PORSCHE CAYMAN 2006 1.G Owners Manual

Manufacturer: PORSCHE, Model Year: 2006, Model line: CAYMAN, Model: PORSCHE CAYMAN 2006 1.GPages: 280, PDF Size: 4.89 MB

Page 221 of 280

Practical Tips, Emergency Service

221

Loading InformationDefinitionsThe Curb weight - actual weight of your vehicle -

vehicle weight including standard and optional

equipment, fluids and emergency tools. This

weight does not include passengers and cargo.

The Gross Vehicle Weight is sum of the curb

weight and the weight of passengers and cargo

combined.

The Gross Vehicle Weight Rating is the maxi-

mum total weight of vehicle, passengers, luggage

and optional equipment.

The Gross Axle Weight Rating is the maximum

load limit for the front or the rear axle. This infor-

mation is located on the safety compliance sticker

located in the driver’s side door jamb.

For determining the compatibility of the tire and

vehicle load capabilities:

fPlease observe the chapter “TIRES, RIMS,

TRACKS” on Page 268.

The load capacity coefficient (e.g. “101”) is a min-

imum requirement.The Gross Combined Weight Rating is the

maximum total weight rating of vehicle, passen-

gers and cargo.

The Vehicle Capacity Weight - Load Limit - is

the maximum total weight limit specified of the

load (passengers and cargo) for the vehicle. This

is the maximum weight of passengers and cargo

that can be loaded into the vehicle. This informa-

tion can be found on the tire pressure plate.

The maximum loaded vehicle weight is the

sum of curb weight, accessory weight, vehicle ca-

pacity weight and production options weight.

The load rating is the maximum load that a tire

is rated to carry for a given inflation pressure.

The maximum load rating is the load rating for

a tire at the maximum permissible inflation pres-

sure.

The cargo capacity is the permissible weight of

cargo, the subtracted weight of passengers from

the load limit.

fNever exceed the permissible limits.

Danger!

Risk of personal injury, loss of control and

damage to vehicle.

fNever exceed the specified axle loads. Over-

loading can shorten the service life of the tires

and car, as well as lead to dangerous vehicle

reactions and long braking distances. Damage

due to overloading is not covered by the vehi-cle warranty.

Page 222 of 280

222

Practical Tips, Emergency Service

Example for determining the combined weight of occu-

pants and cargoVehicle Load CapacityfThe combined weight of occupants and cargo

should never exceed the weight shown on the

tire plate in the vehicle.

Please observe the chapter “VEHICLE IDENTI-

FICATION NUMBER” on Page 264.

fNever exceed the number of passengers

shown on the tire pressure plate in the vehicle.Determining the combined weight of

occupants and cargo:

fAdd the weight of all occupants and then add

the total luggage weight (figure).

Steps for determining correct load limit

1. Locate the statement "The combined weight of

occupants and cargo should never exceed XXX

pounds" on your vehicle’s placard (depending

on the date of manufacture).

2. Determine the combined weight of the driver

and passenger that will be riding in your vehi-

cle.3. Subtract the combined weight of the driver and

passenger from XXX kilograms or XXX pounds.

4. The resulting figure equals the available

amount of cargo and luggage load capacity.

For example, if the "XXX" amount equals 400

lbs. and there will be two - 150 lb passengers

in your vehicle, the amount of available cargo

and luggage load capacity is 100 lbs. (400 -

300 (2 x 150) = 100 lbs.).

5. Determine the combined weight of luggage

and cargo being loaded on the vehicle. That

weight may not safely exceed the available car-

go and luggage load capacity calculated in

Step 4.

Page 223 of 280

Practical Tips, Emergency Service

223

Front jacking pointLifting the Vehicle with a Lifting

Platform or Garage Lift The car must be raised only at the illustrated jack-

ing points.

Rear jacking point

Caution!

Serious injury and/or serious damage to the

engine or the vehicle may occur, if you lift

the vehicle improperly.

fNever lift the vehicle at any other place than

the jacking points.

fNever lift the vehicle by the engine, transmis-

sion or axles.

fDo not damage any sensitive components in the vicinity of the jacking points.

Platform lift Before the car is driven on to a lifting platform, it

must be ensured that there is enough space be-

tween the lifting platform and the vehicle. Garage lift A garage lift must be used only at the illustrated

jacking points.

Page 224 of 280

224

Practical Tips, Emergency Service

Flat Tire

Warning!

Failure to follow these instructions may result

in serious personal injuries to you or to by-

standers.

fIf you have a flat tire, move a safe distance off

the road. Turn the emergency flasher on and

use other warning devices to alert other

motorists. Set the parking brake.

fDo not park your vehicle where it may contact

dry grass, brush or other flammable materials.

The hot parts of the exhaust system could set

such materials on fire, thereby causing both

property damage and severe or fatal physical injury.

A tire sealant and compressor with pressure

tester are located in the toolbox in the luggage

compartment.

fPlease observe the safety and operating in-

structions on the special sealant bottle with a

special Porsche part number and on the com-

pressor – these are essential.Important note

Sealing the tire with the tire repair kit is only

an emergency repair. Even with the tire air-

tight, it may be used only for short trips in an

emergency.

The maximum permitted speed is 50 mph

(80 km/h).

fDo not use commercially available sealant or

tire inflating bottles.

Use only the tire sealant located in the tool box

in the luggage compartment.

Warning!

Risk of accident.

fHave tires replaced by a specialist workshop

as soon as possible.

fAvoid hard acceleration and high cornering speeds.

Page 225 of 280

Practical Tips, Emergency Service

225

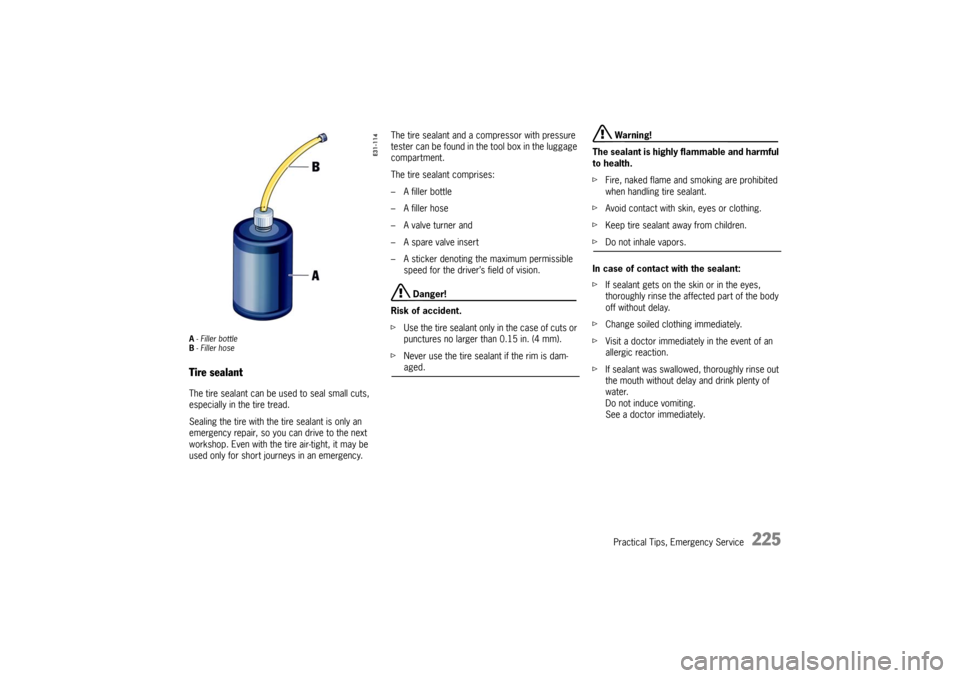

A- Filler bottle

B- Filler hoseTire sealantThe tire sealant can be used to seal small cuts,

especially in the tire tread.

Sealing the tire with the tire sealant is only an

emergency repair, so you can drive to the next

workshop. Even with the tire air-tight, it may be

used only for short journeys in an emergency.The tire sealant and a compressor with pressure

tester can be found in the tool box in the luggage

compartment.

The tire sealant comprises:

– A filler bottle

– A filler hose

– A valve turner and

– A spare valve insert

–A sticker denoting the maximum permissible

speed for the driver’s field of vision.

Danger!

Risk of accident.

fUse the tire sealant only in the case of cuts or

punctures no larger than 0.15 in. (4 mm).

fNever use the tire sealant if the rim is dam-aged.

Warning!

The sealant is highly flammable and harmful

to health.

fFire, naked flame and smoking are prohibited

when handling tire sealant.

fAvoid contact with skin, eyes or clothing.

fKeep tire sealant away from children.

fDo not inhale vapors.

In case of contact with the sealant:

fIf sealant gets on the skin or in the eyes,

thoroughly rinse the affected part of the body

off without delay.

fChange soiled clothing immediately.

fVisit a doctor immediately in the event of an

allergic reaction.

fIf sealant was swallowed, thoroughly rinse out

the mouth without delay and drink plenty of

water.

Do not induce vomiting.

See a doctor immediately.

Page 226 of 280

226

Practical Tips, Emergency Service

A- Filler bottle

B- Filler hose

C- Plug of the filler hose

D-Valve turner

E-Valve insert

F- Tire valveInserting sealant

1. Leave the object that caused the puncture in

the tire.

2. Remove sealant and the enclosed sticker from

the luggage compartment.

3. Adhere the sticker in the driver's field of vision.

4. Shake filler bottle A.5. Screw filler hose B onto the filler bottle.

The filler bottle is now open.

6. Unscrew valve cap from tire valve F.

7. Remove valve insert E from the tire valve with

valve turner D.

Keep the valve insert in a clean and dry place.

8. Remove plug C of the filler hose B.

9. Push filler hose onto the tire valve.

10.Hold filler bottle higher than the level of the tire

valve and press it together forcefully until the

bottle is completely emptied into the tire.

11.Pull filler hose off the tire valve.

12.Twist the valve insert firmly into the tire valve

using the valve turner.

13.Connect the compressor to the cigarette light-

er and inflate the tire to the prescribed tire

pressure.

Please observe the chapter “TIRE PRESSURE

FOR COLD TIRES” on Page 269.

14.Screw valve cap onto the tire valve.

15.Check the tire pressure after driving for around

10 minutes.

If the tire pressure is less than 22 psi (1.5 bar),

do not continue driving.

If a value of more than 22 psi (1.5 bar) is indi-

cated, correct the pressure to the prescribed

value.16.Please consult your authorized Porsche

dealer.

Care Instructions

After drying, any sealant that emerges can be

peeled off like a film.

Warning!

Risk of accident.

fHave the tire replaced by an authorized

Porsche dealer immediately.

fAvoid hard acceleration and high cornering

speeds.

fDo not exceed maximum speed of 50 mph

(80 km/h).

fPlease always observe the safety and oper-

ating instructions, which can be found in the

separate operating instructions for the sealant and on the compressor.

Page 227 of 280

Practical Tips, Emergency Service

227

Wheel Bolts

Warning!

Risk of wheel bolt breakage and wheel sepa-

ration, resulting in severe personal injury or

death.

fFollow all instructions concerning wheel bolts. fAlways clean the wheel bolts before fitting.

fApply a thin coat of Optimoly TA (aluminum

paste) on the thread and between the bolt head

and movable spherical cap ring (arrows).

The bearing surface of the spherical cap

facing the wheel must not be greased.

fReplace damaged wheel bolts.

Only use the Original Porsche wheel bolts

specially designed for this vehicle type.

Tightening torque Tightening torque of wheel bolts:

130 Nm/96 ftlb. Wheel Securing Bolts The wrench socket for the wheel securing bolts is

in the tool box.

To loosen or tighten the wheel bolt with anti-theft

protection, a wrench socket with the appropriate

coding must be used between the wheel bolt and

the wheel-bolt spanner.

fWhen positioning the wrench socket, ensure

that it engages fully in the teeth of the wheel

bolt.

If the wheels have to be removed at the workshop,

please do not forget to hand over the wrench

socket for the wheel securing bolts along with the

car key.

Checking tire pressure with a

pressure gaugefPlease observe the chapter “TPC TIRE PRES-

SURE MONITORING” on Page 103.

1. Remove the valve stem cap from the tire.

2. Press the pressure gauge onto the valve stem.

Note on operation

fDo not press too hard or force the valve stem

sideways, or air will escape.

If the sound of air escaping from the tire is

heard, reposition the pressure gauge.

3. Read the tire pressure on the gauge stem and

compare it to the permissible tire pressure.

This information can be found on the tire pres-

sure plate or in the chapter Technical Data.

Please observe the chapter “TIRE PRESSURE

FOR COLD TIRES” on Page 269.

4. Remove the pressure gauge.

Page 228 of 280

228

Practical Tips, Emergency Service

Changing a wheel

Warning!

Risk of injury. The car may slip off the jack.

fMake sure that no one is in the vehicle when

jacking up and changing a wheel.

fAlways place the car on stable supports if work

has to be carried out under the car.

Risk of damage to the brake discs of the

Porsche Ceramic Composite Brake (PCCB).

fAlways screw in both assembly aids when changing a wheel.

Note

The tools required for changing a wheel (e.g. jack,

wheel bolt wrench, assembly aids) are not sup-

plied with the car. They are available at your

authorized Porsche dealer.

1. Fully apply the handbrake, engage 1st gear or

select position P and withdraw the ignition key.

2. Secure the car against rolling away, e.g. by

means of wedges under the wheels on the op-

posite side.

This is particularly important on slopes.

Screw in assembly aid for vehicles without

Porsche Ceramic Composite Brake3. Slightly slacken the wheel bolts of the wheel to

be changed.

4. Raise the car until the wheel lifts off the

ground.

Please observe the chapter “LIFTING THE VE-

HICLE WITH A LIFTING PLATFORM OR GARAGE

LIFT” on Page 223.

Screw in two assembly aids for vehicles with

Porsche Ceramic Composite BrakeNote on operation

fTo remove or mount the spacers:

Please observe the chapter “SPACERS” on

Page 230.

5. Remove 1 or 2 wheel bolts (see respective

illustration). Screw in assembly aids instead of

the wheel bolts.

Remove the remaining wheel bolts.

Page 229 of 280

Practical Tips, Emergency Service

229

6. Take the wheel off and put a new wheel on.

7. Please observe the chapter “WHEEL BOLTS”

on Page 227.

Screw in wheel bolts; remove assembly aids

and screw in the remaining wheel bolts. Initially

tighten bolts in diagonally opposite sequence

so that the wheel is centered.

8. Lower the car completely.

9. Tighten wheel bolts in diagonally opposite

sequence.

Immediately after changing a wheel, use a

torque wrench to check the prescribed

tightening torque (130 Nm/96 ftlb.).

Page 230 of 280

230

Practical Tips, Emergency Service

SpacersfUse the spacers only together with wheels and

fastening parts approved by Porsche.

Before having spacers fitted, find out about the

current authorization status.

Mounting an emergency spare wheel

If 5 mm spacers are fitted, these must not be

removed to mount an emergency spare wheel.

Fitting snow chains

The use of snow chains is not permitted when

5 mm spacers are mounted.

Caution!

Risk of damage to wheel housings if the

5 mm spacers are not removed before fitting

snow chains.

fIn order to enable the fitting of snow chains,

have the 5 mm spacers removed on all 4wheels.Note on operation

fTo fit/remove the spacers:

Please consult an authorized Porsche dealer.

Removing the spacersfPlease observe the chapter “CHANGING A

WHEEL” on Page 228.

1. Unscrew both countersunk screws (M6x16) on

the wheel hub.

2. Remove the spacer.

3. Fasten the brake disc with the short M6x12

countersunk screws, part No.

900.269.047.09.

Tightening torque 10 Nm (7.5 ftlb.).

4. For wheel mounting without a spacer, 5 mm

shorter wheel bolts (part No:

996.361.203.02) must be used.

Tightening torque 130 Nm (96 ftlb.).Required scope of parts if the spacers are

removed

Short countersunk screws (M6x12)

Part No: 900.269.047.09

1 set of short wheel bolts

Part No: 996.361.203.02

Short anti-theft protection devices

Part No: 996.361.057.01