PONTIAC FIERO 1988 Service Repair Manual

Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 711 of 1825

6E3-B-2 2.8L (VIN 5) DRIVEABILITY AND EMISSIONS

Problem may or may not turn "ON" the "Service Engine SoonJ' light, or store a code.

DO NOT use the trouble code charts in Section

"A" for intermittent problems. The fault must be

present to locate the problem. If a fault is

intermittent, use of trouble code charts may result

in replacement of good parts.

@ Most intermittent problems are caused by

faulty electrical connections or wiring. Perform

careful check as described at start of Section

"B". Check for:

@ Poor mating of the connector halves, or

terminals not fully seated in the connector

body (backed out).

@ Improperly formed or damaged terminals.

All connector terminals in problem circuit

should be carefully reformed to increase

contact tension.

@ Poor terminal to wire connection. This

requires removing the terminal from the

connector body to check. See "Introduction"

to Section

"6E".

@ If a visual check does not find the cause of the

problem, the car can be driven with a voltmeter

connected to a suspected circuit. A "Scan" tool

can also be used for monitoring input signals to

the ECM to help detect intermittent conditions.

An abnormal voltage, or "Scan" reading, when

the problem occurs, indicates the problem may

be in that circuit. If the wiring and connectors

check OK and a trouble code was stored for a

circuit having a sensor, except for Codes

43, 44,

and 45, substitute a known good sensor and

recheck. An

intermittent "Service Engine Soon" light

with no stored code may be caused by:

@ Ignition coil shorted to ground and arcing at

spark plug wires or plugs.

@ "Service Engine Soon" light wire to ECM

shorted to ground. (CKT 419).

@ Diagnostic "Test" terminal wire to ECM,

shorted to

ground.(CKT 451)

@ ECM power grounds. See ECM wiring

diagrams.

@ Loss of trouble code memory. To check,

disconnect TPS and idle engine until "Service

Engine Soon" light comes "ON". Code

22 should

be stored, and kept in memory when ignition is

turned "OFF". If not, the ECM is faulty.

@ Check for an electrical system interference

caused by a defective relay, ECM driven

solenoid, or switch. They can cause

a sharp

electrical surge. Normally, the problem will

occur when the faulty component is operated.

@ Check for improper installation of electrical

options, such as lights, 2-way radios, etc.

@ EST wires should be kept away from spark plug

wires, distributor wires, distributor housing,

coil, and generator. Wire from ECM to

distributor (CKT

453) should be a good

connection.

@ Check for open diode across A/C compressor

clutch, and for other open diodes (see wiring

diagrams).

HARD START

Definition: Engine cranks OK, but does not start for a long

time. Does eventually run, or may start hut immediately dies.

@ Perform careful check as described at start of -

Section "B".

@ Make sure driver is using correct starting

procedure.

@ CHECK:

- TPS for sticking or binding or a high TPS

voltage with the throttle closed (should read

less than

,700 volts).

- High resistance in coolant sensor circuit or

sensor itself. See Code 15 chart or with

a.

"Scan" tool compare coolant temperature with

ambient temperature on

a cold engine. 8

- Fuel pressure CHART A-7. Water contaminated

fuel.

EGR operation. Be sure valve seats properly and

is not staying open. See CHART C-7.

Both injector fuses (visually inspect).

Ignition system

- Check distributor for:

Proper output with ST-125.

Worn shaft.

Bare and shorted wires.

Pickup coil resistance and connections.

Loose ignition coil ground.

Moisture in distributor cap.

If problem exists in cold weather, check cold start

valve. See CHART A-9.

Page 712 of 1825

DRIVEABILITY AND EMISSIONS 2.8L (VIN S) 6E3-B-3

e A faulty in-tank fuel pump check valve will @ If engine starts but then immediately stalls,

allow the fuel in the lines to drain back to the open

distributor by-pass line. If engine then

tank after the engine is stopped. To check for starts

and runs OK, replace pickup coil.

this condition:

@ If engine starts and stalls, disconnect MAF

Perform Fuel System Diagnosis, CHART A-7. sensor. If engine then runs and sensor

@ Remove spark plugs. Check for wet plugs, connections are OK, replace the sensor.

cracks, wear, improper gap, burned

f lectrodes,

or heavy deposits. Repair or replace as

necessary.

HESITATION, SAG, STUMBLE

Definition: Momentary lack of response as the accelerator is pushed down. Can

occur at all car speeds.

Usually most severe when first trying to make the car move, as

from a stop sign. May cause the engine to stall if severe enough.

Perform careful visual check as described at

start of Section

"B".

a CHECK:

- Fuel pressure. See CHART A-7. Also check for

water contaminated fuel.

- Air leaks at air duct between MAF sensor and

throttle body.

- Spark plugs for being fouled or faulty wiring.

- PROM (2.8L) or MEM-CAL (5.OL & 5.7L)

number. Also check service bulletins for latest

MEM-CAL or PROM.

- TPS for binding or sticking. Voltage should

increase at a steady rate as throttle is moved

toward WOT.

- Ignition timing. See Emission Control

Information label.

- Generator output voltage. Repair if less than 9

or more than 16 volts.

- HE1 ground, CKT 453.

- Canister purge system for proper operation.

See CHART C-3.

- EGR - See CHART C-7.

@ Perform injector balance test CHART C-2A.

SURGES AND/OR CHUGGLE

Definition: Engine power variation under steady

throttle or cruise. Feels like the car speeds up and

slows down with no change in the accelerator pedal.

Be sure driver understands transmission

converter clutch and

A/C compressor operation

in Owner's Manual.

e Perform careful visual inspection as described

at start of Section

"B".

CHECK:

- TCC and 4th gear switch operation - See

CHART C-8A.

- Loose or leaking air duct between MAF sensor

and throttle body.

- Generator output voltage. Repair if less than 9

or more than 16 volts.

- EGR - There should be no EGR at idle. See

CHART C-7. Also check for plugged EGR

solenoid filter.

- Vacuum lines for kinks or leaks.

- Ignition timing. See Emission Control

Information label.

- In-line fuel filter. Replace ifdirty or plugged.

- Fuel pressure while condition exists. See

CHART A-7.

@ Inspect oxygen sensor for silicone contamination

from fuel, or use of improper RTV sealant. The

sensor may have a white, powdery coating and

result in a high but false signal voltage (rich

exhaust indication). The ECM will then reduce

the amount of fuel delivered to the engine,

causing a severe driveability problem.

@ Remove spark plugs. Check for cracks, wear,

improper gap, burned electrodes, or heavy

deposits. Also check condition of distributor cap,

rotor, and spark plug wires.

@ To help determine if the condition is caused by a

rich or lean system, the car should be driven at

the speed of the complaint. Monitoring block

learn at the complaint speed will help identify the

cause of the problem. If the system is runnig lean

(block learn greater than

138), refer to

"Diagnostic Aids" on

facing page of Code 44. If

the system is running rich (block learn less than

118), refer to "Diagnostic Aids" on facing page of

Code 45.

Page 713 of 1825

&E3-B-4 %.8L (VIN S) DRIVEABILITY AND EMISSIONS

LACK OF POWER, SLUGGISH, OR SPONGY

Definition: Engine delivers less than expected power. Little or

no increase in speed when accelerator pedal is pushed down part way.

Perform careful visual check as described at

- EGR operation for being open or partly open all

start of Section

"B". the time - CHART C-7.

e Compare customer's car to similar unit. - Exhaust system for possible restriction: See

Make sure the customer's car has an actual CHART

B-1,

problem.

@ Remove air cleaner and check air filter for

dirt, or for being plugged. Replace as

necessary.

@ CHECK:

- For loose or leaking air duct between MAF

Sensor and throttle body.

- Ignition timing. See Emission Control

Information label.

- Restricted fuel filter, contaminated fuel or

improper fuel pressure. See CHART A-7.

- ECM ground circuits - See ECM wiring

diagrams.

- Inspect exhaust system for damaged or

collapsed pipes.

- Inspect muffler for heat distress or possible

internal failure.

- Generator output voltage. Repair if less than 9

or more than 16 volts.

- Engine valve timing and compression.

- Engine for proper or worn camshaft. See

Section

"6A".

- Secondary voltage using a shop ocilliscope or a

spark tester

5-26792 (ST-125) or equivalent.

DETONATION ISPARK KNOCK

Definition: A mild to severe ping, usually worse under

acceleration. The engine makes sharp metallic knocks that

change with throttle opening. Sounds like popcorn popping.

@ Check for obvious overheating problems:

- Low coolant.

- Loose water pump belt.

- Restricted air flow to radiator, or restricted

water flow thru radiator.

- Inoperative electric cooling fan circuit. See

CHART C-12.

@ CHECK:

- Ignition timing. See Vehicle Emission

Control Information label.

- EGR system for not opening - CHART C-7.

- TCC operation - CHART C-8.

- Fuel system pressure. See CHART A-7.

- PROM or MEM-CAL - Be sure it's the correct

one. (See Service Bulletins)

- Valve oil seals for leaking.

@ Check for incorrect basic engine parts such as

cam, heads, pistons, etc.

@ Check for poor fuel quality.

@ Remove carbon with top engine cleaner. Follow

instructions on can.

@ Check ESC system (5.OL & 5.7L)

See CHART C-5

o To help determine if the condition is caused by a

rich or lean system, the car should be driven at

the speed of the complaint.

Monitoring block

learn at the complaint speed will help identify the

cause of the problem.

If the system is runnig lean

(block learn greater than

1381, refer to

"Diagnostic Aids" on facing page of Code 44.

If

the system is running rich (block learn less than

l18), refer to "Diagnostic Aids" on facing page of

Code 45.

Page 714 of 1825

DWI\/EABILITV AND EMISSIONS 2.8L (VIN 5) 6E3-B-5

CU"T SUP, MISSES

Definition: Steady pulsation or jerking that follows engine

speed, usually more pronounced as engine load increases. The

exhaust has a steady spitting sound at idle or low speed.

@ Perform careful visual check as described at

start of Section

"B".

@ Check for missing cylinder by:

1. Disconnect IAC valve. Start engine.

Remove one spark plug wire at a time

using insulated pliers.

2. If there is an rpm drop on all cylinders

(equal to within

50 rpm), go to "ROUGH,

UNSTABLE, OR INCORRECT IDLE,

STALLING" symptom. Reconnect IAC

valve.

3. If

there is no rprn drop on one or more

cylinders, or excessive variation in drop,

check for spark on the suspected

cylinder(s) with J 26792 (ST-125) Spark

Gap Tool or equivalent.

If no spark, see

Section

"6D" for intermittent operation or

miss. If there is spark, remove spark

plug(s) in these cylinders and check for:

- Cracks

- Wear

- Improper gap

- Burned electrodes

- Iieavy deposits

@ Perform compression check on questionable

cylinder(s) found above. If compression is low,

repair as necessary. See Section

"6".

@ Disconnect all injector harness connectors.

Connect

5-34730-2 injector test light or

equivalent 6 volt test light between the

harness terms, of each injector connector and

note light while cranking. If test light fails to blink

at any connector, it is a faulty injector drive

circuit harness, connector, or terminal.

@ Perform the injector balance test. See CHART C-

2A.

s CHECK:

- Spark plug wires by connecting ohmmeter to

ends of each wire in question. If meter reads over

30,000 ohms, replace wire(s1.

- Fuel System - Plugged fuel filter, water, low

pressure. See

CHART A-7.

- Valve timing.

- Secondary voltage using a shop ocilliscope or a

spark tester 5-26792 (ST-125) or equivalent.

@ Visually inspect distributor cap and rotor for

moisture, dust, cracks, burns, etc. Spray cap and

plug wires with, fine water mist to check for

shorts.

@ A miss condition can be caused by EM1

(Electromagnetic Interference) on the reference

circuit.

EM1 can usually be detected by

monitoring engine rpm with a "Scan" tool. A

sudden increase in rpm with little change in

actual engine rpm change, indicates

EM1 is

present. If the problem exists, check routing of secondary

wires, check all distributor ground circuits.

@ Remove rocker covers. Check for bent pushrods,

worn rocker arms, broken valve springs, worn

camshaft lobes. Repair as necessary. See Section

"6A".

BACKFIRE

Definition: Fuel ignites in intake manifold, or

in exhaust system, making a loud popping noise.

CHECK:

- Loose wiring connector or air duct at MAF

sensor.

- Compression - Look for sticking or leaking

valves.

- EGR operation for being open all the time. See

CHART C-7.

- EGR gasket for faulty or loose fit .

- Valve timing.

- Output voltage of ignition coil using a shop

ocilliscope or spark tester 5-26792 (ST-125) or

equivalent.

- Spark plugs for crossfire also inspect (distributor

cap, spark plug wires, and proper routing of plug

wires).

- Ignition system for intermittent condition. (See

Section

"6D").

- Engine timing - see Emission Control

Information label.

- Perform fuel system diagnosis check, CIIART A-

7A.

- Perform injector balance test, CHART C-2A.

- Deceleration valve (2.8L ~nanualltrans) - See

Section

"C6".

- A.I.R. system check valves - See Section "C-6".

Page 715 of 1825

6E3-B-6 2.8L (VIN 5) DRIVEABILITY AND EMISSIONS

POOR FUEL ECONOMY

Definition: Fuel economy, as measured by an actual road test, is

noticeably lower than expected. Also, economy is noticeably lower than

it was on this car at one time, as previously shown by an actual road test.

@ Perform careful visual check as described at

start of Section "B".

8 CHECK:

- Coolant level.

- Engine thermostat for faulty part (always

open) or for wrong heat range. See Section

"6B".

- Compression

- Ignition timing. See Emission Control

Information label.

- TCC for proper operation. A "ScanJ' should

indicate an rpm drop when the TCC is

commanded "ON". See CHART C-8.

- Induction system and crankcase for air leaks.

8 Check for exhaust restriction.

See CHART

B-1.

DIESELING, RUN-ON

Definition: Engine continues to run after key is

turned "OFF", but runs very roughly. If engine runs

smoothly, check ignition switch and adjustment.

8 Check injectors for leaking. See CHART A-7.

ROUGH, UNSTABLE, OR INCORRECT IDLE, STALLING

Definition: The engine runs unevenly at idle. If bad enough, the car may

shake. Also, the idle may vary in rpm (called "hunting"). Either

condition

may be bad enough to cause stalling. Engine idles at incorrect speed.

@ Perform careful visual check as described at

start of Section "B".

@ CHECK:

- Throttle linkage for sticking or binding. Also

check TPS adjustment. Refer to Section

"C2".

- Ignition timing. See Emission Control

Information label.

- ECM ground circuits.

- IAC system. See CHART C-2C.

- Generator output voltage. Repair if less than 9

or more than 16 volts.

- PIN switch circuit. See CHART C-lA, or use

"SCAN" tool.

- Injector balance. See CHART C-'LA.

- PCV valve for proper operation by placing

finger over inlet hole in valve end several times.

Valve should snap back. If not, replace valve.

- Evaporative Emission Control System. CHART

C-3.

- A/C signal to ECM terminal "B8" (5.OL & 5.7L).

"Scan" tool should indicate AIC is being

requested when ever

A/C is selected and the

pressure cycling switch is closed.

- A/C system operation (2.8L) - See CHAR'l' (2-10.

- Minimum idle speed. See Section "C2".

- Loose or damaged MAF sensor duct between

sensor and throttle body.

- Power Steering Pressure Switch (2.81, - See

CHART

C-1E.

Check AIR system. There should be no AIR to

ports while in "Closed Loop". See CHART C-6.

EGR valve: There should be no EGR at idle.

Run a cylinder compression check. See Section

"6". Inspect oxygen sensor for silicon contamination

from fuel, or use of improper RTV sealant. The

sensor will have a white, powdery coating, and

will result in a high but false signal voltage (rich

exhaust indication). The ECM will then reduce

the

amount of fuel delivered to the engine,

causing a severe driveability problem.

Check for fuel in pressure regulator hose. If

present replace regulator assembly.

Check ignition system; wires, plugs, rotor, etc.

Check for loose or damaged air duct between

MAF sensor and throttle body.

Ilisconnect MAF sensor and if condition is

corrected replace sensor.

Clean injectors.

Monitoring block learn will help identify the

cause of the problem. If the system is runnig lean

(block learn greater than

138), refer to

"Diagnostic Aids" on facing page of Code

44. If

the system is running rich (block learn less than

118), refer to "Diagnostic Aids'' on facing page of

Code 45.

Page 716 of 1825

DRIVEABILITY AND EMISSIONS 2.8L (VIN S) 6E3-B-7

EXCESSIVE EXHAUST EMISSIONS 08 ODORS

Definition: Vehicle fails an emission test. Vehicle has excessive "rotten egg" smell.

Excessive odors do not necessarily indicate excessive emissions.

r Perform "Diagnostic Circuit Check."

e IF TEST SHOWS EXCESSIVE CO AND HC,

(or also has excessive odors):

@ Check items which cause car to run RICH.

@ Make sure engine is at normal

operating temperature.

@ CHECK:

- Fuel pressure. See CHART A-7.

- Incorrect timing. See vehicle emission

control information label.

- Canister for fuel loading. See CHART C-3.

- Injector balance. See CHART C-2A.

- PCV valve for being plugged, stuck, or

blocked PCV hose, or fuel in the crankcase.

- Spark plugs, plug wires, and ignition

components. See Section

"6D".

- Check for lead contamination of catalytic

converter (look for removal of fuel filler

neck restrictor).

- Check for properly installed fuel cap.

@ If the system is running rich, (block learn

less than

118), refer to "Diagnostic Aids" on

facing page of Code

45.

e IF TEST SHOWS EXCESSIVE NOx:

e Check items which cause car to run LEAN,

or to run too hot.

- EGR valve for not opening. See CHART

C-7.

- Vacuum leaks. - Coolant system and coolant fan for

proper operation. See CHART C-12.

- Remove carbon with top engine cleaner.

Follow instructions on can.

- Check ignition timing for excessive base

advance. See emission control

information label.

@ If the system is running lean, (block learn

greater than

138), refer to "Diagnostic Aids" on

facing page of Code

44.

Page 717 of 1825

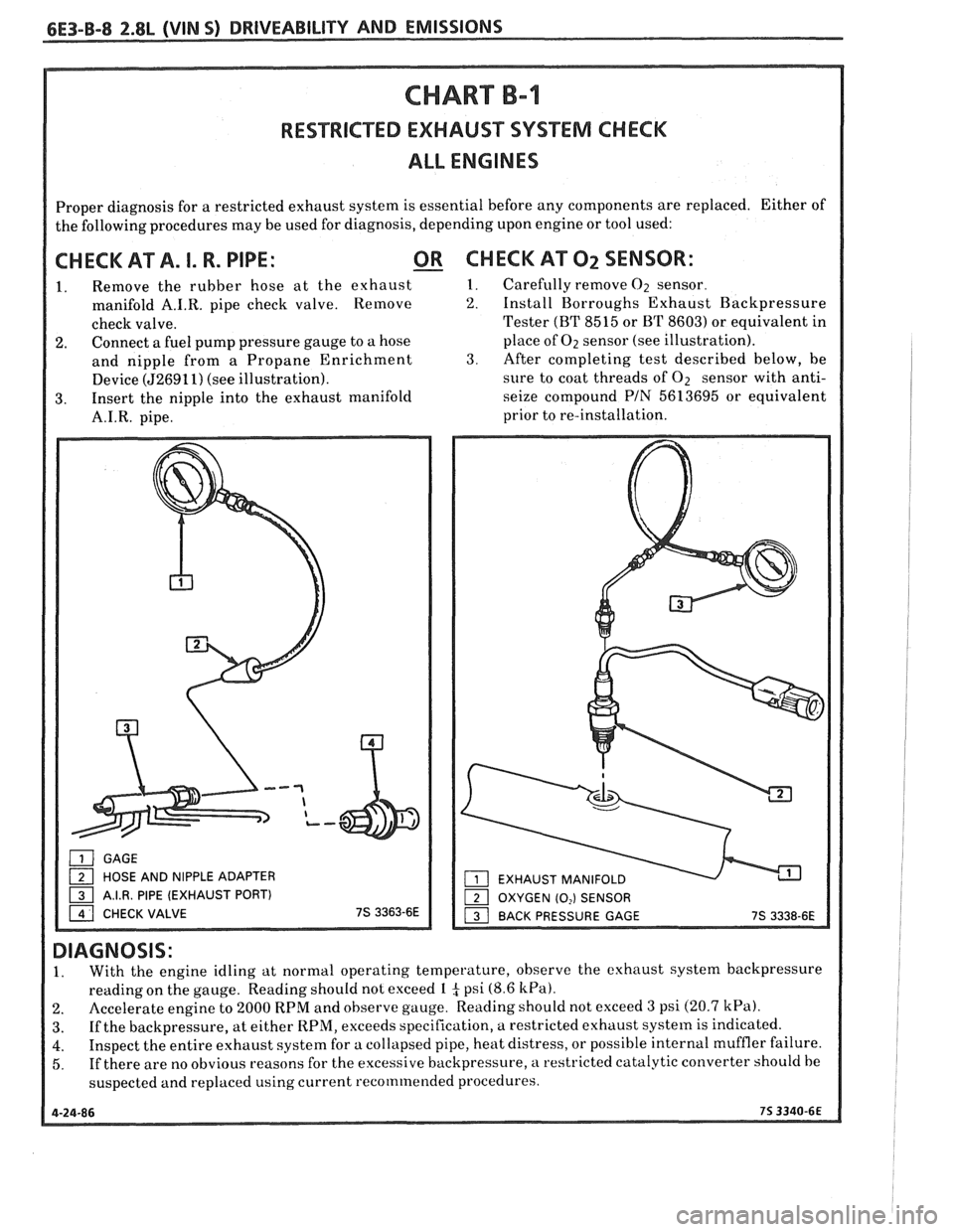

CHART B-l

RESTRICTED EXHAUST SYSEEM CHECK

ALL ENGINES

Proper diagnosis for a restricted exhaust system is essential before any components are replaced. Either of

the following procedures may be used for diagnosis, depending upon engine or tool used:

CHECK AT A. I. R. PIPE: - OR

1. Remove the rubber hose at the exhaust

manifold A.I.R. pipe check valve. Remove

check valve.

2. Connect a fuel pump pressure gauge to a hose

and nipple from a Propane Enrichment

Device (526911) (see illustration).

3. Insert the nipple into the exhaust manifold

A.I.R. pipe.

GAGE

1 HOSE AND NIPPLE ADAPTER

1 3,I.R. PIPE (EXHAUST PORT)

1 CHECK VALVE 7s 3363-6E

CHECK AT 02 SENSOR:

1. Carefully remove 02 sensor.

2. Install Borroughs Exhaust Backpressure

Tester (BT 8515 or BT 8603) or equivalent in

place of

02 sensor (see illustration).

3. After

completing test described below, be

sure to coat threads of

02 sensor with anti-

seize compound PIN 5613695 or equivalent

prior to re-installation.

DIAGNOSIS:

1. With the engine idling at normal operating temperature, observe the exhaust system backpressure

reading on the gauge. Reading should not exceed

I $ psi (8.6 kPa).

2. Accelerate engine to 2000 RPM and observe gauge. Reading should not exceed 3 psi (20.7 kPa).

3. If the backpressure, at either RPM, exceeds specification, a restricted exhaust system is indicated.

4. Inspect the entire exhaust system for a collapsed pipe, heat distress, or possible internal muffler failure.

5. If

there are no obvious reasons for the excessive backpressure,

a restricted catalytic converter should be

suspected and replaced using current

recom~nended procedures.

Page 718 of 1825

BLANK

Page 719 of 1825

6E3-C-1 2.8L (VIN S) DRIVEABILITY AND EMISSIONS

COMPONENT SYSTEMS

Section C provides information on the following:

@ General description of components and systems .

e On-vehicle service .

@ Part names and group numbers .

@ Diagnostic charts . These include a functional check of the system as well as diagnosis of any problem

found in the functional check

.

For locations of components. wiring diagrams and ECM Terminal End View refer to the front of the A Sections of

the engine being diagnosed

.

Following are the sub-section identification and the system covered:

Electronic Control Module (ECM) and Sensors

........................... Page C1-I

Fuel Control System ............................................... Page C2-1

Evaporative Emission Control (EECS) System ............................ Page C3-1

Ignition SystemIEST ............................................... Page C4-1

Air Injection Reaction (A.I.R.) System Manual Transmission Only .............. Page C6-1

Exhaust Gas Recirculation (EGR) System ................................ Page C7-1

Transmission Converter Clutch (TCC) System and Manual Transmission Shift Light Page C8-1

ECM Controlled Air Conditioning .................................... Page C10-I

Cooling Fan Control ............................................... Page C12-1

Positive Crankcase Ventilation (PCV) .................................. Page C13-1

DIAGNOSTIC CHARTS

The Diagnostic Charts for each system are found after the on-car service and parts information at the back of

each section

. Following are the charts found in this section .

@ Chart C-I

@ Chart C-1A

e ChartC-1E

@ Chart C-2A

e Chart C-2C

@ Chart C-3

@ Chart C-4A

@ Chart C-6

@ Chart C-7

@ Chart C-8

@ Chart C-8

@ Chart C-10

@ Chart C-12

@ Chart C-12 ECM

QDR Check ........................................... Page C1-10

Park

Neutral Switch ........................................ Page C1-12

Power Steering Pressure Switch Check .......................... Page C1-14

Injector Balance Test ....................................... Page C2-18

Idle Air Control ........................................... Page C2-20

Canister Purge Valve Check .................................. Page C3-4

Ignition System Check ...................................... Page C4-4

Electric Control (Divert) . (Manual Transmission) .................. Page C6-6

Exhaust Gas Recirculation Check .............................. Page C7-6

Automatic Transmission Converter Clutch (TCC) . 1 of 2 ............. Page C8-2

Automatic Transmission Converter Clutch (TCC) . 2 of 2 ............. Page C8-4

NC Clutch Control ......................................... Page C10-2

. ............. ............... Cooling Fan Control Circuit 1 of 2 Page C12-2

. ............................. Cooling Fan Control Circuit 2 of 2 Page C12-4

Page 720 of 1825

DRIVEABILITY AND EMISSIONS 2.8L WIN S) 6E3-C1-1

SECTION C1

ELECTRONIC CONTROL MODULE (ECM) AND SENSORS

CONTENTS

GENERAL DESCRIPTION ................ C1-1 MAF Sensor ..................... C1-5

ELECTRONIC CONTROL MODULE (ECM) , . C1-1 MAT Sensor ..................... C1-5

ECMTYPES.. ...................... C1-I O2 Sensor ....................... C1-5

PROM ........................... C1-1 TPS............................ C1-5

CALPAK .......................... C1-2 VSS ........................... C1-5

ECM Function..

.................. C1-2 PIN Switch ...................... C1-5

INFORMATION SENSORS ............. C1-2 A/C Request Signal ................ C1-5

........ Engine Coolant Temp. Sensor C1-2 Power Steering Pressure Switch ...... C1-5

Mass Air Flow (MAF) Sensor ......... C1-2 Reference Signal ................. C1-5

A/C MAF Sensor .................. C1-2 ON-CAR SERVICE ..................... C1-5

..... Manifold Air Temp. (MAT) Sensor C1-2 ELECTRONIC CONTROL MODULE (ECM) . . C1-5

Oxygen (Oz) Sensor ............... C1-3 ECM & COMPONENTS REPLACEMENT

........ Throttle Position Sensor (TPS) C1-3 PROMORECM ..................... C1-6

Vehicle Speed Sensor

.............. C1-3 Functional Check ................. C1-7

...... ParkINeutral Switch (Auto Only) C1-4 CALPAK.......................... C1-7

AIC "ON" Signal .................. C1-4 COOLANTSENSOR .................. C1-7

Distributor Reference Signal

......... C1-4 MAFSENSOR ...................... C1-7

DIAGNOSIS ......................... C1-4 MAF SENSOR POWER & BURN-OFF RELAY. C1-7

ECM .......e.........e........... C1-4 OXYGENSENSOR ................... C1-8

PROM ........................... C1-4 Throttle Position Sensor ............ C1-8

ECM Inputs..

.................... C1-5 PARKJNEUTRALSWITCH .............. C1-9

Coolant Temp. Sensor ............. C1-5 PARTS INFORMATION ................. C1-9

GENERAL DESCRIPTION

ELECTRONIC CONTROL MODULE (ECM)

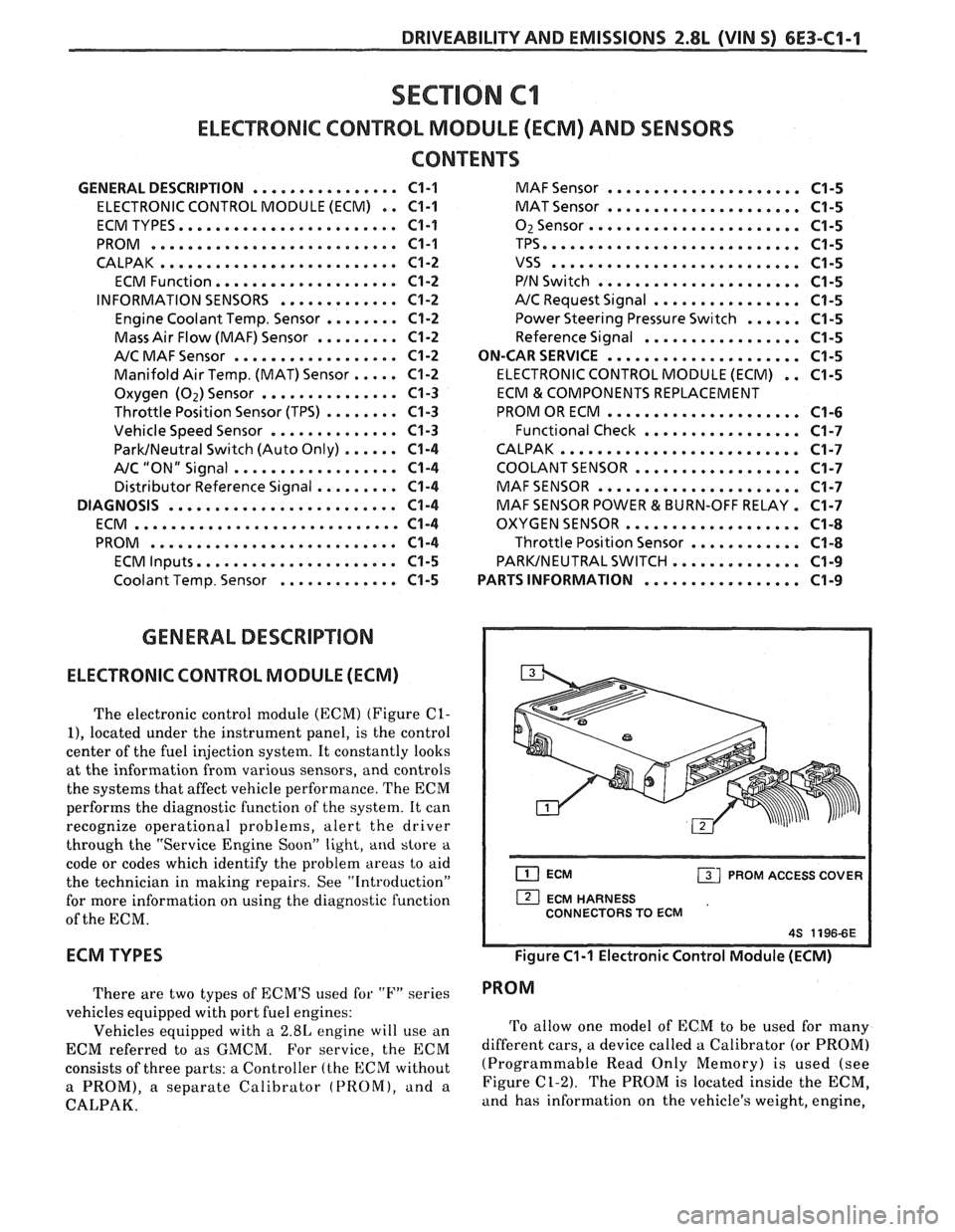

The electronic control module (ECM) (Figure C1-

I), located under the instrument panel, is the control

center of the fuel injection system. It constantly looks

at the information from various sensors, and controls

the systems that affect vehicle performance. The ECM

performs the diagnostic function of the system. It can

recognize operational problems, alert the driver

through the "Service Engine Soon"

light, and store a

code or codes which identify the problem areas to aid

the technician in making repairs. See "Introduction"

for more information on using the diagnostic function

of the ECM.

ECM TYPES

There are two types of ECM'S used for "I?" series

vehicles equipped with port fuel engines:

Vehicles equipped with a

2.8L engine will use an

ECM referred to as GMCM. For

service, the ECM

consists of three parts: a Controller (the ECM without

a PROM), a separate Calibrator (PROM), and a

CALPAK.

ECM PROM ACCESS COVER I

1 ECM HARNESS

CONNECTORS TO ECM

Figure C1-1 Electronic Control Module (ECM)

PROM

To allow one model of ECM to be used for many

different cars, a device called a Calibrator (or PROM)

(Programmable Read Only Memory) is used (see

Figure

C1-2). The PROM is located inside the ECM,

and has information on the vehicle's weight, engine,