wheel Ram 3500 Chassis Cab 2019 Owners Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2019, Model line: 3500 Chassis Cab, Model: Ram 3500 Chassis Cab 2019Pages: 607, PDF Size: 10.72 MB

Page 376 of 607

374 IN CASE OF EMERGENCY

(Continued)

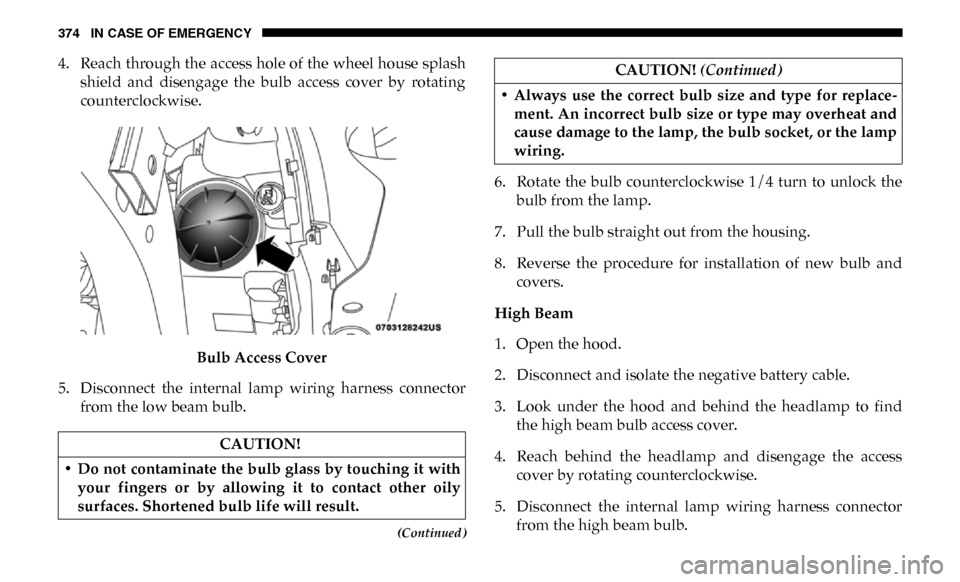

4. Reach through the access hole of the wheel house splashshield and disengage the bulb access cover by rotating

counterclockwise.

Bulb Access Cover

5. Disconnect the internal lamp wiring harness connector from the low beam bulb. 6. Rotate the bulb counterclockwise 1/4 turn to unlock the

bulb from the lamp.

7. Pull the bulb straight out from the housing.

8. Reverse the procedure for installation of new bulb and covers.

High Beam

1. Open the hood.

2. Disconnect and isolate the negative battery cable.

3. Look under the hood and behind the headlamp to find the high beam bulb access cover.

4. Reach behind the headlamp and disengage the access cover by rotating counterclockwise.

5. Disconnect the internal lamp wiring harness connector from the high beam bulb.

CAUTION!

• Do not contaminate the bulb glass by touching it with your fingers or by allowing it to contact other oily

surfaces. Shortened bulb life will result.

• Always use the correct bulb size and type for replace -

ment. An incorrect bulb size or type may overheat and

cause damage to the lamp, the bulb socket, or the lamp

wiring. CAUTION!

(Continued)

Page 378 of 607

376 IN CASE OF EMERGENCY

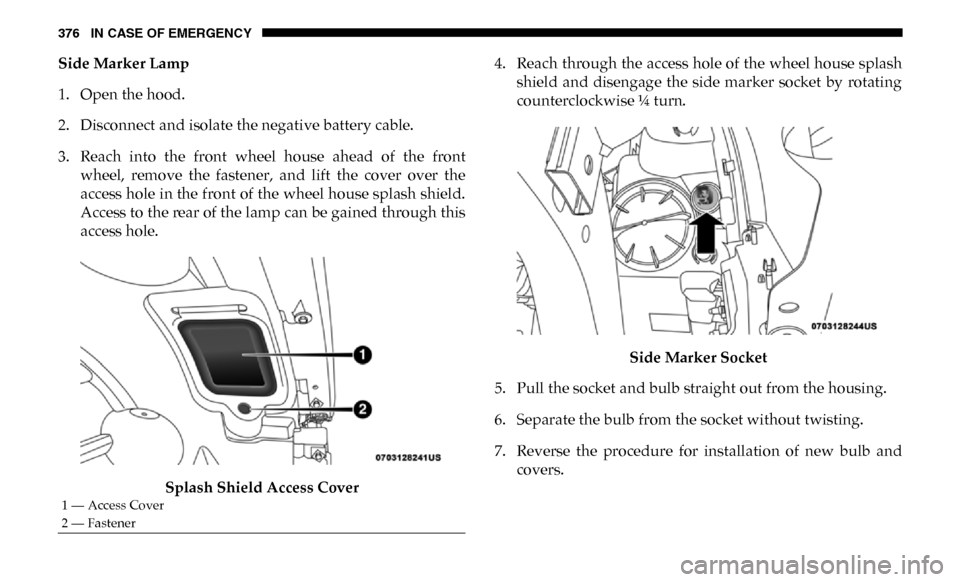

Side Marker Lamp

1. Open the hood.

2. Disconnect and isolate the negative battery cable.

3. Reach into the front wheel house ahead of the frontwheel, remove the fastener, and lift the cover over the

access hole in the front of the wheel house splash shield.

Access to the rear of the lamp can be gained through this

access hole.

Splash Shield Access Cover 4. Reach through the access hole of the wheel house splash

shield and disengage the side marker socket by rotating

counterclockwise ¼ turn.

Side Marker Socket

5. Pull the socket and bulb straight out from the housing.

6. Separate the bulb from the socket without twisting.

7. Reverse the procedure for installation of new bulb and covers.

1 — Access Cover

2 — Fastener

Page 386 of 607

384 IN CASE OF EMERGENCY

F3430 Amp Pink –Vehicle System Interface Module #2 – If Equipped

(HD Only)

SSV (DS 1500 Only)

F35 30 Amp Pink –Sunroof – If Equipped

F36 30 Amp Pink –Electric Back Light – If Equipped

F37 30 Amp Pink –Fuel Heater #2, Aux Relay 2 – If Equipped (HD Only)

SSV (DS 1500 Only)

F38 30 Amp Pink –Integrated Trailer Brake Module – If Equipped

(HD Only)

Power Inverter 115V AC – If Equipped (DS 1500 Only)

F39 20 Amp Blue

–

Power Outlet – SSV Only

F40 –10 Amp Red Ventilated Seats – If Equipped (HD Only)

F41 –10 Amp Red Active Grille Shutter / Active Air Dam – If Equipped

F42 –20 Amp Yellow Horn

F43 –15 Amp Blue Heated Steering Wheel – If Equipped (HD Only)

F44 –10 Amp Red Diagnostic Port

F46 –10 Amp Red Upfitters Relay Coil – If Equipped (HD Only)

Spare (DS 1500 Only)

F49 –10 Amp Red Instrument Panel Cluster / HVAC (DS 1500 Only)

Instrument Cluster / MOD CSG (HD Only)

Cavity Cartridge Fuse

Micro FuseDescription

Page 391 of 607

IN CASE OF EMERGENCY 389

F94–10 Amp Red Shift-By-Wire / Transfer Case Switch (DS 1500 Only)

Shift-By-Wire / Transfer Case Switch / Module TPM

Trailer (HD Only) / Module Gateway Can-C Trailer

TPM (HD Only)

F95 –10 Amp Red Rearview Camera / Park Assist / CHMSL Camera /

Blind Spot Sensor / Surround View Camera (HD Only)

Rear Camera / Park Assist / Blind Spot Sensor /

Compass (DS 1500 Only)

F96 –10 Amp Red Rear Seat Heater Switch / Trunk Lamp With Flashlamp

Charger / Truck Lamp - If Equipped (DS 1500 Only)

Trailer Camera – If Equipped (HD Only)

F97 –25 Amp Clear Rear Heated Seats And Heated Steering Wheel – If

Equipped (DS 1500 Only)

F97 –20 Amp Yellow Front Heated Seat Passenger – If Equipped (HD Only)

F98 –25 Amp Clear Front Heated Seats – If Equipped (DS 1500 Only)

F98 –20 Amp Yellow Front Heated Seat Driver – If Equipped (HD Only)

F99 –10 Amp Red HVAC / DASM (DS 1500 Only)

HVAC / In-Car Temperature Sensor / CSG MOD /

Humidity Sensor (HD Only)

F100 –10 Amp Red Upfitters – If Equipped (HD Only)

F101 –15 Amp Blue SSV Only

F101 –20 Amp Yellow Rear Heated Seat Right (HD Only)

Cavity Cartridge Fuse

Micro FuseDescription

6

Page 392 of 607

390 IN CASE OF EMERGENCY

(Continued)

JACKING AND TIRE CHANGING

F102–20 Amp Yellow Rear Heated Seat Left / Run RLY #3 Coil (HD Only)

F103 –10 Amp Red HeadLamp AFLS (HD Only)

F104 –20 Amp Yellow Power Outlets (Instrument Panel / Center Console) /

Trunk – If Equipped (DS 1500 Only)

UCI Port / USB Rear (HD Only)

Cavity Cartridge Fuse

Micro FuseDescription

CAUTION!

• When installing the power distribution center cover, it is important to ensure the cover is properly positioned

and fully latched. Failure to do so may allow water to

get into the power distribution center and possibly

result in an electrical system failure.

• When replacing a blown fuse, it is important to use only a fuse having the correct amperage rating. The use

of a fuse with a rating other than indicated may result

in a dangerous electrical system overload. If a properly

rated fuse continues to blow, it indicates a problem in

the circuit that must be corrected.

WARNING!

• Do not attempt to change a tire on the side of the vehicle close to moving traffic. Pull far enough off the road to

avoid the danger of being hit when operating the jack

or changing the wheel.

• Being under a jacked-up vehicle is dangerous. The vehicle could slip off the jack and fall on you. You

could be crushed. Never put any part of your body

under a vehicle that is on a jack. If you need to get

under a raised vehicle, take it to a service center where

it can be raised on a lift.

• Never start or run the engine while the vehicle is on a jack.

Page 393 of 607

IN CASE OF EMERGENCY 391

4500/5500 Models

These vehicles do not come equipped with a jack.

NOTE:

Jacking and tire changing on 4500/5500 models should be

performed by an authorized dealer, or knowledgeable

service personnel with the appropriate heavy duty equip-

ment, like a tire service company.

Preparations For Jacking

1. Park the vehicle on a firm, level surface. Avoid ice or slip -

pery areas.

2. Place the gear selector into PARK. On four-wheel drive vehicles, shift the transfer case to the 4L position.

3. Turn on the Hazard Warning flasher.

4. Apply the parking brake.

5. Turn the ignition OFF.

• The jack is designed to be used as a tool for changing

tires only. The jack should not be used to lift the

vehicle for service purposes. The vehicle should be

jacked on a firm level surface only. Avoid ice or slip -

pery areas.

WARNING! (Continued)

WARNING!

Do not attempt to change a tire on the side of the vehicle

close to moving traffic. Pull far enough off the road to

avoid being hit when operating the jack or changing the

wheel.

6

Page 394 of 607

392 IN CASE OF EMERGENCY

(Continued)

6. Block both the front and rear of the wheel diagonallyopposite the jacking position. For example, if the right

front wheel is being changed, block the left rear wheel.

Wheel Blocked

NOTE:

Passengers should not remain in the vehicle when the

vehicle is being jacked.Jacking Instructions 4500 And 5500 Series

WARNING!

Carefully follow these tire changing warnings to help

prevent personal injury or damage to your vehicle:

• Always park on a firm, level surface as far from the edge of the roadway as possible before raising the

vehicle.

• Turn on the Hazard Warning flasher.

• Block the wheel diagonally opposite the wheel to be raised.

• Apply the parking brake firmly and set the transmis -

sion in PARK.

• Never start or run the engine with the vehicle on a jack.

• Do not let anyone sit in the vehicle when it is on a jack.

• Do not get under the vehicle when it is on a jack. If you need to get under a raised vehicle, take it to a service

center where it can be raised on a lift.

• Only use the jack in the positions indicated and for lifting this vehicle during a tire change.

• If working on or near a roadway, be extremely careful of motor traffic.

Page 395 of 607

IN CASE OF EMERGENCY 393

Jack Warning Label1. If equipped, remove the spare wheel, jack, and tools from

storage.

2. Using the lug wrench, loosen, but do not remove, the lug nuts by turning them counterclockwise one turn while

the wheel is still on the ground.

• To assure that spare tires, flat or inflated, are securely

stowed, spares must be stowed with the valve stem

facing the ground.

WARNING! (Continued)CAUTION!

Do not attempt to raise the vehicle by jacking on

locations other than those indicated in the Jacking

Instructions for this vehicle.

6

Page 396 of 607

394 IN CASE OF EMERGENCY

3. When changing the front wheel, assemble the jack driverto the jack and connect the jack driver to the extension

tube. Place the jack under the axle as close to the tire as

possible with the jack driver extending to the front.

Connect the extension tubes and lug wrench.

Front Jacking Locations

When changing a rear wheel, assemble the jack driver to

the jack and connect the jack driver to the extension tubes.

Securely place the jack under the sway bar bracket (unless

both tires are flat on one side, then place jack under shock

bracket) facing forward in vehicle. Connect the extension

tubes and lug wrench. Rear Jacking Location

Before raising the wheel off the ground, make sure that

the jack will not damage surrounding truck parts and

adjust the jack position as required.

NOTE:

If the jack will not lower by turning the dial (thumbwheel) by

hand, it may be necessary to use the jack driver in order to

lower the jack.

4. By rotating the lug wrench clockwise, raise the vehicle until the wheel just clears the surface.

Page 397 of 607

IN CASE OF EMERGENCY 395

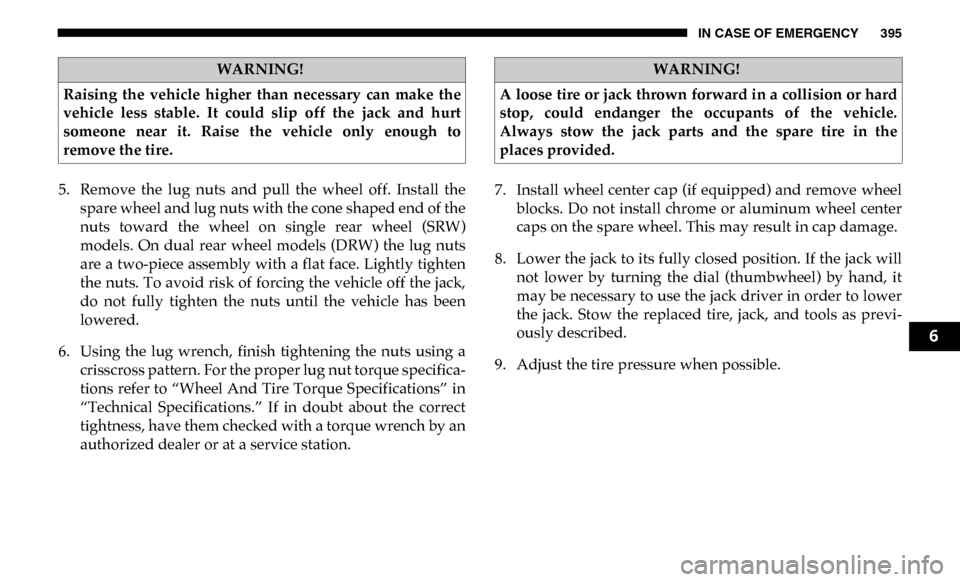

5. Remove the lug nuts and pull the wheel off. Install thespare wheel and lug nuts with the cone shaped end of the

nuts toward the wheel on single rear wheel (SRW)

models. On dual rear wheel models (DRW) the lug nuts

are a two-piece assembly with a flat face. Lightly tighten

the nuts. To avoid risk of forcing the vehicle off the jack,

do not fully tighten the nuts until the vehicle has been

lowered.

6. Using the lug wrench, finish tightening the nuts using a crisscross pattern. For the proper lug nut torque specifica -

tions refer to “Wheel And Tire Torque Specifications” in

“Technical Specifications.” If in doubt about the correct

tightness, have them checked with a torque wrench by an

authorized dealer or at a service station. 7. Install wheel center cap (if equipped) and remove wheel

blocks. Do not install chrome or aluminum wheel center

caps on the spare wheel. This may result in cap damage.

8. Lower the jack to its fully closed position. If the jack will not lower by turning the dial (thumbwheel) by hand, it

may be necessary to use the jack driver in order to lower

the jack. Stow the replaced tire, jack, and tools as previ -

ously described.

9. Adjust the tire pressure when possible.

WARNING!

Raising the vehicle higher than necessary can make the

vehicle less stable. It could slip off the jack and hurt

someone near it. Raise the vehicle only enough to

remove the tire.WARNING!

A loose tire or jack thrown forward in a collision or hard

stop, could endanger the occupants of the vehicle.

Always stow the jack parts and the spare tire in the

places provided.

6