PONTIAC FIERO 1988 Service Repair Manual

Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 651 of 1825

6E3-6 2.8L (VIN S). 5.OL (&BIN F) & 5.7L (WIN 8) BRllVEABlhlPY AND EMISSIONS

......... Fuel Pump Electrical Circuit C2-5

DIAGNOSiS ......................... CZ-5

.............. FUEL CONTROL SYSTERA C2.5

............ IDLE AIR CONTROLVALVE CZ-5

......... FUEL SYSTEM PRESSURE TEST C2-5

ON-CAR SERVICE ..................... C2-5

PORT FUEL INJECTION COMPONENTS .... Cf-5

FUEL PRESSURE RELIEF PROCEDURE ..... C2-5

Plenum ......................... C2-5

................ FUEL RAILASSEMBLY CP-6

FUEL RAIL SERVICE ................... C2-7

................... IDENTIFICATION C2-7

........... UNIT SERVICE PROCEDURES C2-7

COLD START .TUBE & VALVE ASSEMBLY ... ~2-7

PARTS INFORMATION ............... CZ-9

.... FUEL PRE5Si.J RE COPdNECl'ION ASSY C2-10

FUEL INJECTORS (Rail Removed) ........ C2-10

PRESSURE REGULATOR (Ball Removed) ... C2-10

COLD START FUEL INJEClION SWITCH ... C2-1%

THROTTLE BODY ................... CZ-11

VWROTTLE BODY SERVICE IDENTIFICATION . C2-12

............ UNIT REPAIR PROCEDURES Cf-112

TPS Adjcistment .............. C2-12

MiNIRilUM IDLE SPEED CHECK ........... CE-'I2

................. PARTS INFORMATION C2-15

IDLE AIR C'NT' L VALVE ASSY (3r: GASKET . . C2-15

CLEAN AIR COVER & GASKET .......... C2-15

SECTION C4 . 5.0h (VIN F) & 5.7L (VIN 8)

lGNITlON SYSTEMIEST

................ GENERAL DESCRIPTION C4-1

......................... PURPOSE C4-1

OPERATION ....................... C4-1

RESULTS OF INCORRECT OPERATION .... C4-1

......................... DIAGNOSIS C4-1

CODE 12 .......................... C4-1

ON-CAR SERVICE ..................... C4-2

SETTING TIMING .................... C4-2

HOW CODE 42 IS DETERMINED ......... C4-2

................. PARTS INFORMATION C4-2

lgn~tion System Check

Chart C-4

......................... C4-4

SECTION C5 . 5.0L (VIM F) & 5.7L JVIN 8)

ELECTRONIC SPARK CONTROL (ESC) SYSTEM

................ GENERAL DESCRIPTION C5-1

......................... PURPOSE C5-1

.............. GENERAL DESCRIPTION C5-1

......................... DlAGNOSiS C5-1

..................... ON-CAR SERVICE C5-1

....................... ESCSENSOR 65-1

.......... E4C MODULE AiYD BRACKET 165-2

................. PARTS INFORMATXBM C5-2

Electronic Spark Control

Chiirt C-5 ......................... C5-4

IDLE AIR CBi\~TROVCOOLANl'CVR . AS57 0

Throlrle Body Reinovecl Froti.1 Engine . .

FUEL PUlVlP RELAY ..................

................ OIL PRESSURE 5WETCI-I

P/%RVS INFORMATION .................

Irilector Halarlce Test

Chart

C-2A ........................

Idle Air Control

Chart

C-%C ........................

C2-I 5 SECYlOM Ct; . 5.0L (VlN F) & 5.7L (VIN 8)

62-1 5 A8W INJECTION REACTION (A.I.R.) SYSTEM

C2-16 GENERAL DESCRbPTION ............... CG-I

C2-16 PURPOSE ....................... C6-1

C2-76 OPE RATION ...................... C6-1

AIR COPJTROL PEDES VALVE ......... C6-I

C2-'18 RESULTS OF INCORRECT OPERATION .... C6-2

DIAGNOSIS ........................ C6-2

............. Cf -20 OPERATIONAL CHECKS C6-2

SbCTIBN C3 . 5.0L (VIN F) h 5.7L (V1N 8)

I:itAPORAIIVE EMISSlON CONTROL (EECS) SYSTEM

LZNERA. L DESCRIP'rION ............... C3-'!

PURPOSE ........................ C3-1

VAPOR CANISTER

.............. $3-1

EVAF'OFt/?ITIVE EMISSION SYSTEM .me.e. C3-4

FUEL TANK PRESSURE CONTROL VALVE . . C3-2

IN-'TANK PRESSURE CONTROL VALVE . . 63-2

RESULTS OF IRiCORRECT OPERATIGN .... C3-2

DIAGNOSIS ........................ C3-2

VISUAL CHECK OF CANIS'rkR .......... C3-2

FUNCPIONAL TEST

Vapor

Can~saer Purge Valve ........ C3-9

Tank Pressure Control Valve ..... C3-2

ON-CAR SERVICE ................. C3-3

FUEL VAPOR CANISTER ............ C3-3

CANISTER HOSES.

................... C3-3

PARTS INFORiblAT%BN ................ C3-3

Canister Purge Valve Check

Chart

C-3 ......................... C3-4

...................... Air Pump C6-2

................. Hoses and Pipes C6-3

.................... Check \/alve C6-3

.................... ON-CAR SERVICE C6-3

...................... DRIVE BELT C6-3

AIR INJECTION PUMP ............... C6-3

AIR INJECTION CONTROL

.................. (PEDES) VALVE C6-3

AIR ~NJECTION CIIECK VALVE ......... ~6-4

................ PARTS INFORMATION C6-4

AIR Management Check (PEDES)

........................ Chart C-6 C6-6

SECTlON C7 . 5.OL (VlN F) & 5.7L (VIN 8)

EXHAUST GAS RECIRCULATION {EGR) SYSTEM

GENERAL DESCRIPI'ION ..............*. C7-1

......................... PURPOSE C7-I

OPERATION

....................... C7-1

EGR

CONTROL .................... C7-1

NEGATIVE BACKPRESSURE EGR VALVE . . C7-2

EGR \/ALVE IDEhITIFICATION ........... C7-2

Page 652 of 1825

DRIVEABILITY AND EM10010NS 2.8L (WIN S). 5.8L (VIN F) & 5.7L (VlN 8) 6E3-7

RESULTS OF INCORRECT OPERATION ..... C7-2

DIAGNOSIS

....................... C7-2

EGRVALVE ...................... 0-3

EGR Manifold Passage ............... C7-3

EGR CONTROL SOLENOID ............ C7-3

PARTS INFORMATION

................. C7-3

Exhaust Gas Recirculation Check

Chart C-7

......................... C7-4

SECTION

C8 . 5.01 (VIN F) & 5.7L (VIN 8)

TRANSMISISON CONVERTER CLUTCH (TCC) SYSTEM

AND MANUAL TRANSMISSION SHIFT LIGHT

GENERAL DESCRIPTION

................ C8-1

PURPOSE ......................... C8-1

OPERATION ....................... C8-1

DIAGNOSIS ......................... C8-1

SHIFT LlGHT(M1T) DE5CRlPTlON ........ C8-1

DIAGNOSIS ......................... C8-1

ON-CAR SERVICE

..................... C8-1

Automatic Transmission

Converter Clutch

(TCC) (1 of 2)

Chart C-8A ........................ C8-2

MIT Shift Light Check

Chart C-8B

........................ C8-6

SECTION C12 . 5.OL (WIN F) & 5.7L (WIN 8)

eoOLlNe FAN CONTROL

GENERAL DESCRIPTION ................ C12-1

OPERATION ....................... C12-1

DIAGNOSIS ................... .. .... C12-1

ON-CAR SERVICE ..................... C12-1

PARTS INFORMATION .*............... ~12-1

Cooling Fan Control Circuit (I of 2)

Chart C-12 ........................ C12-2

Cooling Fan Control Circuit (2 of 2)

Chart C- 12 ........................ C9 2 -4

SECTION C13

. 5.OL (VIN F) & 5.7L (VIN 8)

POSITIVE CRANKCASE VENTILATION (PCV)

GENERALDESCRIPTION ................ 643-1

RESULTS OF INCORRECT OPERATION .... 613-9

DIAGNOSIS ......................... C13-1

FUNCTIONAL CHECK OF PCV VALVE .... C13-4

ON-CARSERVICE ..................... C13-2

PARTS INFORMATION ................. C13-2

Page 653 of 1825

6E3-8 2.8L (VIM $1, 5.OL (VIN F) & 5.7L(VlN 8) BRlVEABILlTY AND EMISSIOMS

ALL NEW GENERAL MOTORS VEHICLES ARE CERTIFIED BY THE UNITED STAEES

ENVIRONMENTAL PROTECTION AGENCY AS CONFOWMlNG TO "THE REQUIREMENTS QF THE

REGULATIONS FOR THE CONTROL OF AIR POLLUTION FROM NEW MOTOR VEHICLES. THIS

CERTlFlCATlON IS CONTINGENT ON CERTAIN ADJUSTMENTS BEING SET TO FACTORY

STANDARDS. IN MOST CASES, THESE ADJUSTMENT POINTS EITHER HAVE BEEN

PERMANENTLY SEALED ANDIOR MADE

INACCESSlBLE TO PREVENT INDISCRIMINATE OR

ROUTINE ADJUSTM&M"FIN THE FIELD. FOR THIS REASON, THE FACTORY PROCEDURE FOR

TEMPORARILY REMOVING PLUGS, CAPS, ETC., FOR PURPOSES OF SERVICING THE PRODUCT,

MUST

BE STRICTLY FOLLOWED AND, WHEREVER PRACTICABLE, RETURNED TO THE

ORIGINAL INTENT QF THE DESIGN.

INTRODUCTION

GENERAL BESCRIPT18N DIAGNOSIS PROCEDURE

This section applies to engines which have a fuel

injector in the intake manifold near the intake valve

for each cylinder. It is commonly referred to as "Port

Fuel Injection".

These engines have controls to reduce exhaust

emissions, while maintaining good driveability and

fuel economy.

An engine control module

(ECM) is the heart of

this control system and has sensors used to provide

information about engine operation and the various

systems it controls. Details of basic operation,

diagnosis, functional checks, and on-vehicle service

are covered in Section "C", "Component Systems".

The ECM has the ability to do some diagnosis of

itself, and of other parts of the system. When it finds a

problem, it lights a "Service Engine Soon" light on the

instrument panel and

a trouble code will be stored in

the ECM memory. This does not mean that the engine

should be stopped right away, but that the cause of the

light coming

"ON" should be checked as soon as

reasonably possible. The

following

sections(s) are written for specific

engine applications and are clearly indentified. Be

sure to use only the section which applies to the

engine family being diagnosed.

Before using this section of the manual, you

should be familiar with the information and the

proper diagnosing procedures as described in Section

"GE". If the proper diagnosis procedures are not

followed, as described in Section

"6EM, it may result in

unnecessary replacement of good parts.

Trouble tree charts incorporate diagnosis

procedures using an ALDL "SCAN" tool where

possible.

The "SCANJ' tool has the ability to save time

in diagnosis and prevent the replacement of good

parts. The

key to using the "SCAN" tool

successfully for diagnosis lies in the technician's

ability to understand the system he is

trving to

diagnose. as well as an understanding of the

"SCAN" tool's limitations. See Section "6E" for

more information.

Page 654 of 1825

DRIVEABILITY AND EMISSIONS f.8b (VIN S) 6E3-A-1

Cold Oxygen Sensor

The "Diagnostic Circuit Check" verifies the On some engines.

the oxygen sensor will cool off

system is functioning correctly . some special after only a short period of operation at idle . This will

considerations to keep in mind while making the put the system into "Open Loop" . To restore "Closed

"Diagnostic Circuit Check" are: Loop"

operation. run the engine

at part throttle

several minutes and accelerate from idle to part

Blocking Drive Wheels throttle a few times .

The vehicle drive wheels should always be blocked Basic Procedure

while checking the system . If you have not reviewed the basic information on

how to

use the diagnostic procedures. go to the

introduction of this section

.

ENGINE COMPONENTS /WIRING DIAGRAMS / DIAGNOSTIC CHARTS

ComponentLocations ........................................................ PageA-2

Wiring Diagrams (1 of 3) ...................................................... Page A.3.4. 5

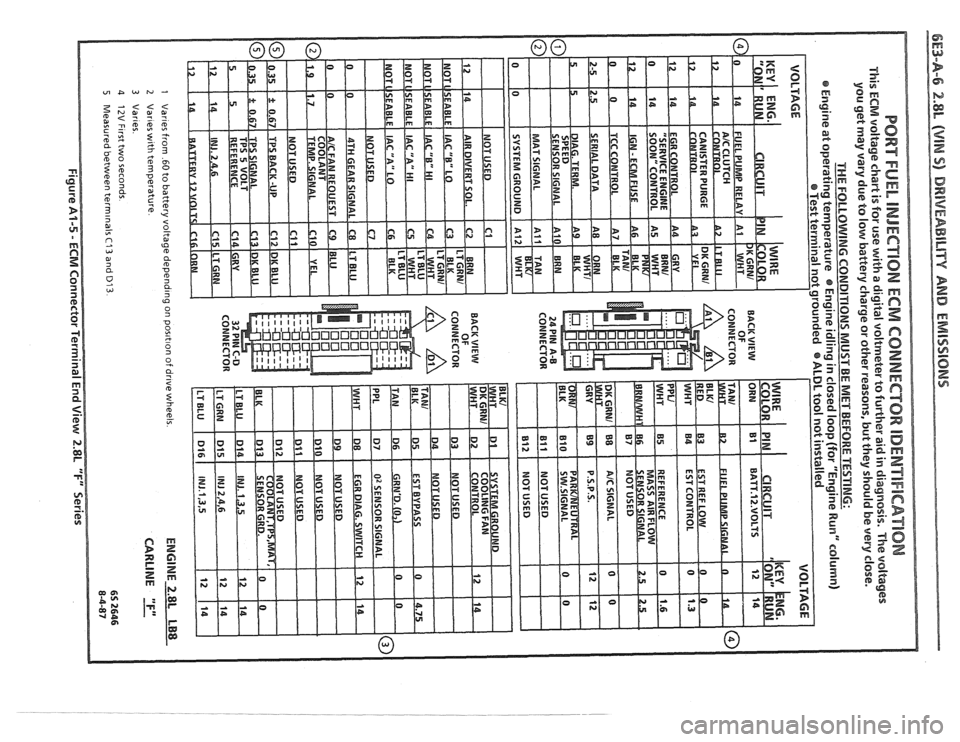

ECM Connector Terminal End View

.............................................. Page A-6

Diagnostic Circuit Check

...................................................... Page A-8

No "Service Engine Soon" bight

. Chart A-1 ........................................ Page A-10

No

ALBL or Won't Flash Code 12 . "Serv~ce Engine Soon" Light On Steady . Chart A-2 ........ Page A-12

. Engine Cranks But Won't Run Chart A-3 (1 of 2) .................................... Page 8-14

. Fuel System Diagnosis Chart A-7 (1 of

2) .......................................... Page A-18

Cold Start Valve

. Chart A-9 .................................................... Page A-22

Code 13 Oxygen Sensor Circuit (Open Circuit)

...................................... Page A-24

Code 14 Coolant Temperature Sensor Circuit (High Temp

. Indicated) ..................... Page A-26

Code 15 Coolant Temperature Sensor Circuit (Low Temp

. Indicated) ..................... Page A-28

Code 21 Throttle Position Sensor (TPS) Circuit (Signal Voltage High)

...................... Page A-30

Code 22 Throttle Position Sensor (TPS) Circuit (Signal Voltage Low)

...................... Page A-32

Code 23 Manifold Air Temperature (MAT) Sensor Circuit (Low Temp

. Indicated) ............ Page A-34

Code 24 Vehicle Speed Sensor (VSS) Circuit

........................................ Page A-36

Code

25 Manifold Air Temperature (MAT) Sensor Circuit (High Temp . Indicated) ............ Page A-38

Code 32

EGR System Failure .................................................... Page A-40

Code 33 Mass Air Flow (MAF) Sensor Circuit

(GMISEC High) ............................. Page A-42

Code 34 Mass Air Flow (MAF) Sensor Circuit

(GMISEC bow) ............................. Page 8-44

Code

41 Cylinder Select Error .................................................. Page A-46

Code 42 Electronic Spark Timing Fault

................... .... .................... Page 8-48

Code 44 Oxygen Sensor Circuit (Lean Exhaust Indicated)

.............................. Page A-50

Code

45 Oxygen Sensor Circuit (Rich Exhaust Indicated) ............................... Page A-52

Code 54 Fuel Pump Circuit

(Lowvoltage) .......................................... Page A-54

Code

51 PROM Error (Faulty or Incorrect PROM) ..................................... Page A-56

Code 52 CALPAK Error (Faulty or Incorrect CALPAK)

................................. Page 44-56

Code 53 System Over Voltage .................................................. Page A-56

Code55ECMError ............................O.~o.~.~e.~e~e.~e....... .. PageA-56

Page 655 of 1825

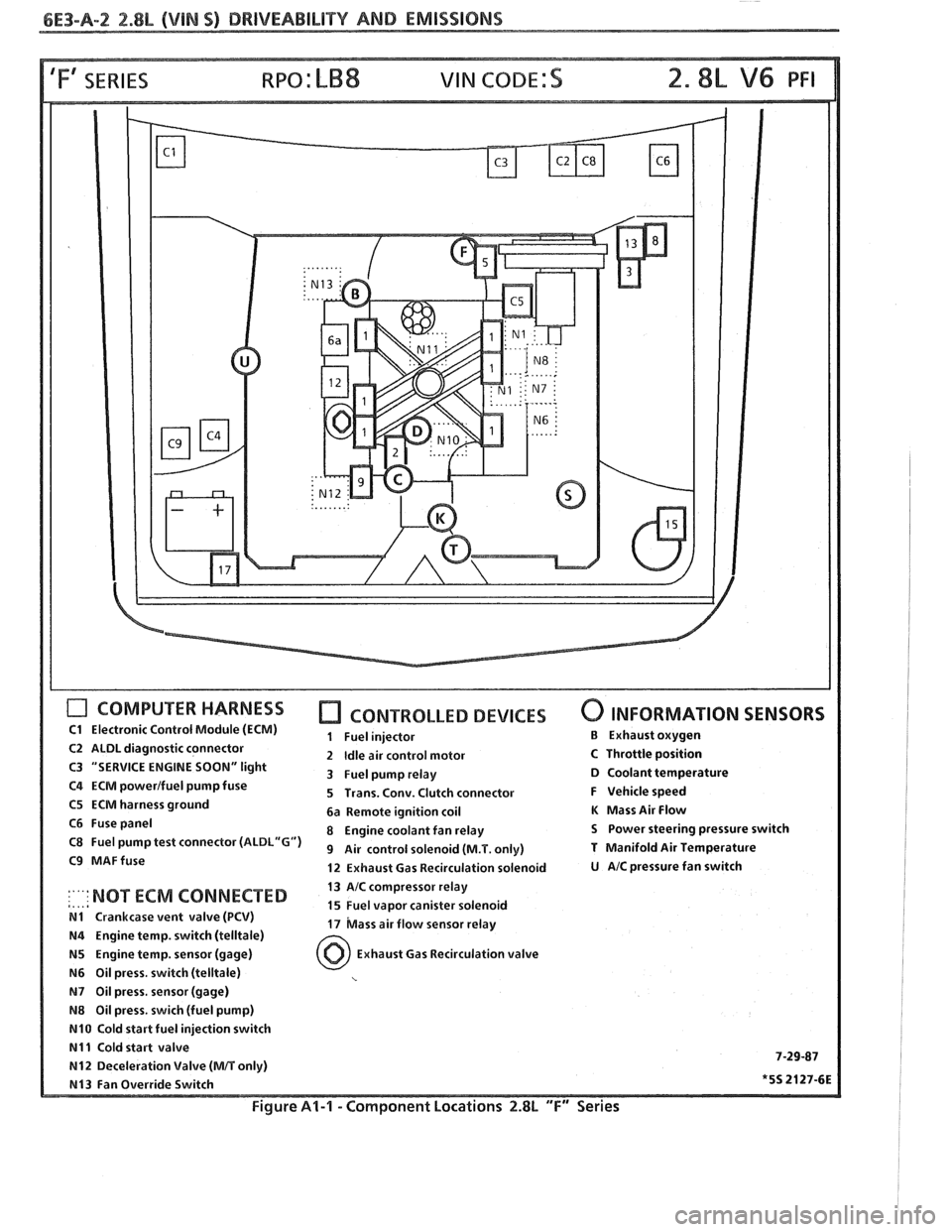

6E3-A-2 2.88, (VIM S) DRIVEABILITY AND EMISSIONS

'Fa SERIES

COMPUTER HARNESS

C1 Electronic Control Module (ECM)

C2 ALDL diagnostic connector

C3 "SERVICE ENGINE

SOON" light

C4 ECM powerlfuel pump fuse

C5 ECM harness ground

C6 Fuse panel

C8 Fuel pump test connector

(ALDL"G")

C9 MAFfuse

CONTROLLED DEVICES

1 Fuel injector

2

Idle air control motor

3 Fuel pump relay

5 Trans. Conv. Clutch connector

6a Remote ignition coil

8 Engine coolant fan relay

9 Air control solenoid (M.T. only)

12 Exhaust Gas Recirculation solenoid

0 INFORMATION SENSORS

B Exhaust oxygen

C Throttle position D Coolant temperature

F Vehicle speed

K Mass Air Flow

S Power steering pressure switch

T Manifold Air Temperature

U AIC pressure fan switch

13 AIC compressor relay

,..,a :'"' NOT ECM 'ONNECTED 15 Fuel vapor canister solenoid N1 Crankcase vent valve (PCV) 17 bass air flow sensor relay N4 Engine temp. switch (telltale)

N5 Engine temp. sensor (gage) Exhaust Gas Recirculation valve

N6 Oil press. switch (telltale)

N7 Oil press, sensor (gage)

N8 Oil press. swich (fuel pump)

N10 Cold start fuel injection switch

N11 Cold start valve 7-29-87 N12 Deceleration Valve (MIT only)

N13 Fan Override Switch *5S 2127-6E

Figure Al-l - Component Locations 2.8L "F" Series

Page 656 of 1825

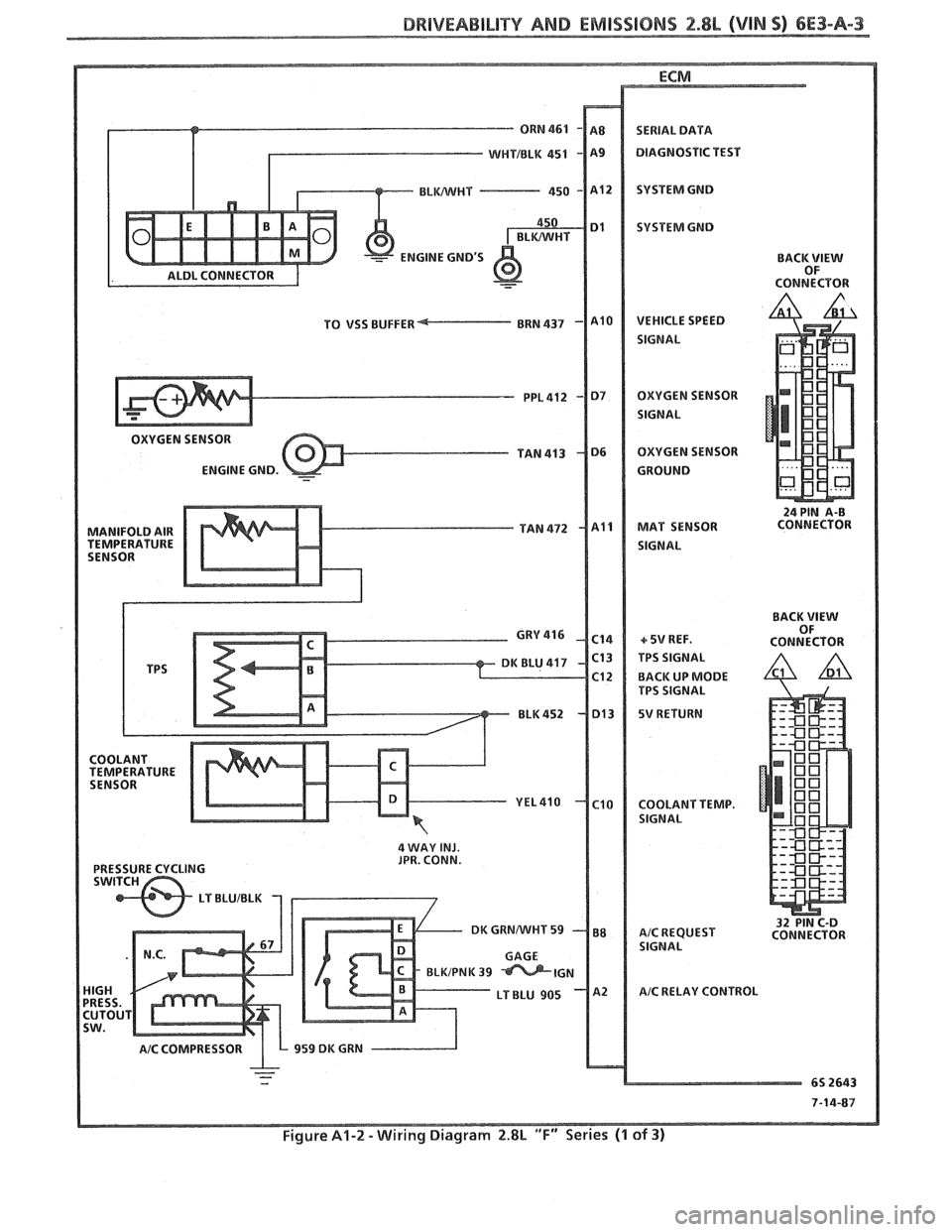

BRlVEABlLlTY AND EMISSIONS 2.8L (VIN 5) 6E3-A-3

ENGINE GND'S BACK VIEW

OF

CONNECT OR

TO VSS BUFFER

OXYGEN SENSOR

ENGINE GND.

MANIFOLD AIR

TEMPERATURE

4 WAY INJ.

JPR. CONN.

7-14-87

Figure A1-2 -Wiring Diagram 2.8L "F" Series (1 of 3)

Page 657 of 1825

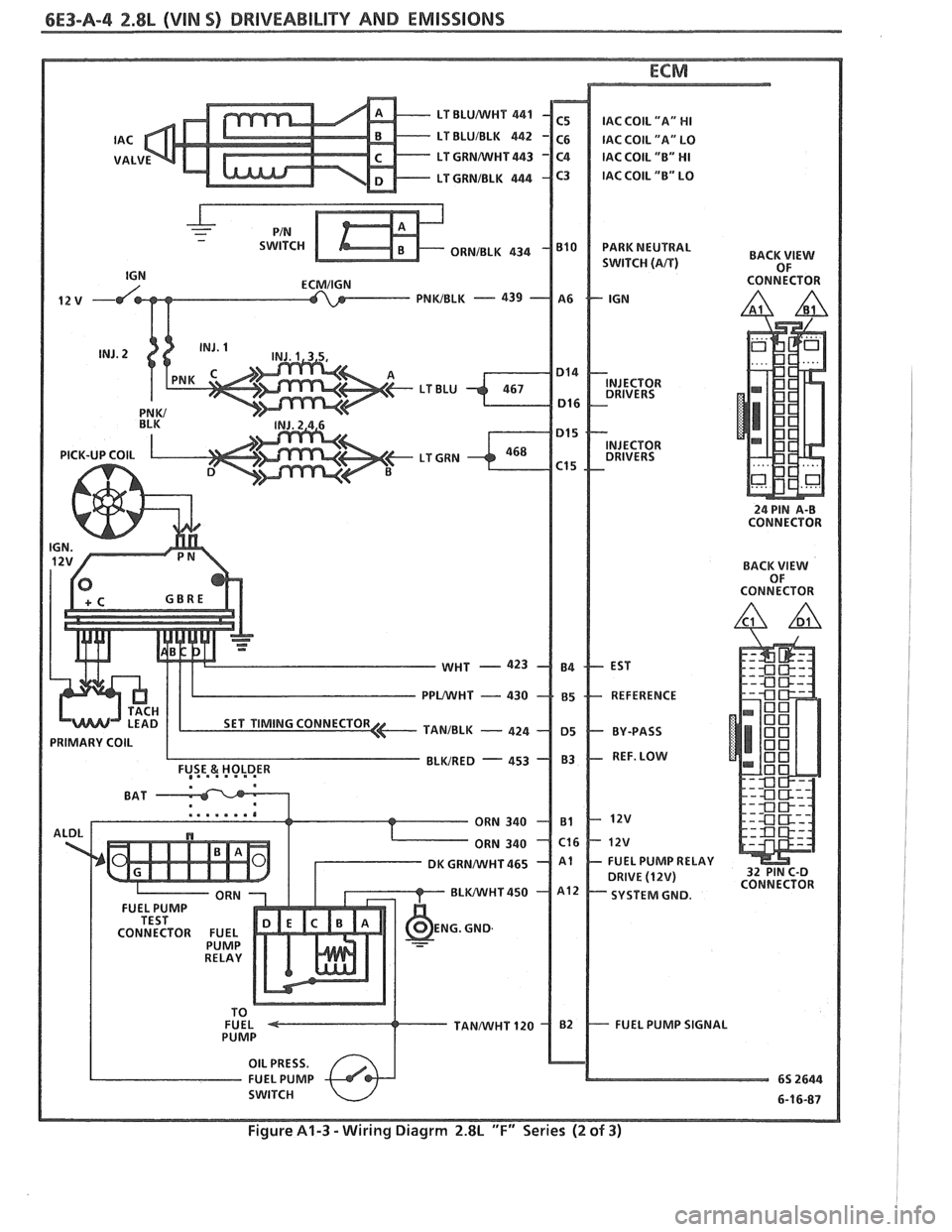

6E3-A-4 2.8L (VIN S) DRIVEABILITY AND EMISSIONS

ECMIIGN

I I

I

1

I

I

I I

I

PRIMARY COIL I

I

I

I

I

FUEL PUMP

CONNECTOR FUEL

FUEL PUMP SIGNAL

Page 658 of 1825

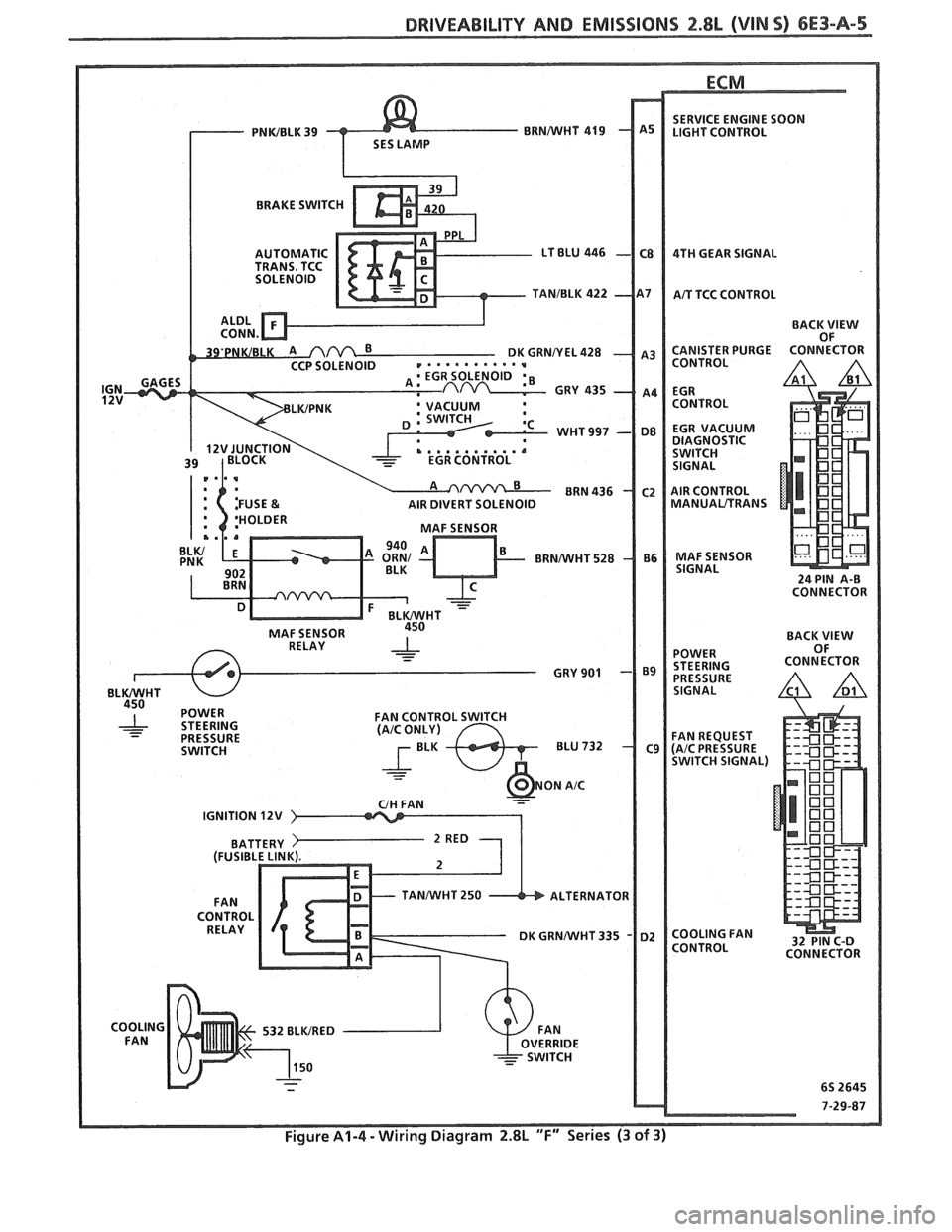

DRIVEABILITY AND EMISSIONS 2.8L (VIN S) 6E3-A-5

ECM

BRAKE SWITC

BACK

VIEW OF

AIR DIVERT SOLENOID

MANUALITRANS

IGNITION 12V

TANMIHT 250 ALTERNATOR

Figure A1-4 - Wiring Diagram 2.8L "F" Series (3 of 3)

Page 659 of 1825

Page 660 of 1825

DRIVEABILITY AND EMISSIONS f.8L (VIM 9) 6E3-A-7

BLANK