service Ram 2500 2020 Manual PDF

[x] Cancel search | Manufacturer: RAM, Model Year: 2020, Model line: 2500, Model: Ram 2500 2020Pages: 553, PDF Size: 21.99 MB

Page 344 of 553

342IN CASE OF EMERGENCY

(Continued)

NOTE:

Your vehicle may be transmitting data as

authorized by the subscriber.

Never place anything on or near the vehicle’s

LTE (voice/data) or 4G (data) and GPS

antennas. You could prevent LTE (voice/

data) or 4G (data) and GPS signal reception,

which can prevent your vehicle from placing

an emergency call. An operable LTE (voice/

data) or 4G (data) network connection and a

GPS signal is required for the SOS Call

system to function properly.

General Information

The following regulatory statement applies to all

Radio Frequency (RF) devices equipped in this

vehicle:

This device complies with Part 15 of the FCC

Rules and with Innovation, Science and

Economic Development Canada license-exempt

RSS standard(s). Operation is subject to the

following two conditions:

1. This device may not cause harmful interfer

-

ence, and

2. This device must accept any interference received, including interference that may

cause undesired operation.

Le présent appareil est conforme aux CNR

d`Innovation, Science and Economic Develop -

ment applicables aux appareils radio exempts

de licence. L'exploitation est autorisée aux deux

conditions suivantes:

1. l'appareil ne doit pas produire de brouil -

lage, et

2. l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, même si le

brouillage est susceptible d'en comprom -

ettre le fonctionnement.

La operación de este equipo está sujeta a las

siguientes dos condiciones:

1. es posible que este equipo o dispositivo no cause interferencia perjudicial y

2. este equipo o dispositivo debe aceptar cual -

quier interferencia, incluyendo la que

pueda causar su operación no deseada. NOTE:

Changes or modifications not expressly

approved by the party responsible for compli

-

ance could void the user’s authority to operate

the equipment.

JACKING AND TIRE CHANGING

WARNING!

Do not attempt to change a tire on the side

of the vehicle close to moving traffic. Pull

far enough off the road to avoid the danger

of being hit when operating the jack or

changing the wheel.

Being under a jacked-up vehicle is

dangerous. The vehicle could slip off the

jack and fall on you. You could be crushed.

Never put any part of your body under a

vehicle that is on a jack. If you need to get

under a raised vehicle, take it to a service

center where it can be raised on a lift.

Never start or run the engine while the

vehicle is on a jack.

20_DJD2_OM_EN_USC_t.book Page 342

Page 345 of 553

IN CASE OF EMERGENCY343

NOTE:

If your vehicle is equipped with an air suspen -

sion system, there is a feature which allows the

automatic leveling to be disabled to assist with

changing a tire.

This feature can be activated through the Ucon -

nect system.

Refer to “Uconnect Settings” in “Multimedia”

for further information.

Jack Location

The jack and jack tools are stored under the

front passenger seat.

Removal Of Jack And Tools

To access the jack and jack tools, you must

remove the plastic access cover located on the

side of the front passenger’s seat. To remove

the cover, pull the front part of the cover

(closest to the front of the seat) toward you to

release a locking tab. Once the front of the

cover is loose, slide the cover toward the front

of the seat until it is free from the seat frame.

Jack Access Cover

Remove the jack and tools by turning the wing

bolt counterclockwise, remove the wing bolt

and then slide the assembly out from under the

seat.

Wing Bolt/Jack And Tools

The jack is designed to be used as a tool for

changing tires only. The jack should not be

used to lift the vehicle for service purposes.

The vehicle should be jacked on a firm level

surface only. Avoid ice or slippery areas.

WARNING! (Continued)

6

20_DJD2_OM_EN_USC_t.book Page 343

Page 349 of 553

IN CASE OF EMERGENCY347

(Continued)

Jacking Instructions

Jack Warning Label Lug Wrench Adapter Shown In Jack And Tools Assembly

1. Remove the spare wheel, jack, and tools

from storage.

2. Using the lug wrench, loosen, but do not remove, the wheel nuts by turning them

counterclockwise one turn while the wheel

is still on the ground. Changing a dually tire

requires the lug wrench adapter.

WARNING!

Carefully follow these tire changing warnings

to help prevent personal injury or damage to

your vehicle:

Always park on a firm, level surface as far

from the edge of the roadway as possible

before raising the vehicle.

Turn on the Hazard Warning Flashers.

Apply the parking brake firmly and set the

transmission in PARK.

Block the wheel diagonally opposite the

wheel to be raised.

Never start or run the engine with the

vehicle on a jack.

Do not let anyone sit in the vehicle when it

is on a jack.

Do not get under the vehicle when it is on a

jack. If you need to get under a raised

vehicle, take it to a service center where it

can be raised on a lift.

Only use the jack in the positions indicated

and for lifting this vehicle during a tire

change.

If working on or near a roadway, be

extremely careful of motor traffic.

To assure that spare tires, flat or inflated,

are securely stowed, spares must be

stowed with the valve stem facing the

ground.

WARNING! (Continued)

CAUTION!

Do not attempt to raise the vehicle by jacking

on locations other than those indicated in the

Jacking Instructions for this vehicle.

6

20_DJD2_OM_EN_USC_t.book Page 347

Page 352 of 553

350IN CASE OF EMERGENCY

Dual Rear Wheel Jack Placement

6. Finish tightening the lug nuts. Push down on the lug wrench while at the end of the handle

for increased leverage. Tighten the lug nuts in

a star pattern until each nut has been tight -

ened twice. For the correct lug nut torque refer

to “Wheel And Tire Torque Specifications” in

“Technical Specifications”. If in doubt about

the correct tightness, have them checked with

a torque wrench by an authorized dealer or

service station. 7. Install the wheel center cap and remove the

wheel blocks. Do not install chrome or

aluminum wheel center caps on the spare

wheel. This may result in cap damage.

8. Lower the jack to its fully closed position. Stow the replaced tire, jack, and tools as

previously described.

NOTE:

The bottle jack will not lower by turning the dial

(thumbwheel) by hand, it may be necessary to

use the jack driver in order to lower the jack.

9. Adjust the tire pressure when possible.

NOTE:

Do not oil wheel studs. For chrome wheels, do

not substitute with chrome plated lug nuts.

To Stow The Flat Or Spare

NOTE:

Have the flat tire repaired or replaced immedi -

ately.

1. Turn the wheel so that the valve stem is facing the ground and toward the rear of

the vehicle for convenience in checking the

spare tire inflation. Slide the wheel retainer

through the center of the wheel.

Reinstalling The Retainer

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop, could endanger the

occupants of the vehicle. Always stow the jack

parts and the spare tire in the places

provided.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the jack

parts and the spare tire in the places

provided. Have the deflated (flat) tire repaired

or replaced immediately.

20_DJD2_OM_EN_USC_t.book Page 350

Page 355 of 553

IN CASE OF EMERGENCY353

For 2500/3500 Single Rear Wheel (SRW)

models, use the flat end of the lug wrench to

hook and pull off the hub cap. Find the opening

in the hub cap, insert the lug wrench, and pull

off the cap. If you need to pry against the wheel,

protect the wheel surface.

Lug Wrench Insertion Location — Hub Cap

On 3500 models with Dual Rear Wheels (DRW),

you must first remove the hub caps—use the

procedure noted for the single rear wheel. For

the wheel covers (wheel skins), insert the flat

end of the lug wrench between the outer edge

of the wheel cover and the wheel. Pry against

the wheel to remove the wheel cover. Repeat

this procedure around the wheel until the cover

pops off.

Lug Wrench Insertion Location — Wheel Cover

Replace the wheel covers using a rubber mallet

to ease the installation. Align the wheel cover

vent holes to the wheel vent holes. Tap on the

wheel cover as needed to firmly seat it evenly

around the wheel.FUSES

CAUTION!

Use a pulling motion to remove the hub

cap. Do not use a twisting motion when

removing the hub cap, damage to the hub

cap; finish may occur.

The rear hub caps on the dual rear wheel

has two pull off notches. Make sure that the

hook of the jack handle driver is located

squarely in the cap notch before attempting

to pull off.

WARNING!

When replacing a blown fuse, always use

an appropriate replacement fuse with the

same amp rating as the original fuse. Never

replace a fuse with another fuse of higher

amp rating. Never replace a blown fuse with

metal wires or any other material. Do not

place a fuse inside a circuit breaker cavity

or vice versa. Failure to use proper fuses

may result in serious personal injury, fire

and/or property damage.

Before replacing a fuse, make sure that the

ignition is off and that all the other services

are switched off and/or disengaged.

If the replaced fuse blows again, contact an

authorized dealer.

If a general protection fuse for safety

systems (air bag system, braking system),

power unit systems (engine system, trans -

mission system) or steering system blows,

contact an authorized dealer.

6

20_DJD2_OM_EN_USC_t.book Page 353

Page 356 of 553

354IN CASE OF EMERGENCY

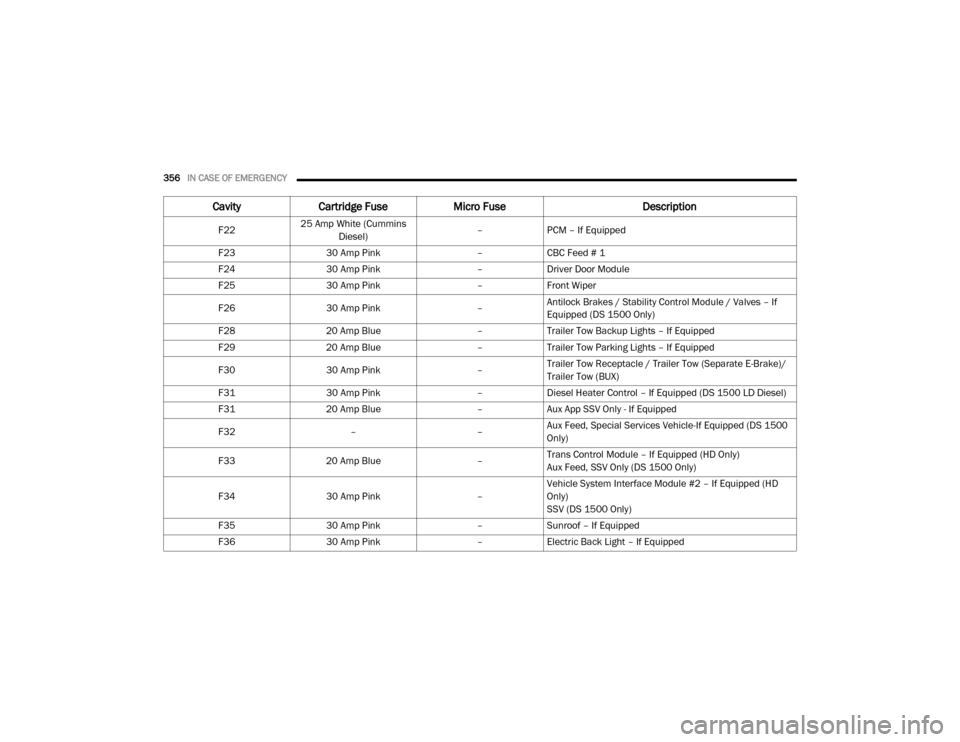

Power Distribution Center

The Power Distribution Center is located in the

engine compartment near the battery. This

center contains cartridge fuses, micro fuses,

relays, and circuit breakers. A description of

each fuse and component may be stamped on

the inside cover, otherwise the cavity number of

each fuse is stamped on the inside cover that

corresponds to the following chart.

Power Distribution Center Location

CavityCartridge Fuse Micro Fuse Description

F0180 Amp Black –Rad Fan Control Module – If Equipped (DS 1500 Only)

F02 60 Amp Yellow –ABS Pump Motor (HD Only)

F03 60 Amp Yellow –Rad Fan – If Equipped

F04 50 Amp Red 400W Inverter – If Equipped (HD Only)

F05 40 Amp Green

50 Amp Red (Special

Services Vehicle (SSV)) –

Compressor For Air Suspension – If Equipped

F06 40 Amp Green –ABS Pump Motor (DS 1500 Only)

Steering Torque Overlay Module (STOM) (HD Only)

F07 40 Amp Green –Starter Solenoid

F08 20 Amp Blue (DS 1500 LD/

Cummins Diesel)40 Amp Green –

–

NOX Sensor – If Equipped

Aux Relay Output- SSV Only

20_DJD2_OM_EN_USC_t.book Page 354

Page 358 of 553

356IN CASE OF EMERGENCY

F2225 Amp White (Cummins

Diesel) –

PCM – If Equipped

F23 30 Amp Pink –CBC Feed # 1

F24 30 Amp Pink –Driver Door Module

F25 30 Amp Pink –Front Wiper

F26 30 Amp Pink –Antilock Brakes / Stability Control Module / Valves – If

Equipped (DS 1500 Only)

F28 20 Amp Blue –Trailer Tow Backup Lights – If Equipped

F29 20 Amp Blue –Trailer Tow Parking Lights – If Equipped

F30 30 Amp Pink –Trailer Tow Receptacle / Trailer Tow (Separate E-Brake)/

Trailer Tow (BUX)

F31 30 Amp Pink –Diesel Heater Control – If Equipped (DS 1500 LD Diesel)

F31 20 Amp Blue –Aux App SSV Only - If Equipped

F32 ––Aux Feed, Special Services Vehicle-If Equipped (DS 1500

Only)

F33 20 Amp Blue –Trans Control Module – If Equipped (HD Only)

Aux Feed, SSV Only (DS 1500 Only)

F34 30 Amp Pink –Vehicle System Interface Module #2 – If Equipped (HD

Only)

SSV (DS 1500 Only)

F35 30 Amp Pink –Sunroof – If Equipped

F36 30 Amp Pink –Electric Back Light – If Equipped

Cavity Cartridge Fuse Micro Fuse Description

20_DJD2_OM_EN_USC_t.book Page 356

Page 369 of 553

IN CASE OF EMERGENCY367

To Reset The Manual Park Release:

1. Push the locking tab to the right, to unlock

the lever.

2. Rotate the Manual Park Release lever forward to its original position, until the

locking tab snaps into place to secure the

lever.

3. Pull gently on the tether strap to confirm that the lever is locked in its stowed posi-

tion.

4. Re-install the access cover.

IF YOUR ENGINE OVERHEATS

In any of the following situations, you can

reduce the potential for overheating by taking

the appropriate action.

On the highways — slow down.

In city traffic — while stopped, place the trans -

mission in NEUTRAL, but do not increase the

engine idle speed while preventing vehicle

motion with the brakes. NOTE:

There are steps that you can take to slow down

an impending overheat condition:

If your Air Conditioner (A/C) is on, turn it off.

The A/C system adds heat to the engine

cooling system and turning the A/C off can

help remove this heat.

You can also turn the temperature control to

maximum heat, the mode control to floor and

the blower control to high. This allows the

heater core to act as a supplement to the

radiator and aids in removing heat from the

engine cooling system.

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand, or

snow, it can often be moved using a rocking

motion. Turn the steering wheel right and left to

clear the area around the front wheels. Then

shift back and forth between DRIVE (D) and

REVERSE (R), while gently pressing the acceler

-

ator. Use the least amount of accelerator pedal

pressure that will maintain the rocking motion,

without spinning the wheels or racing the

engine.

WARNING!

You or others can be badly burned by hot

engine coolant (antifreeze) or steam from

your radiator. If you see or hear steam coming

from under the hood, do not open the hood

until the radiator has had time to cool. Never

try to open a cooling system pressure cap

when the radiator or coolant bottle is hot.

CAUTION!

Driving with a hot cooling system could

damage your vehicle. If the temperature

gauge reads HOT (H), pull over and stop the

vehicle. Idle the vehicle with the air

conditioner turned off until the pointer drops

back into the normal range. If the pointer

remains on HOT (H), and you hear continuous

chimes, turn the engine off immediately and

call for service.

6

20_DJD2_OM_EN_USC_t.book Page 367

Page 371 of 553

IN CASE OF EMERGENCY369

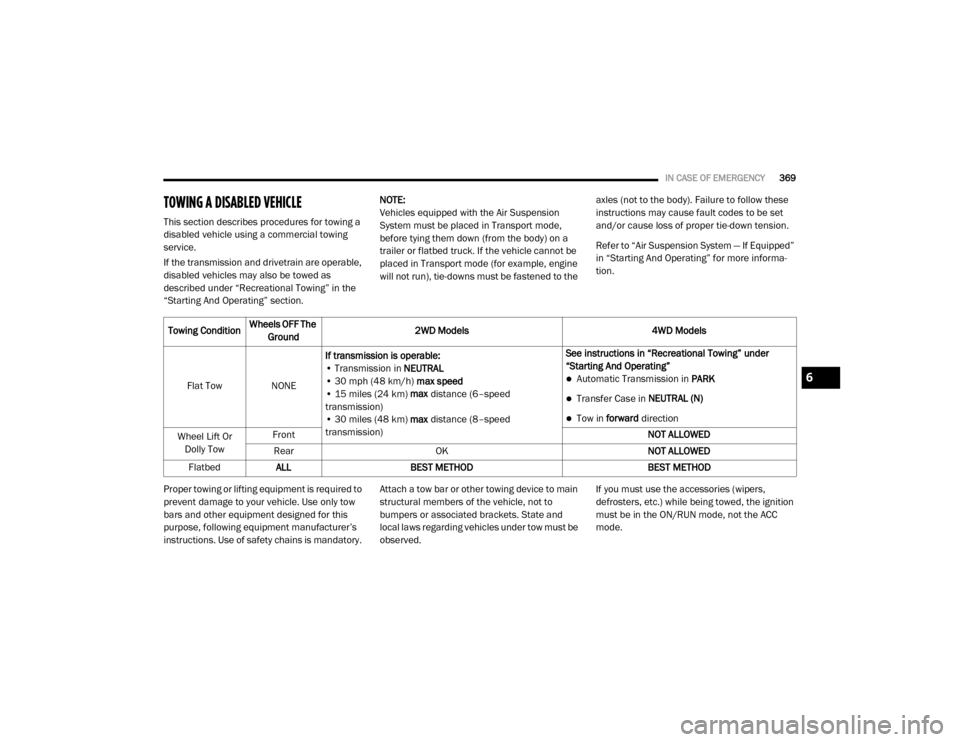

TOWING A DISABLED VEHICLE

This section describes procedures for towing a

disabled vehicle using a commercial towing

service.

If the transmission and drivetrain are operable,

disabled vehicles may also be towed as

described under “Recreational Towing” in the

“Starting And Operating” section. NOTE:

Vehicles equipped with the Air Suspension

System must be placed in Transport mode,

before tying them down (from the body) on a

trailer or flatbed truck. If the vehicle cannot be

placed in Transport mode (for example, engine

will not run), tie-downs must be fastened to the

axles (not to the body). Failure to follow these

instructions may cause fault codes to be set

and/or cause loss of proper tie-down tension.

Refer to “Air Suspension System — If Equipped”

in “Starting And Operating” for more informa

-

tion.

Proper towing or lifting equipment is required to

prevent damage to your vehicle. Use only tow

bars and other equipment designed for this

purpose, following equipment manufacturer’s

instructions. Use of safety chains is mandatory. Attach a tow bar or other towing device to main

structural members of the vehicle, not to

bumpers or associated brackets. State and

local laws regarding vehicles under tow must be

observed.If you must use the accessories (wipers,

defrosters, etc.) while being towed, the ignition

must be in the ON/RUN mode, not the ACC

mode.

Towing Condition

Wheels OFF The

Ground 2WD Models

4WD Models

Flat Tow NONE If transmission is operable:

• Transmission in NEUTRAL

• 30 mph (48 km/h) max speed

• 15 miles (24 km) max distance (6–speed

transmission)

• 30 miles (48 km) max distance (8–speed

transmission) See instructions in “Recreational Towing” under

“Starting And Operating”

Automatic Transmission in

PARK

Transfer Case in NEUTRAL (N)

Tow in forward direction

Wheel Lift Or Dolly Tow Front

NOT ALLOWED

Rear OK NOT ALLOWED

Flatbed ALL BEST METHOD BEST METHOD

6

20_DJD2_OM_EN_USC_t.book Page 369

Page 374 of 553

372IN CASE OF EMERGENCY

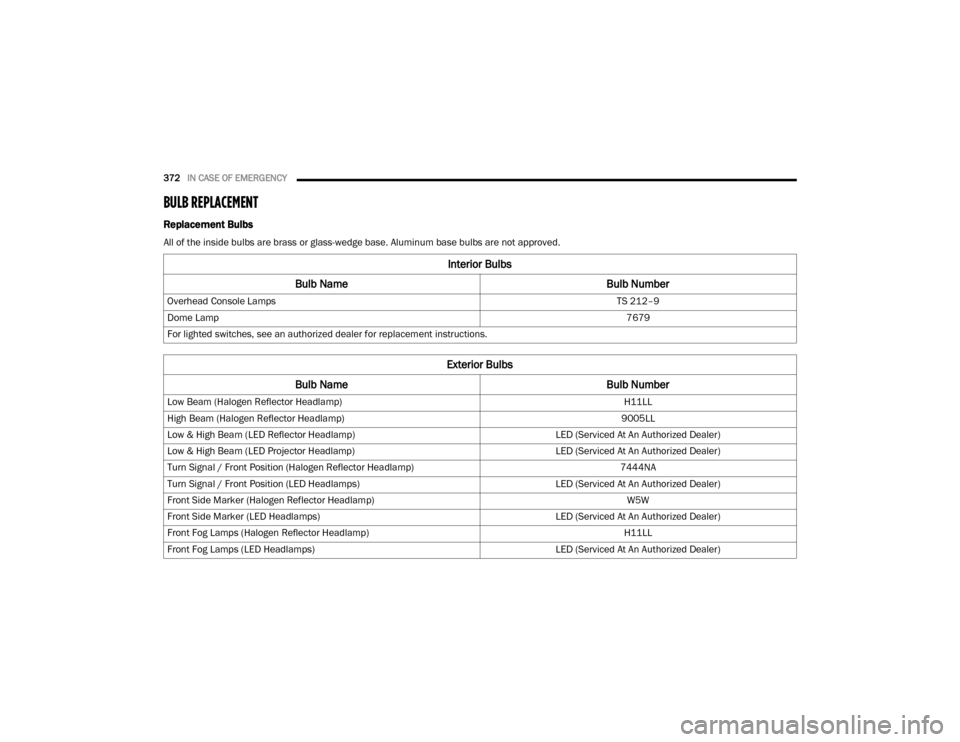

BULB REPLACEMENT

Replacement Bulbs

All of the inside bulbs are brass or glass-wedge base. Aluminum base bulbs are not approved.

Interior Bulbs

Bulb Name Bulb Number

Overhead Console Lamps TS 212–9

Dome Lamp 7679

For lighted switches, see an authorized dealer for replacement instructions.

Exterior Bulbs

Bulb Name Bulb Number

Low Beam (Halogen Reflector Headlamp) H11LL

High Beam (Halogen Reflector Headlamp) 9005LL

Low & High Beam (LED Reflector Headlamp) LED (Serviced At An Authorized Dealer)

Low & High Beam (LED Projector Headlamp) LED (Serviced At An Authorized Dealer)

Turn Signal / Front Position (Halogen Reflector Headlamp) 7444NA

Turn Signal / Front Position (LED Headlamps) LED (Serviced At An Authorized Dealer)

Front Side Marker (Halogen Reflector Headlamp) W5W

Front Side Marker (LED Headlamps) LED (Serviced At An Authorized Dealer)

Front Fog Lamps (Halogen Reflector Headlamp) H11LL

Front Fog Lamps (LED Headlamps) LED (Serviced At An Authorized Dealer)

20_DJD2_OM_EN_USC_t.book Page 372