tires PONTIAC FIERO 1988 Service Owner's Guide

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 240 of 1825

TIRES AND WHEELS 3E-9

Another method is to dismount the tire and

rotate it 180 degrees on the rim. It is important that

this be done on tire and wheel assemblies which are

known to be causing a vibration as it is just as likely to

cause good assemblies to vibrate.

Refer to Section 3, "Vibration Diagnosis" for

more details.

ALUMINUM WHEEL CLEANING

Aluminum wheels should be cleaned and waxed

regularly. Do not use abrasive cleaners, as they could

damage the protective coating.

ALUMINUM WHEEL HUB CAP

Remove or Disconnect

1. Tire and wheel assembly

2. Place a block of wood approximately 2" in

diameter with a squared off end against the back

surface of the cap.

A sharp hammer biow on the

block of wood will

remove the cap.

Install or Connect

1. Place

cap into position at wheel opening and

place a block of wood at least three inches in

diameter against cap face. Install cap by striking

block of wood with hammer.

2. Tire and wheel assembly

NOTICE: Failure to hit cap squarely without the

load distributed evenly could result in permanent

damage to the cap.

ALUMINUM WHEEL POROSITY REPAIR

1. Remove tire and wheel assembly.

2. Locate

leaking areas by inflating tire to 345

kPa

(50 psi) and dipping tire and wheel assembly into

a water bath.

3. Mark

leak areas and remove tire from wheel.

4. Scuff inside surface at leak area with 80 grit

sandpaper and clean area with general purpose

cleaner such as

3M #08984 or equivalent.

5. Apply 1/8" thick layer of adhesive/sealant P/N

1052366 or equivalent to leak area and allow

twelve hours of drying time.

6. Mount tire on wheel, pressurize to 345 kPa (50

psi) and check for leaks.

CAUTION: To avoid serious personal

injury, do not stand over tire when

inflating. Bead may break when bead

snaps over safety hump. Do not

exceed

275 kPa (40 psi) pressure

when inflating any tire if beads are

not seated.

14 275 kPa (40 psi)

pressure will not seat beads, deflate,

relubricate the beads and reinflate.

Overinflation may cause the bead to

break and cause serious personal

injury.

7. Adjust

tire pressure to meet specifications.

8. Balance tire and wheel assembly.

9. Install tire and wheel assembly.

ALUMINUM WHEEL REFINISHING

A protective clear or color coating is applied to

the surface of original equipment cast aluminum

wheels.

A surface degradation condition can begin to

develop if frequent, repeated automatic car wash

cleaning abrades or wears off the factory applied

protective coating. This can happen at some automatic

car wash facilities using aggressive silicon carbide

tipped tire brushes

to clean white walls and tires. Once

the protective coating is

damaged, exposure to caustic

cleaners and/or road salt further causes surface

degradation. The following procedure details how to

strip, clean

and recoat aluminum wheels that are

affected by these conditions.

Required Materials:

A~nchern Alumi Prep #33 - stock

#DX533 or equivalent - cleaning and

conditioning chemical for aluminum.

Amchem Alodine

# 1001 - stock #DXSOT

or equivalent - coating chemical for

aluminum.

Ditzler Delclear Acrylic Urethane Clear

-

stock #DAU-75 or equivalent.

Ditzler Delthane Ultra-Urethane Additive

- stock DXR-80 or equivalent.

Service Procedure:

1. Mark wheel and wheel stud for position on car.

2. Remove tire and wheel assembly from car.

3. Mark location of outboard weights and remove.

4. Wash wheel inside and out with water base all

purpose cleaner. Remove grease and oil with

solvent cleaner.

5. Mask off tire prior to painting.

6. Select and follow the correct procedure,

"Aluminum Damage on Wheel Surface" or

"Clear Coat Damage on Unpainted Wheels".

7. Replace wheel weights with nylon coated

weights.

8. Install tire and wheel assembly on car and tighten

wheel nuts to proper torque.

Accent Color Preparation

1. Sand over painted areas that will not require

recoloring with 400 grit (wet or dry) to promote

adhesion of clear coat.

Aluminum Damage on Wheel Surface

1. Mount tire and wheel on brake lathe and spin

slowly.

2. Sand wheel with backing block or pad by holding

abrasive flat to surface of wheel and moving

slowly back and forth from center to outer edge

to remove damage. Use the following sandpaper

grits in the order listed.

A. Sand with 80 grit

B. Sand with 150 grit

C. Sand with 240 grit

3. Continue with "Recoating Procedure."

Page 241 of 1825

3E-10 TIRES AND WHEELS

Clear Coat Damage on Unpainted Wheels

I.

Apply chemical stripper. Use small 1/4" detail

brush dipped in stripper to apply material around

perimeter and spoke-like areas.

2. Remove stripper following manufacturers

recommendations.

3. Sand wheel with 240 grit while rotating wheel on

a slow spinning brake lathe or by mounting on car

and spinning by hand. This will restore the

machined appearance and promote adhesion.

CAUTION: Do not use engine power to

rotate wheel while sanding to avoid

serious personal injury.

4. Continue with "Recoating Procedure."

Recoating Procedure

1. Clean surface of contaminants.

2. Soak wheel with Amchem #33 or equivalent

from

1 to 3 minutes, then rinse with water and

blow dry.

3. Soak wheel with Amchem

#I001 or equivalent

for

1 to 3 minutes, then rinse with water and blow

dry. 4.

Finish with Ditzler Delclear Acrylic Urethane

and Ditzler Ultra-Urethane Additive or

equivalent using three coats.

1st Coat

- Light mist coat, let flash

2nd Coat

- Light, let flash

3rd Coat

- Heavy double wet coat

CAUTION: To avoid serious personal

injury when applying any two part

component paint system, follow the

specific precautions provided by the

paint manufacturer. Failure to follow

these precautions may cause lung

irritation and allergic respiratory

reaction.

5. Let dry for 24 hours - (or flash for 30 minutes,

force dry at

140" for 30 minutes, and allow to cool

for 30 minutes before mounting.

WHEEL NUT TORQUE

F Carline - M 12X 1.5 .............. 1 10 N . m (80 Ibs. ft.)

Page 255 of 1825

4819 REAR AXLE

bears against the inner race of the front bearing and a

shoulder on the pinion stem. This spacer is used to

enable accurate bearing pre-load adjustment and

maintain a pre-load on both front and rear pinion

bearings, Adjustment of the fore and aft position of the

pinion is obtained by placing a shim between the rear

pinion bearing cup and axle housing. The differential

case is of two-piece construction and is supported in

the carrier by two tapered roller side bearings. Pre-load

rear axle case by inserting shims between the bearings

and the carrier. The rear axle case assembly is

positioned for proper ring gear to pinion backlash by

varying the shim thickness from side to side. The ring

gear is bolted to the case. Two side gears have splined

bores for driving the axle shafts. They are positioned

to turn in counterbored cavities in the case. The four

rear axle pinions have smooth bores and are held in

position by a pinion cross shaft, mounted and locked

in the rear axle case. All six gears are in mesh with each

other and because the pinion gears turn freely on their

shaft, they act as idler gears when the rear wheels are

turning at different speeds. The pinions and side gears

are backed by steel thrust washers.

LIMITED-SLIP REAR AXLE

The operation of the Limited-Slip differential is

the same as the standard differential, except that there

is additional friction provided by the conical clutches.

Under ordinary driving and cornering conditions, the

cones slip, allowing the outside wheel to turn faster

than the inner. Under poor traction conditions, such as

ice, snow, or loose gravel under one driving wheel, the

increased friction provided by the cones increases the

driving torque available to the wheel with the better

traction. The cones are spring loaded to provide the

increased driving torque under extremely low traction

conditions.

Operation

When the vehicle turns a corner, the outer rear

wheel must turn faster than the inner wheel. The inner

wheel, turning slower than the outer wheel, slows its

differential side gear (as the axle shaft is splined to the

side gear) and the differential pinion gears will roll

around the slowed differential side gear, driving the

other differential side gear and wheel faster.

DIAGNOSIS AND TESTING

Many noises reported as coming from the rear

axle assembly actually originate from other sources

such as tires, road surfaces, front wheel bearings, axle

bearing, engine, transmission, muffler or body

drumming. A thorough and careful check should be

made to determine the source of the noise before

disassembling the rear axle. Noise which originates in

other places cannot be corrected by adjustment or

replacement of parts in the differential. It should also

be remembered that rear axle gears, like any other

mechanical device, are not absolutely quiet and should

be accepted as being commercially quiet unless some

abnormal noise is present.

To make a systematic check for axle noise under

standard conditions, observe the following:

1. Select a level smooth asphalt road to reduce tire

noise and body drumming.

2. Check rear axle lubricant to assure correct level,

then drive car far enough to thoroughly warm up

rear axle lubricant, approximately 10 miles.

3. Note speed and RPM at which noise occurs. Stop

car and put transmission in neutral. Run engine

slowly up and down through engine speeds,

corresponding to car speed at which noise was

most pronounced, to determine if it is caused by

exhaust, muffler roar or other engine conditions.

4. Tire noise changes with different road surfaces,

but rear axle noise does not. Temporarily

inflating all tires to approximately 50 pounds

pressure

for test purposes only will materially

alter noise caused by tires, but will not affect noise

caused by rear axle. Rear axle noise usually stops

when coasting at speeds under 30 miles per hour;

however, tire noise continues, but with lower

tone, as car speed is reduced. Rear axle noise

usually changes when comparing acceleration

and coast, but tire noise remains about the same.

Distinguish between tire noise and rear axle noise

by noting if noise varies with various speeds or

sudden acceleration and deceleration; exhaust

and axle noise show variations under these

conditions while tire noise remains constant and

is more pronounced at speeds of 20 to 30 miles

per hour. Further check for tire noise by driving

car over smooth pavements or dirt roads (not

gravel) with tires at normal pressure. If noise is

caused by tires, it will noticeably change or

disappear and reappear with changes in road

surface.

5. Loose or rough front wheel bearings will cause

noise which may be confused with rear axle

noises; however, front wheel bearing noise does

not change when comparing drive and coast.

Light application of brakes while holding car

speed steady will often cause wheel bearing noise

to diminish, as this takes some weight off the

bearing. Front wheel bearings may be easily

checked for noise by jacking up the wheels and

spinning them, also by shaking wheels to

determine if bearings are loose.

6. Rear suspension rubber bushings and spring

insulators dampen out rear axle noise when

correctly installed. Check to see that no metallic

contact exists between the spring and spring seat

opening in frame or between upper and lower

control arm bushings and frame or axle housing

brackets. The track bar and torque arm must be

bolted securely. Metal-to-metal contact at those

points may result in telegraphing road noise and

normal axle noise which would not be

objectionable if dampened by bushings.

AXLE NOISES

After the noise has been determined as being in

the axle by following the above appraisal procedure,

the type of axle noise should be determined to aid in

making repairs if necessary.

Page 271 of 1825

484-18 REAR AXLE

4. With transmission in park and both wheels and

tires clear of ground, (wheels will r~tate in opp-

osite directions), measure torque required to

rotateaxle shafts with a torque

wrenchattached

to J 2619-1. If the torque reading is less than

48 N.m (35 1b.ft.) the unit should be disassembled

and repaired as required.

5. Reinstall wheel and tire assembly.

Disassemble

Limited Slip Differential.

1. Remove ring gear bolts.

NOTICE: Left hand threaded ring gear bolts.

2. Tap

ring gear off differential housing with soft

face hammer.

NOTICE: Mark differential case halves with

alignment mark before disassembly because they

could be assembled

180" off from original position.

3. Remove 8 screws holding differential housing

halves together and separate halves. 4.

Remove pinion shaft, 4 differential pinions,

thrust washers side gears, side gear shims

(if

required), spring plates, and compression springs

from housing. Discard compression springs. New

springs are required for assembly.

5. Mark each cone during disassembly to ensure

that the same brake cone will be assembled with

the same case as originally assembled. If shims

are used they must be marked so that they will be

assembled in original case half.

6. If differential bearings are damaged remove with

tool J-22888-D. (Fig. 15).

Inspect

Disassemble

The inspection procedures for the positraction

differential are the same as those for the standard

rear axle except for the side gear positioning

shims. The side gear positioning shims are used

to control case size.

1. The shims should be free of cracks, nicks, or

burrs.

2. Assemble brake cones in case and measure to

determine correct shim size. Measure the

distance from case mating surface to flat surface

on brake cone when fully seated. Select shim size

from chart below.

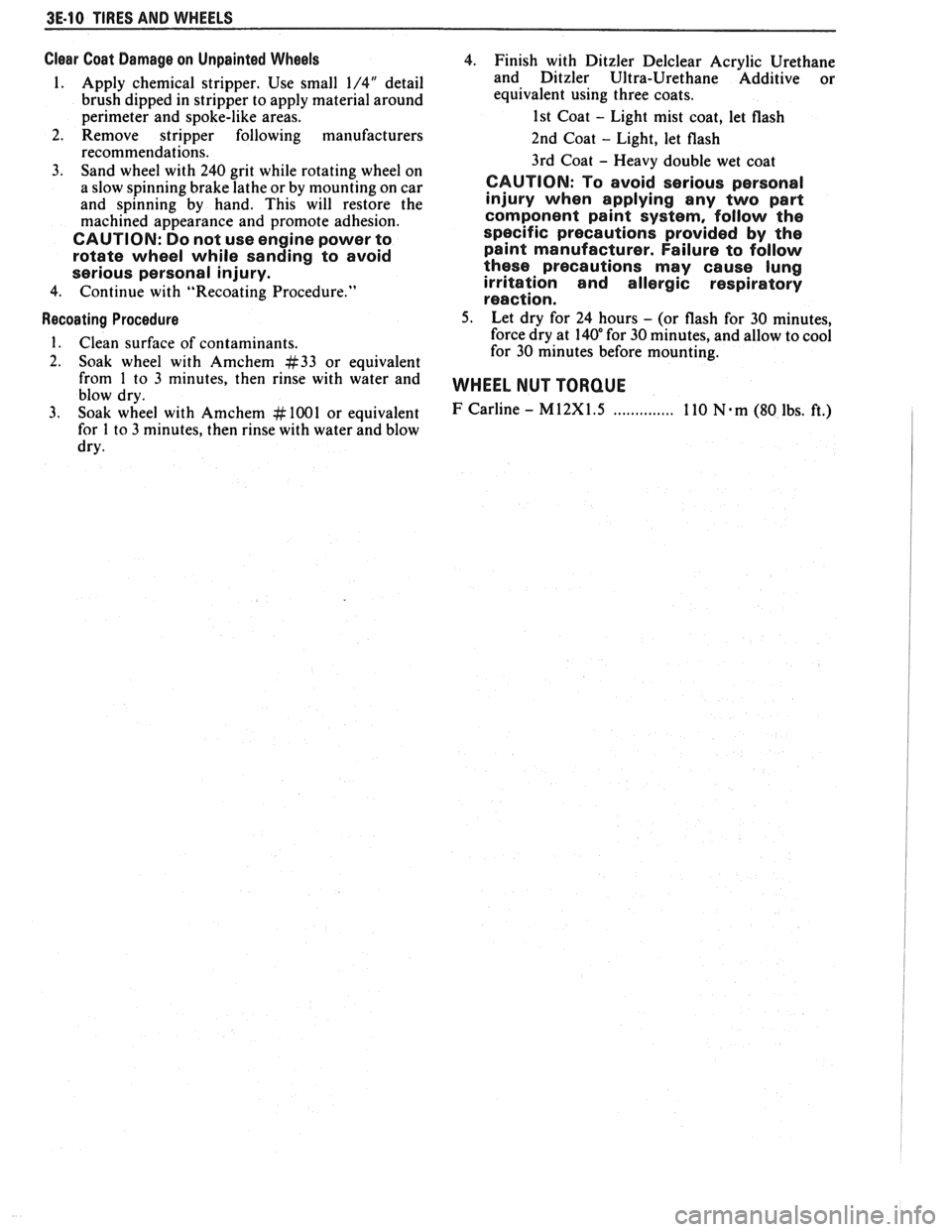

DISASSEMBLY INSPECTION CHART

Distance Measured mm (ins) Size

Shim Required

29.51/29.34 (1.162/1/155) no shim required.

29.64/29.54 (1.167/1.163) 0.13 (.005) shim required.

29.77D9.67 (1.172/1.168) 0.25 (.010) shim required.

Assemble

Limited Slip Differential

1.

Lubricate both sides of pinion thrust washers,

pinion bores and differential pinion shafts with

specified rear axle lube before assembling.

2. Install the 4 pinions and spherical thrust washers.

3. Replace original brake cone, shim if required, and

side gear in cap half of differential case. For shim

selection, if needed, refer to Disassembly

Inspection Chart. Apply mixture of molybdenum

disulphide and specified axle oil to face of side

gear.

NOTICE: Do not 1.eplace cone or case

independently. They must be replaced as a unit

together.

4. Install spring

plate on side gear with convex side

towards flange half.

5. Assemble differential pinion shaft, pinions, and

spherical thrust washers into cap half of

differential case with pinions meshing with side

gear. 6.

Install three new concentric thrust springs

through the center of the pinion shaft spider.

7. Assemble second spring plate and springs with

cgnvex side towards springs.

8. Coat other side gear face with molybdenum

disulphide and axle lubricant and install side gear

shim if required. Install brake cone on spring

plate.

9. Install

flange half of case on top of assembly with

oil channels aligned.

10. Install

two bolts through cases

180" apart and

tighten finger tight.

11. Axle shafts are used to align the side gear and

brake cone splines. Put a clamp on one axle shaft

so 75 mm (3 inches) extends beyond clamp.

Install differential housing onto axle shaft splines,

flanged half first.

12. Install other axle shaft through cap side of

differential case and align side gear and cone

splines.

13. Install remaining

bolts and tighten to specified

torque.

14. Install

ring gear and tighten bolts to specified

torque.

Page 274 of 1825

REAR AXLE 4B-1

SECTION 4B

REAR AXLE

NOTICE: All rear axle attaching fasteners are an necessary.

Do not use a replacement part of lesser

important part in that they could affect the quality

or substitute design. Torque values must

performance of vital parts and systems, and/or be

used as specified during reassembly to assure

could result in major repair expense. They must proper retention

of all parts. (There is to be no

be replaced with one of the same part number or welding

as it may result in extensive damage and

with an equivalent part if replacement becomes weakening

of the metal.)

CONTENTS

General Description .................................. 4B-1

Standard Rear Axle ................... .. ............ 4B- 1

Diagnosis and Testing ............................... 4B-1

Axle Noises ......................... .. ................ 4B-3

Gear Noise ...................... .. .................. 4B-3

Bearing Noise ........................................ 4B-3

Rear Wheel Bearing Noise ....................... 4B-3

Knock at Low Speeds ............................. 4B-3

Backlash Clunk ...................................... 4B-3

Rear Axle Standard and Limited Slip .......... 4B-3

Pre-Repair Investigation and Trouble

Diagnosis

................................................. 4B-4

Gear Tooth Nomenclature ....................... 4B-4

Tooth Contact Pattern Test ..................... 4B-4

Effects of Increasing Load on

Teeth Contact Pattern

.......................... 4B-4

Adjustments Affecting Tooth

Contact

.................................................. 4B-6

Effects of Pinion Position on Tooth

Pattern

................... ... .................... 4B-6

General information ....................... .. ..... 4B-8

Limited-Slip Rear Axle ............................... 4B-8

On-Vehicle Service ............................. .. ....... 4B-8

Carrier Cover and Gasket .......................... 4B-8

............................................. Axle Shaft 4B-8

Oil Seal and/or Bearing (With

Axle Shaft Removed)

............................. 4B-9

........................................ Pinion Oil Seal 4B-9

........................................... Pinion Flange 4B- 10

..................................... Rear Wheel Bolt 4B- 1 1

.................................................... Unit Repair 4B-1 1

..................................... Rear Axle Assembly 4B- 1 1

Disassembly of Rear Axle

............................................... Assembly 4B- 1 1

.. ..................................... Case Assembly ... 4B- 12

Drive Pinion, Bearing and Races ............. 4B- 12

............................... Bearing Replacement 4B- 12

...................... Setting Drive Pinion Depth 4B- 13

........................................ Rear Axle Case 4B- 14

Side Bearing Preload Adjustment ............ 4B- 15

.................................................. Drive Pinion 4B- 16

Rear Axle Backlash Adjustment .............. 4B- 17

........... Limited Slip Rear Axle (Cone Type) 4B-17

...................................... Auburn Cone Type 4B- 18

.............................................. Specifications 4B- 19

.............................................. Special Tools 4B-20

GENERAL DESCRIPTION

STANDARD REAR AXLE Operation

The rear axle assembly is of the semi-floating type

in which the car weight is carried on the axle housing.

The rear axle assembly is designed for use with an open

drive line and coil springs. The rear axle has a

hypoid

type ring gear and pinion with the centerline of the

pinion gear below the centerline of the ring gear.

All parts necessary to transmit power from the

propeller shaft to the rear wheels are enclosed in a When

the vehicle turns a corner, the outer rear

wheel must turn faster than the inner wheel. The inner

wheel, turning slower than the outer wheel, slows its

differential side gear (as the axle shaft is splined to the

side gear) and the differential pinion gears will roll

around the slowed differential side gear, driving the

other differential side gear and wheel faster.

DIAGNOSIS AND "TESTING

salisbury type axle housing (a carrier casting with tubes Many

noises reported as coming from the rear

pressed and welded into the carrier to form a complete axle assembly actually

originate from other sources

carrier and tube assembly). A removable steel cover such as

tires, road surfaces, wheel bearings, engine,

bolted to the rear of the carrier permits service of the transmission,

muffler or body drumming. A thorough

rear axle without removing the entire assembly from and

careful check should be made to determine the

the car. source

of the noise before disassembling the rear axle.

Page 276 of 1825

REAR AXLE 4B-3

Noise which originates in other places cannot be

corrected by adjustment or replacement of parts in the

differential. It should also be remembered that rear

axle gears, like any other mechanical device, are not

absolutely quiet and should be accepted as being

commercially quiet unless some abnormal noise is

present.

To make a systematic check for axle noise under

standard conditions, observe the following:

1. Select a level smooth asphalt road to reduce tire

noise and body drumming.

2. Check rear axle lubricant to assure correct level,

then drive car far enough to thoroughly warm up

rear axle lubricant.

3. Note speed and RPM at which noise occurs. Then

stop car and with automatic transmission in neutral,

run engine slowly up and down through engine speeds, corresponding to car speed at which noise

was most pronounced, to determine if it is caused by

exhaust, muffler roar or other engine conditions.

4. Tire noise changes with different road surfaces,

but rear axle noise does not. Temporarily

inflating all tires to approximately 50 pounds

pressure for

test purposes only will materially

alter noise caused by tires, but will not affect noise

caused by rear axle. Rear axle noise usually stops

when coasting at speeds under 30 miles per hour;

however, tire noise continues, but with lower

tone, as car speed is reduced. Rear axle noise

usually changes when comparing acceleration

and coast, but tire noise remains about the same.

Distinguish between tire noise and rear axle noise

by noting if noise varies with various speeds or

sudden acceleration and deceleration; exhaust

and axle noise show variations under these

conditions while tire noise remains constant and

is more pronounced at speeds of 20 to 30 miles

per hour. Further check for tire noise by driving

car over smooth pavements or dirt roads (not

gravel) with tires at normal pressure. If noise is

caused by tires, it will noticeably change or

disappear and reappear with changes in road

surface.

5. Loose or rough front wheel bearings will cause

noise which may be confused with rear axle

noises; however, front wheel bearing noise does

not change when comparing drive and coast.

Light application of brakes while holding car

speed steady will often cause wheel bearing noise

to diminish, as this takes some weight off the

bearing. Front wheel bearings may be easily

checked for noise by jacking up the wheels and

spinning them, also by shaking wheels to

determine if bearings are loose.

6. Rear suspension rubber bushings and spring

insulators dampen out rear axle noise when

correctly installed. Check to see that no metallic

contact exists between the spring and spring

opening in frame or between upper and lower

control arm bushings and frame or axle housing

brackets.

Metal-to-metal contact at those points

may result in telegraphing road noise and normal axle

noise which would not be objectionable if

dampened by bushings.

AXLE NOISES

Gear Noise

After the noise has been determined as being in

the

axle by following the above appraisal procedure,

the type of axle noise should be determined to aid in

maki~~g repairs if necessary.

Gear noise (whine) is audible from 20 to

55 mph

under four driving conditions:

1. Drive - Acceleration or heavy pull.

2. Road Load - Car driving load or constant speed.

3. Float

- Using

enough throttle to keep the car from

driving the engine

- car slows down gradually but

engine still pulls slightly.

4. Coast

- Throttle closed and car in gear. Gear

noise most frequently has periods where noise is

more prominent, usually 30 to 40 mph and 50 to

55 mph.

Bearing Noise

Bad bearings generally produce more of a rough

growl or grating sound, rather than the whine typical

of gear noise. Bearing noise frequently "wow-wows" at

bearing rpm, indicating a defective pinion or rear axle

case side bearing. This noise could easily be confused

with rear wheel bearing noise. Inspect and replace as

required.

Rear Wheel Bearing Noise

A rough rear wheel bearing produces a noise

which continues with car coasting at low speed and

transmission in neutral. Noise may diminish some by

gentle braking. With rear wheels jacked up, spin rear

wheels by hand while listening at hubs for evidence of

rough (noisy) wheel bearing.

I(noclc At Low Speeds

Low speed knock can be caused by worn

universal joints or a side gear hub counterbore in a case

that has worn oversize. Inspect and replace universal

joint or case and side gear as required.

Baclclash Clunk

Excessive clunk with acceleration and

deceleration is caused by worn differential pinion shaft,

excessive clearance between axle shaft and side gear

splines, excessive clearance between side gear hub and

counterbore in case worn pinion and side gear teeth,

worn thrust washers and excessive drive pinion and

rear gear backlash. Remove worn parts and replace as

required, selecting close fitting parts when possible.

Adjust pinion and ring gear backlash.

REAR AXLE STANDARD AND LIMITED-SLIP

1. Noise is the same in "Drive" or "Coast".

a. Road noise.

b. Tire noise.

c. Front wheel bearing noise.

Page 291 of 1825

4B-18 REAR AXLE

tire wear patterns. One indication of this condition is

"swerving on acceleration." If swerving on

acceleration is encountered, check the rear wheels for

different tire size, air pressure, or excessively different

wear patterns, and tread depths, before proceeding into

an overhaul operation.

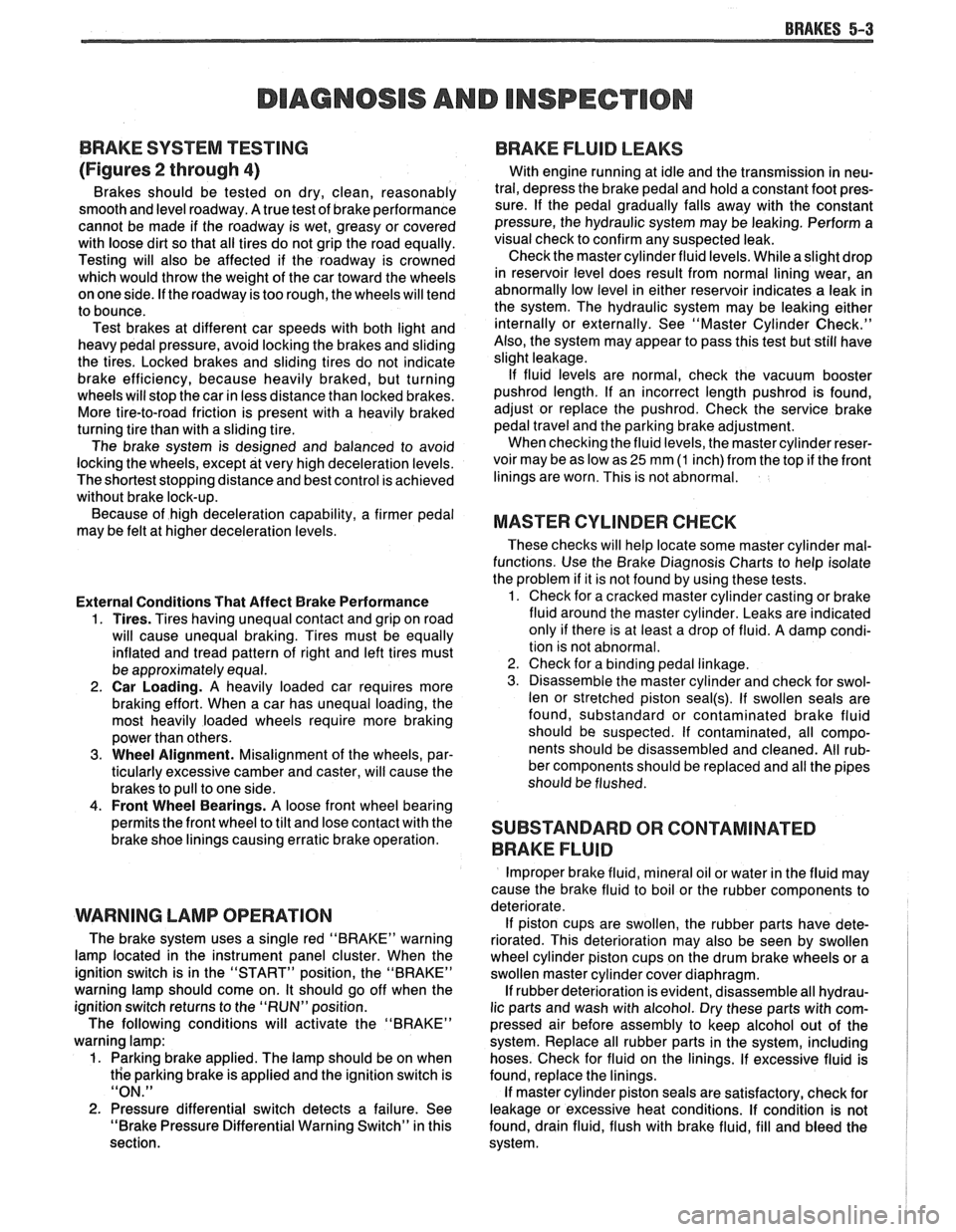

Checking Limited-Slip Operation

1. Place transmisison

in Park position.

2. Raise

rear of vehicle until wheels are off the

ground, remove one wheel and tire assembly.

3. Attach Adapter J 2619-1 to axle shaft flange and

install a 1/2-13 bolt into adapter as shown in Fig.

617,

4. With opposite wheel and tire assembly still on

vehicle and held firmly to prevent turning,

measure torque required to rotate opposite axle

shaft with a torque wrench attached to J 2619-1.

If the torque reading is less than 48

N.m (35 lb.

ft.) the unit should be disassembled and repaired

as required.

5. The Auburn rear axle check with both tires

elevated and transmission in park (differential

case not allowed to rotate).

The torque required to rotate one wheel should

be 169 to 305

N-m (125 to 225 1bs.ft.).

6. This is the Auburn rear axle check with only one

rear wheel raised and transmission in neutral (dif-

ferential case free to rotate). The torque required

to rotate one wheel is

60 to 136 N-m (45 to 100

lbs. ft.)

7. Reinstall wheel and tire assembly.

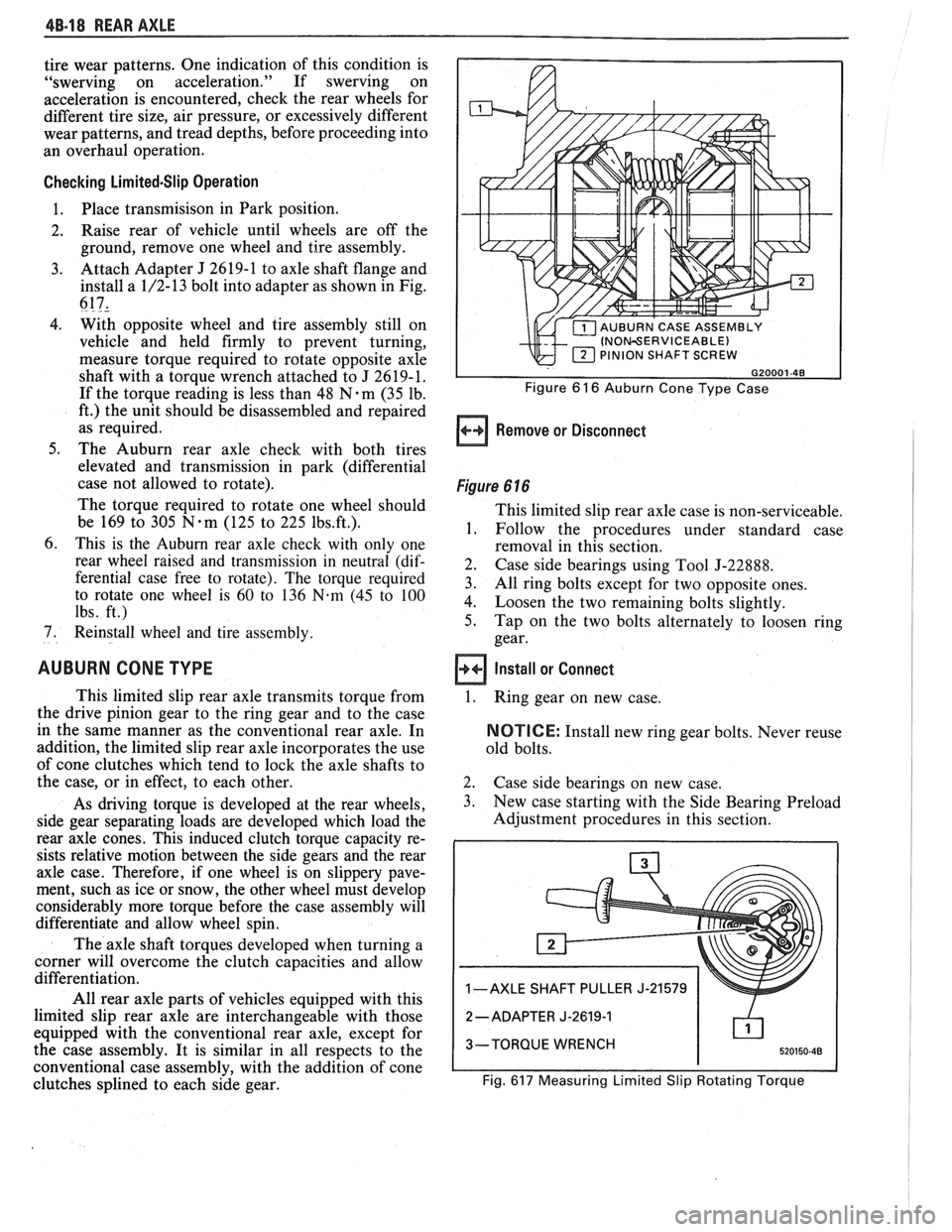

AUBURN CONE TYPE

This limited slip rear axle transmits torque from

the drive pinion gear to the ring gear and to the case

in the same manner as the conventional rear axle. In

addition, the limited slip rear axle incorporates the use

of cone clutches which tend to lock the axle shafts to

the case, or in effect, to each other.

As driving torque is developed at the rear wheels,

side gear separating loads are developed which load the

rear axle cones. This induced clutch torque capacity re-

sists relative motion between the side gears and the rear

axle case. Therefore, if one wheel is on slippery pave-

ment, such as ice or snow, the other wheel must develop

considerably more torque before the case assembly will

differentiate and allow wheel spin.

The axle shaft torques developed when turning a

corner will overcome the clutch capacities and allow

differentiation.

All rear axle parts of vehicles equipped with this

limited slip rear axle are interchangeable with those

equipped with the conventional rear axle, except for

the case assembly. It is similar in all respects to the

conventional case assembly, with the addition of cone

clutches splined to each side gear.

INOWERVICEABLE) PINION SHAFT SCREW

Figure 6 16 Auburn Cone Type Case

Remove or Disconnect

Figure 6 16

This limited slip rear axle case is non-serviceable,

1. Follow the procedures under standard case

removal in this section.

2. Case side bearings using Tool J-22888.

3. All ring bolts except for two opposite ones.

4. Loosen the two remaining bolts slightly.

5. Tap on the two bolts alternately to loosen ring

gear.

Install or Connect

1.

Ring gear on new case.

NOTICE: Install new ring gear bolts. Never reuse

old bolts.

2. Case side bearings on new case.

3. New case starting with the Side Bearing Preload

Adjustment procedures in this section.

1 -AXLE SHAFT PULLER J-21579

2

-ADAPTER J-2619-1

3-TORQUE WRENCH

Fig.

617 Measuring Limited Slip Rotating Torque

Page 296 of 1825

BRAKES 5-3

DIAGNOSIS AND INSPECTION

BRAKE SYSTEM TESTING

(Figures

2 through 4)

Brakes should be tested on dry, clean, reasonably

smooth and level roadway. A true test of brake performance

cannot be made if the roadway is wet, greasy or covered

with loose dirt so that all tires do not grip the road equally.

Testing will also be affected if the roadway is crowned

which would throw the weight of the car toward the wheels

on one side. If the roadway is too rough, the wheels will tend

to bounce. Test brakes at different car speeds with both light and

heavy pedal pressure, avoid locking the brakes and sliding

the tires. Locked brakes and sliding tires do not indicate

brake efficiency, because heavily braked, but turning

wheels will stop the car in less distance than locked brakes.

More tire-to-road friction is present with a heavily braked

turning tire than with a sliding tire. The brake system is designed and balanced to avoid

locking the wheels, except at very high deceleration levels.

The shortest stopping distance and best control is achieved

without brake lock-up.

Because of high deceleration capability, a firmer pedal

may be felt at higher deceleration levels.

External Conditions That Affect Brake Performance

1. Tires. Tires having unequal contact and grip on road

will cause unequal braking. Tires must be equally

inflated and tread pattern of right and left tires must

be approximately equal.

2. Car Loading. A heavily loaded car requires more

braking effort. When a car has unequal loading, the

most heavily loaded wheels require more braking

power than others.

3. Wheel Alignment. Misalignment of the wheels, par-

ticularly excessive camber and caster, will cause the

brakes to pull to one side.

4. Front Wheel Bearings. A loose front wheel bearing

BRAKE FLUID LEAKS

With engine running at idle and the transmission in neu-

tral, depress the brake pedal and hold a constant foot pres-

sure.

If the pedal gradually falls away with the constant

pressure, the hydraulic system may be leaking. Perform a

visual check to confirm any suspected leak.

Check the master cylinder fluid levels. While a slight drop

in reservoir level does result from normal lining wear, an

abnormally low level in either reservoir indicates

a leak in

the system. The hydraulic system may be leaking either

internally or externally. See "Master Cylinder Check."

Also, the system may appear to pass this test but still have

slight leakage.

If fluid levels are normal, check the vacuum booster

pushrod length. If an incorrect length pushrod is found,

adjust or replace the

pushrod. Check the service brake

pedal travel and the parking brake adjustment.

When checking the fluid levels, the master cylinder reser-

voir may be as low as

25 mm (1 inch) from the top if the front

linings are worn. This is not abnormal.

MASTER CYLINDER CHECK

These checks will help locate some master cylinder mal-

functions. Use the Brake Diagnosis Charts to help isolate

the problem if it is not found by using these tests.

1. Check for a cracked master cylinder casting or brake

fluid around the master cylinder. Leaks are indicated

only if there is at least a drop of fluid. A damp condi-

tion is not abnormal.

2. Check for a binding pedal linkage.

3. Disassemble the master cylinder and check for swol-

len or stretched piston

seal(s). If swollen seals are

found, substandard or contaminated brake fluid

should be suspected.

If contaminated, all compo-

nents should be disassembled and cleaned. All rub-

ber components should be replaced and all the pipes

should be flushed.

permits the front wheel to tilt and lose contact with the

SUBSTANDARD OR CONTAMINATED brake shoe linings causing erratic brake operation. BRAKE FLUID

WARNING LAMP OPERATION

The brake system uses a single red "BRAKE" warning

lamp located in the instrument panel cluster. When the

ignition switch is in the "START" position, the "BRAKE"

warning lamp should come on. It should go off when the

ignition switch returns to the "RUN" position.

The following conditions will activate the "BRAKE"

warning lamp:

1. Parking brake applied. The lamp should be on when

tfie parking brake is applied and the ignition switch is

"ON."

2. Pressure differential switch detects a failure. See

"Brake Pressure Differential Warning Switch" in this

section. Improper

brake fluid, mineral oil or water in the fluid may

cause the brake fluid to boil or the rubber components to

deteriorate.

If piston cups are swollen, the rubber parts have dete-

riorated. This deterioration may also be seen by swollen

wheel cylinder piston cups on the drum brake wheels or a

swollen master cylinder cover diaphragm.

If rubber deterioration is evident, disassemble all hydrau-

lic parts and wash with alcohol. Dry these parts with com-

pressed air before assembly to keep alcohol out of the

system. Replace all rubber parts in the system, including

hoses. Check for fluid on the linings. If excessive fluid is

found, replace the linings.

If master cylinder piston seals are satisfactory, check for

leakage or excessive heat conditions. If condition is not

found, drain fluid, flush with brake fluid, fill and bleed the

system.

Page 318 of 1825

DISC BRAKE CALIPER ASSEMBLY 581-3

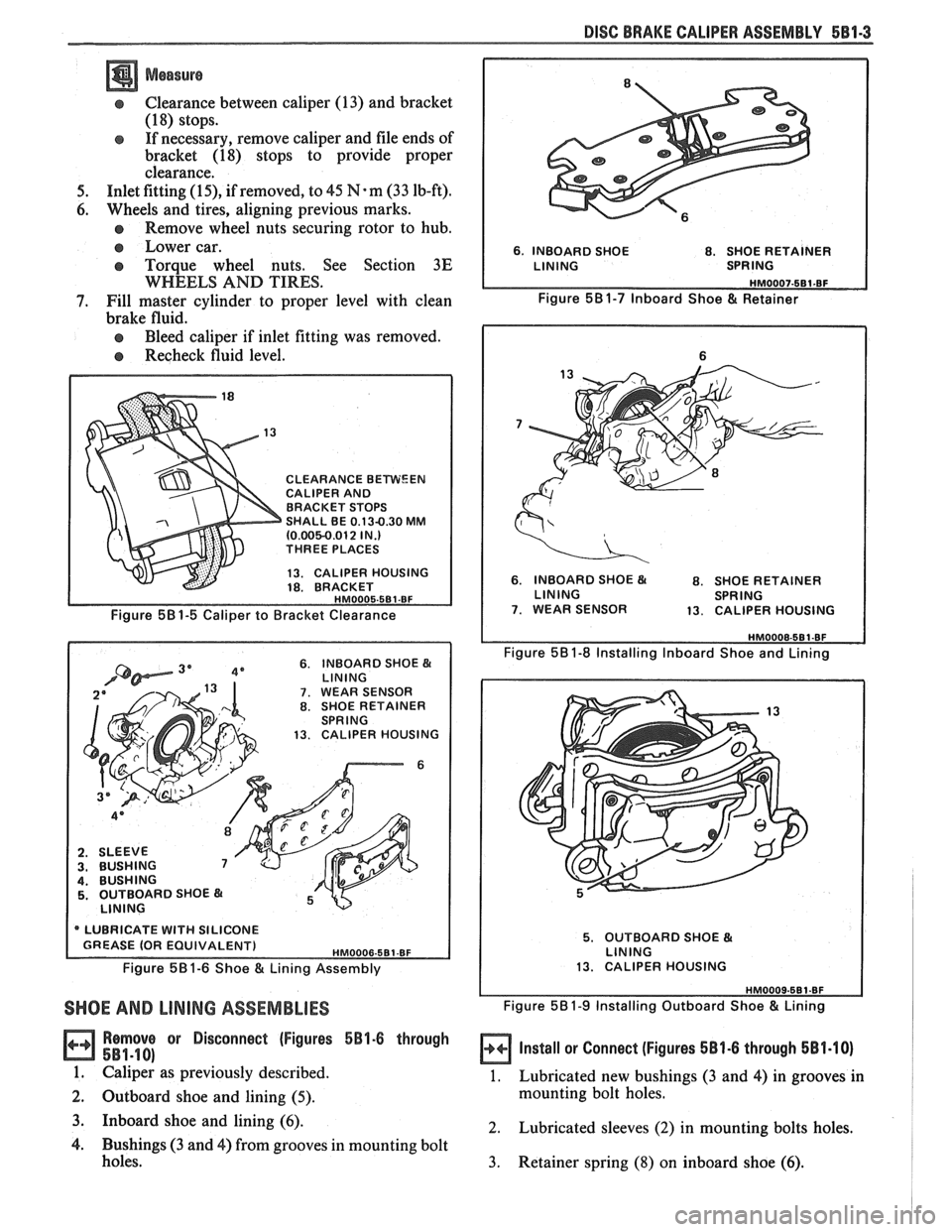

a Measure

Clearance between caliper (13) and bracket

(1 8) stops.

If necessary, remove caliper and file ends of

bracket

(18) stops to provide proper

clearance.

5. Inlet fitting (15), if removed, to 45 N-m (33 lb-ft).

6. Wheels and tires, aligning previous marks.

Remove wheel nuts securing rotor to hub.

e Lower car.

e Torque wheel nuts. See Section 3E

WHEELS AND TIRES.

7. Fill master cylinder to proper level with clean

brake fluid.

Bleed caliper if inlet fitting was removed.

Recheck fluid level.

CLEARANCE BEWEEN CALIPER AND

BRACKET STOPS

SHALL BE

0.13-0.30 MM (0.0050.012 IN.) THREE PLACES

13. CALIPER HOUSING

18. BRACKET

Figure 581-5 Caliper to Bracket Clearance

6. INBOARD SHOE B( LlNlNG 7. WEAR SENSOR 8. SHOE RETAINER

SPRING

13. CALIPER HOUSING

6

2. SLEEVE 3. BUSHING 4. BUSHING 5. OUTBOARD SHOE

LlNlNG

* LUBRICATE WITH SILICONE

Figure 58 1-6 Shoe & Lining Assembly

SHOE AND LINING ASSEMBLIES

Remove or Disconnect (Figures 5B1-6 through

581-18)

1. Calipe; as previously described.

2. Outboard shoe and lining

(5).

6, INBOARD SHOE 8. SHOE RETAINER

Figure 581-7 lnboard Shoe & Retainer

6. INBOARD SHOE B( 8. SHOE RETAINER

LINING SPRING

7. WEAR SENSOR 13. CALIPER HOUSING

Figure 581-8 Installing lnboard Shoe and Lining

5. OUTBOARD SHOE & LINING

13. CALIPER HOUSING

Figure 581-9 Installing Outboard Shoe & Lining

Install or Connect (Figures 581.6 through 581.10)

1. Lubricated new bushings (3 and 4) in grooves in

mounting bolt holes.

3. Inboard shoe and lining (6). 2. Lubricated sleeves (2) in mounting bolts holes.

4. Bushings (3 and 4) from grooves in mounting bolt

holes.

3. Retainer spring (8) on inboard shoe (6).

Page 324 of 1825

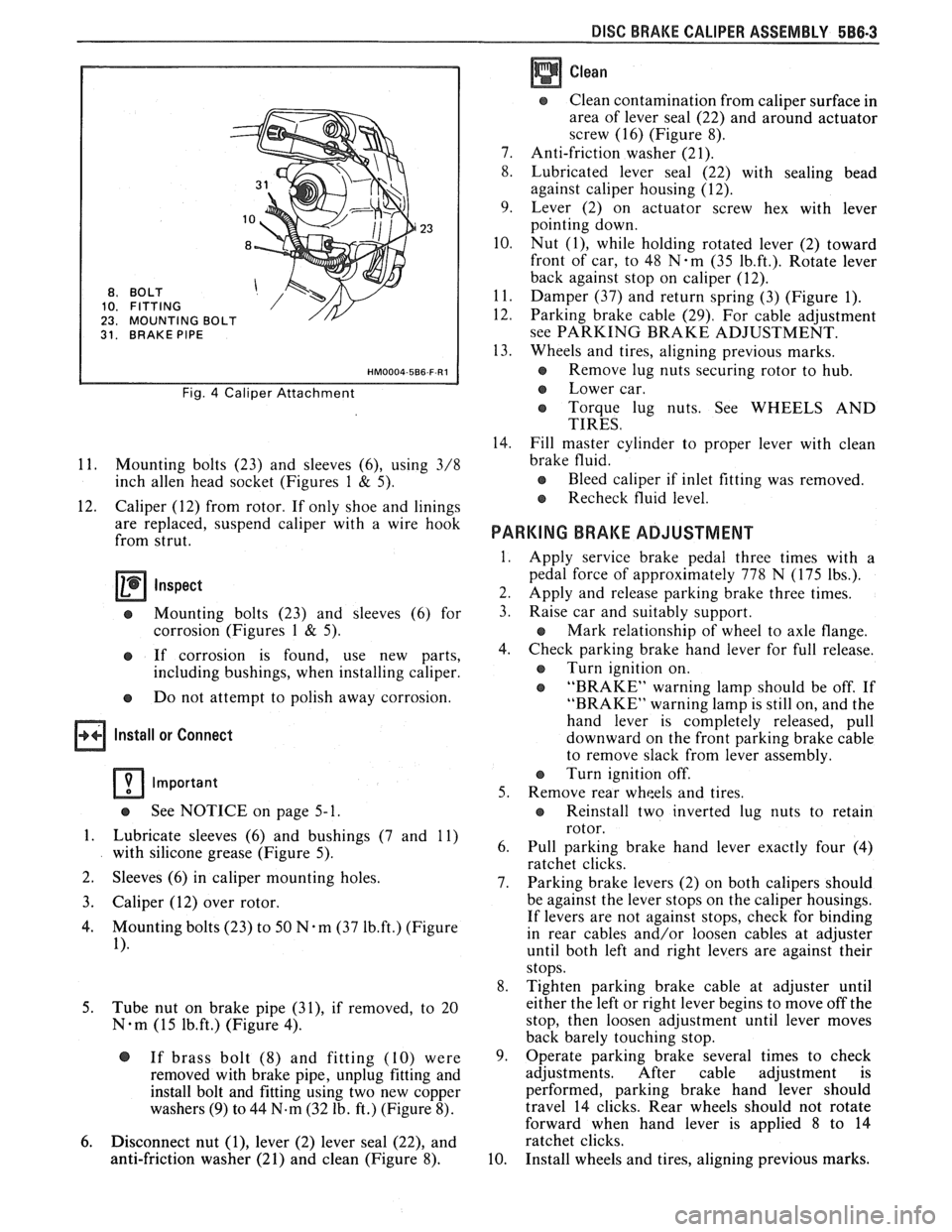

DISC BRAKE CALIPER ASSEMBLY 588-3

BO LT

FITTING

MOUNTING

31. BRAKE PIPE

Fig. 4 Caliper Attachment

11. Mounting bolts (23) and sleeves (6), using 3/8

inch

allen head socket (Figures 1 & 5).

12. Caliper (12) from rotor. If only shoe and linings

are replaced, suspend caliper with a wire hook

from strut.

Inspect

e Mounting bolts (23) and sleeves (6) for

corrosion (Figures

1 & 5).

e If corrosion is found, use new parts,

including bushings, when installing caliper.

e Do not attempt to polish away corrosion.

Install or Connect

Important

See NOTICE on page 5- 1.

1. Lubricate sleeves (6) and bushings (7 and 11)

with silicone grease (Figure 5).

2. Sleeves

(6) in caliper mounting holes.

3. Caliper (12) over rotor.

4. Mounting bolts (23) to 50 N-m (37 1b.ft.) (Figure

1).

5.

Tube nut on brake pipe (31), if removed, to 20

N-m (15 1b.ft.) (Figure 4).

@ If brass bolt (8) and fitting (10) were

removed with brake pipe, unplug fitting and

install bolt and fitting using two new copper

washers

(9) to 44 N.m (32 lb. ft.) (Figure 8).

6. Disconnect nut (I), lever (2) lever seal (22), and

anti-friction washer (21) and clean (Figure 8).

Clean

Clean contamination from caliper surface in

area of lever seal (22) and around actuator

screw (16) (Figure 8).

7. Anti-friction washer (21).

8. Lubricated lever seal (22) with sealing bead

against caliper housing (12).

9. Lever (2) on actuator screw hex with lever

pointing down.

10. Nut

(I), while holding rotated lever (2) toward

front of car, to 48

N-m (35 1b.ft.). Rotate lever

back against stop on caliper (12).

11. Damper (37) and return spring (3) (Figure 1).

12. Parking brake cable (29). For cable adjustment

see PARKING BRAKE ADJUSTMENT.

13. Wheels and tires, aligning previous marks.

s Remove lug nuts securing rotor to hub.

e Lower car.

e Torque lug nuts. See WHEELS AND

TIRES.

14. Fill master cylinder to proper lever with clean

brake fluid.

e Bleed caliper if inlet fitting was removed.

Recheck fluid level.

PARKING BRAKE ADJUSTMENT

Apply service brake pedal three times with a

pedal force of approximately 778 N (175 lbs.).

Apply and release parking brake three times.

Raise car and suitably support.

e Mark relationship of wheel to axle flange.

Check parking brake hand lever for full release.

e Turn ignition on.

e "BRAKE" warning lamp should be off. If

"BRAKE" warning lamp is still on, and the

hand lever is completely released, pull

downward on the front parking brake cable

to remove slack from lever assembly.

Turn ignition off.

Remove rear wheels and tires.

e Reinstall two inverted lug nuts to retain

rotor.

Pull parking brake hand lever exactly four (4)

ratchet clicks.

Parking brake levers (2) on both calipers should

be against the lever stops on the caliper housings.

If levers are not against stops, check for binding

in rear cables and/or loosen cables at adjuster

until both left and right levers are against their

stops.

Tighten parking brake cable at adjuster until

either the left or right lever begins to move off the

stop, then loosen adjustment until lever moves

back barely touching stop.

Operate parking brake several times to check

adjustments. After cable adjustment is

performed, parking brake hand lever should

travel 14 clicks. Rear wheels should not rotate

forward when hand lever is applied

8 to 14

ratchet clicks.

Install wheels and tires, aligning previous marks.