ignition RENAULT KANGOO 1997 KC / 1.G Electrical Equipment Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 83

Page 42 of 83

CONTROLS - SIGNALS

Lights stalk

REMOVAL - REFITTING

Disconnect the battery.

Remove the two half cowlings under the steering

wheel.

Remove the two mounting bolts (B) for the lights

stalk.

Release the stalk from its mounting and dis-

connect the connector.

84

CONNECTION

12970R1

NOTE : the steering wheel does not have to be re-

moved.

13062R

Track Allocation

A1 Front fog lights

A2 Not used

A3 Rear fog light

A4 Horn

A5 Right hand indicators

A6 Central flasher unit

A7 Left hand indicators

B1 Side lights

B2 + before ignition, side lights

B3 + before ignition, dipped headlights

B4 Not used

B5 Dipped headlights

B6 + before ignition, main beam headlights

B7 Main beam headlights

84-2

Page 45 of 83

CONTROLS - SIGNALS

Rotary switch under steering wheel

Special notes for refitting

Ensure the wheels are still straight.

Ensure the rotary switch under the steering wheel

is still immobilised before refitting.

If there is any doubt follow the method for cen-

tring described in section 88 "driver’s airbag".

Renew the steering wheel bolt each time it is re-

moved (pre-bonded bolt).

Observe the correct tightening torque (4.5

daN.m).

84

IMPORTANT

Before reconnecting the driver’s airbag cushion,

check to see if the system is operating correctly as

follows:

•check the airbag warning light on the

instrument panel is illuminated when the

ignition is on,

•connect a dummy ignition module to the

driver’s airbag connector and check that the

warning light extinguishes,

•switch the ignition off, connect the airbag

cushion in place of the dummy ignition module

and secure the cushion to the steering wheel,

•switch the ignition on. Check the warning light

illuminates for three seconds when the ignition

is switched on then extinguishes and remains

extinguished.

If the warning light does not operate exactly as

described above, refer to the fault finding section

and test the system using the XRBAG (Elé. 1288)

(see section 88).

IMPORTANT: if these instructions are not obser-

ved, the systems may not operate normally and

may be incorrectly triggered.

84-5

Page 46 of 83

CONTROLS - SIGNALS

Ignition switch

REMOVAL - REFITTING

Disconnect the battery.

Set the wheels straight.

Remove:

- the half cowlings,

- the radio or glovebox (depending on equip-

ment),

- the immobiliser antenna ring or plastic sur-

round from the ignition switch (depending on

equipment).

Disconnect the ignition switch connectors (F).

84

Remove bolt (G) from the ignition switch.

Position the ignition key in position 3 and tilt re-

taining lugs (H) while releasing the switch.

DI8404

13068R

84-6

Page 51 of 83

ELECTRICAL ASSISTANCE EQUIPMENT

Relay plate

POSITION AND ALLOCATION

(Most complete plate)

87

12965R

The relays are located above the fuse board at the

bottom of the dashboard. To reach them, open

the fuse box cover.

1 Lights on reminder buzzer

2 Front wiper timer

3 Flasher unit

4 Rear wiper timer

5 Heated rear screen relay

6 After ignition relay (electric window feed)

7 Front fog lights relay

87-1

Page 52 of 83

ELECTRICAL ASSISTANCE EQUIPMENT

Relay plate

87

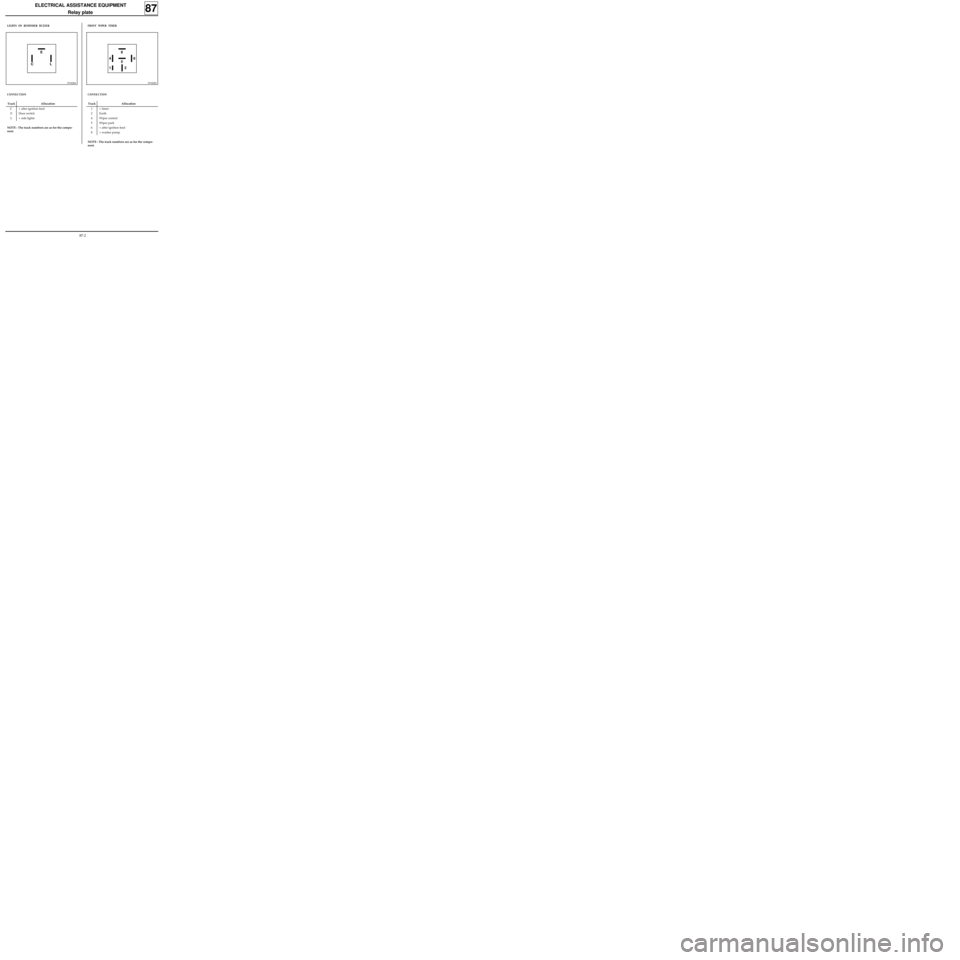

LIGHTS ON REMINDER BUZZER

Track Allocation

C + after ignition feed

E Door switch

L + side lights

95182R4

CONNECTION

NOTE : The track numbers are as for the compo-

nent.

FRONT WIPER TIMER

95182R2

Track Allocation

1 + timer

2 Earth

4 Wiper control

5 Wiper park

6 + after ignition feed

8 + washer pump

CONNECTION

NOTE : The track numbers are as for the compo-

nent.

8

5

2 1 46E

CL

87-2

Page 53 of 83

ELECTRICAL ASSISTANCE EQUIPMENT

Relay plate

87

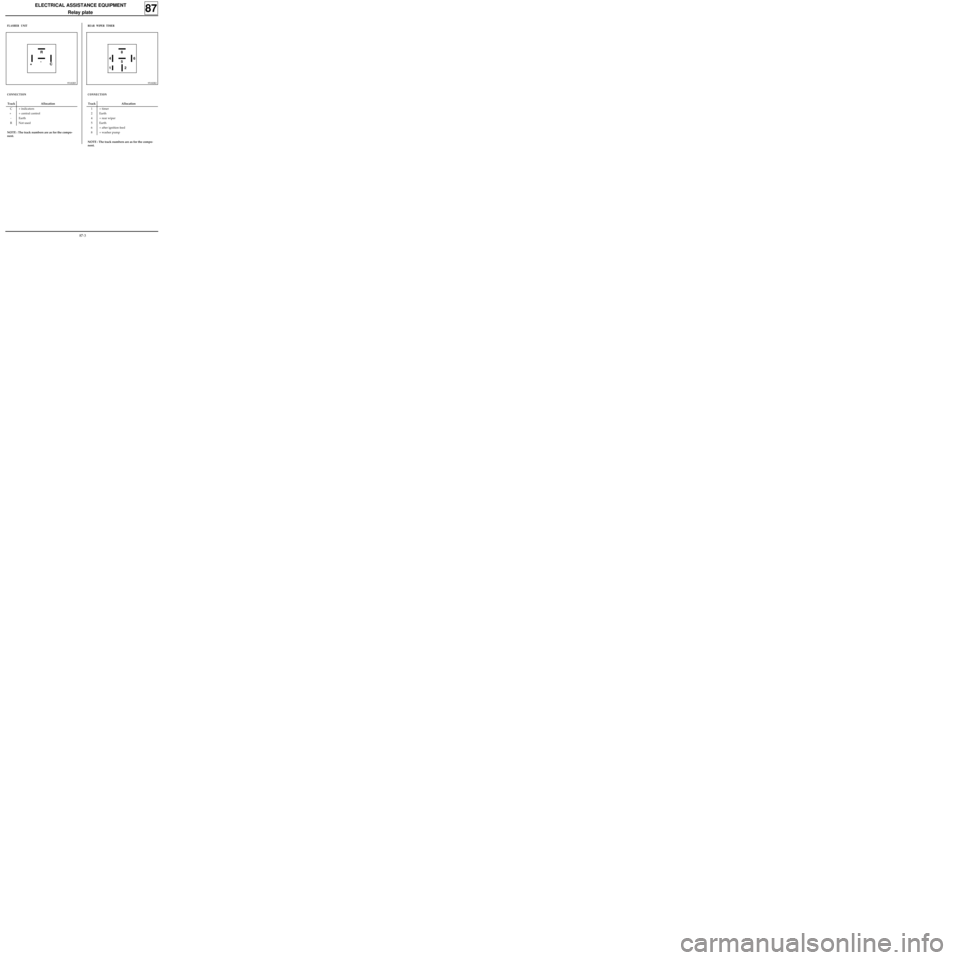

FLASHER UNIT

Track Allocation

C + indicators

+ + central control

- Earth

R Not used

95182R5

CONNECTION

NOTE : The track numbers are as for the compo-

nent.

REAR WIPER TIMER

95182R2

Track Allocation

1 + timer

2 Earth

4 + rear wiper

5 Earth

6 + after ignition feed

8 + washer pump

CONNECTION

NOTE : The track numbers are as for the compo-

nent.

8

5

2 1 46R

-

+C

87-3

Page 54 of 83

ELECTRICAL ASSISTANCE EQUIPMENT

Relay plate

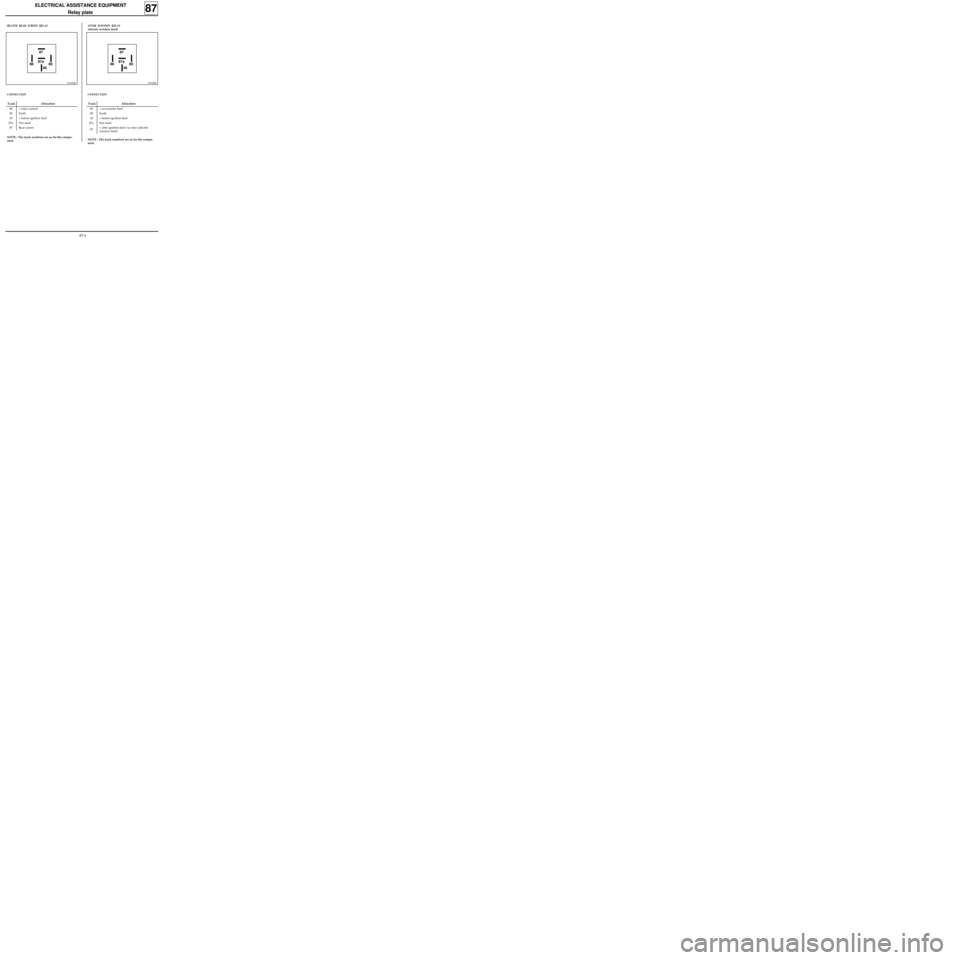

87

HEATED REAR SCREEN RELAY

Track Allocation

86 + relay control

85 Earth

30 + before ignition feed

87a Not used

87 Rear screen

95182R6

CONNECTION

NOTE : The track numbers are as for the compo-

nent.

AFTER IGNITION RELAY

(electric window feed)

95182R6

CONNECTION

NOTE : The track numbers are as for the compo-

nent.

Track Allocation

86 + accessories feed

85 Earth

30 + before ignition feed

87a Not used

87+ after ignition feed via relay (electric

window feed)

87

87a

30 86 8587

87a

30 86 85

87-4

Page 55 of 83

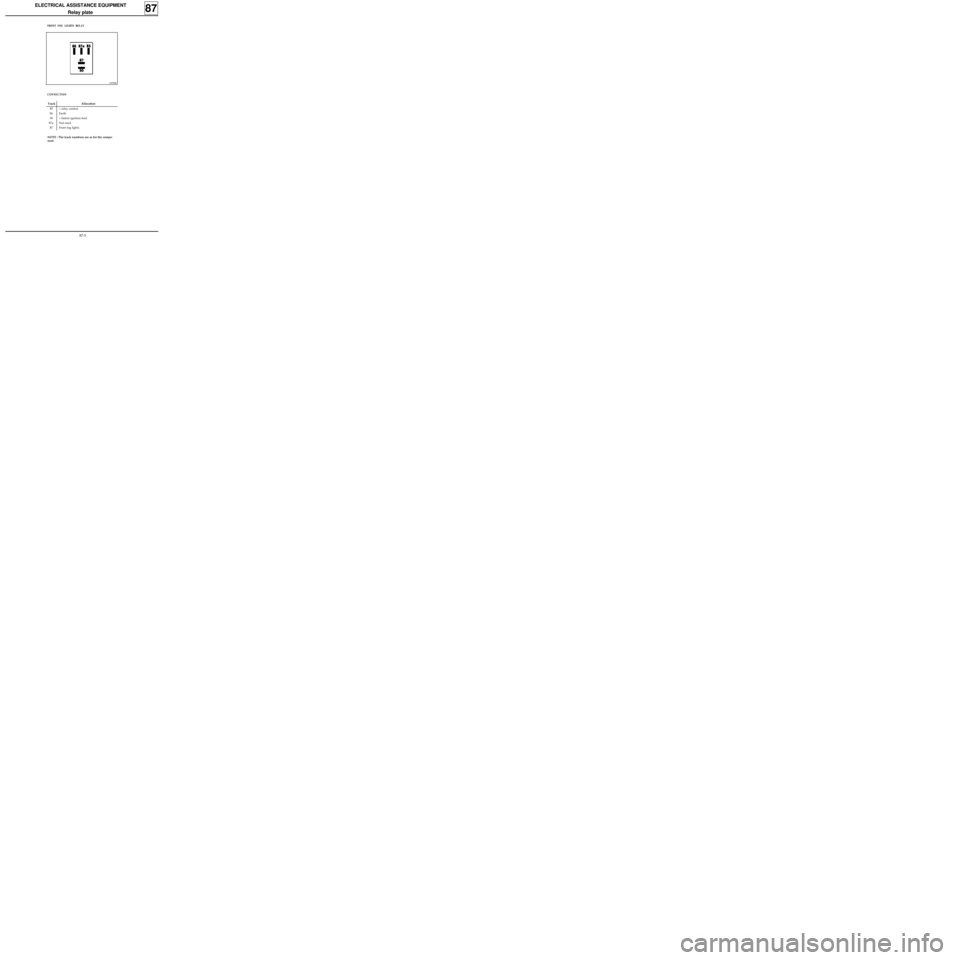

ELECTRICAL ASSISTANCE EQUIPMENT

Relay plate

87

FRONT FOG LIGHTS RELAY

Track Allocation

85 + relay control

86 Earth

30 + before ignition feed

87a Not used

87 Front fog lights

13058R

CONNECTION

NOTE : The track numbers are as for the compo-

nent.

87-5

Page 56 of 83

WIRING

Heated rear screen

88

REPAIR OF THE FILAMENT

Clean the section to be treated locally to remove

all dust or grease, preferably using alcohol or a

glass cleaner, and wipe with a clean, dry cloth.

To obtain a regular line during the repair, apply

scotch adhesive tape on either side of the section

to be repaired, leaving the conducting line free.

Before applying the varnish, shake the bottle to

prevent the deposit of silver particles on the bot-

tom of the bottle.

The heated grid applied to the inner face of the

window may be accidentally cut, making the part

of the grid affected inefficient.

The exact point of the disconnection may be de-

termined by means of a voltmeter.

It is possible to repair such faults by applying the

heated rear screen varnish sold under Part

Number 77 01 421 135 (2 g pack).

DETERMINING THE EXACT POINT OF

DISCONNECTION WITH A VOLTMETER.

Switch on the ignition.

Switch on the heated rear screen feed.

DETECTION BETWEEN LINES B AND A

Connect the + wire of the voltmeter to the +

feed terminal of the rear screen.

Place the - wire of the voltmeter on a filament on

the - terminal side of the rear screen (line B). A

voltage approximately equal to battery voltage

must be obtained.

Move the - wire towards line A (arrow): the vol-

tage drops progressively.

If the voltage drops quickly the filament is cut at

that point (carry out this operation for each fila-

ment).

DI8814

DETECTION BETWEEN LINES C AND A

Connect the - wire of the voltmeter to the - termi-

nal of the rear screen.

Place the + wire of the voltmeter on a filament

on the + terminal side of the rear screen (line C);

essentially a voltage equal to the battery voltage

must be obtained.

Move the + wire towards line A (arrow); the vol-

tage drops progressively.

If the voltage drops quickly, the filament must be

cut at this point (carry out this operation for each

filament).

DI8815

88-1

Page 58 of 83

WIRING

Remote control for door locking

88

.GENERAL

These vehicles are equipped with an infrared or

radio frequency remote control with rolling code,

which prevents the code from being copied.

When a transmitter is replaced it will therefore be

necessary to resynchronise it so that the transmit-

ters are returned to phase with the decoder unit.

This remote control is only used for locking and

unlocking the opening elements (it has no effect

on the immobiliser).

IMPORTANT: this system cannot operate with

three remote controls (the decoder unit can only

manage two different rolling codes).

THE TRANSMITTER (PLIP)

Replacing or adding a remote control with immo-

biliser function without replacing the decoder

unit.

Order a spare key head using the number in the

head of one of the old keys or the label normally

attached to the keys when the vehicle is delivered

(eight alphanumeric characters).

If a key is being added or has been lost, remember

to order the insert with the key number.

Carry out the special resynchronisation procedure

using the XR25.

This procedure resets the remote control into se-

quence with the decoder unit (rolling code) and

should only be used if the decoder unit is not

being replaced (with immobiliser only).

1.Ignition off, connect the XR25 (ISO selector on

S8, code D56).

For vehicles fitted with an infra-red remote

control, enter command mode G04* (forced

protection mode) then switch the ignition on

again and enter the vehicle’s security code

(see procedure in section 82).

For vehicles fitted with a radio frequency re-

mote control, go to point 2.

2.Switch the ignition off and enter command

mode G32*.

From this moment, the operator has 10 se-

conds to carry out the next operation.

NOTE: The 10 seconds are shown by the illu-

mination of the red immobiliser warning light

and bargraph 17 LH on the XR25

(code D56,

fiche n° 56).

3.Press the remote control twice (the doors lock

and unlock and the red warning light extin-

guishes).

NOTE :

- When replacing a key head, resynchronisa-

tion of the second remote control (if fitted)

is not always necessary.

Check that the second control operates,

otherwise resynchronise it.

- If both remote controls (if fitted) are desyn-

chronised, two resynchronisation proce-

dures will have to be carried out (one for

each remote control).

IMPORTANT: To ensure that the infrared code

is correctly transmitted it is essential to direct

the transmitter correctly towards the receiver.

If the procedure fails it will be necessary to

restart from the beginning (infrared remote

control only).

4.The procedure is complete - check that the

doors lock correctly.

88-3