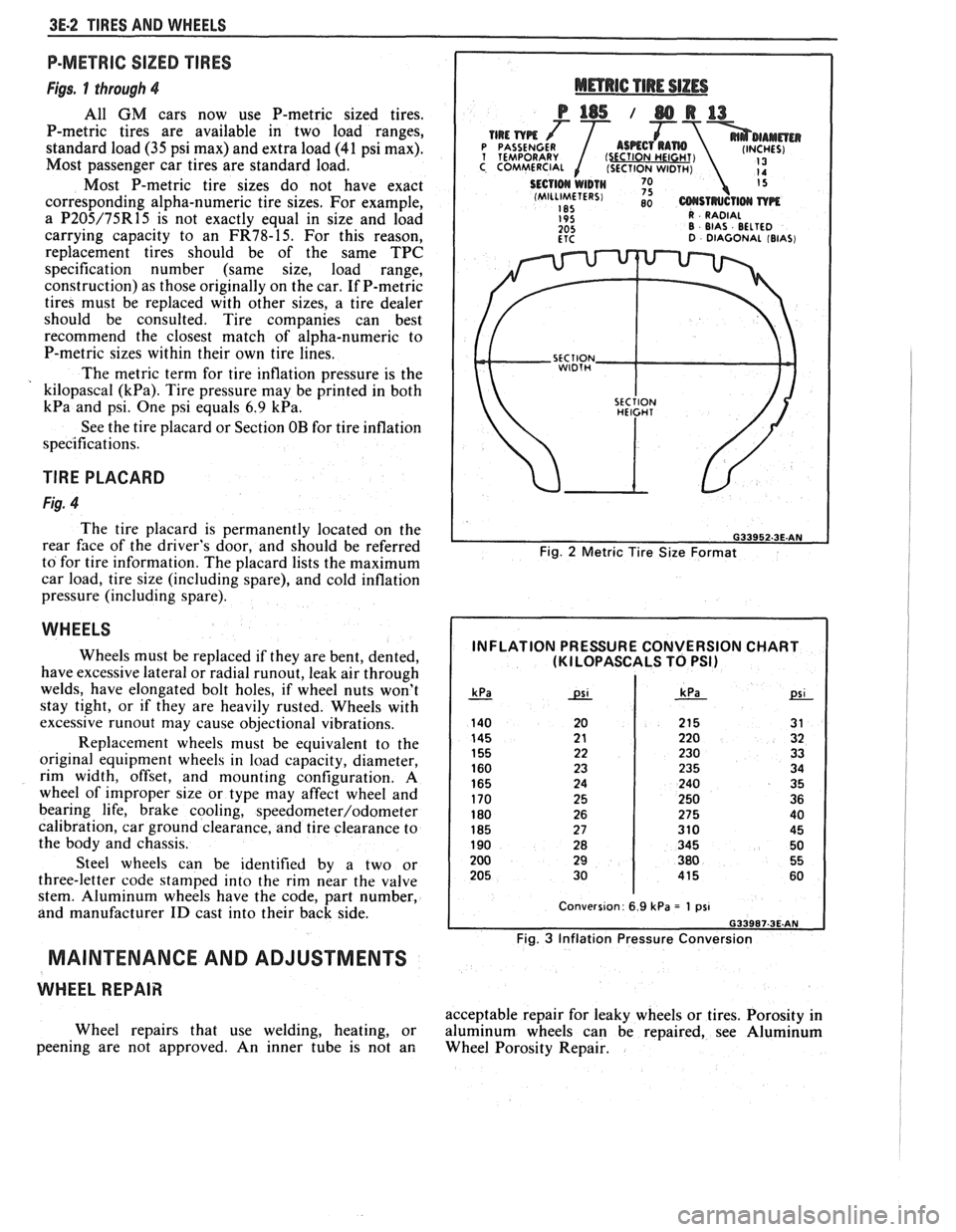

P-METRIC SIZED TIRES

Figs. 1 through 4

All GM cars now use P-metric sized tires.

P-metric tires are available in two load ranges,

standard load

(35 psi max) and extra load (41 psi max).

Most passenger car tires are standard load.

Most P-metric tire sizes do not have exact

corresponding alpha-numeric tire sizes. For example,

a

P205/75R15 is not exactly equal in size and load

carrying capacity to an

FR78-15. For this reason,

replacement tires should be of the same TPC

specification number (same size, load range,

construction) as those originally on the car. If P-metric

tires must be replaced with other sizes, a tire dealer

should be consulted. Tire companies can best

recommend the closest match of alpha-numeric to

P-metric sizes within their own tire lines.

The metric term for tire inflation pressure is the

kilopascal

(kPa). Tire pressure may be printed in both

kPa and psi. One psi equals 6.9 kPa.

See the tire placard or Section OB for tire inflation

specifications.

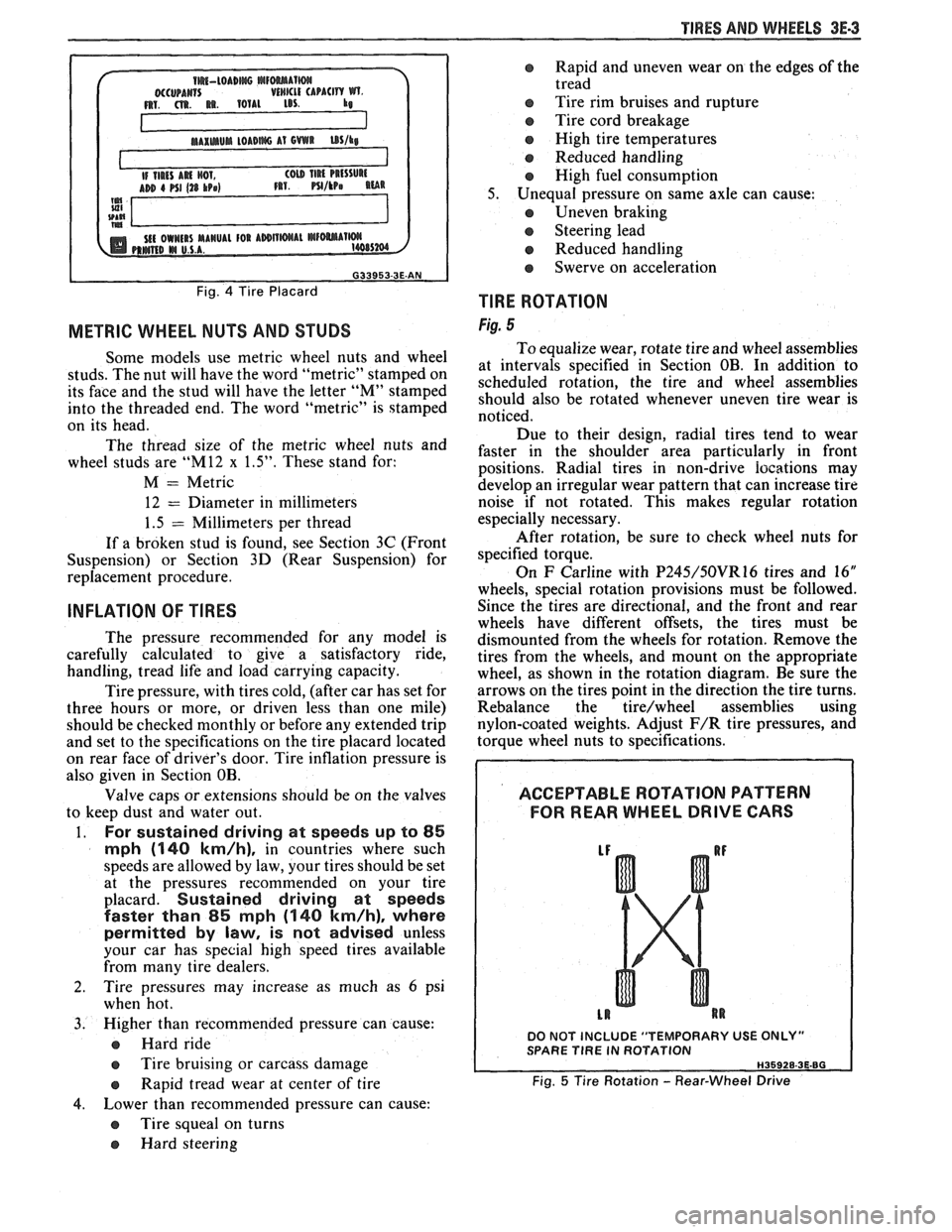

TlRE PLACARD

Fig. 4

The tire placard is permanently located on the

rear

face of the driver's door, and should be referred

to for tire information. The placard lists the maximum

car load, tire size (including spare), and cold inflation

pressure (including spare).

WHEELS

Wheels must be replaced if they are bent, dented,

have excessive lateral or radial

runout, leak air through

welds, have elongated bolt holes, if wheel nuts won't

stay tight, or if they are heavily rusted. Wheels with

excessive

runout may cause objectional vibrations.

Replacement wheels must be equivalent to the

original equipment wheels in load capacity, diameter,

rim width, offset, and mounting configuration.

A

wheel of improper size or type may affect wheel and

bearing life, brake cooling,

speedometer/odometer

calibration, car ground clearance, and tire clearance to

the body and chassis.

Steel wheels can be identified by a two or

three-letter code stamped into the rim near the valve

stem. Aluminum wheels have the code, part number,

and manufacturer

ID cast into their back side.

MAINTENANCE AND ADJUSTMENTS

WHEEL REPAIR

Wheel repairs that use welding, heating, or

peening are not approved. An inner tube is not an

Fig. 2 Metric Tire Size Format

INFLATION PRESSURE CONVERSION CHART (KI LOPASCALS TO PSI)

Fig. 3 Inflation Pressure Conversion

acceptable repair for leaky wheels or tires. Porosity in

aluminum wheels can be repaired, see Aluminum

Wheel Porosity Repair.

Page 234 of 1825

TIRES AND WHEELS 3E-3

METRIC WHEEL NUTS AND STUDS

Some models use metric wheel nuts and wheel

studs. The nut will have the word "metric" stamped on

its face and the stud will have the letter

"M" stamped

into the threaded end. The word "metric" is stamped

on its head.

The thread size of the metric wheel nuts and

wheel studs are

"MI2 x 1.5". These stand for:

M = Metric

12

= Diameter in millimeters

1.5

= Millimeters per thread

If a broken stud is found, see Section 3C (Front

Suspension) or Section 3D (Rear Suspension) for

replacement procedure.

INFLATION OF TIRES

The pressure recommended for any model is

carefully calculated to give a satisfactory ride,

handling, tread life and load carrying capacity.

Tire pressure, with tires cold, (after car has set for

three hours or more, or driven less than one mile)

should be checked monthly or before any extended trip

and set to the specifications on the tire placard located

on rear face of driver's door. Tire inflation pressure is

also given in Section OB.

Valve caps or extensions should be on the valves

to keep dust and water out.

1. For sustained driving at speeds up to 85

mph (140 km/h), in countries where such

speeds are allowed by law, your tires should be set

at the pressures recommended on your tire

placard.

Sustained driving at speeds

faster than

85 mph (140 km/h), where

permitted

by law, is not advised unless

your car has special high speed tires available

from many tire dealers.

2. Tire pressures may increase as much as 6 psi

when hot.

3. Higher

than recommended pressure can cause:

o Hard ride

o Tire bruising or carcass damage

Rapid tread wear at center of tire

4. Lower

than

recommended pressure can cause:

@ Tire squeal on turns

@ Hard steering

o Rapid and uneven wear on the edges of the

tread

Tire rim bruises and rupture

e Tire cord breakage

o High tire temperatures

o Reduced handling

High fuel consumption

5. Unequal pressure on same axle can cause:

Uneven braking

o Steering lead

o Reduced handling

e Swerve on acceleration

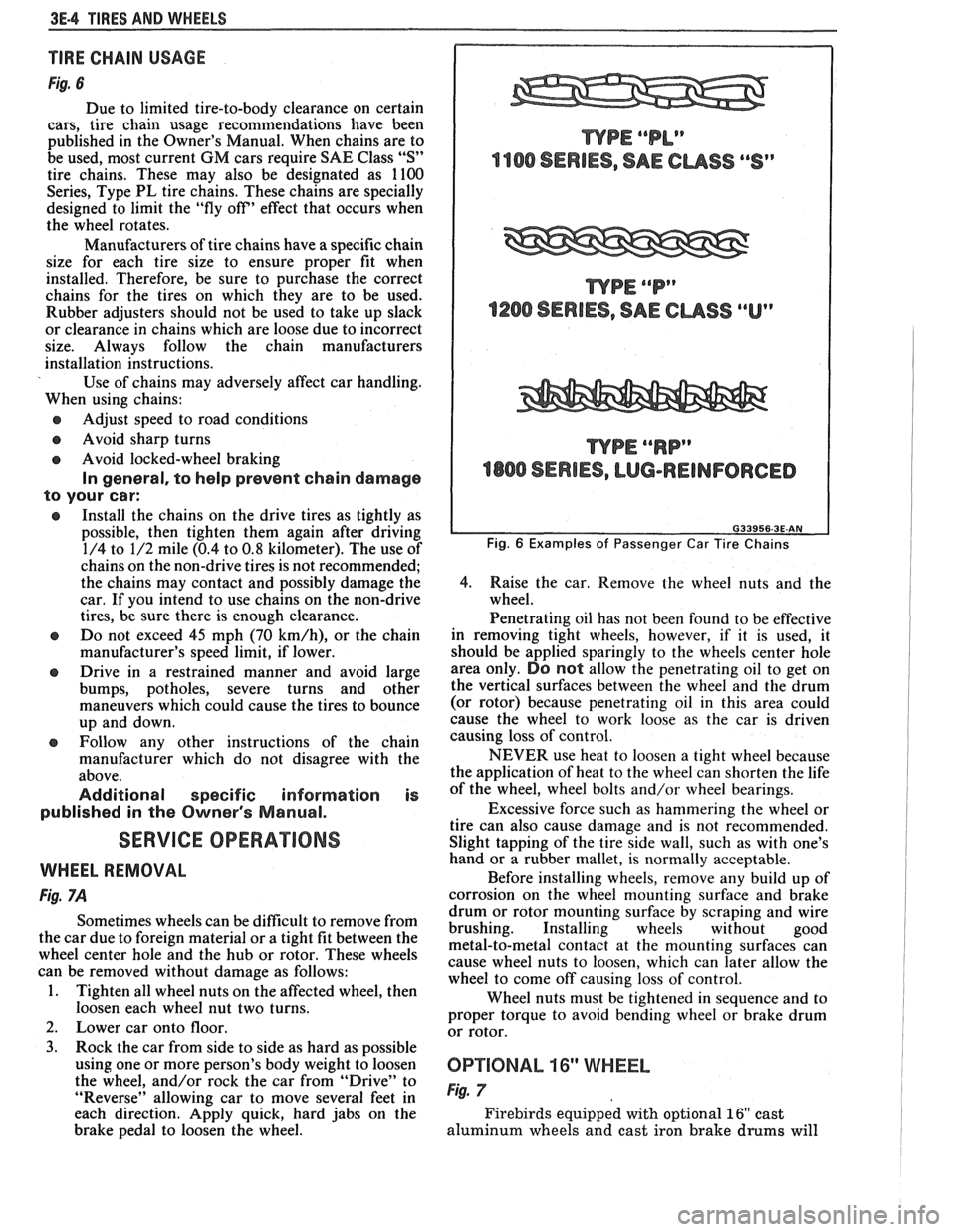

TlRE ROTATION

Fig. 5

To equalize wear, rotate tire and wheel assemblies

at intervals specified in Section OB. In addition to

scheduled rotation, the tire and wheel assemblies

should also be rotated whenever uneven tire wear is

noticed.

Due to their design, radial tires tend to wear

faster in the shoulder area particularly in front

positions. Radial

tires in non-drive

iocations may

develop an irregular wear pattern that can increase tire

noise if not rotated. This makes regular rotation

especially necessary.

After rotation, be sure to check wheel nuts for

specified torque.

On

F Carline with P245/50VR16 tires and 16"

wheels, special rotation provisions must be followed.

Since the tires are directional, and the front and rear

wheels have different offsets, the tires must be

dismounted from the wheels for rotation. Remove the

tires from the wheels, and mount on the appropriate

wheel, as shown in the rotation diagram. Be sure the

arrows on the tires point in the direction the tire turns.

Rebalance the

tire/wheel assemblies using

nylon-coated weights. Adjust

F/R tire pressures, and

torque wheel nuts to specifications.

ACCEPTABLE ROTATION PATTERN

FOR REAR WHEEL

DRIVE GARS

DO NOT INCLUDE "TEMPORARY USE ONLY" SPARE TlRE IN ROTATION

Fig. 5 Tire Rotation - Rear-Wheel Drive

Page 235 of 1825

3E.4 TIRES AND WHEELS

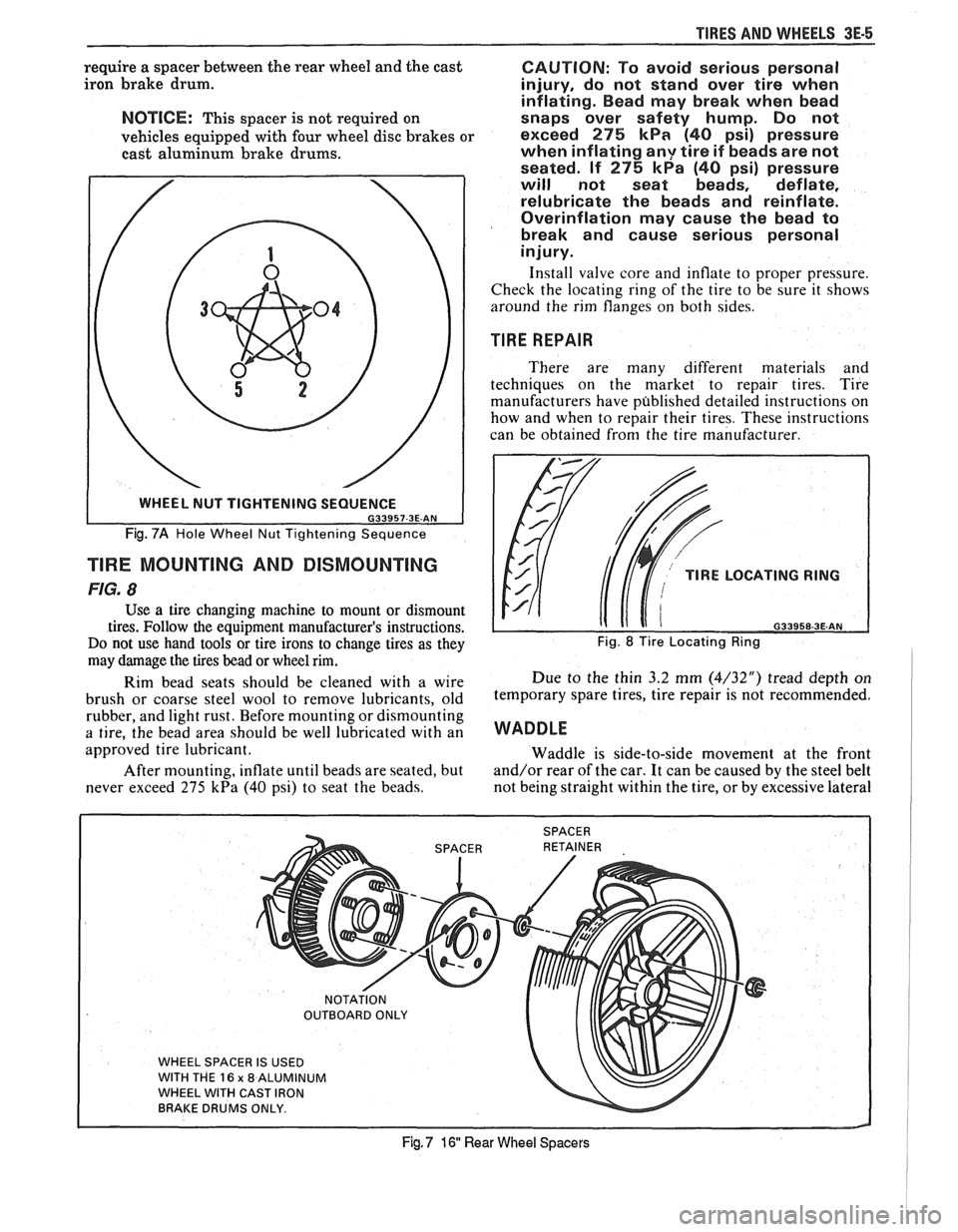

TIRE CHAIN USAGE

Fig. 6

Due to limited tire-to-body clearance on certain

cars, tire chain usage recommendations have been

published in the Owner's Manual. When chains are to

be used, most current

GM cars require SAE Class "S"

tire chains. These may also be designated as 1100

Series, Type PL tire chains. These chains are specially

designed to limit the "fly off' effect that occurs when

the wheel rotates.

Manufacturers of tire chains have a specific chain

size for each tire size to ensure proper fit when

installed. Therefore, be sure to purchase the correct

chains for the tires on which they are to be used.

Rubber adjusters should not be used to take up slack

or clearance in chains which are loose due to incorrect

size. Always follow the chain manufacturers

installation instructions.

Use of chains may adversely affect car handling.

When using chains:

@ Adjust speed to road conditions

@ Avoid sharp turns

@ Avoid locked-wheel braking

In general, to help prevent chain damage

to your car:

@ Install the chains on the drive tires as tightly as

possible, then tighten them again after driving

1/4 to 1/2 mile (0.4 to

0.8 kilometer). The use of

chains on the non-drive tires is not recommended;

the chains may contact and possibly damage the

car. If you intend to use chains on the non-drive

tires, be sure there is enough clearance.

e Do not exceed 45 mph (70 km/h), or the chain

manufacturer's speed limit, if lower.

@ Drive in a restrained manner and avoid large

bumps, potholes, severe turns and other

maneuvers which could cause the tires to bounce

up and down.

e Follow any other instructions of the chain

manufacturer which do not disagree with the

above.

Additional specific information is

published in the Owner's Manual.

SERVICE OPERATIONS

WHEEL REMOVAL

Fig. 7A

Sometimes wheels can be difficult to remove from

the car due to foreign material or a tight fit between the

wheel center hole and the hub or rotor. These wheels

can be removed without damage as follows:

1. Tighten all wheel nuts on the affected wheel, then

loosen each wheel nut two turns.

2. Lower car onto floor.

3. Rock the car from side to side as hard as possible

using one or more person's body weight to loosen

the wheel, and/or rock the car from

"Drive" to

"Reverse" allowing car to move several feet in

each direction. Apply quick, hard jabs on the

brake pedal to loosen the wheel.

WPE ""P"

1200 SERIES, SAE CUSS ""Up

WPE ""RP"

4800 SERIES, LUG-REINFORCED

Fig. 6 Examples of Passenger Car Tire Chains

4.

Raise the car. Remove the wheel nuts and the

wheel.

Penetrating oil has not been found to be effective

in removing tight wheels, however,

if it is used, it

should be applied sparingly to the wheels center hole

area only.

DO not allow the penetrating oil to get on

the vertical surfaces between the wheel and the drum

(or rotor) because penetrating oil in this area could

cause the wheel to work loose as the car is driven

causing loss of control.

NEVER use heat to loosen a tight wheel because

the application of heat to the wheel can shorten the life

of the wheel, wheel bolts and/or wheel bearings.

Excessive force such as hammering the wheel or

tire can also cause damage and is not recommended.

Slight tapping of the tire side wall, such as with one's

hand or a rubber mallet, is normally acceptable.

Before installing wheels, remove any build up of

corrosion on the wheel mounting surface and brake

drum or rotor mounting surface by scraping and wire

brushing. Installing wheels without good

metal-to-metal contact at the mounting surfaces can

cause wheel nuts to loosen, which can later allow the

wheel to come off causing loss of control.

Wheel nuts must be tightened in sequence and to

proper torque to avoid bending wheel or brake drum

or rotor.

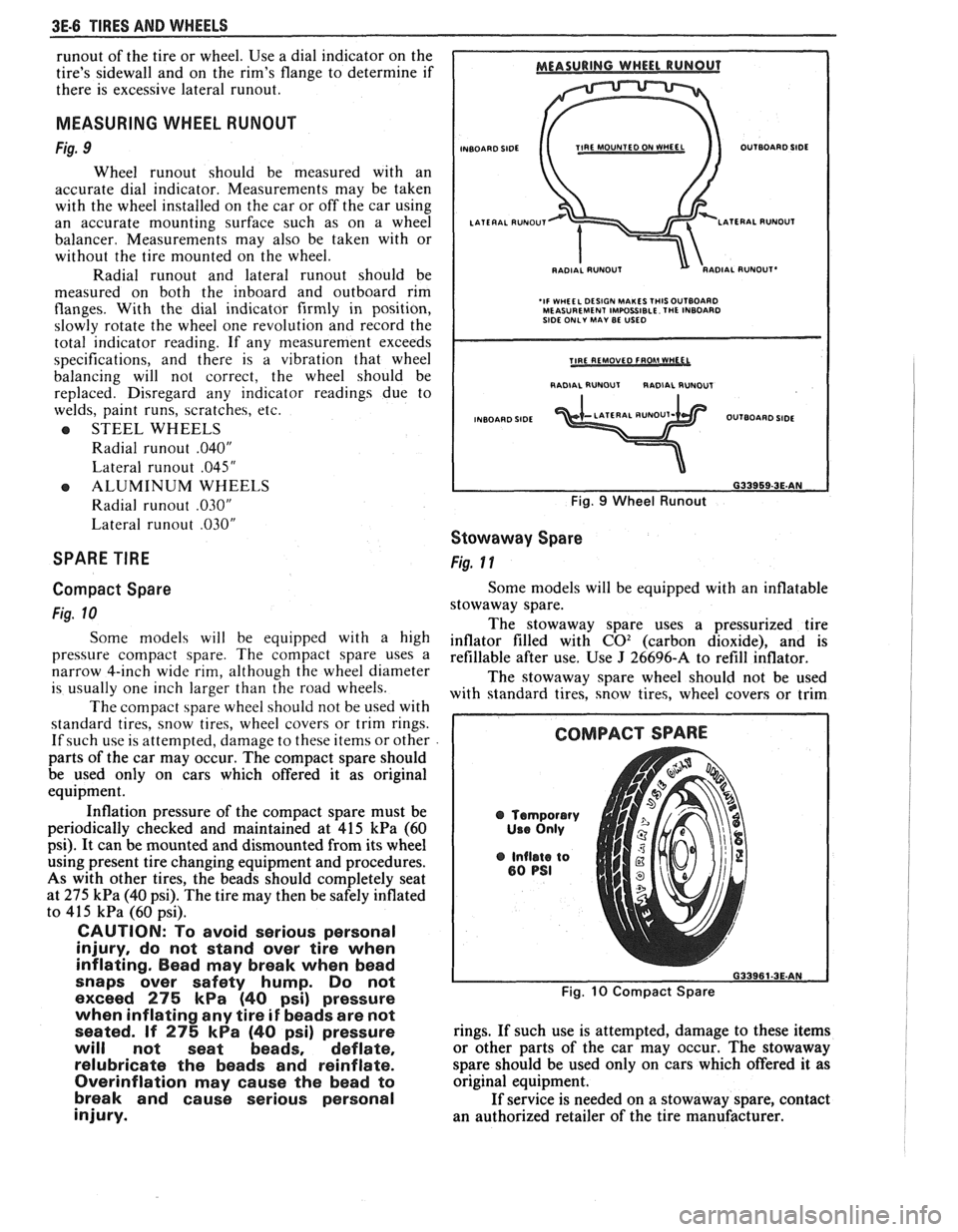

0P"FIONAL 16" WHEEL

Fig. 7

Firebirds equipped with optional 16" cast

aluminum wheels and cast iron brake

drums will

Page 236 of 1825

TIRES AND WI4EELS 3E-5

require a spacer between the rear wheel and the cast

iron brake drum.

NOTICE: This spacer is not required on

vehicles equipped with four wheel disc brakes or

cast aluminum brake drums.

Fig. 7A Hole Wheel Nut Tightening Sequence

TlRE MOUNTING AND DISMOUNTING

FIG. 8

Use a tire changing machine to mount or dismount

tires. Follow the equipment manufacturer's instructions.

Do not use hand tools or tire irons to change tires as they

may damage the tires bead or wheel rim.

Rim bead seats should be cleaned with a wire

brush or coarse steel wool to remove lubricants, old

rubber, and light rust. Before mounting or dismounting

a tire, the bead area should be well lubricated with an

approved tire lubricant.

After mounting, inflate until beads are seated, but

never exceed 275

kPa (40 psi) to seat the beads.

CAUTION: To avoid serious personal

injury, do not stand over tire when

inflating. Bead may break when bead

snaps over safety hump. Do not

exceed

275 kPa (40 psi) pressure

when inflating

any tire if beads are not

seated. If

275 kPa (40 psi) pressure

will not seat beads, deflate,

relubricate the beads and reinflate.

Overinflation may cause the bead to

break and cause serious personal

injury.

Install valve core and inflate to proper pressure.

Check the locating ring of the tire to be sure it shows

around the rim flanges on both sides.

TIRE REPAIR

There are many different materials and

techniques on the market to repair tires. Tire

manufacturers have published detailed instructions on

how and when to repair their tires. These instructions

can be obtained from the tire manufacturer.

TlRE LOCATING RING

naaaca a= AM

Fig. 8 Tire Locating Ring

Due to the thin 3.2 mm (4/32") tread depth on

temporary spare tires, tire repair is not recommended.

WADDLE

Waddle is side-to-side movement at the front

and/or rear of the car. It can be caused by the steel belt

not being straight within the tire, or by excessive lateral

WHEEL SPACER IS USED

WITH THE

16 x 8 ALUMINUM

WHEEL WITH CAST IRON

BRAKE DRUMS ONLY.

Fig, 7 16 Rear Wheel Spacers

Page 237 of 1825

3E-6 TIRES AND WHEELS

runout of the tire or wheel. Use a dial indicator on the

tire's sidewall and on the rim's flange to determine if

there is excessive lateral

runout.

MEASURING WHEEL RUNOUT

Fig. 9

Wheel runout should be measured with an

accurate dial indicator. Measurements may be taken

with the wheel installed on the car or off the car using

an accurate mounting surface such as on a wheel

balancer. Measurements may also be taken with or

without the tire mounted on the wheel.

Radial

runout and lateral runout should be

measured on both the inboard and outboard rim

flanges. With the dial indicator firmly in position,

slowly rotate the wheel one revolution and record the

total indicator reading. If any measurement exceeds

specifications, and there is a vibration that wheel

balancing will not correct, the wheel should be

replaced. Disregard

any indicator readings due to

welds, paint runs, scratches, etc.

e STEEL WHEELS

Radial

runout .040"

Lateral runout .045"

e ALUMINUM WHEELS

Radial

runout .030"

Lateral runout .030"

SPARE TIRE

Compact Spare

Fig. 10

Some models will be equipped with a high

pressure compact spare. The compact spare uses a

narrow 4-inch wide rim, although the wheel diameter

is usually one inch larger than the road wheels.

The compact spare wheel should not be used with

standard tires, snow tires, wheel covers or trim rings.

If such use is attempted, damage to these items or other

parts of the car may occur. The compact spare should

be used only on cars which offered it as original

equipment.

Inflation pressure of the compact spare must be

periodically checked and maintained at

415 kPa (60

psi). It can be mounted and dismounted from its wheel

using present tire changing equipment and procedures.

As with other tires, the beads should completely seat

at

275 kPa (40 psi). The tire may then be safely inflated

to

415 kPa (60 psi).

CAUTION: To avoid serious personal

injury, do not stand over tire when

inflating. Bead may break when bead

snaps over safety hump. Do not

exceed

275 kPa (40 psi) pressure

when inflating any tire

if beads are not

seated. If

275 kPa (40 psi) pressure

will not seat beads, deflate,

relubricate the beads and reinflate.

Overinflation may cause the bead to

break and cause serious personal

injury.

INBOARD SIDE TIRE MOUNTED ON fVHEEL OUTBOARD SIDE

RADIAL

RUNOUT'

'IF WHEEL DESIGN MAKES THISOUTBOARD MEASUREMENT IMPOSSIBLE. THE INBOARD

SIDE ONLY MAY BE USED

I RADIAL RUNOUT RADIAL RUNDUT I

INBOARD SIDE OUTBOARD SIDE

Fig. 9 Wheel Runout

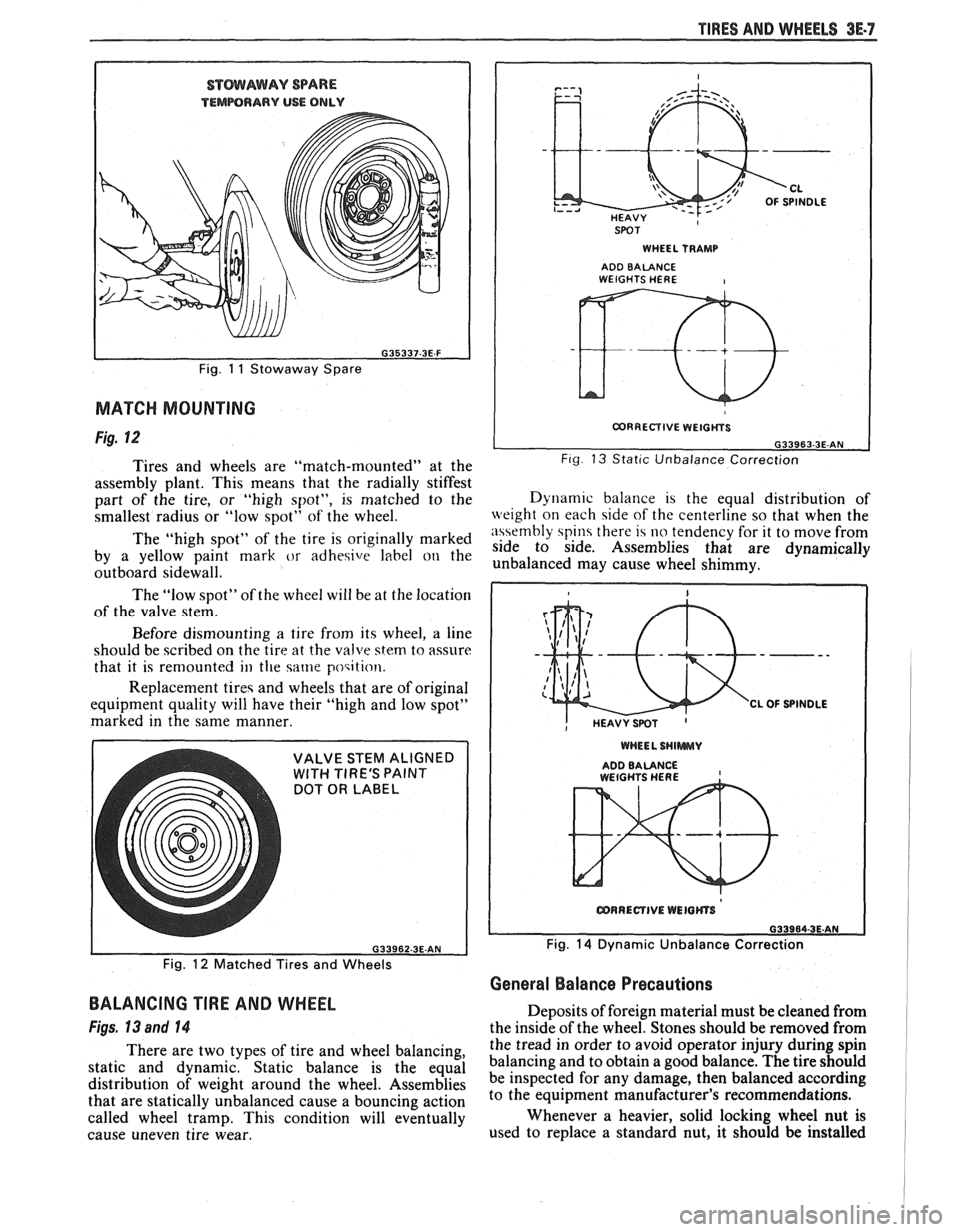

Stowaway Spare

Fig. 11

Some models will be equipped with an inflatable

stowaway spare.

The stowaway spare uses a pressurized tire

inflator filled with

C02 (carbon dioxide), and is

refillable after use. Use

J 26696-A to refill inflator.

The stowaway spare wheel should not be used

with standard tires, snow tires, wheel covers or trim

@ Temporary

Use Only

@ Inflate to 80 PSI

Fig. 10 Compact Spare

rings. If such use is attempted, damage to these items

or other parts of the car may occur. The stowaway

spare should be used only on cars which offered

it as

original equipment.

If service is needed on a stowaway spare, contact

an authorized retailer of the tire manufacturer.

Page 238 of 1825

TIRES AND WHEELS 3E-7

STMAWAY SPARE

TEMPORARY USE ONLV

Fig. 11 Stowaway Spare

MATCH MOUNTING

Fig. 12

Tires and wheels are "match-mounted" at the

assembly plant. This means that the radially stiffest

part of the tire, or "high spot", is matched to the

smallest radius or "low spot" of the wheel.

The "high spot" of the tire is originally marked

by a yellow paint mark

or adhesive label on the

outboard sidewall.

The "low spot" of the wheel will be at the location

of the valve stem.

Before dismounting

a tire from its wheel, a line

should be scribed on the tire at the valve

stem to assure

that it is remounted

ill the same poqition.

Replacement tireq and wheels that are of original

equipment quality will have their "high and low spot"

marked in the same manner.

DOT OR LABEL

SPOT I WHEEL TRAMP I

ADD BALANCE WEIGHTS HERE I

I CORRECTIVE WEIGtiYS I

L G33963-3E.AN Fig 13 Stat~c Unbalance Correction

Dynam~c balance 1s the equal distribution of

weight on each side of the centerline so that when the

n\\embly spin there 14 no tendency for it to move from

side to side. Assemblies that are dynamically

unbalanced may cause wheel shimmy.

WHEEL SHlWWUV

ADDBALANCE , WEtGHTS HERE

Fig. 14 Dynamic Unbalance Correction

Fig.

12 Matched Tires and Wheels

General Balance Precautions

BALANCING TIRE AND WHEEL

Figs, 13 and 14

There are two types of tire and wheel balancing,

static and dynamic. Static balance is the equal

distribution of weight around the wheel. Assemblies

that are statically unbalanced cause a bouncing action

called wheel tramp. This condition will eventually

cause uneven tire wear. Deposits

of foreign material must be cleaned from

the inside of the wheel. Stones should be removed from

the tread in order to avoid operator injury during spin

balancing and to obtain a good balance. The tire should

be inspected for any damage, then balanced according

to the equipment manufacturer's recommendations.

Whenever a heavier, solid locking wheel nut is

used to replace a standard nut, it should

be installed

Page 239 of 1825

3E-8 TIRES AND WHEELS

nearest the valve stem, and a 1/2 ounce balance weight

should be added 180" opposite the locking nut on the

wheel's inboard side.

When rotating tires, always re-install the locking

nut nearest the tire valve stem so that it remains

opposite the 1/2 ounce balance weight. This procedure

will improve the on-car wheel balance by compensating

for the heavy locking wheel nut.

Off-Car Balancing

Most electronic off-car balancers are more

accurate than the on-car spin balancers. They are easy

to use and give a dynamic (two plane) balance.

Although they do not correct for drum or rotor

unbalance as does on-car spin balancing, this is

overcome by their accuracy (usually to within 1/8

ounce). When balancing off-car, the wheel should

locate on the balancer with a cone through the back

side of the center pilot hole (not by the wheel stud

holes).

On-Car Balancing

When needed, on-car balancing will help correct

vibrations due to brake drum, rotor, and wheel cover

imbalance.

When balancing on car, do not remove the

balance weights from the off-car dynamic balance. If

more than one ounce of additional weight is required,

it should be split between the inner and outer rim

flange.

NOTICE: The driven tire and wheel assemblies

should be spun using the engine. Limit speed as

stated in the following Caution.

CAUTION: Do not spin the drive

wheels faster than

35 mph (55 km/h)

as indicated by the speedometer. This

limit is necessary because the

speedometer indicates only one-half

of the actual wheel speed when one

drive wheel is spinning and the other

drive wheel is stopped. Personal injury

and damage may result from high

speed spinning.

CAUTION: On cars equipped with

limited slip rear axles, do not attempt

to balance a tire on a

drive wheel with

the other drive wheel on the ground.

The car may drive through this wheel

and cause the car to move

unexpectedly, resulting in personal

injury and property damage.

To distinguish between standard rear axle and

limited slip, raise rear of car so both tires are clear of

ground. With the transmission in park (in gear with

manual transmission), attempt to turn one wheel by

hand. If the wheel can be turned, it is a standard rear

axle; if the wheel cannot be turned, it is a limited slip

rear axle. Also, check for Limited Slip

(G80) on Service

Parts Identification label.

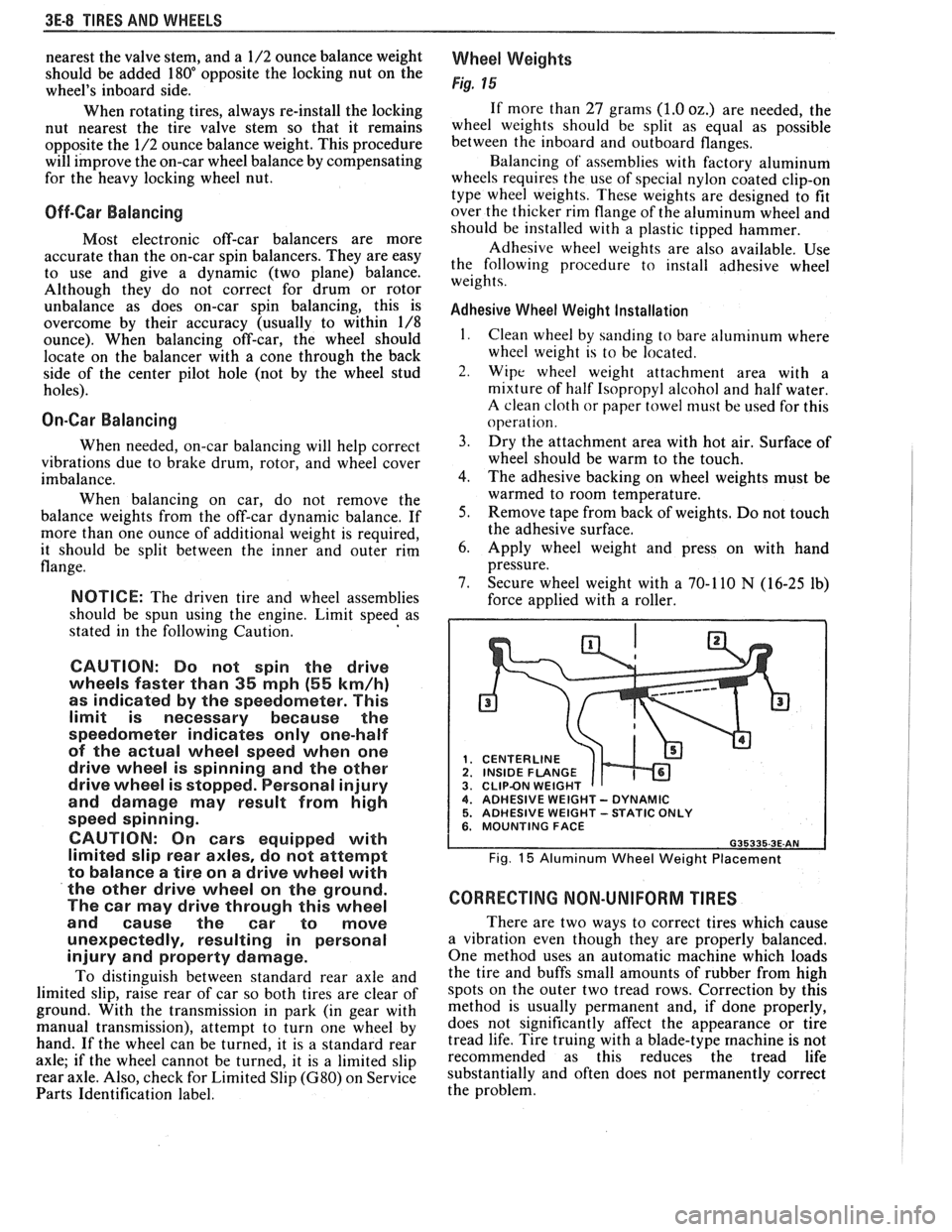

Wheel Weights

Fig. 15

If more than 27 grams (1.0 oz.) are needed, the

wheel weights should be split as equal as possible

between the inboard and outboard flanges.

Balancing of' assemblies with factory aluminum

wheels requires the use of special nylon coated clip-on

type wheel weights. These weights are designed to fit

over the thicker rim flange of the aluminum wheel and

should be installed with a plastic tipped hammer.

Adhesive wheel weights are also available. Use

the following procedure to install adhesive wheel

weights.

Adhesive Wheel Weight Installation

1. Clean wheel by sanding to bare aluminum where

wheel weight is to be located.

2. Wipe wheel weight attachment area with a

mixture of half Isopropyl alcohol and half water.

A clean cloth or paper towel niust be used for this

operat ion.

3. Dry the attachment area with hot air. Surface of

wheel should be warm to the touch.

4. The adhesive backing on wheel weights must be

warmed to room temperature.

5. Remove tape from back of weights. Do not touch

the adhesive surface.

6. Apply wheel weight and press on with hand

pressure.

7. Secure wheel weight with a 70-1 10

N (16-25 lb)

force applied with a roller.

CENTERLINE

1 INSIDE FLANGE CLIPBN WEIGHT 4. ADHESIVE WEIGHT - DYNAMIC 5. ADHESIVE WEIGHT -STATIC ONLY 6. MOUNTING FACE

Fig. 15 Aluminum Wheel Weight Placement

CORRECTING NON-UNIFORM TIRES

There are two ways to correct tires which cause

a vibration even though they are properly balanced.

One method uses an automatic machine which loads

the tire and buffs small amounts of rubber from high

spots on the outer two tread rows. Correction by this

method is usually permanent and, if done properly,

does not significantly affect the appearance or tire

tread life. Tire truing with a blade-type

machine is not

recommended as this reduces the tread life

substantially and often does not permanently correct

the problem.