turn signal Ram ProMaster 2020 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2020, Model line: ProMaster, Model: Ram ProMaster 2020Pages: 264, PDF Size: 10.11 MB

Page 65 of 264

SAFETY63

The TPMS is not a substitute for proper tire

maintenance, and it is the driver’s responsi -

bility to maintain correct tire pressure using

an accurate tire pressure gauge, even if

under-inflation has not reached the level to

trigger illumination of the TPMS Warning

Light.

Seasonal temperature changes will affect

tire pressure, and the TPMS will monitor the

actual tire pressure in the tire.

Base System

This is the TPMS warning indicator

located in the instrument cluster.

The TPMS uses wireless technology

with wheel rim mounted electronic

sensors to monitor tire pressure levels.

Sensors, mounted to each wheel as part of the

valve stem, transmit tire pressure readings to

the Receiver Module.

NOTE:

It is particularly important for you to check the

tire pressure in all of the tires on your vehicle

regularly and to maintain the proper pressure.

The TPMS consists of the following components:

Receiver Module

Four Tire Pressure Monitoring sensors

Tire Pressure Monitoring System Warning

Light

Tire Pressure Monitoring Low Pressure Warnings

The Tire Pressure Monitoring System Warning

Light will illuminate in the instrument cluster, an

audible chime will be activated, and the “Check

tire pressure” message will display when one or

more of the four active road tire pressures are

low. Should this occur, you should stop as soon

as possible, check the inflation pressure of

each tire on your vehicle, and inflate each tire to

the vehicle’s recommended cold placard pres

-

sure value. The system will automatically

update and the Tire Pressure Monitoring Light

will extinguish once the updated tire pressures

have been received. The vehicle may need to be

driven for up to 20 minutes above 15 mph

(24 km/h) to receive this information.

Check TPMS Warnings

The Tire Pressure Monitoring System Warning

Light will flash on and off for 75 seconds and

remain on solid when a system fault is detected,

an audible chime will be activated and the “Tire

Pressure Monitoring Unavailable” message will

display. If the ignition key is cycled, this

sequence will repeat providing the system fault

still exists. The TPMS Warning Light will turn off

when the fault condition no longer exists. A

system fault can occur with any of the following

scenarios:

Jamming due to electronic devices or driving

next to facilities emitting the same radio

frequencies as the TPM sensors

Installing some form of aftermarket window

tinting that affects radio wave signals

Snow or ice around the wheels or wheel

housings

Using tire chains on the vehicle

Using wheels/tires not equipped with TPM

sensors

4

20_VF_OM_EN_US_t.book Page 63

Page 68 of 264

66SAFETY

Seat Belt Systems

Buckle up even though you are an excellent

driver, even on short trips. Someone on the road

may be a poor driver and could cause a collision

that includes you. This can happen far away

from home or on your own street.

Research has shown that seat belts save lives,

and they can reduce the seriousness of injuries

in a collision. Some of the worst injuries happen

when people are thrown from the vehicle. Seat

belts reduce the possibility of ejection and the

risk of injury caused by striking the inside of the

vehicle. Everyone in a motor vehicle should be

belted at all times.

Enhanced Seat Belt Use Reminder System

(BeltAlert)

Driver and Passenger BeltAlert — If Equipped

BeltAlert is a feature intended to remind

the driver and outboard front seat passenger

(if equipped with outboard front passenger

seat BeltAlert) to buckle their seat belts. The

BeltAlert feature is active whenever the igni -

tion switch is in the AVV/START or MAR/RUN

position. Initial Indication

If the driver is unbuckled when the ignition

switch is first in the AVV/START or MAR/RUN

position, a chime will signal for a few seconds. If

the driver or outboard front seat passenger (if

equipped with outboard front passenger seat

BeltAlert) is unbuckled when the ignition switch

is first in the AVV/START or MAR/RUN position

the Seat Belt Reminder Light will turn on and

remain on until both outboard front seat belts

are buckled. The outboard front passenger seat

BeltAlert is not active when an outboard front

passenger seat is unoccupied.

BeltAlert Warning Sequence

The BeltAlert warning sequence is activated

when the vehicle is moving above a specified

vehicle speed range and the driver or outboard

front seat passenger is unbuckled (if equipped

with outboard front passenger seat BeltAlert)

(the outboard front passenger seat BeltAlert is

not active when the outboard front passenger

seat is unoccupied). The BeltAlert warning

sequence starts by blinking the Seat Belt

Reminder Light and sounding an intermittent

chime. Once the BeltAlert warning sequence

has completed, the Seat Belt Reminder Light will remain on until the seat belts are buckled.

The BeltAlert warning sequence may repeat

based on vehicle speed until the driver and

occupied outboard front seat passenger seat

belts are buckled. The driver should instruct all

occupants to buckle their seat belts.

Change of Status

If the driver or outboard front seat passenger (if

equipped with outboard front passenger seat

BeltAlert) unbuckles their seat belt while the

vehicle is traveling, the BeltAlert warning

sequence will begin until the seat belts are

buckled again.

The outboard front passenger seat BeltAlert is

not active when the outboard front passenger

seat is unoccupied. BeltAlert may be triggered

when an animal or other items are placed on

the outboard front passenger seat or when the

seat is folded flat (if equipped). It is recom

-

mended that pets be restrained in the rear seat

(if equipped) in pet harnesses or pet carriers

that are secured by seat belts, and cargo is

properly stowed.

BeltAlert can be activated or deactivated by an

authorized dealer. FCA US LLC does not recom -

mend deactivating BeltAlert.

20_VF_OM_EN_US_t.book Page 66

Page 93 of 264

SAFETY91

(Continued)

Periodic Safety Checks You Should Make

Outside The Vehicle

Tires

Examine tires for excessive tread wear and

uneven wear patterns. Check for stones, nails,

glass, or other objects lodged in the tread or

sidewall. Inspect the tread for cuts and cracks.

Inspect sidewalls for cuts, cracks, and bulges.

Check the wheel bolts for tightness. Check the

tires (including spare) for proper cold inflation

pressure.

Lights

Have someone observe the operation of brake

lights and exterior lights while you work the

controls. Check turn signal and high beam indi -

cator lights on the instrument panel.

Door Latches

Check for proper closing, latching, and locking.

Fluid Leaks

Check area under the vehicle after overnight

parking for fuel, coolant, oil, or other fluid leaks.

Also, if gasoline fumes are detected or if fuel, or

brake fluid leaks are suspected, the cause

should be located and corrected immediately.

ONLY install floor mats designed to fit your

vehicle. NEVER install a floor mat that

cannot be properly attached and secured to

your vehicle. If a floor mat needs to be

replaced, only use a FCA approved floor

mat for the specific make, model, and year

of your vehicle.

ONLY use the driver’s side floor mat on the

driver’s side floor area. To check for inter -

ference, with the vehicle properly parked

with the engine off, fully depress the accel -

erator, the brake, and the clutch pedal (if

present) to check for interference. If your

floor mat interferes with the operation of

any pedal, or is not secure to the floor,

remove the floor mat from the vehicle and

place the floor mat in your trunk.

ONLY use the passenger’s side floor mat on

the passenger’s side floor area.

WARNING!

(Continued)

ALWAYS make sure objects cannot fall or

slide into the driver’s side floor area when

the vehicle is moving. Objects can become

trapped under accelerator, brake, or clutch

pedals and could cause a loss of vehicle

control.

NEVER place any objects under the floor

mat (e.g., towels, keys, etc.). These objects

could change the position of the floor mat

and may cause interference with the accel -

erator, brake, or clutch pedals.

If the vehicle carpet has been removed and

re-installed, always properly attach carpet

to the floor and check the floor mat

fasteners are secure to the vehicle carpet.

Fully depress each pedal to check for inter -

ference with the accelerator, brake, or

clutch pedals then re-install the floor mats.

It is recommended to only use mild soap

and water to clean your floor mats. After

cleaning, always check your floor mat has

been properly installed and is secured to

your vehicle using the floor mat fasteners

by lightly pulling mat.

WARNING!

(Continued)

4

20_VF_OM_EN_US_t.book Page 91

Page 110 of 264

108STARTING AND OPERATING

While audible signals are emitted, the audio

system is not muted.

The audible signal is turned off immediately if

the distance increases. The tone cycle remains

constant if the distance measured by the inner

sensors is constant. If this condition occurs for

the external sensors, the signal is turned off

after three seconds (stopping warnings during

maneuvers parallel to walls).

ParkSense Rear Park Assist Failure

Indications

A malfunction of the ParkSense Rear Park

Assist sensors or system is indicated, during

REVERSE gear engagement, by the instrument

panel warning icon.

The warning icon is illuminated and a

message is displayed in the instru -

ment cluster display (if equipped).

Refer to “Warning Lights And

Messages” in “Getting To Know Your Instru -

ment Panel” for further information.

The sensors and wiring are tested continuously

when the ignition is in the MAR (ACC/ON/RUN)

position. Failures are indicated immediately if

they occur when the system is on. Even if the system is able to identify that a

specific sensor is in failure condition, the instru

-

ment cluster display shall indicate that the Park-

Sense Rear Park Assist system is unavailable,

without reference to the sensor in failure condi -

tion. If even a single sensor fails, the entire

system must be disabled. The system is turned

off automatically.

Cleaning The ParkSense System

Clean the Rear Park Assist sensors with water,

car wash soap and a soft cloth. Do not use

rough or hard cloths. In washing stations, clean

sensors quickly keeping the vapor jet/high pres -

sure washing nozzles at least 4 inches (10 cm)

from the sensors. Do not scratch or poke the

sensors. Otherwise, you could damage the

sensors.

ParkSense Rear Park Assist System Usage

Precautions

NOTE:

Ensure that the outer surface and the under -

side of the rear bumper is clean and clear of

snow, ice, mud, dirt or other obstruction to

keep the Rear Park Assist system operating

properly.

Jackhammers, large trucks, and other vibra -

tions could affect the performance of Rear

Park Assist.

Clean the Rear Park Assist sensors regularly,

taking care not to scratch or damage them.

The sensors must not be covered with ice,

snow, slush, mud, dirt or debris. Failure to do

so can result in the system not working prop -

erly. The Rear Park Assist system might not

detect an obstacle behind the fascia/

bumper, or it could provide a false indication

that an obstacle is behind the fascia/

bumper.

Objects such as bicycle carriers, etc., must

not be placed within 12 inches (30 cm) from

the rear fascia/bumper while driving the

vehicle. Failure to do so can result in the

system misinterpreting a close object as a

sensor problem, causing a failure indication

to be displayed in the instrument cluster

display.

20_VF_OM_EN_US_t.book Page 108

Page 120 of 264

118STARTING AND OPERATING

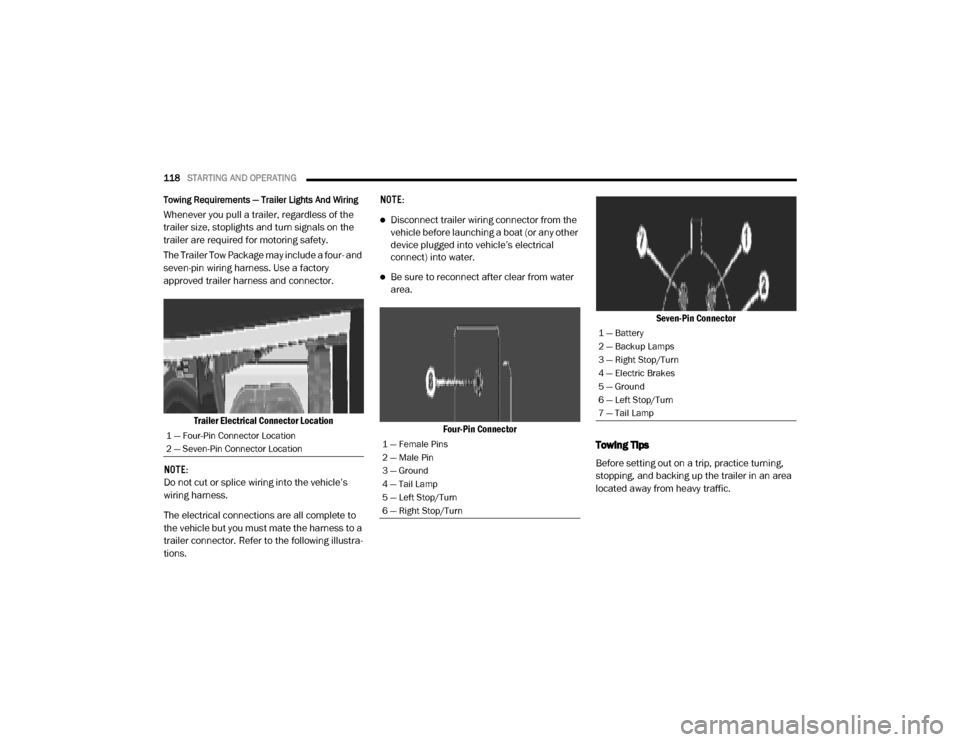

Towing Requirements — Trailer Lights And Wiring

Whenever you pull a trailer, regardless of the

trailer size, stoplights and turn signals on the

trailer are required for motoring safety.

The Trailer Tow Package may include a four- and

seven-pin wiring harness. Use a factory

approved trailer harness and connector.

Trailer Electrical Connector Location

NOTE:

Do not cut or splice wiring into the vehicle’s

wiring harness.

The electrical connections are all complete to

the vehicle but you must mate the harness to a

trailer connector. Refer to the following illustra -

tions. NOTE:Disconnect trailer wiring connector from the

vehicle before launching a boat (or any other

device plugged into vehicle’s electrical

connect) into water.

Be sure to reconnect after clear from water

area.

Four-Pin Connector Seven-Pin Connector

Towing Tips

Before setting out on a trip, practice turning,

stopping, and backing up the trailer in an area

located away from heavy traffic.

1 — Four-Pin Connector Location

2 — Seven-Pin Connector Location1 — Female Pins

2 — Male Pin

3 — Ground

4 — Tail Lamp

5 — Left Stop/Turn

6 — Right Stop/Turn

1 — Battery

2 — Backup Lamps

3 — Right Stop/Turn

4 — Electric Brakes

5 — Ground

6 — Left Stop/Turn

7 — Tail Lamp

20_VF_OM_EN_US_t.book Page 118

Page 125 of 264

123

IN CASE OF EMERGENCY

HAZARD WARNING FLASHERS

The Hazard Warning flashers switch is located

on the instrument panel below the climate

controls.Push the switch to turn on the Hazard

Warning flashers. When the switch is

activated, all directional turn signals will flash on and off to warn oncoming traffic of

an emergency. Push the switch a second time to

turn off the Hazard Warning flashers.

This is an emergency warning system and it

should not be used when the vehicle is in

motion. Use it when your vehicle is disabled and

it is creating a safety hazard for other motorists.

When you must leave the vehicle to seek assis

-

tance, the Hazard Warning flashers will

continue to operate even though the ignition is

placed in the OFF position.

NOTE:

With extended use, the Hazard Warning

flashers may wear down your battery.

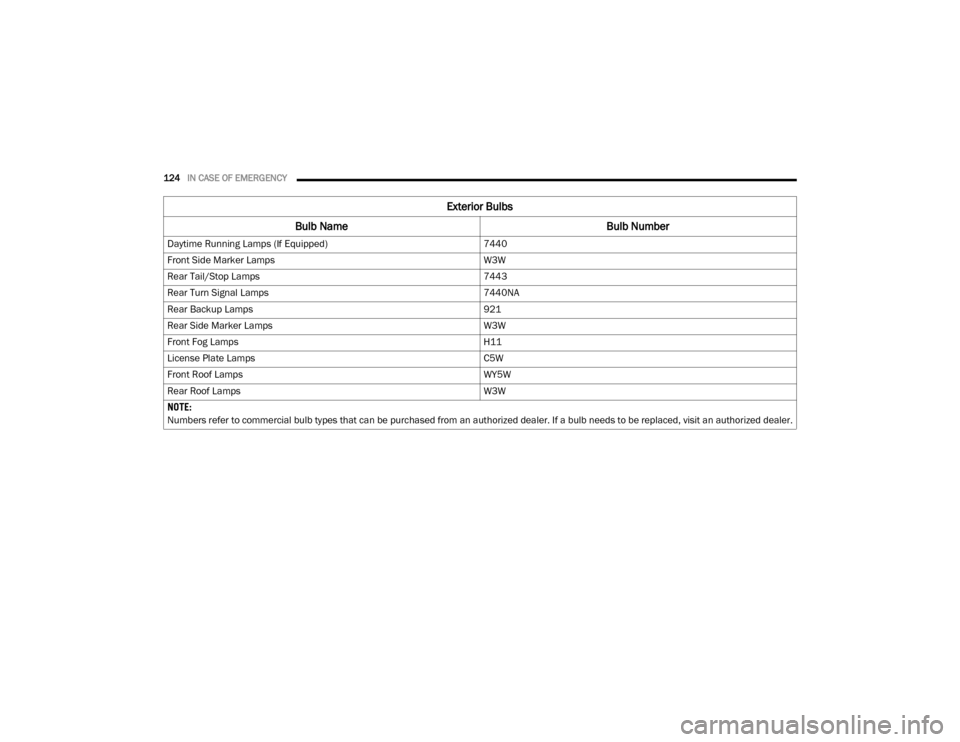

BULB REPLACEMENT

Replacement Bulbs

Interior Bulbs

Bulb Name Bulb Number

Dome Lamp C5W

Courtesy Lamp FF500

Cargo Lamp C5W

Exterior Bulbs

Bulb Name Bulb Number

Front Low and High Beam Headlamp H7SLL

Front Park/Turn Signal Lamps 7444NA

6

20_VF_OM_EN_US_t.book Page 123

Page 126 of 264

124IN CASE OF EMERGENCY

Daytime Running Lamps (If Equipped) 7440

Front Side Marker Lamps W3W

Rear Tail/Stop Lamps 7443

Rear Turn Signal Lamps 7440NA

Rear Backup Lamps 921

Rear Side Marker Lamps W3W

Front Fog Lamps H11

License Plate Lamps C5W

Front Roof Lamps WY5W

Rear Roof Lamps W3W

NOTE:

Numbers refer to commercial bulb types that can be purchased from an authorized dealer. If a bulb needs to be replaced, visit an authorized dealer.

Exterior Bulbs

Bulb Name Bulb Number

20_VF_OM_EN_US_t.book Page 124

Page 127 of 264

IN CASE OF EMERGENCY125

Replacing Exterior Bulbs

Headlamps Low Beam And High beam

1. Remove one retaining screw on the lower

headlamp filler panel. Remove filler panel.

2. Remove two retaining screws on the upper headlamp filler panel. Remove filler panel.

3. Remove one upper retaining screw from the headlamp housing.

4. Remove two lower retaining screws from the headlamp housing.

5. Pull Headlamp forward, disconnect harness electrical connector and remove the head -

lamp assembly from vehicle.

6. Remove appropriate plastic cap from the back of the headlamp housing.

7. Push down on the upper portion of the socket.

8. Pull the socket outward from reflector.

9. Pull bulb outward from socket.

10. Install new bulb. 11. Push socket back into reflector until it locks

back into place.

12. Install access cap.

13. Carefully reinstall headlamp in the same position on the vehicle, so as not to affect

headlamp aiming.

14. Install one upper retaining screw on the headlamp housing.

15. Install two lower retaining screws on the headlamp housing.

16. Carefully reinstall the lower headlamp filler panel and one retaining screw.

17. Carefully reinstall the upper headlamp filler panel and two retaining screws.

Front Turn Signal/Parking Lamps

1. Remove one retaining screw on the lowerheadlamp filler panel. Remove filler panel.

2. Remove two retaining screws on the upper headlamp filler panel. Remove filler panel.

3. Remove one upper retaining screw from the headlamp housing. 4. Remove two lower retaining screws from

the headlamp housing.

5. Pull Headlamp forward, disconnect the harness electrical connector and remove

the headlamp assembly from vehicle.

6. Rotate the bulb counterclockwise and remove.

7. Install the bulb into socket, and rotate bulb/ socket clockwise into lamp locking it in

place.

8. Carefully reinstall headlamp in the same position on the vehicle, so as not to affect

headlamp aiming.

9. Install the one upper retaining screw on headlamp housing.

10. Install the two lower retaining screws on headlamp housing.

11. Carefully reinstall the lower headlamp filler panel and one retaining screw.

12. Carefully reinstall the upper headlamp filler panel and two retaining screws.

6

20_VF_OM_EN_US_t.book Page 125

Page 128 of 264

126IN CASE OF EMERGENCY

Daytime Running Lamp (DRL)/Front Side Marker

Lamp

1. Remove one retaining screw on the lower headlamp filler panel. Remove filler panel.

2. Remove two retaining screws on the upper headlamp filler panel. Remove filler panel.

3. Remove one upper retaining screw from the headlamp housing.

4. Remove two lower retaining screws from the headlamp housing.

5. Pull Headlamp forward, disconnect the harness electrical connector and remove

the headlamp assembly from vehicle.

6. Remove the Daytime Running Lamp (DRL), side marker bulb by pulling straight out.

7. Replace lamp as required and lock in place.

8. Reinstall plastic cap.

9. Carefully reinstall headlamp in the same position on the vehicle, as not to affect

headlamp aiming.

10. Install the one upper retaining screw on the headlamp housing. 11. Install the two lower retaining screws on the

headlamp housing.

12. Carefully reinstall the lower headlamp filler panel and one retaining screw.

13. Carefully reinstall the upper headlamp filler panel and two retaining screws.

Front Fog Lamps

1. Turn front wheels inboard to access cover inwheel liner.

2. Open the cover on the front of the wheel liner.

3. Remove connection and replace the bulb.

4. Connect the wire and rotate bulb/socket clockwise into lamp locking it in place.

5. Reinstall the plastic cap and close the cover on the wheel liner.

Front, Rear Roof Lamps

1. Remove two screw and remove the lampassembly.

2. Remove the socket bulb by turning counter -

clockwise. 3. Remove bulb and replace as needed.

4. Reinstall the bulb socket and rotate clock-

wise to lock in place.

5. Reinstall lamp.

Rear Tail, Stop, Backup, Turn Signal And Rear Side

Marker Lamps

1. Open rear doors.

2. Remove the seven (7) fasteners from the rear access cover and remove cover to gain

access to the Tail lamp assembly fasteners.

Rear Access Cover

20_VF_OM_EN_US_t.book Page 126

Page 129 of 264

IN CASE OF EMERGENCY127

3. Remove the two (2) 17mm tail light

assembly fasteners.

4. Disconnect the tail light harness connector and remove tail light assembly from the

vehicle.

5. Remove the tail/stop, turn signal, backup and rear side marker bulb/socket by

rotating counterclockwise.

6. Remove the bulb and replace as needed.

7. Reinstall bulb/socket and rotate clockwise to lock in place.

8. Reinstall lamp.

Replacing Interior Bulbs

Cargo Lamp

1. Using a suitable tool, remove either the lamp above the back door or the sliding

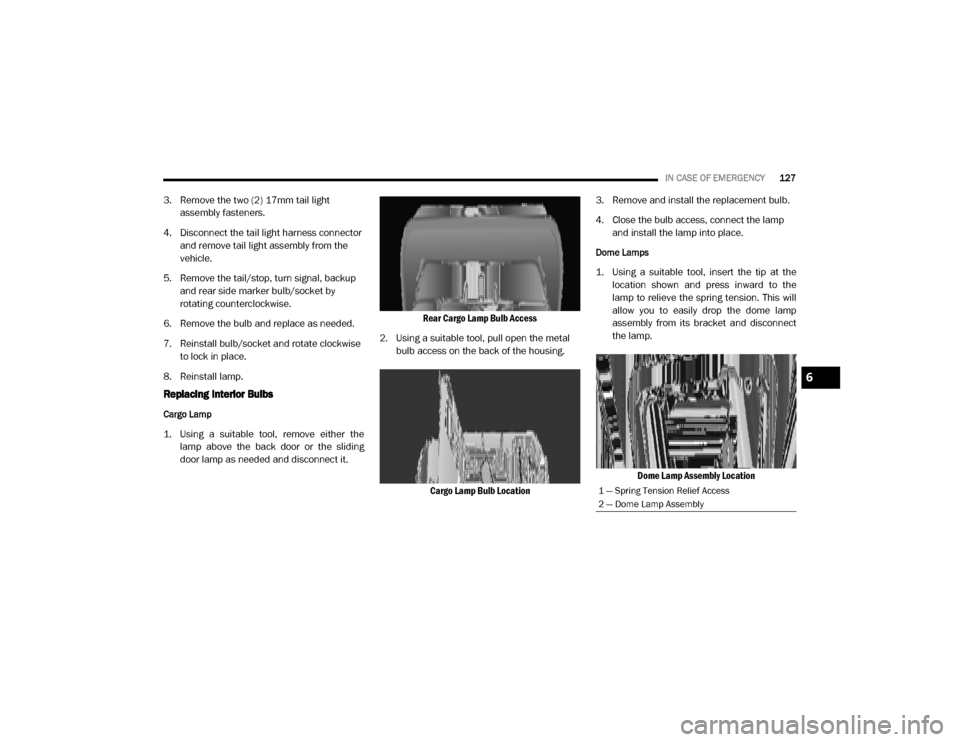

door lamp as needed and disconnect it. Rear Cargo Lamp Bulb Access

2. Using a suitable tool, pull open the metal bulb access on the back of the housing.

Cargo Lamp Bulb Location 3. Remove and install the replacement bulb.

4. Close the bulb access, connect the lamp

and install the lamp into place.

Dome Lamps

1. Using a suitable tool, insert the tip at thelocation shown and press inward to the

lamp to relieve the spring tension. This will

allow you to easily drop the dome lamp

assembly from its bracket and disconnect

the lamp.

Dome Lamp Assembly Location

1 — Spring Tension Relief Access

2 — Dome Lamp Assembly

6

20_VF_OM_EN_US_t.book Page 127