trailer RAM 1500 2021 Workshop Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2021, Model line: 1500, Model: RAM 1500 2021Pages: 496, PDF Size: 20.89 MB

Page 323 of 496

SAFETY321

The BSM system will not alert you of objects that

are traveling in the opposite direction of the

vehicle in adjacent lanes Ú page 482.

Opposing Traffic

For information on how Blind Spot Monitoring

functions when pulling a trailer Ú page 322.Rear Cross Path (RCP)

RCP is intended to aid the driver when backing

out of parking spaces where their vision of

oncoming vehicles may be blocked. Proceed

slowly and cautiously out of the parking space

until the rear end of the vehicle is exposed. The

RCP system will then have a clear view of the

cross traffic, and if an oncoming vehicle is

detected, alert the driver.

RCP Detection Zones

RCP monitors the rear detection zones on both

sides of the vehicle, for objects that are moving

toward the side of the vehicle with a minimum

speed of approximately 3 mph (5 km/h), to

objects moving a maximum of approximately

20 mph (32 km/h), such as in parking lot

situations. When RCP is on and the vehicle is in REVERSE

(R), the driver is alerted using both the visual

and audible alarms, including reducing the

radio volume.

NOTE:

In a parking lot situation, oncoming vehicles can

be blocked by vehicles parked on either side. If

the sensors are blocked by other structures or

vehicles, the system will not be able to alert the

driver.

WARNING!

The Blind Spot Monitoring system is only an

aid to help detect objects in the blind spot

zones. The BSM system is not designed to

detect pedestrians, bicyclists, or animals.

Even if your vehicle is equipped with the BSM

system, always check your vehicle’s mirrors,

glance over your shoulder, and use your turn

signal before changing lanes. Failure to do so

can result in serious injury or death.

WARNING!

Rear Cross Path Detection (RCP) is not a

backup aid system. It is intended to be used

to help a driver detect an oncoming vehicle in

a parking lot situation. Drivers must be

careful when backing up, even when using

RCP. Always check carefully behind your

vehicle, look behind you, and be sure to

check for pedestrians, animals, other

vehicles, obstructions, and blind spots before

backing up. Failure to do so can result in

serious injury or death.6

21_DT_OM_EN_USC_t.book Page 321

Page 324 of 496

322SAFETY

Blind Spot Modes

Blind Spot has three selectable modes of

operation that are available in the Uconnect

system.

Blind Spot Alert Lights Only

When operating in Blind Spot Alert mode, the

BSM system will provide a visual alert in the

appropriate side view mirror based on a

detected object. However, when the system is

operating in Rear Cross Path (RCP) mode, the

system will respond with both visual and

audible alerts when a detected object is

present. Whenever an audible alert is

requested, the radio is muted.

Blind Spot Alert Lights/Chime

When operating in Blind Spot Alert Lights/

Chime mode, the BSM system will provide a

visual alert in the appropriate side view mirror

based on a detected object. If the turn signal is

then activated, and it corresponds to an alert

present on that side of the vehicle, an audible

chime will also be sounded. Whenever a turn

signal and detected object are present on the

same side at the same time, both the visual and

audible alerts will be issued. In addition to the

audible alert the radio (if on) will also be muted. NOTE:

Whenever an audible alert is requested by the

BSM system, the radio is also muted.

When the system is in RCP, the system shall

respond with both visual and audible alerts

when a detected object is present. Whenever

an audible alert is requested, the radio is also

muted. Turn/hazard signal status is ignored;

the RCP state always requests the chime.

Blind Spot Alert Off

When the BSM system is turned off there will be

no visual or audible alerts from either the BSM,

RCP, or Trailer Merge Assist systems.

NOTE:

The BSM system will store the current operating

mode when the vehicle is shut off. Each time

the vehicle is started the previously stored

mode will be recalled and used.

Trailer Merge Assist – If Equipped

Trailer Merge Assist is a function of the Blind

Spot Monitoring (BSM) system that extends the

blind spot zone to work while pulling a trailer.

NOTE:

When Trailer Merge Assist is activated, Rear

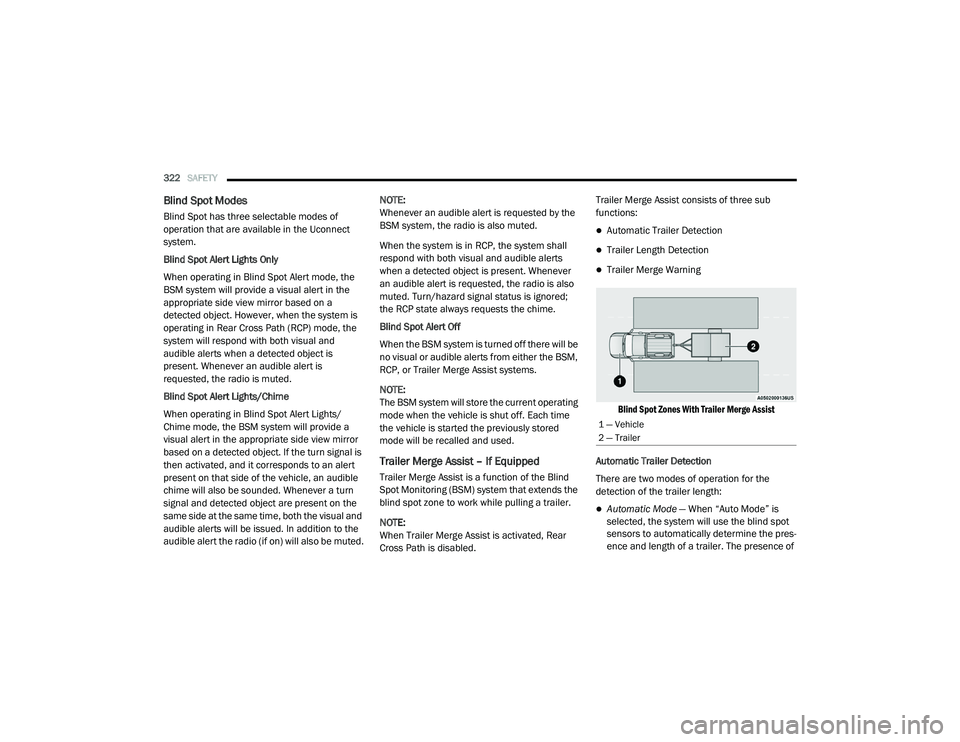

Cross Path is disabled.Trailer Merge Assist consists of three sub

functions:

Automatic Trailer Detection

Trailer Length Detection

Trailer Merge Warning

Blind Spot Zones With Trailer Merge Assist

Automatic Trailer Detection

There are two modes of operation for the

detection of the trailer length:

Automatic Mode — When “Auto Mode” is

selected, the system will use the blind spot

sensors to automatically determine the pres -

ence and length of a trailer. The presence of

1 — Vehicle

2 — Trailer

21_DT_OM_EN_USC_t.book Page 322

Page 325 of 496

SAFETY323

a trailer will be detected using the blind spot

radar within 90 seconds of forward move -

ment of the vehicle. The vehicle must be

moving above 6 mph (10 km/h) to activate the feature. Once the trailer has been

detected, the system will default to the

maximum blind spot zone until the length has

been verified. You will see “Auto” in the

instrument panel cluster .

Maximum Mode — When “Max Mode” is

selected, the system will default to the

maximum blind spot zone regardless of what

size trailer is attached .

NOTE:

Selected setting is stored when the ignition is

placed in the OFF position. To change this

setting, it must be selected through the

Uconnect settings Ú page 237.

Trailer Length Detection

Once the trailer presence has been established,

the trailer length will be established (by making

a 90 degree turn) and then the trailer length

category (example 10-20 ft (3 m to 6 m)) will be

displayed. This can take up to 30 seconds after

completing the turn. NOTE:

During the same ignition cycle, if the vehicle is

at a standstill for a minimum of 90 seconds, a

new “trailer detection request” is enabled by

the system once the vehicle resumes motion.

Maximum length supported by the Trailer Merge

Assist feature is 39.5 ft (12 m). Trailer length is

considered the forward most portion of the

trailer hitch to the rearward most portion of the

body, fascia/bumper, or ramp of the trailer.

Maximum width supported by the Trailer Merge

Assist feature is 8.5 ft (2.59 m). Trailer width is

measured at the widest portion of the trailer

and may include wheels, tires, finders, or rails.

NOTE:

Fifth wheel or gooseneck trailers are not

supported by Trailer Merge Assist.

NOTE:

The ability to detect a trailer may be degraded in

crowded or busy environments. Busy parking

lots, narrow areas surrounded with trees, or any

other crowded area may prevent the radar

sensors from being able to adequately detect

the trailer. The system will try to detect a trailer

at every ignition cycle or 90 seconds of stand

-

still.

Trailer Length Detection

Trailer length will be identified and placed into

one of the following categories:

Trailer length up to 10 ft (3 m) — Blind spot

zone will be adjusted to 10 ft (3 m) .

Trailer length between 10 ft to 20 ft (3 m to

6 m) — Blind spot zone will be adjusted to

20 ft (6 m) .

Trailer length between 20 ft to 30 ft (6 m to

9 m) — Blind spot zone will be adjusted to

30 ft (9 m) .

1 — Trailer Length

2 — Trailer Width

3 — Trailer Hitch

6

21_DT_OM_EN_USC_t.book Page 323

Page 326 of 496

324SAFETY

Trailer length between 30 ft and 39.5 ft (9 m

to 12 m) — Blind spot zone will be adjusted to

Max distance .

NOTE:

Trailer length is determined within +/- 3 ft (1 m)

of actual length. Trailers that are the same size

as the category limit, 10/20/30 ft (3/6/9 m),

could be subject to being placed in the category

above or below the correct one.

Trailer Merge Warning

Trailer Merge Warning is the extension of the

blind spot function to cover the length of the

trailer, plus a safety margin, to warn the driver

when there is a vehicle in the adjacent lane. The

driver is alerted by the illumination of the BSM

warning light located in the outside mirror on

the side the other vehicle is detected on. In

addition, an audible (chime) alert will be heard

and radio volume will be reduced Ú page 322.

NOTE:

The Trailer Merge Alert system DOES NOT

alert the driver about rapidly approaching

vehicles that are outside the detection zones.

The Blind Spot Monitoring (BSM) system may

experience drop outs (blinking on and off) of the side mirror warning indicator lamps when

a motorcycle or any small object remains at

the side of the vehicle for extended periods of

time (more than a couple of seconds).

Crowded areas such as parking lots, neigh

-

borhoods, etc. may lead to an increased

amount of false alerts. This is normal opera -

tion.

FORWARD COLLISION WARNING (FCW)

W

ITH MITIGATION — IF EQUIPPED

FCW with Mitigation provides the driver with

audible warnings, visual warnings (within the

instrument cluster display), and may apply a

brake jerk to warn the driver when it detects a potential frontal collision. The warnings and

limited braking are intended to provide the

driver with enough time to react, avoid or

mitigate the potential collision.

NOTE:

FCW monitors the information from the forward

looking sensors as well as the Electronic Brake

Controller (EBC), to calculate the probability of a

forward collision. When the system determines

that a forward collision is probable, the driver

will be provided with audible and visual warn-

ings as well as a possible brake jerk warning.

If the driver does not take action based upon

these progressive warnings, then the system

will provide a limited level of active braking to

help slow the vehicle and mitigate the potential

forward collision. If the driver reacts to the warn

-

ings by braking and the system determines that

the driver intends to avoid the collision by

braking but has not applied sufficient brake

force, the system will compensate and provide

additional brake force as required.

If a FCW with Mitigation event begins at a speed

below 32 mph (52 km/h), the system may

provide the maximum braking possible to miti -

gate the potential forward collision. If the

WARNING!

The Blind Spot Monitoring system is only an

aid to help detect objects in the blind spot

zones. The BSM system is not designed to

detect pedestrians, bicyclists, or animals.

Even if your vehicle is equipped with the BSM

system, always check your vehicle’s mirrors,

glance over your shoulder, and use your turn

signal before changing lanes. Failure to do so

can result in serious injury or death.

21_DT_OM_EN_USC_t.book Page 324

Page 334 of 496

332SAFETY

Operation:

The horn will sound once to let the user know

when to stop filling the tire, when it reaches

recommended pressure.

The horn will sound three times if the tire is

overfilled and will continue to sound every

five seconds if the user continues to inflate

the tire.

The horn will sound once again when enough

air is let out to reach proper inflation level.

The horn will also sound three times if the tire

is then underinflated and will continue to

sound every five seconds if the user

continues to deflate the tire.

Trailer Tire Pressure Monitoring System

(TTPMS) — If Equipped

The Trailer Tire Pressure Monitoring System

(TTPMS) is a feature that displays the trailer tire

pressure values and warns the driver of a low

tire pressure event based on the drivers set

target tire pressure value, through TTPMS

settings found in the radio.

The TTPMS monitors the pressure of each tire

and warns the driver through the instrument

cluster, when either a low tire pressure condition falls below 25% of the drivers set

pressure or if a system malfunction occurs. The

instrument cluster will display the actual tire

pressure or dashes for each of the trailer tires in

the correct trailer position, based on trailer

configuration. The TTPMS can support up to

12 trailer tires per configured trailer on up to

four configurable trailers Ú

page 237.

Trailer Tire Pressure Monitoring System

Trailer Tire Pressure Sensor Pairing

In order use this feature, the provided tire

pressure sensors must be installed in the

desired trailer tires and the sensors must be

paired to the truck. If the target trailer requires

more than the provided four sensors, additional

sensors can be purchased at an authorized

Ram dealership. With the sensors installed and the trailer near

or connected to your Ram truck, initiate the

pairing process by entering the settings menu in

the radio and selecting trailer. Select the

desired trailer profile to pair to, open the “Tire

Pressure” menu, and hit “Setup All Tires”

Ú

page 237.

NOTE:

The vehicle may not be driven until the pairing

process is complete.

Trailer Tire Pressure Settings

21_DT_OM_EN_USC_t.book Page 332

Page 335 of 496

SAFETY333

Trailer Tire Pressure Pairing

Follow the on screen prompts to select the

number of axles (1 - 3), the number of trailer

tires (2, 4, 6, 8, or 12), and the set trailer tire

pressure. The range is selectable anywhere

between 25-125 PSI (172-862 kPa).

Once PSI (kPa) is programmed, the pairing

screen appears. Tire sensors must be paired in

order shown. Starting with Tire 1, deflate tire by

5 PSI (34 kPa) and wait for a horn chirp. It may

take up to three minutes for the chirp to occur,

indicating that the sensor has paired. Repeat

process on each tire, in order, until complete.

Do not exit the pairing screen until process is

complete. If pairing was unsuccessful, a double

horn chirp will sound, and a prompt on the

touchscreen will allow you to retry the

procedure; “Retry” will only appear when setup fails. Each tire must be successfully paired

during a single pairing process to receive the

success screen.

NOTE:

If the pairing process times out after three

minutes of no communication with a sensor, a

double horn chip will occur indicating the

pairing has failed and a message will display on

the radio indicating the process was unsuc

-

cessful. Under certain circumstances, the

double horn chirp may continue to happen

every three minutes indicating the failed

pairing. If this happens, the horn chirping may

be canceled by cycling the ignition button OFF

and then back to RUN position.

Tire Pressure Monitoring Low Pressure

Warnings

When a tire pressure low in one or more of the

active road tires is detected, the instrument

cluster will display a message stating “Trailer

Tire Pressure Low”. The instrument cluster will

then display the TTPMS graphic showing the

pressure values of each tire with the low tire

pressure values in a different color.

Should this occur, you should stop as soon as

possible and inflate the tires with a low pressure condition (those in a different color in the

instrument cluster graphic) to the customer

programmed target tire pressure value as

shown at the top of the TTPMS instrument

cluster graphic. Once the tire(s) are inflated, the

system will automatically update the graphic

display in the instrument cluster, returning to its

original color. The vehicle may need to be driven

for up to 10 minutes above 15 mph (24 km/h)

in order for the TTPMS to receive the updated

information.

Service TTPMS Warning

If a system fault is detected, the instrument

cluster will display a “Trailer Tire Pressure

System Service Required” message for a

minimum of five seconds.

Once the system fault is corrected the "Trailer

Tire Pressure System Service Required"

message will no longer be displayed. The

vehicle may need to be driven for up to

10 minutes above 15 mph (24 km/h) in order

for the TTPMS to receive the trailer tire pressure

information.

6

21_DT_OM_EN_USC_t.book Page 333

Page 336 of 496

334SAFETY

Trailer Tire Pres sure System Not Configured

A “Trailer Tire Pressure System Not Configured”

message will be displayed in the instrument

cluster on the TTPMS instrument cluster

graphic when a trailer number is selected that

has not had trailer tire pressure sensors paired.

To correct this condition, see Ú page 237.

Trailer Sensors Detected Do Not Match Active

Trailer

The “Trailer Sensors Detected Do Not Match

Active Trailer” message will be displayed in the

instrument cluster when the trailer sensors

being received by the TTPMS module do not

match the trailer sensors paired to the current

trailer number selected. This message will be

displayed when the sensors being received

completely match the sensors paired to another

trailer number configured in the TTPMS module.

To correct this condition, the correct trailer

number must be selected in the radio

Ú page 237.OCCUPANT RESTRAINT SYSTEMS

Some of the most important safety features in

your vehicle are the restraint systems:

OCCUPANT RESTRAINT SYSTEMS

F

EATURES

Seat Belt Systems

Supplemental Restraint Systems (SRS) Air

Bags

Child Restraints

Some of the safety features described in this

section may be standard equipment on some

models, or may be optional equipment on

others. If you are not sure, ask an authorized

dealer.

IMPORTANT SAFETY PRECAUTIONS

Please pay close attention to the information in

this section. It tells you how to use your restraint

system properly, to keep you and your

passengers as safe as possible.

Here are some simple steps you can take to

minimize the risk of harm from a deploying air

bag:

1. Children 12 years old and under should

always ride buckled up in the rear seat of a

vehicle with a rear seat.

2. A child who is not big enough to wear the vehicle seat belt properly must be secured

in the appropriate child restraint or

belt-positioning booster seat in a rear

seating position Ú page 355.

3. If a child from 2 to 12 years old (not in a rear-facing child restraint) must ride in the

front passenger seat, move the seat as far

back as possible and use the proper child

restraint Ú page 355.

4. Never allow children to slide the shoulder belt behind them or under their arm.

5. You should read the instructions provided with your child restraint to make sure that

you are using it properly.

6. All occupants should always wear their lap and shoulder belts properly.

7. The driver and front passenger seats should be moved back as far as practical to allow

the front air bags room to inflate.

21_DT_OM_EN_USC_t.book Page 334

Page 394 of 496

392IN CASE OF EMERGENCY

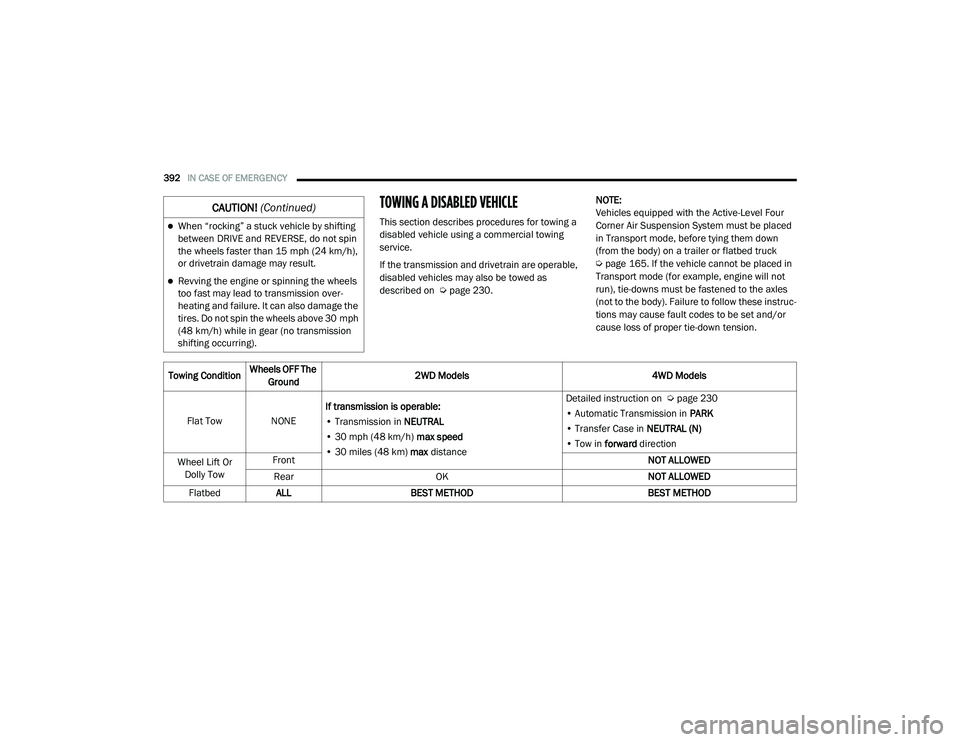

TOWING A DISABLED VEHICLE

This section describes procedures for towing a

disabled vehicle using a commercial towing

service.

If the transmission and drivetrain are operable,

disabled vehicles may also be towed as

described on Úpage 230. NOTE:

Vehicles equipped with the Active-Level Four

Corner Air Suspension System must be placed

in Transport mode, before tying them down

(from the body) on a trailer or flatbed truck

Ú

page 165. If the vehicle cannot be placed in

Transport mode (for example, engine will not

run), tie-downs must be fastened to the axles

(not to the body). Failure to follow these instruc -

tions may cause fault codes to be set and/or

cause loss of proper tie-down tension.When “rocking” a stuck vehicle by shifting

between DRIVE and REVERSE, do not spin

the wheels faster than 15 mph (24 km/h), or drivetrain damage may result.

Revving the engine or spinning the wheels

too fast may lead to transmission over -

heating and failure. It can also damage the

tires. Do not spin the wheels above 30 mph

(48 km/h) while in gear (no transmission

shifting occurring).

CAUTION! (Continued)

Towing Condition Wheels OFF The

Ground 2WD Models

4WD Models

Flat Tow NONE If transmission is operable:

• Transmission in NEUTRAL

• 30 mph (48 km/h) max speed

• 30 miles (48 km) max distance Detailed instruction on

Ú page 230

• Automatic Transmission in PARK

• Transfer Case in NEUTRAL (N)

• Tow in forward direction

Wheel Lift Or Dolly Tow Front

NOT ALLOWED

Rear OK NOT ALLOWED

Flatbed ALL BEST METHOD BEST METHOD

21_DT_OM_EN_USC_t.book Page 392

Page 397 of 496

395

SERVICING AND MAINTENANCE

SCHEDULED SERVICING — GASOLINE

ENGINE

Your vehicle is equipped with an automatic oil

change indicator system. The oil change

indicator system will remind you that it is time to

take your vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate. This

means that service is required for your vehicle.

Operating conditions such as frequent

short-trips, trailer tow, and extremely hot or cold

ambient temperatures will influence when the

“Oil Change Required” message is displayed.

Severe operating conditions can cause the

change oil message to illuminate as early as

3,500 miles (5,600 km) since last reset. Have

your vehicle serviced as soon as possible,

within the next 500 miles (805 km).

An authorized dealer will reset the oil change

indicator message after completing the

scheduled oil change. If a scheduled oil change

is performed by someone other than an authorized dealer, the message can be reset by

referring to the steps described under

Instrument Cluster Display Ú

page 114.

NOTE:

Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km),

12 months or 350 hours of engine run time,

whichever comes first. The 350 hours of engine

run or idle time is generally only a concern for

fleet customers.

Severe Duty All Models

NOTE:

Vehicles that are operated in a dusty and

off-road environment, or predominately at idle

or very low engine RPM are known as Severe

Duty vehicles. It is recommended that you

change the engine oil at 4,000 miles

(6,500 km) or 350 hours of engine run time.

Once A Month Or Before A Long Trip:

Check engine oil level.

Check windshield washer fluid level.

Check tire pressure and look for unusual

wear or damage. Rotate tires at the first sign

of irregular wear, even if it occurs before the

oil indicator system turns on.

Check the fluid levels of the coolant reservoir,

brake master cylinder, and fill as needed.

Check function of all interior and exterior

lights.

MAINTENANCE PLAN

Refer to the Maintenance Plan for required

maintenance. More frequent maintenance may

be needed in severe conditions, such as dusty

areas and very short trip driving. In some

extreme conditions, additional maintenance

not specified in the maintenance schedule may

be required.

8

21_DT_OM_EN_USC_t.book Page 395

Page 399 of 496

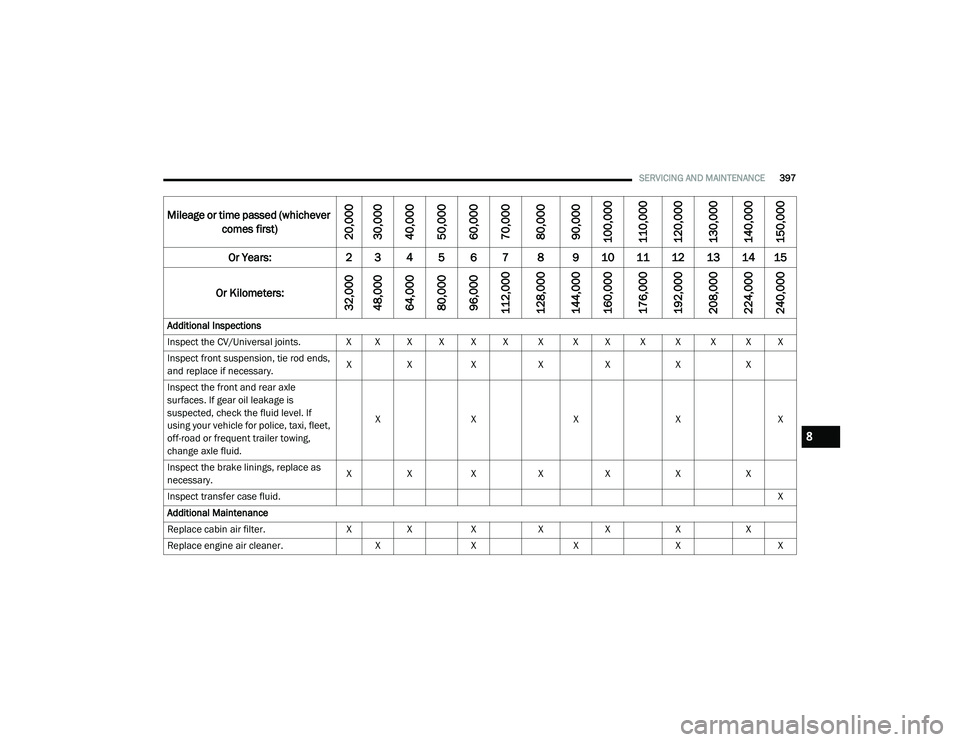

SERVICING AND MAINTENANCE397

Mileage or time passed (whichever

comes first)

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

Additional Inspections

Inspect the CV/Universal joints. X X X X X X X X X X X X X X Inspect front suspension, tie rod ends,

and replace if necessary. X

X X XX XX

Inspect the front and rear axle

surfaces. If gear oil leakage is

suspected, check the fluid level. If

using your vehicle for police, taxi, fleet,

off-road or frequent trailer towing,

change axle fluid. X

X XXX

Inspect the brake linings, replace as

necessary. X

X X XX XX

Inspect transfer case fluid. X

Additional Maintenance

Replace cabin air filter. XX X XX XX

Replace engine air cleaner. XX XXX

8

21_DT_OM_EN_USC_t.book Page 397