service Ram ProMaster 2020 Owner's Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2020, Model line: ProMaster, Model: Ram ProMaster 2020Pages: 264, PDF Size: 10.11 MB

Page 115 of 264

STARTING AND OPERATING113

The best way to figure out the total weight of

your vehicle is to weigh it when it is fully loaded

and ready for operation. Weigh it on a commer -

cial scale to ensure that it is not over the GVWR.

Figure out the weight on the front and rear axle

of the vehicle separately. It is important that you

distribute the load evenly over the front and rear

axles.

Overloading can cause potential safety hazards

and shorten useful service life. Heavier axles or

suspension components do not necessarily

increase the vehicle's GVWR.

Loading

To load your vehicle properly, first figure out its

empty weight, axle-by-axle and side-by-side.

Store heavier items down low and be sure you

distribute their weight as evenly as possible.

Stow all loose items securely before driving. If

weighing the loaded vehicle shows that you

have exceeded either Gross Axle Weight Rating

(GAWR), but the total load is within the specified

Gross Vehicle Weight Rating (GVWR), you must

redistribute the weight. Improper weight distri -

bution can have an adverse effect on the way

your vehicle steers and handles and the way the

brakes operate. NOTE:

Refer to the “Vehicle Certification Label” affixed

to the rear of the driver's door for your vehicle's

GVWR and GAWRs.

TRAILER TOWING

In this section you will find safety tips and infor

-

mation on limits to the type of towing you can

reasonably do with your vehicle. Before towing a

trailer, carefully review this information to tow

your load as efficiently and safely as possible.

To maintain the New Vehicle Limited Warranty

coverage, follow the requirements and recom -

mendations in this manual concerning vehicles

used for trailer towing.

Common Towing Definitions

The following trailer towing related definitions

will assist you in understanding the following

information:

Gross Vehicle Weight Rating (GVWR)

The Gross Vehicle Weight Rating (GVWR) is the

total allowable weight of your vehicle. This

includes driver, passengers, cargo and tongue

weight. The total load must be limited so that you do not exceed the GVWR. Refer to “Vehicle

Loading/Vehicle Certification Label” in “Starting

And Operating” for further information.

Gross Combination Weight Rating (GCWR)

The Gross Combination Weight Rating (GCWR)

is the total allowable weight of your vehicle and

trailer when weighed in combination.

Gross Trailer Weight (GTW)

The Gross Trailer Weight (GTW) is the weight of

the trailer plus the weight of all cargo, consum

-

ables and equipment (permanent or temporary)

loaded in or on the trailer in its “loaded and

ready for operation” condition.

The recommended way to measure GTW is to

put your fully loaded trailer on a vehicle scale.

The entire weight of the trailer must be

supported by the scale.

Gross Axle Weight Rating (GAWR)

The Gross Axle Weight Rating (GAWR) is the

maximum capacity of the front and rear axles.

Distribute the load over the front and rear axles

evenly. Make sure that you do not exceed either

front or rear GAWR. Refer to “Vehicle Loading/

Vehicle Certification Label” in “Starting And

Operating” for further information.

5

20_VF_OM_EN_US_t.book Page 113

Page 130 of 264

128IN CASE OF EMERGENCY

(Continued)

2. Using a suitable tool, flex the housing to lift

the light pod cover away from the unit.

Dome Lamp Light Pod Cover

3. Remove and replace the bulbs as needed.

Dome Lamp Light Bulbs 4. Close the housing cover making sure it

snaps together properly and connect the

lamp.

5. Install overhead console into place making sure to seat the assembly’s forward end

first and then snapping it flush so that the

tension spring is fully seating in the housing.

FUSESUnderhood Fuses

The Front Power Distribution Center is located

on the driver’s side of the engine compartment.

To access the fuses, remove the cover.

Front Power Distribution Center

The ID number of the electrical component

corresponding to each fuse can be found on the

back of the cover.WARNING!

When replacing a blown fuse, always use

an appropriate replacement fuse with the

same amp rating as the original fuse. Never

replace a fuse with another fuse of higher

amp rating. Never replace a blown fuse with

metal wires or any other material. Do not

place a fuse inside a circuit breaker cavity

or vice versa. Failure to use proper fuses

may result in serious personal injury, fire

and/or property damage.

Before replacing a fuse, make sure that the

ignition is off and that all the other services

are switched off and/or disengaged.

If the replaced fuse blows again, contact an

authorized dealer.

If a general protection fuse for safety

systems (air bag system, braking system),

power unit systems (engine system, trans -

mission system) or steering system blows,

contact an authorized dealer.

WARNING!

(Continued)

20_VF_OM_EN_US_t.book Page 128

Page 135 of 264

IN CASE OF EMERGENCY133

JACKING AND TIRE CHANGING Jack Location

The jack and jack tools are stored under the

front passenger seat in a box, or next to or

behind the driver seat in a tool bag. The box and

the tool bag contain the same items.

Jack Kit Location

To release the jack kit for it’s storage location,

turn the lock knob a quarter turn counterclock -

wise to the unlock position. Lock Knob

To open the jack kit container, you must push

the container’s release to separate the top and

bottom.

Container ReleaseWARNING!

Do not attempt to change a tire on the side

of the vehicle close to moving traffic. Pull

far enough off the road to avoid the danger

of being hit when operating the jack or

changing the wheel.

Being under a jacked-up vehicle is

dangerous. The vehicle could slip off the

jack and fall on you. You could be crushed.

Never put any part of your body under a

vehicle that is on a jack. If you need to get

under a raised vehicle, take it to a service

center where it can be raised on a lift.

Never start or run the engine while the

vehicle is on a jack.

The jack is designed to be used as a tool for

changing tires only. The jack should not be

used to lift the vehicle for service purposes.

The vehicle should be jacked on a firm level

surface only. Avoid ice or slippery areas.

CAUTION!

Do not force lock knob over limit. Damage to

lock knob may occur.

1 — Unlock Position

2 — Lock Position

6

20_VF_OM_EN_US_t.book Page 133

Page 138 of 264

136IN CASE OF EMERGENCY

(Continued)

6. Block both the front and rear of the wheel

diagonally opposite the jacking position. For

example, if the right front wheel is being

changed, block the left rear wheel.

Wheel Blocked

NOTE:

Passengers should not remain in the vehicle

when the vehicle is being lifted or raised.Jacking Instructions

Jack Warning Label

WARNING!

Carefully follow these tire changing warnings

to help prevent personal injury or damage to

your vehicle:

Always park on a firm, level surface as far

from the edge of the roadway as possible

before raising the vehicle.

Turn on the Hazard Warning flashers.

Block the wheel diagonally opposite the

wheel to be raised.

Apply the parking brake firmly and place an

automatic transmission in PARK; a manual

transmission in REVERSE.

Never start or run the engine with the

vehicle on a jack.

Do not let anyone sit in the vehicle when it

is on a jack.

Do not get under the vehicle when it is on a

jack. If you need to get under a raised

vehicle, take it to a service center where it

can be raised on a lift.

Only use the jack in the positions indicated

and for lifting this vehicle during a tire

change.

If working on or near a roadway, be

extremely careful of motor traffic.

To assure that spare tires, flat or inflated,

are securely stowed, spares must be

stowed with the valve stem facing the

ground.

WARNING!

(Continued)

20_VF_OM_EN_US_t.book Page 136

Page 140 of 264

138IN CASE OF EMERGENCY

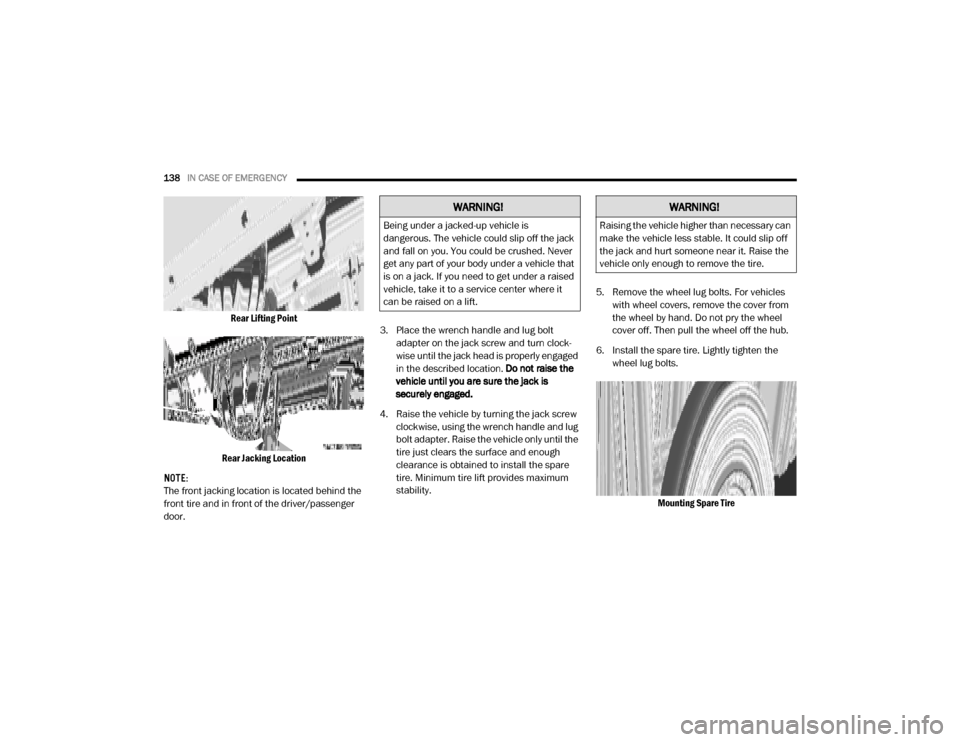

Rear Lifting Point

Rear Jacking Location

NOTE:

The front jacking location is located behind the

front tire and in front of the driver/passenger

door. 3. Place the wrench handle and lug bolt

adapter on the jack screw and turn clock -

wise until the jack head is properly engaged

in the described location. Do not raise the

vehicle until you are sure the jack is

securely engaged.

4. Raise the vehicle by turning the jack screw clockwise, using the wrench handle and lug

bolt adapter. Raise the vehicle only until the

tire just clears the surface and enough

clearance is obtained to install the spare

tire. Minimum tire lift provides maximum

stability. 5. Remove the wheel lug bolts. For vehicles

with wheel covers, remove the cover from

the wheel by hand. Do not pry the wheel

cover off. Then pull the wheel off the hub.

6. Install the spare tire. Lightly tighten the wheel lug bolts.

Mounting Spare Tire

WARNING!

Being under a jacked-up vehicle is

dangerous. The vehicle could slip off the jack

and fall on you. You could be crushed. Never

get any part of your body under a vehicle that

is on a jack. If you need to get under a raised

vehicle, take it to a service center where it

can be raised on a lift.

WARNING!

Raising the vehicle higher than necessary can

make the vehicle less stable. It could slip off

the jack and hurt someone near it. Raise the

vehicle only enough to remove the tire.

20_VF_OM_EN_US_t.book Page 138

Page 141 of 264

IN CASE OF EMERGENCY139

NOTE:

Do not install the wheel cover on the spare tire.

7. Lower the vehicle by turning the jack screw

counterclockwise.

8. Refer to “Wheel And Tire Torque Specifica -

tions” in “Technical Specifications” for

proper wheel lug bolt torque.

9. Lower the jack to its fully-closed position.

10. Stow the damaged wheel/spare tire with the cable and wheel spacer before driving

the vehicle. 11. Install the winch extension and

rotate the

wrench handle clockwise until the winch

mechanism operator hears “3 clicks” from

the device to indicate the wheel is properly

stowed under the vehicle.

12. Stow the jack, jack handle and winch handle tools back in the storage compartment.

13. Check the spare tire pressure as soon as possible. Correct the tire pressure, as

required.

For vehicles with aluminum wheels:

The center cap must be pushed out from the

rear to install the retainer and stow the tire.

Wheel Covers

The wheel covers on the vehicle are held in

place by the wheel lug bolts and can be

removed after the wheel lug bolts are taken off.

TIRE SERVICE KIT — IF EQUIPPED

Small punctures up to 1/4 inch (6 mm) in the

tire tread can be sealed with Tire Service Kit.

Foreign objects (e.g., screws or nails) should not

be removed from the tire. Tire Service Kit can be

used in outside temperatures down to approxi -

mately -4°F (-20°C).

This kit will provide a temporary tire seal,

allowing you to drive your vehicle up to

100 miles (160 km) with a maximum speed of 50 mph (80 km/h).

Tire Service Kit Storage

The Tire Service Kit is located under the

passenger seat or the driver side door.

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the wheel nuts fully until

the vehicle has been lowered. Failure to

follow this warning may result in serious

injury.

CAUTION!

Be sure to mount the spare tire with the valve

stem facing outward. The vehicle could be

damaged if the spare tire is mounted

incorrectly.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the jack

parts and the spare tire in the places

provided. Have the deflated (flat) tire repaired

or replaced immediately.

CAUTION!

Use a back-and-forth motion to remove the

hub cap. Do not use a twisting motion when

removing the hub cap, damage to the hub

cap finish may occur.

6

20_VF_OM_EN_US_t.book Page 139

Page 142 of 264

140IN CASE OF EMERGENCY

Tire Service Kit Components And Operation

Tire Service Kit Components

Using The Mode Select Knob And Hoses

Your Tire Service Kit is equipped with the

following symbols to indicate the air or sealant

mode.

Selecting Air Mode

Push in the Mode Select Knob (2)

and turn to this position for air

pump operation only. Use the Black

Air Pump Hose (5) when selecting

this mode.

Selecting Sealant Mode

Push in the Mode Select Knob (2)

and turn to this position to inject

the Tire Service Kit Sealant and to

inflate the tire. Use the Sealant

Hose (3) when selecting this mode.

Using The Power Button

Push and release the Power Button

(1) once to turn on the Tire Service

Kit. Push and release the Power

Button (1) again to turn Off the Tire

Service Kit.

Using The Deflation Button

Push the Deflation Button (9) to

reduce the air pressure in the tire if

it becomes over-inflated.

Tire Service Kit Usage Precautions

Replace the Tire Service Kit Sealant Bottle

(4) and Sealant Hose (3) prior to the expira -

tion date (printed at the upper right hand

corner on the bottle label) to assure optimum

operation of the system. Refer to “Sealing A

Tire With Tire Service Kit” section (F) “Sealant

Bottle And Hose Replacement in this section

for further information”.

Tire Service Kit Sealant Expiration Date Location

1 — Power Button

2 — Mode Select Knob

3 — Sealant Hose (Clear)

4 — Sealant Bottle

5 — Air Pump Hose (Black)

6 — Sealant Bottle Release Button

7 — Power Plug

8 — Pressure Gauge

9 — Deflation Button

20_VF_OM_EN_US_t.book Page 140

Page 143 of 264

IN CASE OF EMERGENCY141

(Continued)

The Sealant Bottle (4) and Sealant Hose (3)

are a one tire application use and need to be

replaced after each use. Always replace

these components immediately at your orig -

inal equipment vehicle dealer.

When the Tire Service Kit sealant is in a liquid

form, clean water and a damp cloth will

remove the material from the vehicle or tire

and wheel components. Once the sealant

dries, it can easily be peeled off and properly

discarded.

For optimum performance, make sure the

valve stem on the wheel is free of debris

before connecting the Tire Service Kit.

You can use the Tire Service Kit air pump to

inflate bicycle tires. The kit also comes with

two needles, located in the Accessory Storage

Compartment (on the bottom of the air pump)

for inflating sport balls, rafts, or similar inflat -

able items. However, use only the Air Pump

Hose (5) and make sure the Mode Select

Knob (2) is in the Air Mode when inflating such

items to avoid injecting sealant into them. The

Tire Service Kit Sealant is only intended to

seal punctures less than 1/4 inch (6 mm)

diameter in the tread of your tire.

Do not lift or carry the Tire Service Kit by the

hoses.

WARNING!

Do not attempt to seal a tire on the side of

the vehicle closest to traffic. Pull far enough

off the road to avoid the danger of being hit

when using the Tire Service Kit.

Do not use Tire Service Kit or drive the

vehicle under the following circumstances:

If the puncture in the tire tread is

approximately 1/4 inch (6 mm) or

larger.

If the tire has any sidewall damage.

If the tire has any damage from driving

with extremely low tire pressure.

If the tire has any damage from driving

on a flat tire.

If the wheel has any damage.

If you are unsure of the condition of the

tire or the wheel.

Keep Tire Service Kit away from open

flames or heat source.

A loose Tire Service Kit thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the

Tire Service Kit in the place provided.

Failure to follow these warnings can result

in injuries that are serious or fatal to you,

your passengers, and others around you.

Take care not to allow the contents of Tire

Service Kit to come in contact with hair,

eyes, or clothing. Tire Service Kit sealant is

harmful if inhaled, swallowed, or absorbed

through the skin. It causes skin, eye, and

respiratory irritation. Flush immediately

with plenty of water if there is any contact

with eyes or skin. Change clothing as soon

as possible, if there is any contact with

clothing.

Tire Service Kit Sealant solution contains

latex. In case of an allergic reaction or rash,

consult a physician immediately. Keep Tire

Service Kit out of reach of children. If swal -

lowed, rinse mouth immediately with plenty

of water and drink plenty of water. Do not

induce vomiting! Consult a physician imme -

diately.

WARNING!

(Continued)

6

20_VF_OM_EN_US_t.book Page 141

Page 144 of 264

142IN CASE OF EMERGENCY

Sealing A Tire With Tire Service Kit

(A) Whenever You Stop To Use Tire Service Kit:

1. Pull over to a safe location and turn on the

vehicle’s Hazard Warning flashers.

2. Verify that the valve stem (on the wheel with the deflated tire) is in a position that is near

to the ground. This will allow the Tire Service

Kit Hoses (3) and (5) to reach the valve

stem and keep the Tire Service Kit flat on

the ground. This will provide the best posi -

tioning of the kit when injecting the sealant

into the deflated tire and running the air

pump. Move the vehicle as necessary to

place the valve stem in this position before

proceeding.

3. Place the transmission in PARK (P) (auto transmission) or in Gear (manual transmis -

sion) and place the ignition in the OFF posi -

tion.

4. Apply the parking brake.

(B) Setting Up To Use Tire Service Kit:

1. Push in the Mode Select Knob (2) and turn to the Sealant Mode position. 2. Uncoil the Sealant Hose (3) and then

remove the cap from the fitting at the end of

the hose.

3. Place the Tire Service Kit flat on the ground next to the deflated tire.

4. Remove the cap from the valve stem and then screw the fitting at the end of the

Sealant Hose (3) onto the valve stem.

5. Uncoil the Power Plug (7) and insert the plug into the vehicle’s 12 Volt power outlet.

NOTE:

Do not remove foreign objects (e.g., screws or

nails) from the tire.

(C) Injecting Tire Service Kit Sealant Into The

Deflated Tire:

Always start the engine before turning ON the

Tire Service Kit.

NOTE:

Manual transmission vehicles must have the

parking brake engaged and the gear selector in

NEUTRAL.

After pushing the Power Button (1), the

sealant (white fluid) will flow from the Sealant

Bottle (4) through the Sealant Hose (3) and

into the tire. NOTE:

Sealant may leak out through the puncture in

the tire.

If the sealant (white fluid) does not flow within 0

– 10 seconds through the Sealant Hose (3):

1. Push the Power Button (1) to turn Off the

Tire Service Kit. Disconnect the Sealant

Hose (3) from the valve stem. Make sure

the valve stem is free of debris. Reconnect

the Sealant Hose (3) to the valve stem.

Check that the Mode Select Knob (2) is in

the Sealant Mode position and not Air

Mode. Push the Power Button (1) to turn On

the Tire Service Kit.

2. Connect the Power Plug (7) to a different 12 Volt power outlet in your vehicle or another

vehicle, if available. Make sure the engine is

running before turning ON the Tire Service

Kit.

3. The Sealant Bottle (4) may be empty due to previous use. Call for assistance.

NOTE:

If the Mode Select Knob (2) is on Air Mode and

the pump is operating, air will dispense from the

Air Pump Hose (5) only, not the Sealant Hose

(3).

20_VF_OM_EN_US_t.book Page 142

Page 145 of 264

IN CASE OF EMERGENCY143

(Continued)

If the sealant (white fluid) does flow through the

Sealant Hose (3):

1. Continue to operate the pump until sealant

is no longer flowing through the hose (typi -

cally takes 30 - 70 seconds). As the sealant

flows through the Sealant Hose (3), the

Pressure Gauge (8) can read as high as 70

psi (4.8 Bar). The Pressure Gauge (8) will

decrease quickly from approximately 70 psi

(4.8 Bar) to the actual tire pressure when

the Sealant Bottle (4) is empty.

2. The pump will start to inject air into the tire immediately after the Sealant Bottle (4) is

empty. Continue to operate the pump and

inflate the tire to the pressure indicated on

the tire pressure label on the driver-side

latch pillar (recommended pressure). Check

the tire pressure by looking at the Pressure

Gauge (8).

If the tire does not inflate to at least 26 psi (1.8

Bar) pressure within 15 minutes:

The tire is too badly damaged. Do not attempt

to drive the vehicle further. Call for assis -

tance. NOTE:

If the tire becomes overinflated, push the Defla-

tion Button to reduce the tire pressure to the

recommended inflation pressure before

continuing.

If the tire inflates to the recommended pressure

or is at least 26 psi (1.8 Bar) pressure within

15 minutes:

1. Push the Power Button (1) to turn off the

Tire Service Kit.

2. Remove the Speed Limit sticker from the top of the Sealant Bottle (4) and place the

sticker on the instrument panel.

3. Immediately disconnect the Sealant Hose (3) from the valve stem, reinstall the cap on

the fitting at the end of the hose, and place

the Tire Service Kit in the vehicle storage

location. Quickly proceed to (D) “Drive

Vehicle.”

(D) Drive Vehicle:

Immediately after injecting sealant and inflating

the tire, drive the vehicle 5 miles (8 km) or ten

minutes to ensure distribution of the Tire

Service Kit Sealant within the tire. Do not

exceed 50 mph (80 km/h).

CAUTION!

The metal end fitting from Power Plug (8)

may get hot after use, so it should be

handled carefully.

Failure to reinstall the cap on the fitting at

the end of the Sealant Hose (6) can result

in sealant contacting your skin, clothing,

and the vehicle’s interior. It can also result

in sealant contacting internal Tire Service

Kit components which may cause perma -

nent damage to the kit.

WARNING!

Tire Service Kit is not a permanent flat tire

repair. Have the tire inspected and repaired

or replaced after using Tire Service Kit. Do

not exceed 50 mph (80 km/h) until the tire is

repaired or replaced. Failure to follow this

warning can result in injuries that are serious

or fatal to you, your passengers, and others

around you.

CAUTION!

(Continued)

6

20_VF_OM_EN_US_t.book Page 143