PONTIAC FIERO 1988 Service Repair Manual

Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 661 of 1825

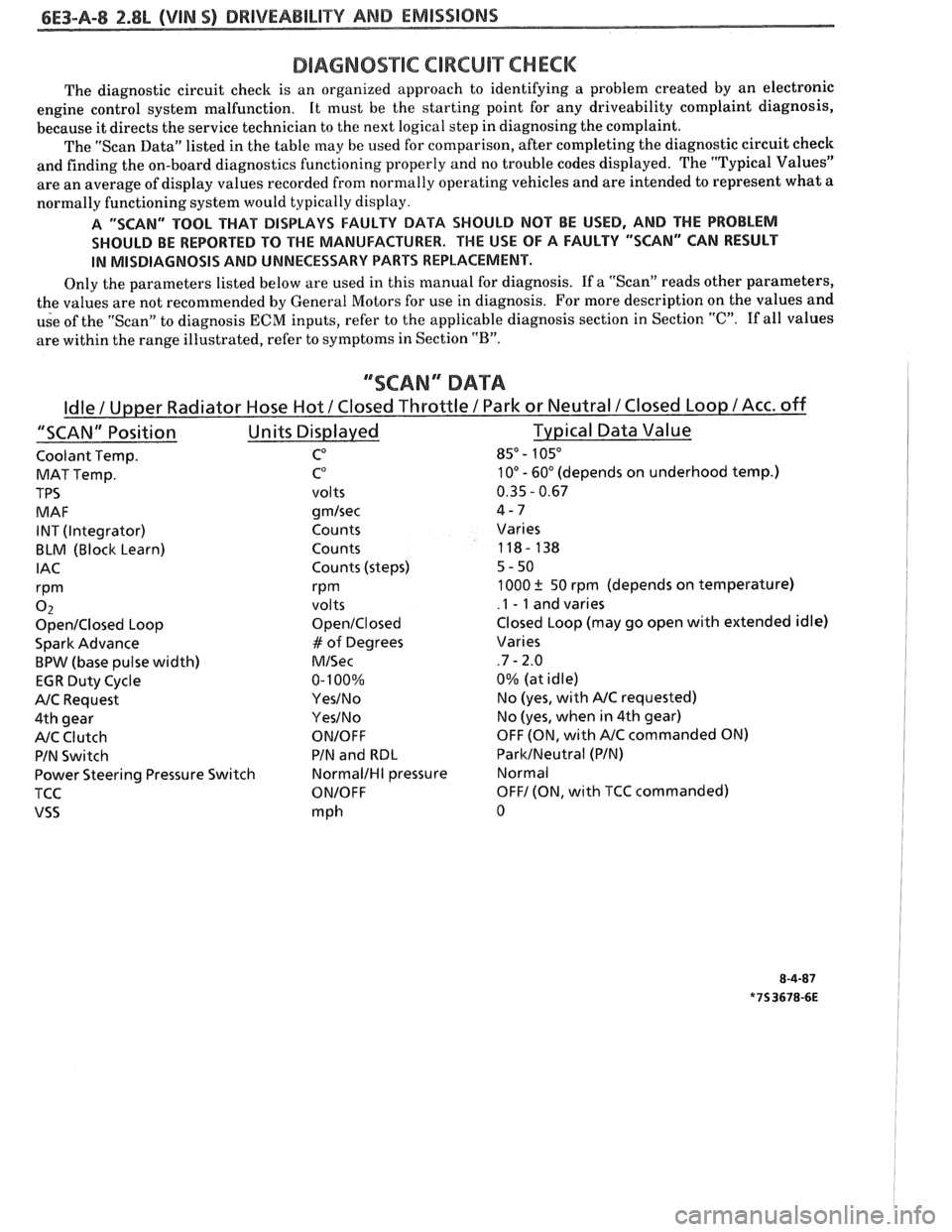

DIAGNOSTIC CIRCUIT CHECK

The diagnostic circuit check is an organized approach to identifying a problem created by an electronic

engine control system malfunction. It

must be the starting point for any driveability complaint diagnosis,

because it directs the service technician to the next logical step in diagnosing the complaint.

The "Scan Data" listed in the table may be used for comparison, after completing the diagnostic circuit check

and finding the on-board diagnostics functioning properly and no trouble codes displayed. The "Typical Values"

are an average of display values recorded from normally operating vehicles and are intended to represent what a

normally functioning system would typically display.

A "SCAN" TOOL THAT BiSPLAYS FAULTY DATA SHOULD NOT BE USED, AND THE PROBLEM

SHOULD BE REPORTED

TO THE MANUFACTURER. THE USE OF A FAULTY "SCAN" CAN RESULT

IN MISDIAGNOSIS AND UNNECESSARY PARTS REPLACEMENT.

Only the parameters listed below are used in this manual for diagnosis. If a "Scan" reads other parameters,

the values are not recommended by General Motors for use in diagnosis. For more description on the values and

use of the "Scan" to diagnosis

ECM inputs, refer to the applicable diagnosis section in Section "C". If all values

are within the range illustrated, refer to symptoms in Section

"B".

""SCAN" DATA

Coolant Temp. CO 85" - 105"

MAT Temp. C0 10" - 60" (depends on underhood temp.)

TPS

volts 0.35 - 0.67

MAF

gmlsec 4-7

INT (Integrator) Counts Varies

BLM (Block Learn) Counts 118- 138

IAC Counts (steps) 5-50

rPm rPm 1000 ? 50 rpm (depends on temperature)

0 2 volts .I - 1 and varies

OpenIClosed Loop OpenIClosed Closed Loop (may go open with extended idle)

Spark Advance

# of Degrees Varies

BPW (base pulse width) MISec .7 - 2.0

EGR Duty Cycle 0-

100% 0%

(at idle)

NC Request YesINo No (yes, with NC requested)

4th gear

YesINo No (yes, when in 4th gear)

NC Clutch ONIOFF OFF (ON, with NC commanded ON)

PIN Switch PIN

and

RBL ParkINeutral (PIN)

Power Steering Pressure Switch

NormalIHI pressure Normal

TCC

ONIOFF OFF1 (ON, with TCC commanded)

VSS mph 0

Page 662 of 1825

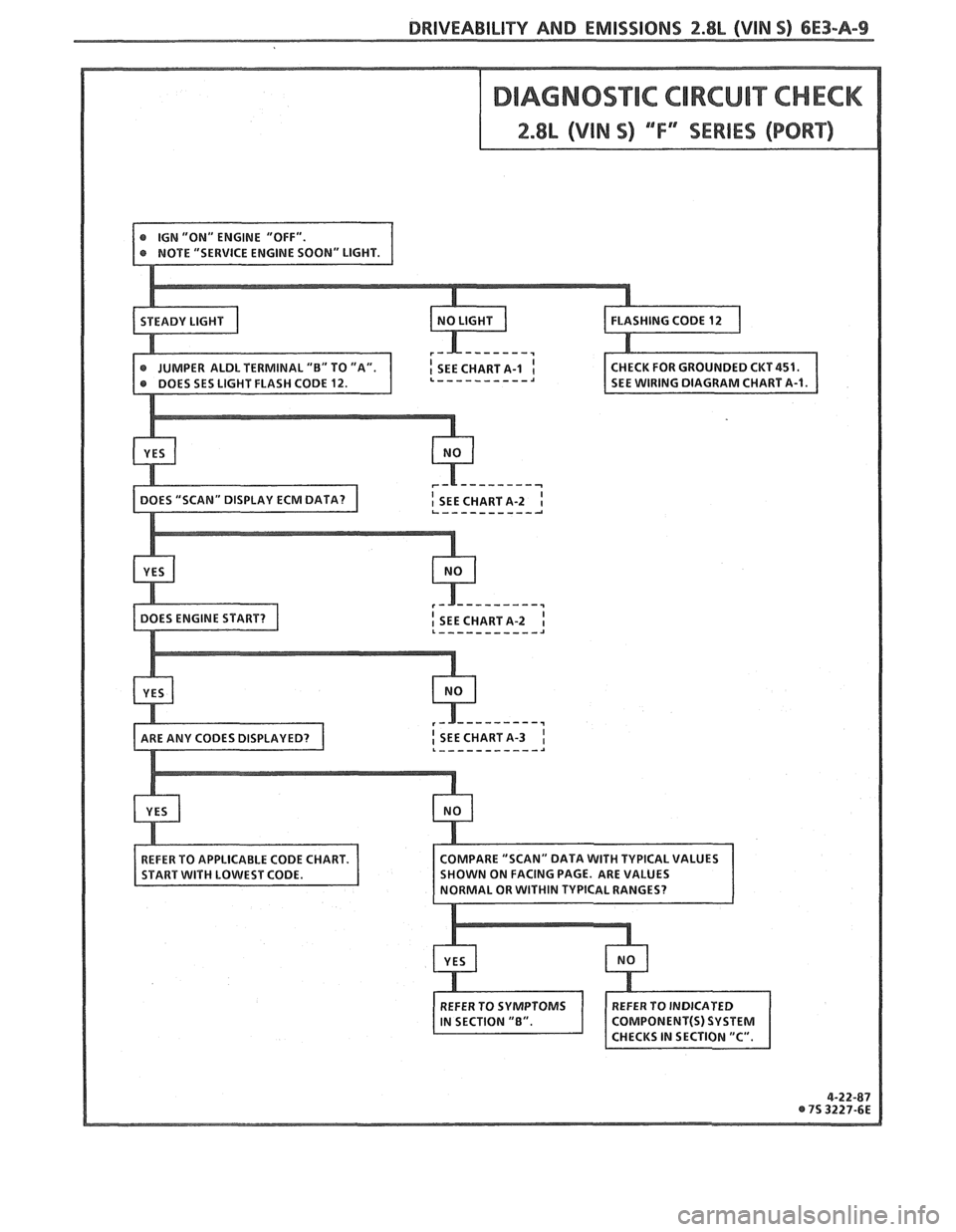

DRIVEABILITY AND EMISSIONS 2.8L (VlN S) 6E3-A-9

Page 663 of 1825

6E3-A-"I 2.8L (VlN S) DRIVEABILITY AND EMlSSlONS

TO OIL PRESS. SW.

&FUEL PUMP RELAY

FUSE

81 HOLDER BATTERY 12 V .. m.. . n.

. . . . . . . . FUSIBLE LINK

439 PNWBLK

419 BRNNVHT

SERIAL

DATA

451

WHTJBLK

450 BLKNVHT

ALDL CONNECTOR

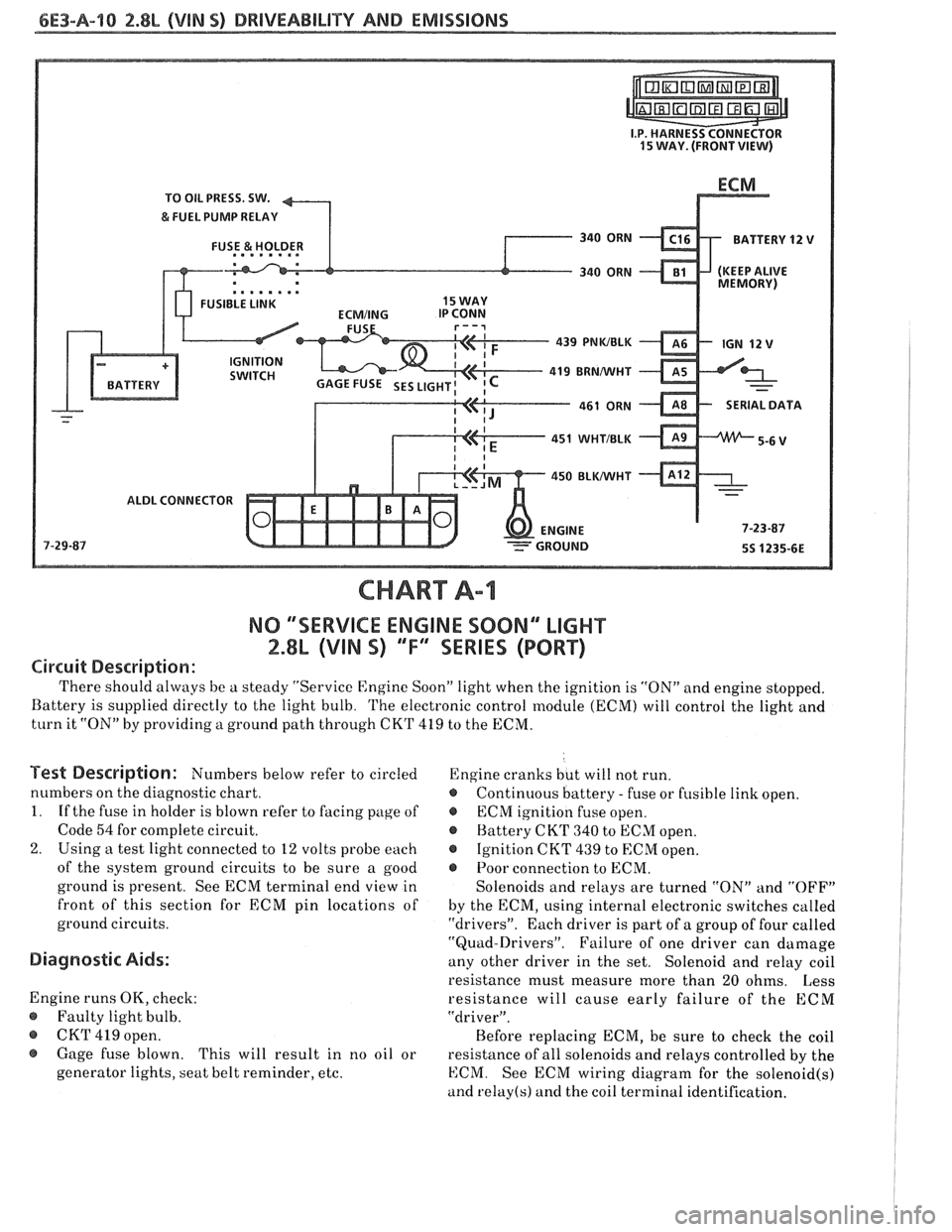

NO "SERVICE ENGlNE SOON" "LIGHT

2.8b (VIM 5) 'T" "SERIES (PORT)

Circuit Description:

There should always be a steady "Service Engine Soon" light when the ignition is "ON" and engine stopped.

Battery is supplied directly to the light bulb. The electronic control module

(ECNI) will control the light and

turn it "ON" by providing a ground path through CKT 419 to the ECM.

Test Description: Numbers below refer to circled

numbers on the diagnostic chart.

1. If the fuse in holder is blown refer to facing page of

Code

54 for complete circuit.

2. Using a test light connected to 12 volts probe each

of the system ground circuits to be sure a good

ground is present. See ECM terminal end view in

front of this section for

ECM pin locations of

ground circuits.

Diagnostic Aids:

Engine runs OK, check:

@ Faulty light bulb.

@ CKT 419 open.

@ Gage fuse blown.

This will result in no oil or

generator lights, seat belt reminder, etc. Engine

cranks but will not run.

@ Continuous battery - fuse or fusible link open.

@ ECM ignition fuse open.

@ Battery CKT 340 to ECM open.

@ Ignition CKT 439 to ECM open.

e Poor connection to ECM.

Solenoids and relays are turned "ON"

and "OFF"

by the ECM, using internal electronic switches called

"drivers". Each driver is part of a group of four called

"Quad-Drivers". Failure of one driver can damage

any other driver in the set. Solenoid and relay coil

resistance must measure more than 20 ohms. Less

resistance will cause early failure of the ECM

"driver".

Before replacing ECM, be sure to check the coil

resistance of all solenoids and relays controlled by the

ECM. See ECM wiring diagram for the

solenoid(s)

and relay(s) and the coil terminal identification.

Page 664 of 1825

DRIVEABILITY AND EMISSIONS 2.8L (VIN 5) 6E3-A-l l

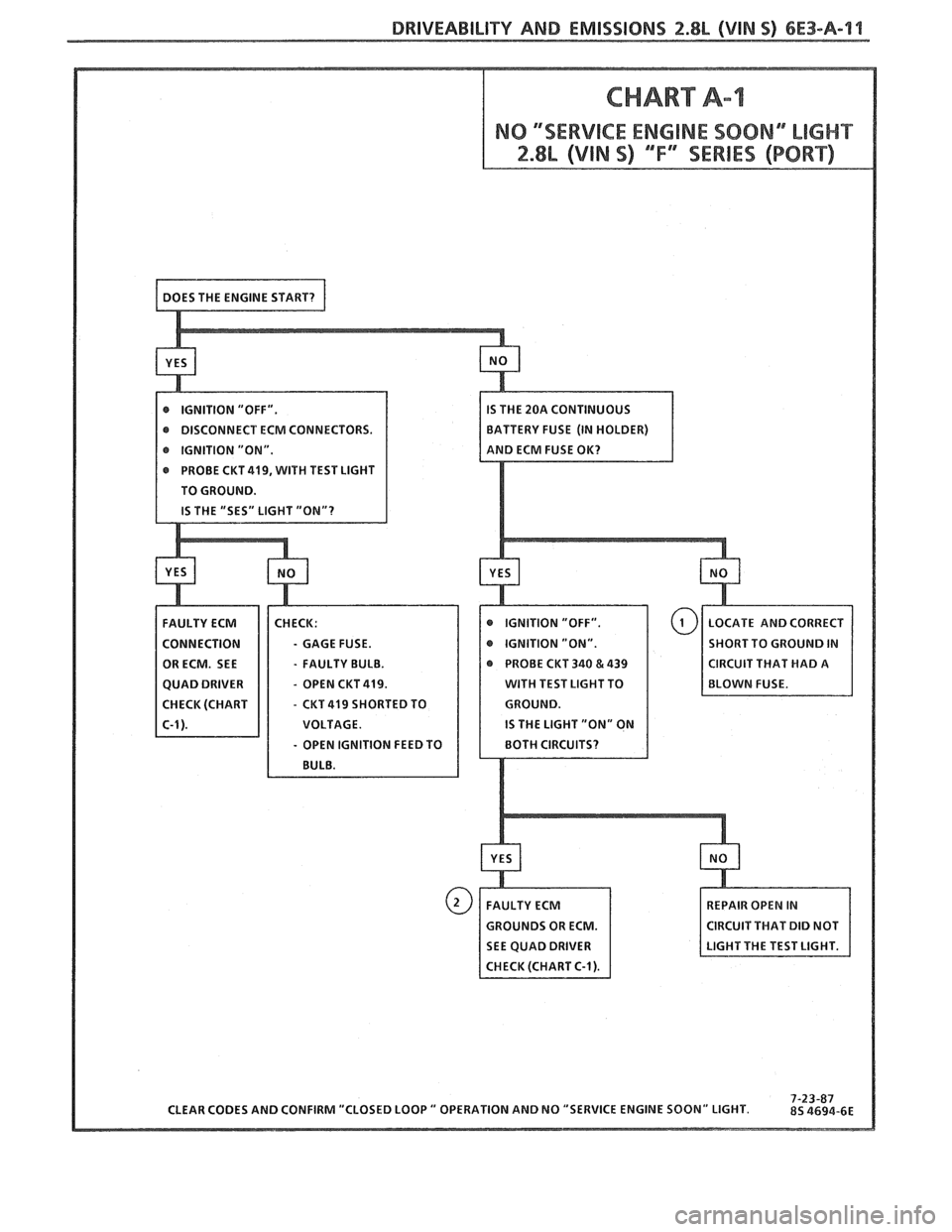

CHART A-1

CLEAR CODES AND CONFIRM "CLOSED LOOP " OPERATION AND NO "SERVICE ENGINE SOON" LIGHT.

DISCONNECT

ECM CONNECTORS. BATTERY

FUSE (IN HOLDER)

IGNITION "ON".

PROBE

CUT 419, WITH TEST LIGHT

TO GROUND.

- GAGE FUSE. SHORT TO GROUND IN

- FAULTY BULB. @ PROBE CKT 340 & 439 CIRCUIT THAT HAD A

- OPEN CUT 419. WITH TEST LIGHT TO

- CKT 419 SHORTED TO

REPAIR OPEN IN

GROUNDS OR ECM. CIRCUIT THAT DID NOT

SEE QUAD DRIVER

CHECK (CHART

C-1).

Page 665 of 1825

6E3-A-92 2.8b (VIN SI DRIVEABILITY AND EMISSIONS

TO OIL PRESS. SW.

&FUEL PUMP RELAY

FUSE

& HOLDER BATTERY 12

V

.. am.. . FUSIBLE LINK 15 WAY

439

PNWBLK

- 419 BUNNVHT

SERIAL DATA

451

WHTIBLK

450 BLWHT

ALDL CONNECTOR

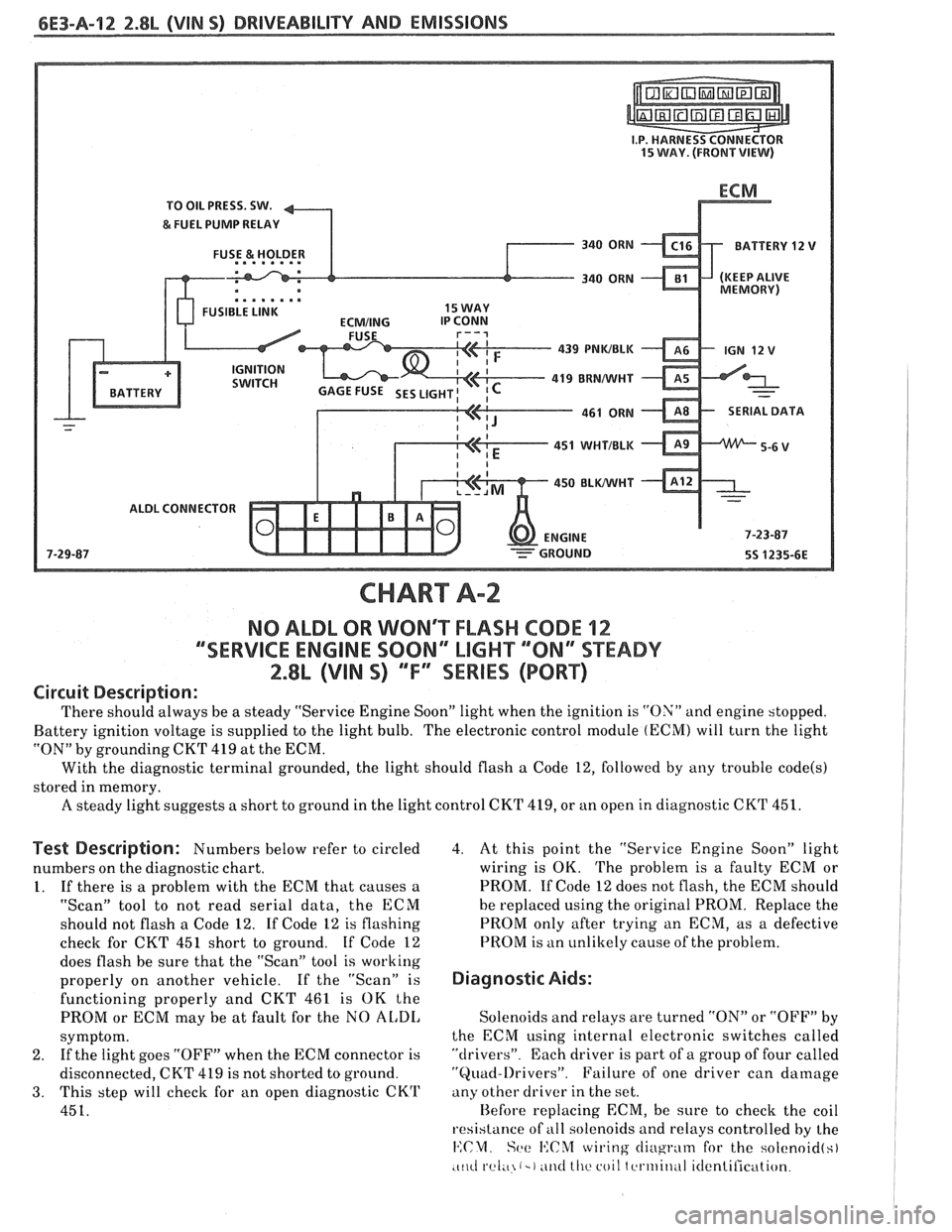

CHART A-2

NO ALDL OR WONT FLASH CODE 12

""SERVICE ENGlNE SOON" MGHT ""8N13SPEADY

2.8L (VIN S) ""FYSERlES (PORT)

Circuit Description:

There should always be a steady "Service Engine Soon" light when the ignition is "ON" and engine stopped.

Battery ignition voltage is supplied to the light bulb. The electronic control module

(ECM) will turn the light

"ON" by grounding CKT

419 at the ECM.

With the diagnostic terminal grounded, the light should flash

a Code 12, followed by any trouble code(s)

stored in memory.

A steady light suggests a short to ground in the light control CKT 419, or an open in diagnostic CKT 451.

Test Description: Numbers below refer to circled

numbers on the diagnostic chart.

1. If there is a problem with the ECM that causes a

"Scan" tool to not read serial data, the ECM

should not flash a Code 12. If Code 12 is flashing

check for CKT

451 short to ground. If Code 12

does flash be sure that the "Scan" tool is working

properly on another vehicle. If the "Scan" is

functioning properly and CKT 461 is OK the

PROM or ECM may be at fault for the NO

AL,DI,

symptom.

2. If

the light goes "OFF" when the ECM connector is

disconnected, CKT 419 is not shorted to ground.

3. This step will check for an open diagnostic CKrl'

451.

4. At this point the "Service Engine Soon" light

wiring is OK. The problem is a faulty ECM or

PROM. If Code 12 does not flash, the ECM should

he replaced using the original PROM. Replace the

PROM only after trying an ECM, as a defective

PROM is an unlikely cause of the problem.

Diagnostic Aids:

Solenoids and relays are turned "ON" or "OFF" by

the ECM using internal electronic switches called

"drivers". Each driver is part of a group of four called

"Quad-l)rivers". Failure of one driver can damage

any other driver in the set.

Hefore replacing ECM, be sure to check the coil

resistance of

all solenoids and relays controlled by the

14:CM. Set: I':C%f wiring cliugrntn for the solcnoid(s)

.c~~cl rel;~ (-1 ~ititl lllc coil tcrtriitlul itlentilication.

Page 666 of 1825

DRIVEABILITY AND EMISSIONS 2.8b (VIN 5) 6E3-A-13

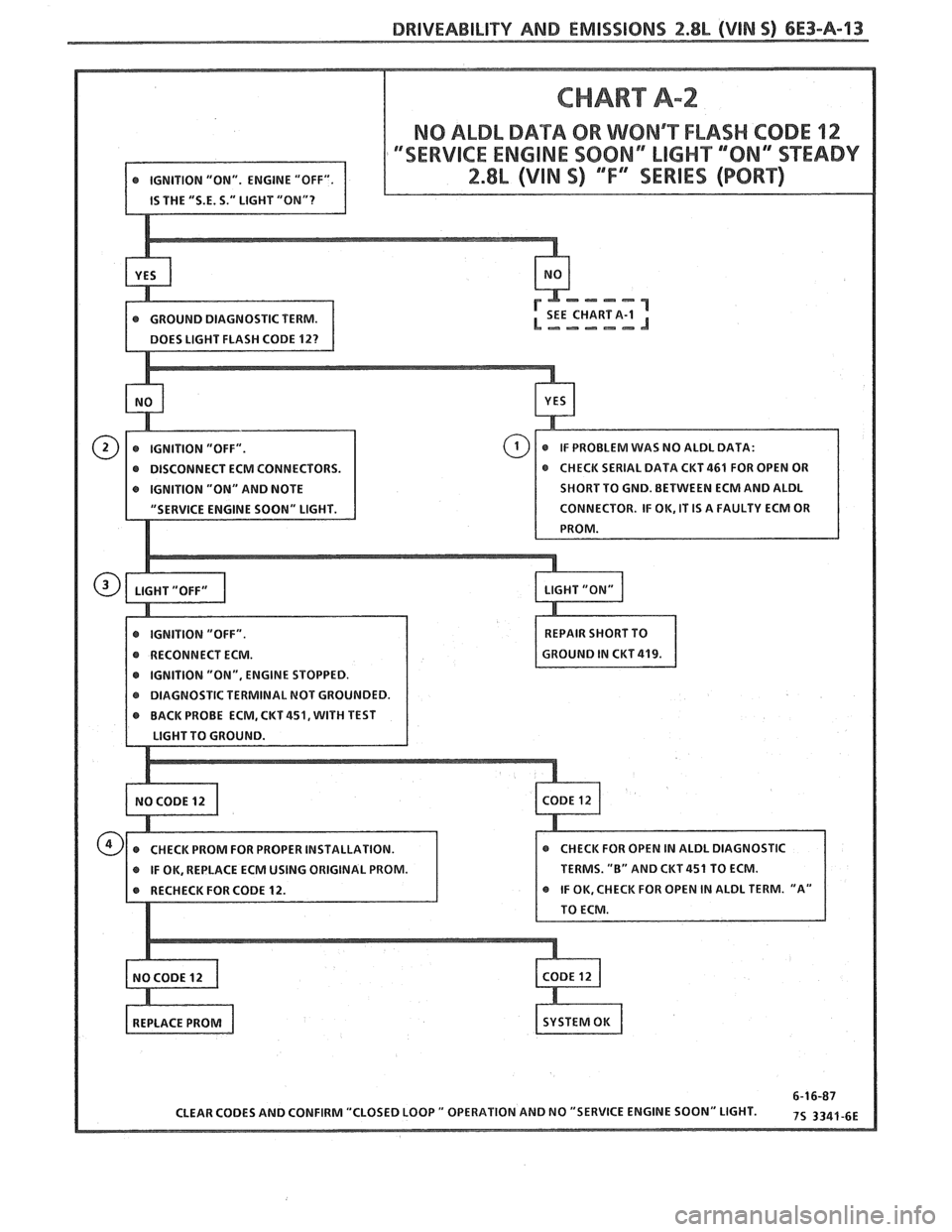

CHART A-2

NO ALDL DATA OR WONRT FLASH CODE 12

DISCONNECT ECM CONNECTORS.

IGNITION "ON" AND NOTE SHORT TO

GND. BETWEEN ECM AND ALDL

IGNITION "ON", ENGINE STOPPED.

KT

451, WITH TEST

IF OK, REPLACE ECM USING ORIGINAL PROM. TERMS.

"B" AND CKT 451 TO ECM.

Page 667 of 1825

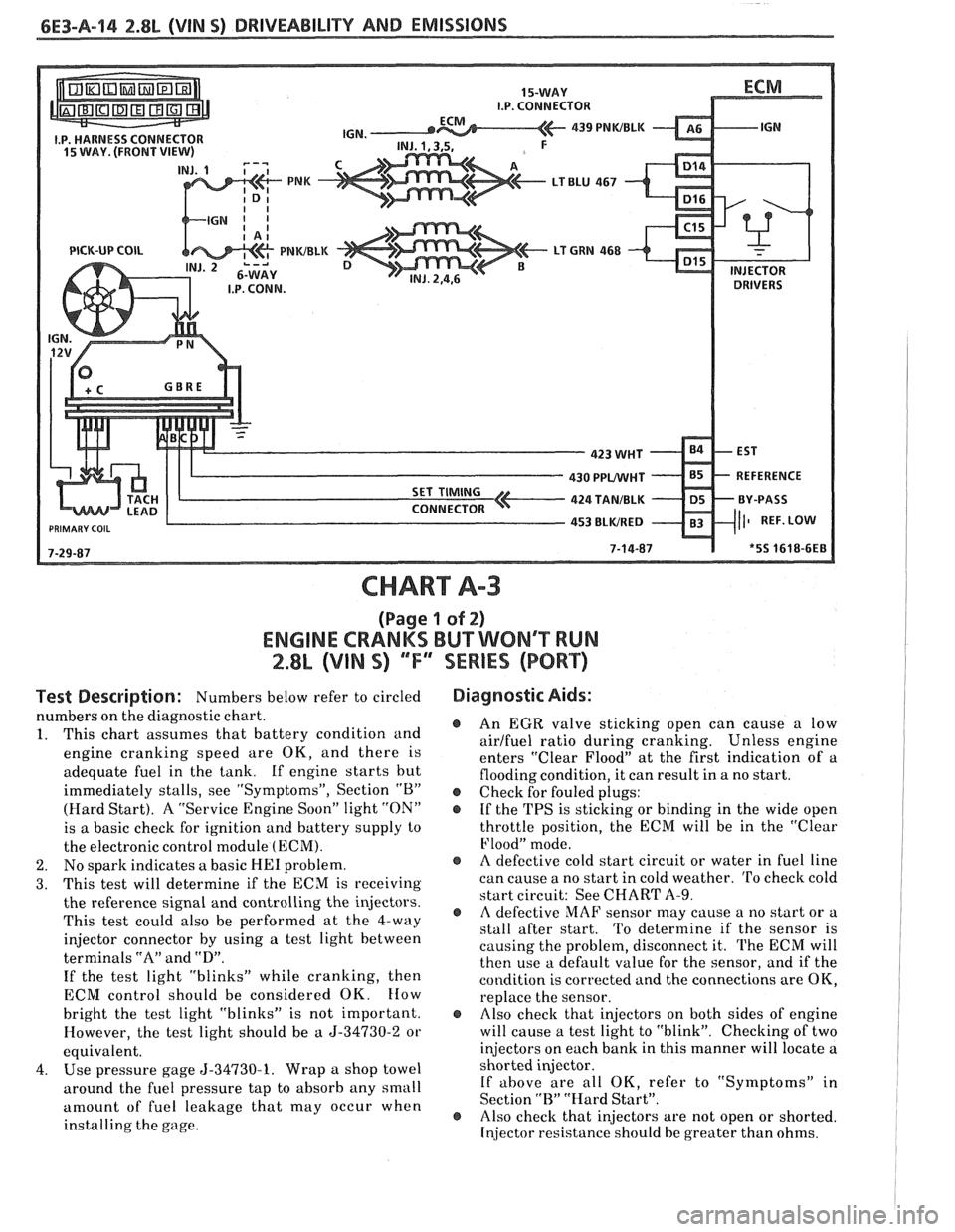

6E3-A-14 2.8L (VIN S) DRIVEABILITY AND EMISSIONS

PICK-UP COIL

CHART A-3

(Page 1 of 2)

ENGINE CRANKS BUT WON'T RUN

2.8L (VIN S) ""F'" SERIES (PORT)

Test Description: Numbers below refer to circled

numbers on the diagnostic chart.

1. This chart

assunles that battery condition and

engine cranking speed are OK, and there is

adequate fuel in the tank. If engine starts but

immediately stalls, see "Symptoms", Section

"B"

(Hard Start). A "Service Engine Soon" light "ON"

is a basic check for ignition and battery supply to

the electronic control module

(ECM).

2. No sparlc indicates a basic HE1 problem.

3. This test will determine if the ECM is receiving

the reference signal and controlling the injectors.

This test could also be performed at the 4-way

injector connector by using a test light between

terminals

"A" and "D".

If the test light "blinks" while cranking, then

ECM control should be considered OK.

How

bright the test light "blinks" is not important.

However, the test light should be a

5-34730-2 or

equivalent.

4. Use pressure gage 5-34730-1. Wrap a shop towel

around the fuel pressure tap to absorb any small

amount of fuel leakage that may occur when

installing the gage.

Diagnostic Aids:

@ An EGR valve sticking open can cause a low

airlfuel ratio during cranking. Unless engine

enters "Clear Flood" at the first indication of a

flooding condition, it can result in a no start.

@ Check for fouled plugs:

@ If the TPS is sticking or binding in the wide open

throttle position, the ECM will be in the "Clear

Flood" mode.

@ A defective cold start circuit or water in fuel line

can cause a no start in cold weather.

To check cold

start circuit: See CHART

A-9.

e A defective MAF sensor may cause a no start or a

stall after start. 'I'o determine if the sensor is

causing the problem, disconnect it. The ECM will

then use a default value for the sensor, and if the

condition is corrected and the connections are OK,

replace the sensor.

@ Also check that injectors on both sides of engine

will cause a test light to "blink". Checking of two

injectors on each bank in this manner will locate a

shorted injector.

If

above are all OK, refer to "Symptoms" in

Section

"R" "Hard Start".

@ Also checlc that injectors are not open or shorted.

Injector resistance should be greater than ohms.

Page 668 of 1825

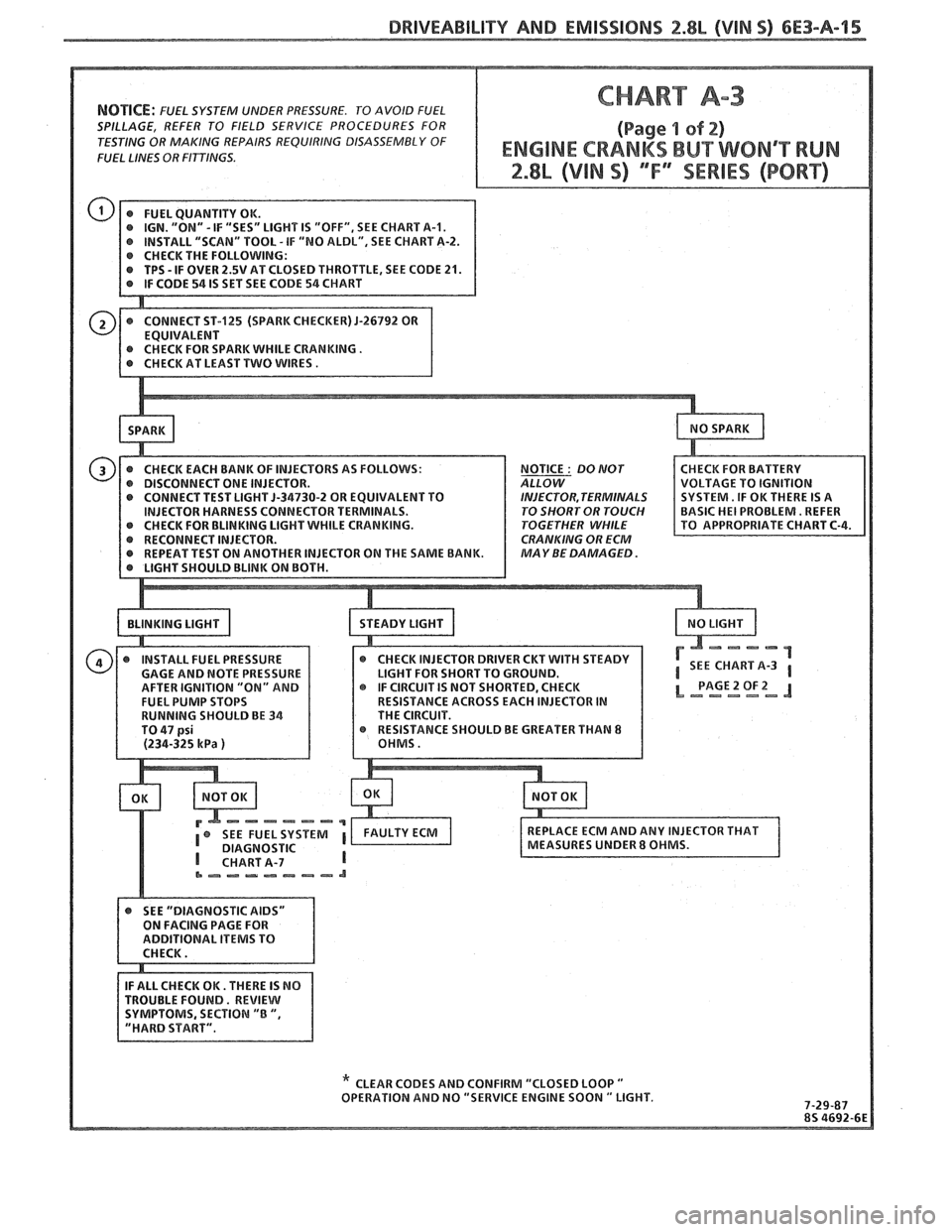

NOTICE: FUEL SYSTEM UNDER PRESSURE. TO AVOID FUEL

SPILLAGE, REFER TO FIELD SERVICE PROCEDURES FOR

TESTING OR MAKING REPAIRS

REQUlRlNG DISASSEMBLY OF

FUEL

LINES OR FITTINGS.

IGN. "ON" -IF "SES" LIGHT IS "OFF", SEE CHART A-I. r INSTALL "SCAN" TOOL - IF "NO ALDL", SEE CHART A-2. r CHECK THE FOLLOWING: r TPS - IF OVER 2.5V AT CLOSED THROTTLE, SEE CODE 21.

NOTICE

: 80 MOT

OR EQUIVALENT TO INJECTOR, TERMINALS R TERMINALS. TO SHORT OR TOUCH ILE CRANKING. TOGETHER WHILE

CRANKING OR ECM

MAY BE

DAMAGED.

SHOULD BE GREATER THAN 8

DIAGNOSTIC

&-,-m.---&?-a

TROUBLE FOUND. REVIEW

" CLEAR CODES AND CONFIRM "CLOSED LOOP " OPERATION AND NO "SERVICE ENGINE SOON " LIGHT.

Page 669 of 1825

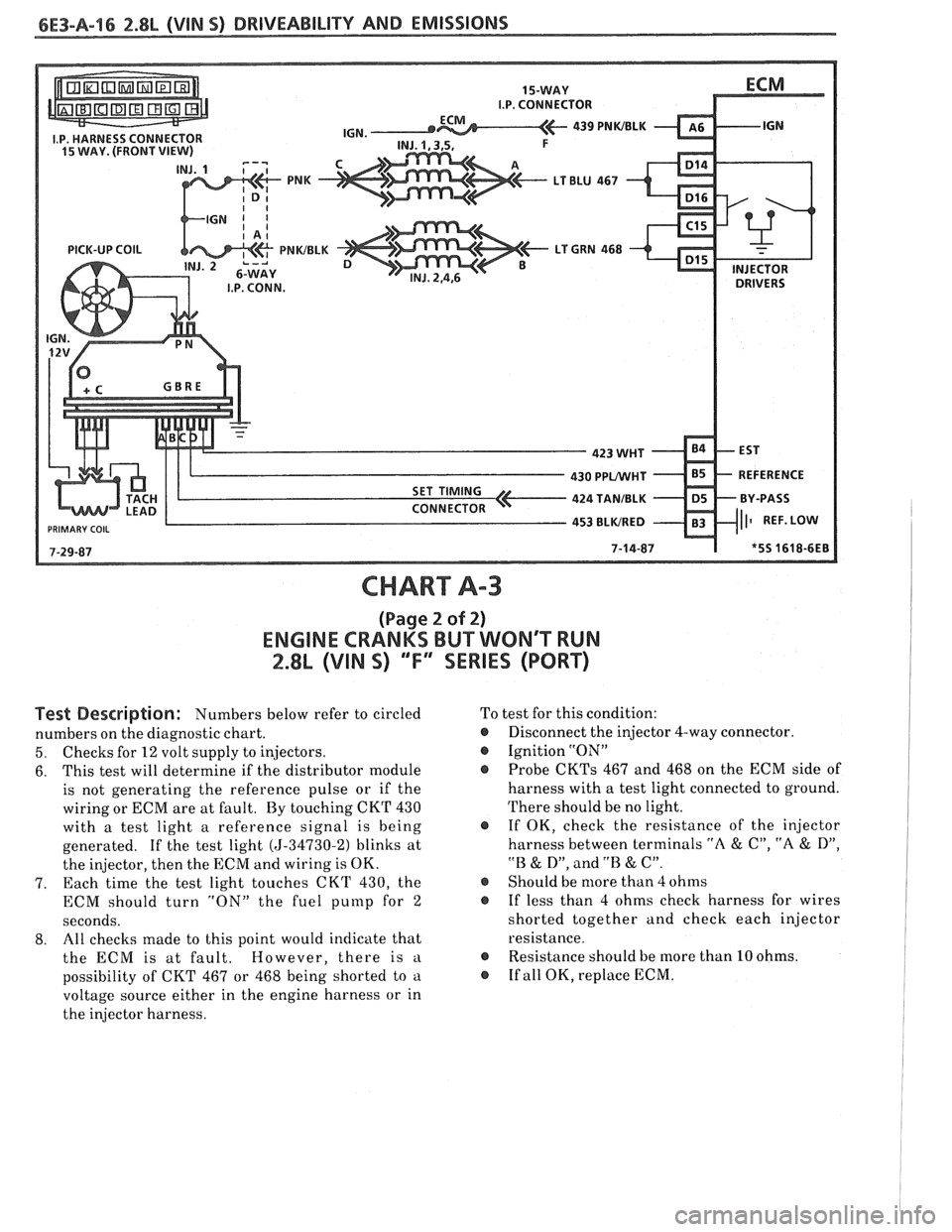

CHART A-3

(Page 2 of 2)

ENGINE CRANKS BUT WONT WN

2.8L (VIN S) ""FYSERIES (PORT)

Test Description: Numbers below refer to circled

numbers on the diagnostic chart.

5. Checks for 12 volt supply to injectors.

6. This

test will determine if the distributor module

is not generating the reference pulse or if the

wiring or ECM are at fault. By touching CKT 430

with a test light a reference signal is being

generated. If the test light

(5-34730-2) blinks at

the injector, then the ECM and wiring is OK.

7. Each time

the test light touches CKT 430, the

ECM should turn "ON" the fuel

punlp for 2

seconds.

8. All

checks made to this point would indicate that

the ECM is at fault. However, there is

a

possibility of CKT 467 or 468 being shorted to a

voltage source either in the engine harness or in

the injector harness. To

test for this condition:

@ Disconnect the injector 4-way connector.

@ Ignition "ON"

Probe

CKTs 467 and 468 on the ECM side of

harness with a test light connected to ground.

There should be no light.

@ If OK, check the resistance of the injector

harness between terminals

"A & C", "A & D",

"B & D", and .'B & C".

@ Should be more than 4 ohms

@ If less than 4 ohms check harness for wires

shorted together and check each injector

resistance.

@ Resistance should be more than 10 ohms.

@ If all OK, replace ECM.

Page 670 of 1825

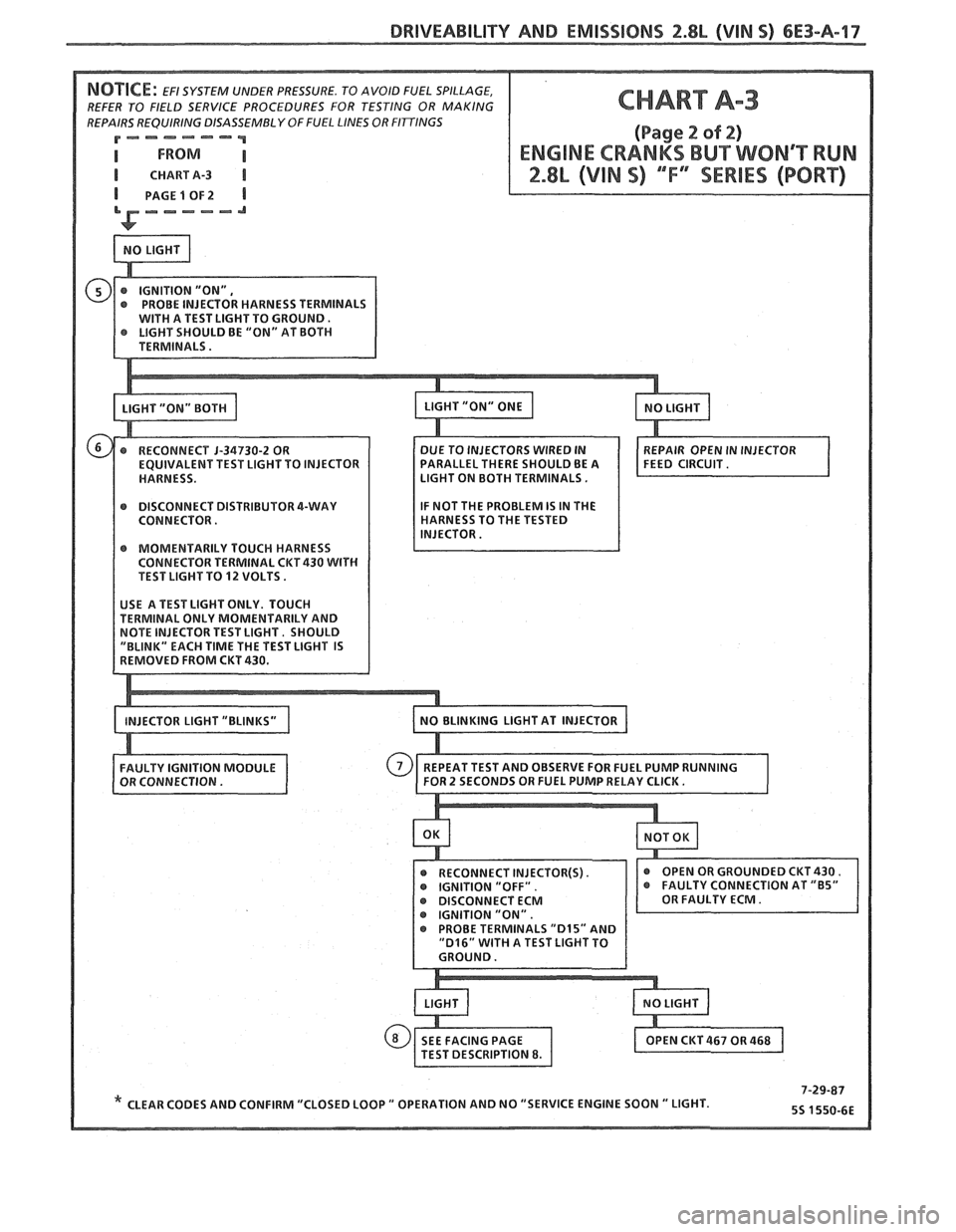

DRIVEABILITY AND EMISSIONS 2.8L (VIM 5) 6E3-A-17

REFER TO FIELD SERVICE PROCEDURES FOR TESTING OR MAKING

REPAIRS REQUIRING DISASSEMBLY

OFFUEL LINES OR FInlNGS

P=---=-'-"""

I CHARTA-3 I

PAGE 1 OF2

ARALLEL THERE SHOULD BE A IGHT ON BOTH TERMINALS.

r DISCONNECT DISTRIBUTOR 4-WAY

CONNECTOR.

r MOMENTARILY TOUCH HARNESS

CONNECTOR TERMINAL CKT 430 WITH TEST LIGHT TO 12 VOLTS.

* CLEAR CODES AND CONFIRM "CLOSED LOOP " OPERATION AND NO "SERVICE ENGINE SOON " LIGHT.