weight RAM 1500 2021 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2021, Model line: 1500, Model: RAM 1500 2021Pages: 496, PDF Size: 20.89 MB

Page 217 of 496

STARTING AND OPERATING215

Gross Trailer Weight (GTW)

The GTW is the weight of the trailer plus the

weight of all cargo, consumables and

equipment (permanent or temporary) loaded in

or on the trailer in its “loaded and ready for

operation” condition.

The recommended way to measure GTW is to

put your fully loaded trailer on a vehicle scale.

The entire weight of the trailer must be

supported by the scale.

Gross Combination Weight Rating (GCWR)

The GCWR is the total allowable weight of your

vehicle and trailer when weighed in

combination.

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum capacity of the front

and rear axles. Distribute the load over the front and rear axles evenly. Make sure that you do

not exceed either front or rear GAWR

Ú

page 213.

Tongue Weight (TW)

The TW is the downward force exerted on the

hitch ball by the trailer. You must consider this

as part of the load on your vehicle.

Trailer Frontal Area

The frontal area is the maximum height

multiplied by the maximum width of the front of

a trailer.

Trailer Sway Control (TSC)

The TSC can be a mechanical telescoping link

that can be installed between the hitch receiver

and the trailer tongue that typically provides

adjustable friction associated with the

telescoping motion to dampen any unwanted

trailer swaying motions while traveling. If equipped, the electronic TSC recognizes a

swaying trailer and automatically applies

individual wheel brakes and/or reduces engine

power to attempt to eliminate the trailer sway.

Weight-Carrying Hitch

A weight-carrying hitch supports the trailer

tongue weight, just as if it were luggage located

at a hitch ball or some other connecting point of

the vehicle. These kinds of hitches are

commonly used to tow small and medium sized

trailers.

Weight-Distributing Hitch

A weight-distributing system works by applying

leverage through spring (load) bars. They are

typically used for heavier loads to distribute

trailer tongue weight to the tow vehicle's front

axle and the trailer axle(s). When used in

accordance with the manufacturer's directions,

it provides for a more level ride, offering more

consistent steering and brake control, thereby

enhancing towing safety. The addition of a

friction/hydraulic sway control also dampens

sway caused by traffic and crosswinds and

contributes positively to tow vehicle and trailer

stability. Trailer sway control and a weight

distributing (load equalizing) hitch are

WARNING!

If the gross trailer weight is 5,000 lbs (2,267 kg)

or more, it is recommended to use a weight-dis

-

tributing hitch to ensure stable handling of your

vehicle. If you use a standard weight-carrying

hitch, you could lose control of your vehicle and

cause a collision.

WARNING!

It is important that you do not exceed the

maximum front or rear GAWR. A dangerous

driving condition can result if either rating is

exceeded. You could lose control of the vehi -

cle and have a collision.

4

21_DT_OM_EN_USC_t.book Page 215

Page 218 of 496

216STARTING AND OPERATING

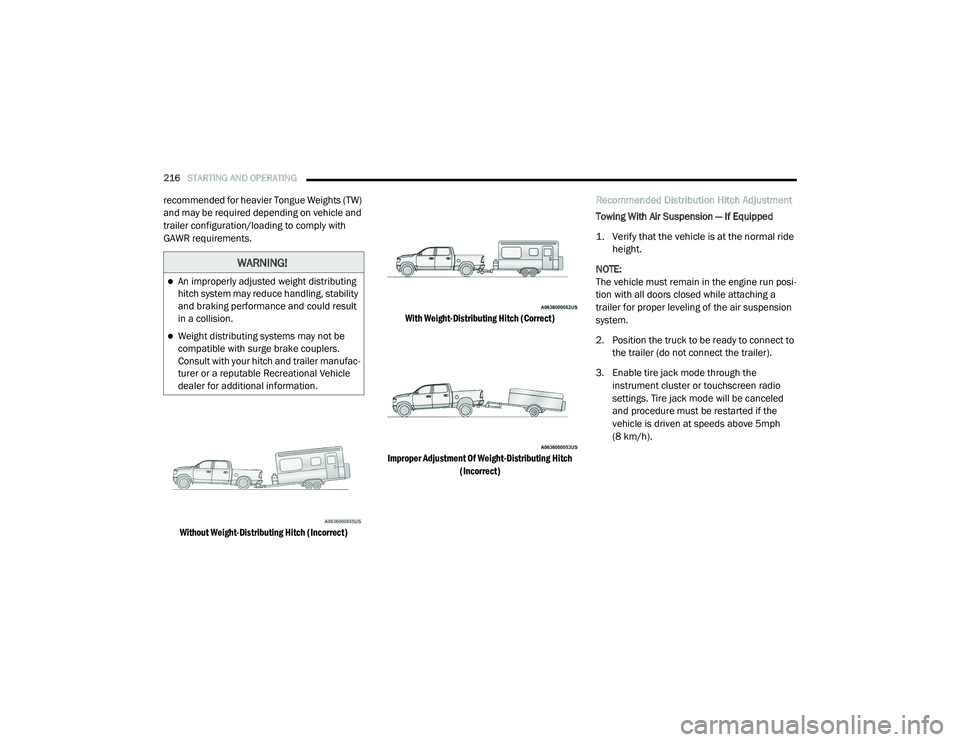

recommended for heavier Tongue Weights (TW)

and may be required depending on vehicle and

trailer configuration/loading to comply with

GAWR requirements.

Without Weight-Distributing Hitch (Incorrect) With Weight-Distributing Hitch (Correct)

Improper Adjustment Of Weight-Distributing Hitch (Incorrect)

Recommended Distribution Hitch Adjustment

Towing With Air Suspension — If Equipped

1. Verify that the vehicle is at the normal ride

height.

NOTE:

The vehicle must remain in the engine run posi -

tion with all doors closed while attaching a

trailer for proper leveling of the air suspension

system.

2. Position the truck to be ready to connect to the trailer (do not connect the trailer).

3. Enable tire jack mode through the instrument cluster or touchscreen radio

settings. Tire jack mode will be canceled

and procedure must be restarted if the

vehicle is driven at speeds above 5mph

(8 km/h).

WARNING!

An improperly adjusted weight distributing

hitch system may reduce handling, stability

and braking performance and could result

in a collision.

Weight distributing systems may not be

compatible with surge brake couplers.

Consult with your hitch and trailer manufac -

turer or a reputable Recreational Vehicle

dealer for additional information.

21_DT_OM_EN_USC_t.book Page 216

Page 219 of 496

STARTING AND OPERATING217

4. Measure the height of the top of the front

wheel opening on the fender to ground; this

is height H1.

Measuring Height (H)

5. Attach the trailer to the vehicle without the weight distribution bars connected. 6. Measure the height of the top of the front

wheel opening on the fender to ground; this

is height H2.

7. Install and adjust the tension in the weight distributing bars per FCA recommendations

so that the height of the front fender is

approximately (H2-H1)/3+H1 (about 1/3

the difference between H2 and H1 above

normal ride height [H1]).

8. Use the instrument cluster or touchscreen radio settings and switch off tire jack mode.

Make sure the truck returns to normal ride

height. Perform a visual inspection of the

trailer and weight distributing hitch to

confirm FCA recommendations have been

met. 9. The truck can now be driven.

NOTE:

For all towing conditions, we recommend towing

with tow haul mode engaged.

Measurement

Example Example Height

(mm)

H1 925

H2 946

H2-H1 21

(H2-H1)/3 7

(H2-H1)/3 + H1 932

4

21_DT_OM_EN_USC_t.book Page 217

Page 220 of 496

218STARTING AND OPERATING

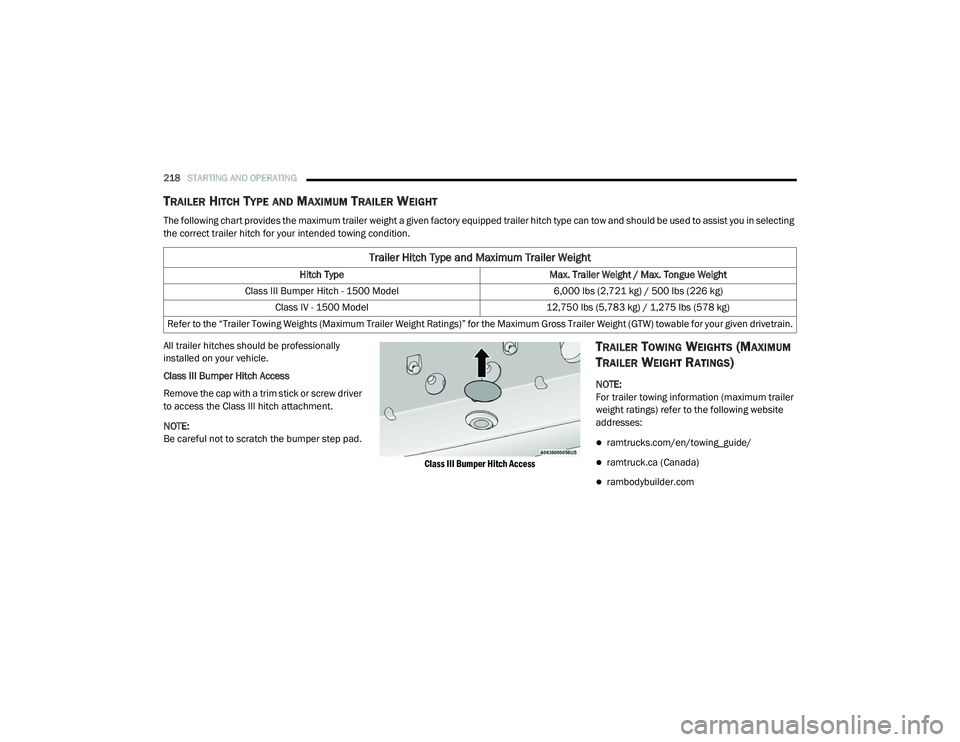

TRAILER HITCH TYPE AND MAXIMUM TRAILER WEIGHT

The following chart provides the maximum trailer weight a given factory equipped trailer hitch type can tow and should be used to assist you in selecting

the correct trailer hitch for your intended towing condition.

All trailer hitches should be professionally

installed on your vehicle.

Class III Bumper Hitch Access

Remove the cap with a trim stick or screw driver

to access the Class III hitch attachment.

NOTE:

Be careful not to scratch the bumper step pad.

Class III Bumper Hitch Access

TRAILER TOWING WEIGHTS (MAXIMUM

T

RAILER WEIGHT RATINGS)

NOTE:

For trailer towing information (maximum trailer

weight ratings) refer to the following website

addresses:

ramtrucks.com/en/towing_guide/

ramtruck.ca (Canada)

rambodybuilder.com

Trailer Hitch Type and Maximum Trailer Weight

Hitch Type Max. Trailer Weight / Max. Tongue Weight

Class III Bumper Hitch - 1500 Model 6,000 lbs (2,721 kg) / 500 lbs (226 kg)

Class IV - 1500 Model 12,750 lbs (5,783 kg) / 1,275 lbs (578 kg)

Refer to the “Trailer Towing Weights (Maximum Trailer Weight Ratings)” for the Maximum Gross Trailer Weight (GTW) towable for your given drivetrain.

21_DT_OM_EN_USC_t.book Page 218

Page 221 of 496

STARTING AND OPERATING219

TRAILER AND TONGUE WEIGHT

Weight Distribution

Consider the following items when computing

the weight on the rear axle of the vehicle:

The tongue weight of the trailer.

The weight of any other type of cargo or

equipment put in or on your vehicle.

The weight of the driver and all passengers.

NOTE:

Remember that everything put into or on the

trailer adds to the load on your vehicle. Also,

additional factory-installed options or

dealer-installed options must be considered as

part of the total load on your vehicle. Refer to

the “Tire And Loading Information” placard for the maximum combined weight of occupants

and cargo for your vehicle.

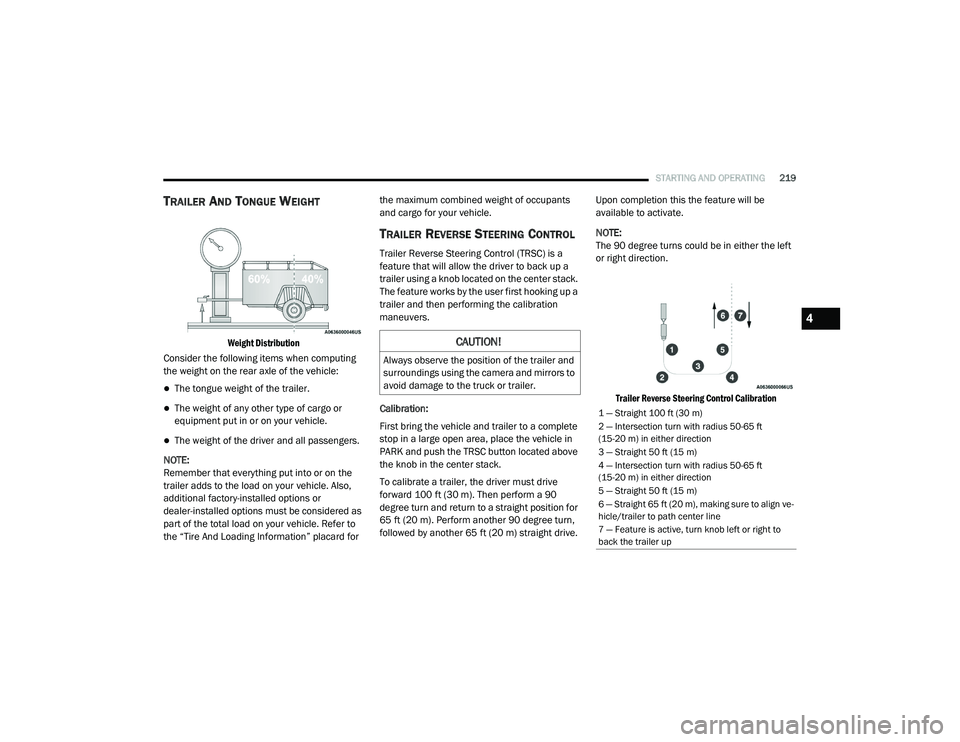

TRAILER REVERSE STEERING CONTROL

Trailer Reverse Steering Control (TRSC) is a

feature that will allow the driver to back up a

trailer using a knob located on the center stack.

The feature works by the user first hooking up a

trailer and then performing the calibration

maneuvers.

Calibration:

First bring the vehicle and trailer to a complete

stop in a large open area, place the vehicle in

PARK and push the TRSC button located above

the knob in the center stack.

To calibrate a trailer, the driver must drive

forward 100 ft (30 m). Then perform a 90

degree turn and return to a straight position for

65 ft (20 m). Perform another 90 degree turn,

followed by another 65 ft (20 m) straight drive. Upon completion this the feature will be

available to activate.

NOTE:

The 90 degree turns could be in either the left

or right direction.

Trailer Reverse Steering Control Calibration

CAUTION!

Always observe the position of the trailer and

surroundings using the camera and mirrors to

avoid damage to the truck or trailer.

1 — Straight 100 ft (30 m)

2 — Intersection turn with radius 50-65 ft

(15-20 m) in either direction

3 — Straight 50 ft (15 m)

4 — Intersection turn with radius 50-65 ft

(15-20 m) in either direction

5 — Straight 50 ft (15 m)

6 — Straight 65 ft (20 m), making sure to align ve -

hicle/trailer to path center line

7 — Feature is active, turn knob left or right to

back the trailer up

4

21_DT_OM_EN_USC_t.book Page 219

Page 224 of 496

222STARTING AND OPERATING

Towing Requirements — Tires

Do not attempt to tow a trailer while using a

compact spare tire.

Do not drive more than 50 mph (80 km/h)

when towing while using a full size spare tire.

Proper tire inflation pressures are essential

to the safe and satisfactory operation of your

vehicle.

Check the trailer tires for proper tire inflation

pressures before trailer usage.

Check for signs of tire wear or visible tire

damage before towing a trailer.

Replacing tires with a higher load carrying

capacity will not increase the vehicle's GVWR

and GAWR limits.

For further information Ú page 443.

Towing Requirements — Trailer Brakes

Do not interconnect the hydraulic brake

system or vacuum system of your vehicle

with that of the trailer.

An electronically actuated trailer brake

controller is required when towing a trailer

with electronically actuated brakes. When

towing a trailer equipped with a hydraulic

surge actuated brake system, an electronic

brake controller is not required.

Trailer brakes are recommended for trailers

over 1,000 lbs (453 kg) and required for

trailers in excess of 2,000 lbs (907 kg).

Vehicles with trailers should not be parked

on a grade. When parking, apply the

parking brake on the tow vehicle. Put the

tow vehicle transmission in PARK. For

four-wheel drive vehicles, make sure the

transfer case is not in NEUTRAL. Always,

block or "chock" the trailer wheels.

GCWR must not be exceeded.

Total weight must be distributed between

the tow vehicle and the trailer such that the

following four ratings are not exceeded :

GVWR

GTW

GAWR

Tongue weight rating for the trailer

hitch utilized.

WARNING! (Continued)WARNING!

Do not connect trailer brakes to your

vehicle's hydraulic brake lines. It can over -

load your brake system and cause it to fail.

You might not have brakes when you need

them and could have an accident.

Towing any trailer will increase your stop -

ping distance. When towing, you should

allow for additional space between your

vehicle and the vehicle in front of you.

Failure to do so could result in an accident.

CAUTION!

If the trailer weighs more than 1,000 lbs

(453 kg) loaded, it should have its own

brakes and they should be of adequate

capacity. Failure to do this could lead to

accelerated brake lining wear, higher brake

pedal effort, and longer stopping distances.

21_DT_OM_EN_USC_t.book Page 222

Page 230 of 496

228STARTING AND OPERATING

BEFORE PLOWING

Check the hydraulic system for leaks and

proper fluid level.

Check the mounting bolts and nuts for proper

tightness.

Check the runners and cutting edge for

excessive wear. The cutting edge should be

¼ to ½ inches (6 cm to 1.2 cm) above ground

in snow plowing position.

Check that snowplow lighting is connected

and functioning properly.

SNOWPLOW PREP PACKAGE MODEL

A

VAILABILITY

For Information about snowplow applications

visit www.ramtrucks.com or refer to the current

Body Builders Guide.

1. The maximum number of occupants in the

truck should not exceed two.

2. The total GVWR, Front GAWR or the Rear GAWR should never be exceeded.

3. Cargo capacity will be reduced by the addition of options or passengers, etc.

The loaded vehicle weight, including the

snowplow system, all aftermarket accessories,

driver, passengers, options, and cargo, must

not exceed either the Gross Vehicle Weight

(GVWR) or Gross Axle Weight (GAWR) ratings.

These weights are specified on the Safety

Compliance Certification Label on the driver's

side door opening. NOTE:

Detach the snowplow when transporting

passengers.

Vehicle front end wheel alignment was set to

specifications at the factory without

consideration for the weight of the plow. Front

end toe-in should be checked and reset if

necessary at the beginning and end of the

snowplow season. This will help prevent uneven

tire wear.

The blade should be lowered whenever the

vehicle is parked.

Maintain and operate your vehicle and

snowplow equipment following the

recommendations provided by the specific

snowplow manufacturer.

WARNING!

Attaching a snowplow to this vehicle could

adversely affect performance of the airbag

system in a collision. Do not expect that the

airbag will perform as described earlier in this

manual.

CAUTION!

The “Lamp Out” indicator could illuminate if

exterior lamps are not properly installed.

21_DT_OM_EN_USC_t.book Page 228

Page 320 of 496

318SAFETY

Ready Alert Braking (RAB)

RAB may reduce the time required to reach full

braking during emergency braking situations. It

anticipates when an emergency braking

situation may occur by monitoring how fast the

throttle is released by the driver. The Electronic

Brake Control System will prepare the brake

system for a panic stop.

Traction Control System (TCS)

TCS monitors the amount of wheel spin of each

of the driven wheels. If wheel spin is detected,

the TCS may apply brake pressure to the

spinning wheel(s) and/or reduce engine power

to provide enhanced acceleration and stability.

A feature of the TCS, Brake Limited Differential

(BLD), functions similarly to a limited slip

differential and controls the wheel spin across a

driven axle. If one wheel on a driven axle is

spinning faster than the other, the system will

apply the brake of the spinning wheel. This will

allow more engine torque to be applied to the

wheel that is not spinning. BLD may remain

enabled even if TCS and Electronic Stability

Control (ESC) are in reduced modes.

Trailer Sway Control (TSC)

TSC uses sensors in the vehicle to recognize an

excessively swaying trailer and will take the

appropriate actions to attempt to stop the sway.

NOTE:

TSC cannot stop all trailers from swaying.

Always use caution when towing a trailer and

follow the trailer tongue weight recommenda -

tions Ú page 214.

When TSC is functioning, the ESC Activation/

Malfunction Indicator Light will flash, the engine

power may be reduced and you may feel the

brakes being applied to individual wheels to

attempt to stop the trailer from swaying. TSC is

disabled when the ESC system is in the “Partial

Off” or “Full Off” modes.AUXILIARY DRIVING SYSTEMS

BLIND SPOT MONITORING (BSM) — IF

E

QUIPPED

BSM uses two radar sensors, located inside the

taillights, to detect highway licensable vehicles

(automobiles, trucks, motorcycles, etc.) that

enter the blind spot zones from the rear/front/

side of the vehicle.

Rear Detection Zones

When the vehicle is started, the BSM Warning

Light will momentarily illuminate in both outside

rearview mirrors to let the driver know that the

system is operational. The BSM system sensors

operate when the vehicle is in any forward gear

or REVERSE and enters standby mode when the

vehicle is in PARK.

WARNING!

If TSC activates while driving, slow the vehicle

down, stop at the nearest safe location, and

adjust the trailer load to eliminate trailer

sway.

21_DT_OM_EN_USC_t.book Page 318

Page 346 of 496

344SAFETY

(Continued)

Driver And Passenger Front Air Bag

Features

The Advanced Front Air Bag system has

multistage driver and front passenger air bags.

This system provides output appropriate to the

severity and type of collision as determined by

the Occupant Restraint Controller (ORC), which

may receive information from the front impact

sensors (if equipped) or other system

components.

The first stage inflator is triggered immediately

during an impact that requires air bag

deployment. A low energy output is used in less severe collisions. A higher energy output is used

for more severe collisions.

This vehicle may be equipped with a driver and/

or front passenger seat belt buckle switch that

detects whether the driver or front passenger

seat belt is buckled. The seat belt buckle switch

may adjust the inflation rate of the Advanced

Front Air Bags.

This vehicle may be equipped with driver and/or

front passenger seat track position sensors that

may adjust the inflation rate of the Advanced

Front Air Bags based upon seat position.

This vehicle is equipped with a right front

passenger Occupant Classification System

(“OCS”) that is designed to provide Passenger

Advanced Front Air Bag output appropriate to

the occupant’s seated weight input, as

determined by the OCS.Front Air Bag Operation

Front Air Bags are designed to provide

additional protection by supplementing the seat

belts. Front air bags are not expected to reduce

the risk of injury in rear, side, or rollover

collisions. The front air bags will not deploy in all

frontal collisions, including some that may

produce substantial vehicle damage — for

example, some pole collisions, truck

underrides, and angle offset collisions.

Never place a rear-facing child restraint in

front of an air bag. A deploying passenger

front air bag can cause death or serious

injury to a child 12 years or younger,

including a child in a rear-facing child

restraint.

Never install a rear-facing child restraint in

the front seat of a vehicle. Only use a

rear-facing child restraint in the rear seat. If

the vehicle does not have a rear seat, do

not transport a rear-facing child restraint in

that vehicle.

WARNING!

(Continued)

WARNING!

No objects should be placed over or near

the air bag on the instrument panel or

steering wheel because any such objects

could cause harm if the vehicle is in a colli -

sion severe enough to cause the air bag to

inflate.

Do not put anything on or around the air

bag covers or attempt to open them manu -

ally. You may damage the air bags and you

could be injured because the air bags may

no longer be functional. The protective

covers for the air bag cushions are

designed to open only when the air bags

are inflating.

Relying on the air bags alone could lead to

more severe injuries in a collision. The air

bags work with your seat belt to restrain you

properly. In some collisions, air bags won’t

deploy at all. Always wear your seat belts

even though you have air bags.

WARNING! (Continued)

21_DT_OM_EN_USC_t.book Page 344

Page 347 of 496

SAFETY345

On the other hand, depending on the type and

location of impact, front air bags may deploy in

crashes with little vehicle front-end damage but

that produce a severe initial deceleration.

Because air bag sensors measure vehicle

deceleration over time, vehicle speed and

damage by themselves are not good indicators

of whether or not an air bag should have

deployed.

Seat belts are necessary for your protection in

all collisions, and also are needed to help keep

you in position, away from an inflating air bag.

When the Occupant Restraint Controller (ORC)

detects a collision requiring the front air bags, it

signals the inflator units. A large quantity of

non-toxic gas is generated to inflate the front air

bags.

The steering wheel hub trim cover and the

upper passenger side of the instrument panel

separate and fold out of the way as the air bags

inflate to their full size. The front air bags fully

inflate in less time than it takes to blink your

eyes. The front air bags then quickly deflate

while helping to restrain the driver and front

passenger.Occupant Classification System (OCS) —

Front Passenger Seat

The OCS is part of a Federally regulated safety

system for this vehicle. It is designed to provide

Passenger Advanced Front Air Bag output

appropriate to the occupant’s seated weight, as

determined by the OCS.

The Occupant Classification System (OCS)

consists of the following:

Occupant Restraint Controller (ORC)

Occupant Classification Module (OCM) and

Sensor located in the front passenger seat

Air Bag Warning Light

Occupant Classification Module (OCM) And

Sensor

The Occupant Classification Module (OCM) is

located underneath the front passenger seat.

The Sensor is located beneath the passenger

seat cushion foam. Any weight on the seat will

be sensed by the Sensor. The OCM uses input

from the Sensor to determine the front

passenger’s most probable classification. The

OCM communicates this information to the ORC. The ORC may reduce the inflation rate of

the Passenger Advanced Front Air Bag

deployment based on occupant classification.

In order for the OCS to operate as designed, it is

important for the front passenger to be seated

properly and properly wearing the seat belt.

The OCS will NOT prevent deployment of the

Passenger Advanced Front Air Bag. The OCS

may reduce the inflation rate of the Passenger

Advanced Front Air Bag if the OCS estimates

that:

The front passenger seat is unoccupied or

has very light objects on it; or

The front passenger seat is occupied by a

small passenger, including a child; or

The front passenger seat is occupied by a

rear-facing child restraint; or

The front passenger is not properly seated or

his or her weight is taken off of the seat for a

period of time.

6

21_DT_OM_EN_USC_t.book Page 345