ignition RENAULT KANGOO 1997 KC / 1.G Electrical Equipment User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 83

Page 22 of 83

IMPORTANT: if an uncoded injection computer or

solenoid valve is being tested from stock (test

part), the decoder unit

MUST NOT be supplied du-

ring the operation.

If the decoder unit is supplied, switching the igni-

tion on causes a coded signal to be sent from the

decoder unit to the injection computer or coded

solenoid valve (and the code is then program-

med).

To avoid memorising a code which could make

the injection computer or coded solenoid valve

electronic unit unusable after the test, the fuse

(+ before ignition feed) for the decoder unit

must be removed (fuse showing the door locking

symbol). This prevents the coded signal being sent

when the ignition is switched on (the computer or

the coded solenoid valve electronic unit remains

uncoded).

For petrol vehicles, the computer used for the test

MUST have the same Part Number as the original

computer on the vehicle (test computer may be

damaged).

Checking (on petrol vehicle only)

If the test computer is to be returned to stock, it is

possible (before it is removed) to check using the

XR25 that the computer has not been coded du-

ring the test (example : incorrect operation).

Connect the XR25 to the diagnostic socket.

Position the ISO selector and enter the injection

code: bargraph

2 RH (immobiliser) should be illu-

minated.

After entering

the message

should be displayed on the XR25.

This shows that the injection computer is not co-

ded and may be returned to stock.

If bargraph

2 RH (immobiliser) is extinguished and

after entering

the message

is displayed on the XR25, this shows that the

computer has been programmed with the immo-

biliser code (incorrect operation). In this case the

computer must be decoded before being returned

to stock.

The procedure for decoding consists of replacing

the decoder unit on the vehicle with another de-

coder unit with a different code (with its key

head) and entering the security code for the vehi-

cle (security code number should be requested

from the local assistance network, example

DELTA

Assistance for France, NVSR for the UK by fax on-

ly) using the number in the head of the key for the

vehicle.

Ignition off, fit in place of the original decoder

unit on the vehicle, a decoder unit coded with a

different number (the procedure will not work

with an uncoded decoder unit or one which has

the same code as the injection computer).

IMMOBILISER

Coded key immobiliser system

SPECIAL NOTES FOR TESTING AN INJECTION

COMPUTER OR A CODED SOLENOID VALVE (test

part)

82

*22

*22

82-11

Page 23 of 83

NOTE : this fault may be shown by the XR25 (in

injection fault finding).

Connect the XR25 and enter the injection code.

The fault is shown by bargraph 2 RH side.

After entering

the message

on the XR25 display indicates a fault on the coded

line.

Diesel vehicle

If a system fault is detected by the decoder unit

when the engine is running, the red immobiliser

warning light will illuminate permanently until

the ignition is switched off.

IMPORTANT: In this case, after repair, the fault

memorised in the decoder unit must be erased by

entering command

on the XR25 to allow the engine immobiliser sys-

tem to operate again.

NOTE: this fault may be shown by the XR25 using

fault finding for the decoder unit (fiche no. 56).

Connect the XR25.

Set the ISO selector to S8.

Enter code

The fault may be shown by bargraph

6 RH or LH

side. Switch the ignition on, the red engine immobiliser

warning light will flash (rapid flashing).

Enter the vehicle security code (number corre-

sponding to the original key number).

After entering the security code, the red warning

light will flash again.

The XR25 display should show

(in injection fault finding). This indicates that the

injection computer has been decoded.

Switch the ignition off, remove the decoded

computer and return it to stock.

Refit the computer and decoder unit to the vehi-

cle.

NOTE : When testing the injection using the XR25

on a vehicle without an immobiliser, bargraph 2

RH side will illuminate (*22 = 2 def = computer

not coded). This is normal.

SYSTEM FAULT, ENGINE RUNNING

Petrol vehicle

If a fault in the system is noted by the injection

computer when the engine is running, the injec-

tion warning light on the instrument panel will

flash during deceleration and at idle speed (en-

gine speed less than 1500 rpm).

IMPORTANT: In this case, after repair, the fault

memorised in the injection computer and the de-

coder unit must be erased by entering command

on the XR25 or by disconnecting the battery (ap-

proximately 30 seconds) to allow the engine im-

mobiliser system to operate again.

IMMOBILISER

Coded key immobiliser system

82

*22

D56G0**

G0**

82-12

Page 24 of 83

4.Enter mode

on the XR25 then the security code number

and validate using

-If the code is correct

is displayed.

Bargraph 10 LH extinguishes.

The engine may be started.

The vehicle is protected once more :

• approximately 10 minutes after switching

the ignition off (automatically),

• after disconnecting the battery.

-If the code is incorrect

is displayed.

Bargraph 10 LH remains illuminated.

The engine may not be started.

The red immobiliser warning light and the in-

jection warning light (depending on version)

flash.

Switch the ignition off, then repeat the proce-

dure for entering the code.

IMPORTANT: you may make 3 attempts to enter

the code. If, after the third attempt, the code is in-

valid, you must wait for approximately 15 mi-

nutes before making another attempt.

When this period has expired, switch the ignition

off and on again and 3 more attempts may be

made.

NOTE : This procedure does not decode the injec-

tion computer or coded solenoid valve (depen-

ding on the type of engine)- it only authorises the

starting of the vehicle.

REMINDER : The ignition must be switched off

and on again between attempts to enter the

code.

IMMOBILISER

Coded key immobiliser system

82

G40*

*

PROCEDURE FOR ENTERING THE SECURITY CODE

With this immobiliser system, the procedure for

entering the security code is managed by the de-

coder unit.

The code is entered using the XR25 only.

The security code can only be entered if the en-

gine immobiliser system is active. The red immobi-

liser warning light must flash when the ignition is

switched on (rapid flashing).

After determining the security code number (re-

quest from the local assistance network, example

DELTA Assistance for France, NVSR for the UK by

fax only) , carry out the following operations:

1.Ignition off, the red engine immobiliser war-

ning light should flash (slow flashing).

2.Switch the ignition on, the injection warning

light (petrol vehicle) illuminates for approxi-

mately 3 seconds then extinguishes, while the

red immobiliser warning light should flash

more quickly.

3.Connect the XR25 to the vehicle and set the

ISO selector on S8.

Enter code

Bargraph 10 LH should be illuminated (fault

finding fiche n° 56).

D56

82-13

Page 25 of 83

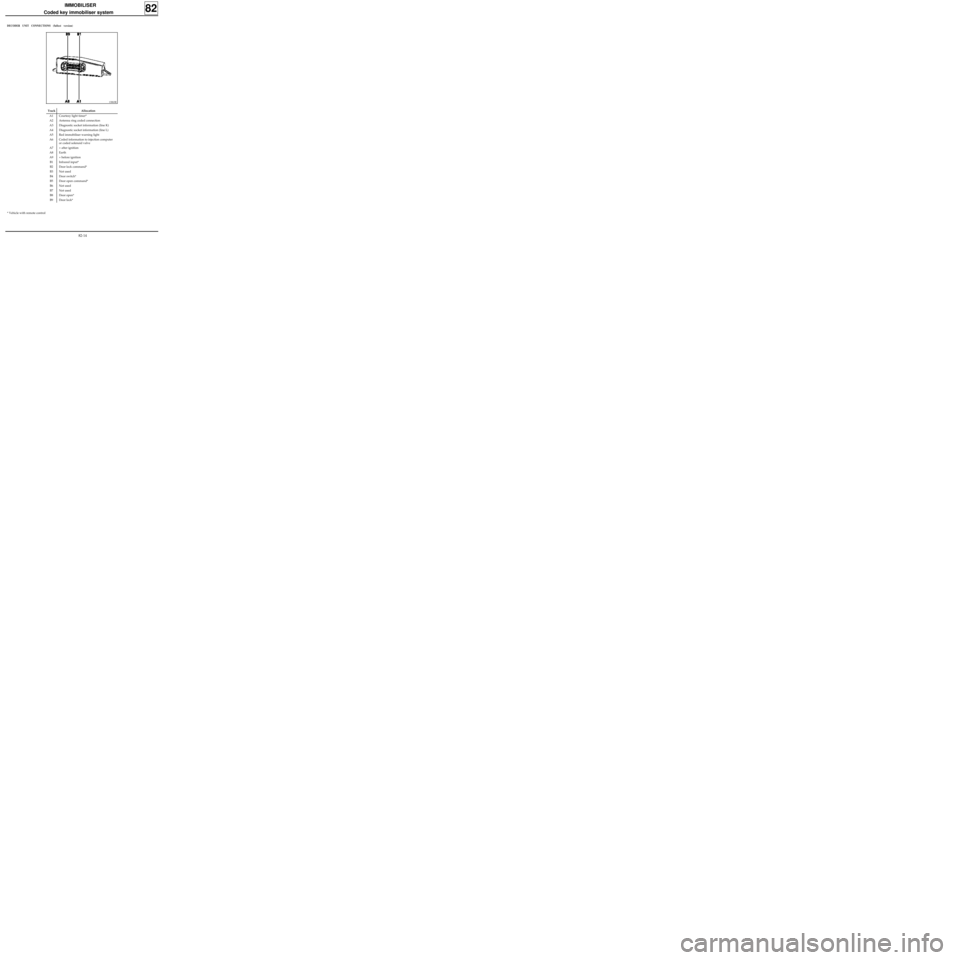

IMMOBILISER

Coded key immobiliser system

82

13063R

Track Allocation

A1 Courtesy light timer*

A2 Antenna ring coded connection

A3 Diagnostic socket information (line K)

A4 Diagnostic socket information (line L)

A5 Red immobiliser warning light

A6 Coded information to injection computer

or coded solenoid valve

A7 + after ignition

A8 Earth

A9 + before ignition

B1 Infrared input*

B2 Door lock command*

B3 Not used

B4 Door switch*

B5 Door open command*

B6 Not used

B7 Not used

B8 Door open*

B9 Door lock*

DECODER UNIT CONNECTIONS (fullest version)

* Vehicle with remote control

82-14

Page 27 of 83

IMMOBILISER

Coded key immobiliser system

82

KEY

104 Ignition switch

120 Injection computer

123 Door locking button

138 Rear right door locking motor

140 Driver’s door locking motor

141 Passenger’s door locking motor

142 Luggage compartment door locking motor

154 Luggage compartment door switch

178 Rear right door switch

180 Driver’s door switch

181 Passenger’s door switch

213 Courtesy light

225 Diagnostic socket

247 Injection warning light and red immobiliser

warning light on instrument panel

249 Remote control receiver

260 Passenger compartment fuse box

503 Decoder unit

711 Coded solenoid valveFAULT FINDING

If this immobiliser system is faulty, fault finding

may be carried out using the XR25.

CONNECTION

Use cassette no° 17 and the corresponding fault

finding fiche no° 56.

92656S2

Connect the XR25 to the diagnostic socket.

Position the ISO selector on S8.

Enter the code for the immobiliser system D56.

NOTE : For information on the interpretation of

the bargraphs, the fault charts, checking confor-

mity and additional tests, refer to the fault fin-

ding section.

82-16

Page 32 of 83

INSTRUMENT PANEL

Dashboard

83

- the loud speaker grilles,

- the dashboard mountings.

Gently pull the dashboard.

Release the wiring retaining clips.

Disconnect:

- the headlight remote adjustment control

connector and hazard warning light connector,

- the remaining connectors (example : decoder

unit).

Remove the dashboard.REFITTING

When refitting, it is important to ensure the va-

rious wires are correctly routed and have suffi-

cient space so that the dashboard can be correctly

centred.

SPECIAL NOTES FOR REFITTING THE STEERING

WHEEL WITH AIRBAG

Ensure the rotary switch under the steering wheel

is correctly positioned.

If there is any doubt that this switch is correctly

centred follow the method for centring described

in section 88 "driver’s airbag".

Renew the steering wheel bolt each time it is re-

moved (pre-bonded bolt) for a steering wheel

with airbag.

Observe the correct tightening torque (4.5

daN.m).

IMPORTANT

Before reconnecting the driver’s airbag cushion,

check to see if the system is operating correctly as

follows:

•check the airbag warning light on the

instrument panel is illuminated when the

ignition is on,

•connect a dummy ignition module to the

driver’s airbag connector and check that the

warning light extinguishes,

•switch the ignition off, connect the airbag

cushion in place of the dummy ignition module

and secure the cushion to the steering wheel,

•switch the ignition on. Check the warning light

illuminates for three seconds when the ignition

is switched on then extinguishes and remains

extinguished.

If the warning light does not operate exactly as

described above, refer to the fault finding section

and test the system using the XRBAG (Elé. 1288)

(see section 88).

12964R

83-5

Page 34 of 83

INSTRUMENT PANEL

Instrument panel

83

DESCRIPTION

- electronic speedometer,

- display : mileometer/trip recorder and clock

- coolant temperature gauge,

- fuel gauge,

- warning light functions.

13054S

1 Trip mileometer reset button and clock reset (rotate).

NOTE :

• Under normal operating conditions, the oil level is only measured if the ignition has been switched off for

over one minute; otherwise the old oil level value is re-displayed.

If a fault is detected, however, an oil level measurement is made each time the ignition is switched on to

check if the fault is persisting.

• It is normal to find that the oil level is not always the same:

- parking on a slope,

- too short a wait after running the engine for a short moment (especially when the oil is cold), ...

83-7

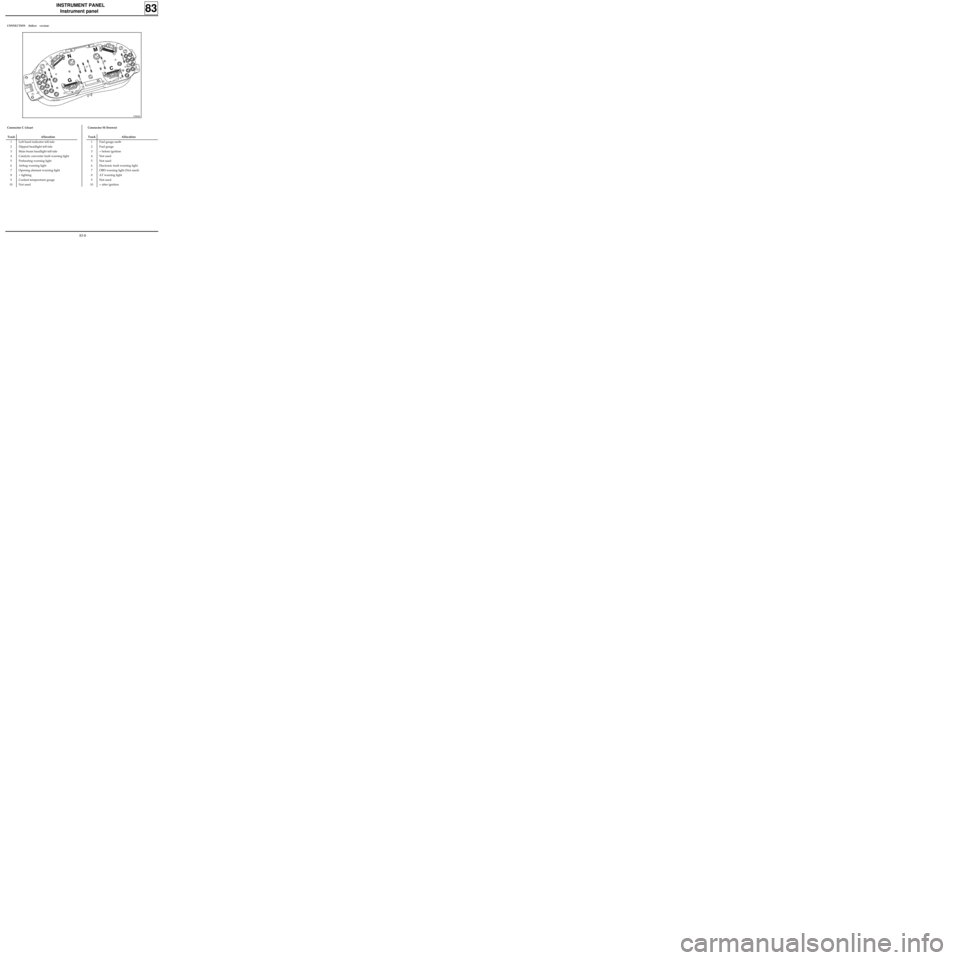

Page 35 of 83

INSTRUMENT PANEL

Instrument panel

83

13066S

CONNECTION (fullest version)

Connector C (clear)

Track Allocation

1 Left hand indicator tell-tale

2 Dipped headlight tell-tale

3 Main beam headlight tell-tale

4 Catalytic converter fault warning light

5 Preheating warning light

6 Airbag warning light

7 Opening element warning light

8 + lighting

9 Coolant temperature gauge

10 Not used

Connector M (brown)

Track Allocation

1 Fuel gauge earth

2 Fuel gauge

3 + before ignition

4 Not used

5 Not used

6 Electronic fault warning light

7 OBD warning light (Not used)

8 AT warning light

9 Not used

10 + after ignition

83-8

Page 39 of 83

INSTRUMENT PANEL

Oil level sensor

83

98898R1

OPERATION

The sensor consists of a wire with a high

coefficient of resistance. When a current passes

through the wire it does not have the same

thermal conductivity when it is immersed in a

liquid as when it is in the open air.

After a fixed time a voltage difference is obtained

at the sensor terminals depending on the depth of

immersion of the wire. This voltage difference is

recorded by the electronic unit which manages

the level display function and also controls the

"low oil level" warning light display on the

central liquid crystal display.

When the ignition is switched on, the central dis-

play shows the oil level in a series of "blocks" for

approximately 30 seconds, before returning to

displaying the trip mileometer and total mileome-

ter functions (or "odometer" function).

NOTE : Turning the trip mileometer reset button

before the end of the timed period will display

the "odometer" function.

LOOKING FOR FAULTS

If a short circuit or an open circuit is detected

when the oil level is measured, the display will im-

mediately show the trip mileometer / clock dis-

plays.

CHECKING

The sensor resistance must be between 6 and 20

ohms.

The sensor is deemed to be in short circuit for a va-

lue lower than 4 ohms.

The sensor is deemed to be in open circuit for a va-

lue higher than 22 ohms.

LOCATION

Example : F engine

83-12

Page 41 of 83

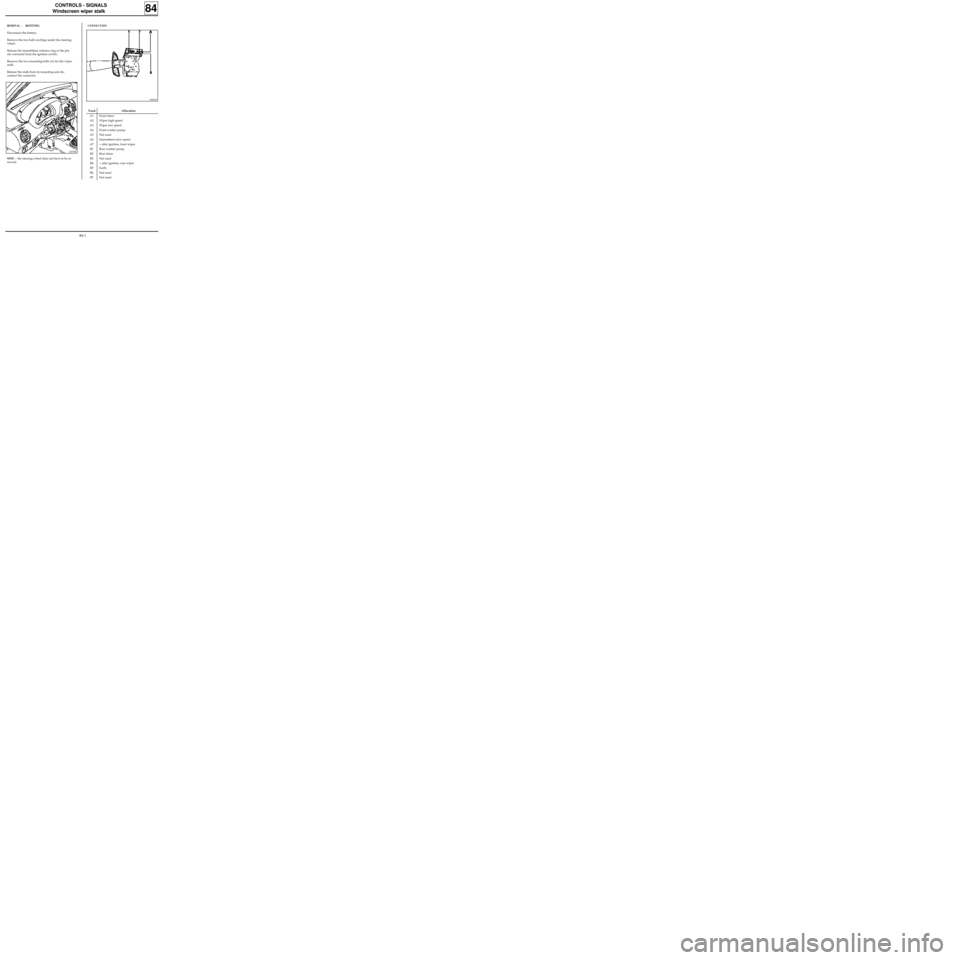

CONTROLS - SIGNALS

Windscreen wiper stalk

REMOVAL - REFITTING

Disconnect the battery.

Remove the two half cowlings under the steering

wheel.

Release the immobiliser antenna ring or the pla-

stic surround from the ignition switch.

Remove the two mounting bolts (A) for the wiper

stalk.

Release the stalk from its mounting and dis-

connect the connector.

84

CONNECTION

12970R

NOTE : the steering wheel does not have to be re-

moved.

13061R

Track Allocation

A1 Front timer

A2 Wiper high speed

A3 Wiper low speed

A4 Front washer pump

A5 Not used

A6 Intermittent slow speed

A7 + after ignition, front wiper

B1 Rear washer pump

B2 Rear timer

B3 Not used

B4 + after ignition, rear wiper

B5 Earth

B6 Not used

B7 Not used

84-1