RENAULT KANGOO 1997 KC / 1.G Engine And Peripherals User Guide

KANGOO 1997 KC / 1.G

RENAULT

RENAULT

https://www.carmanualsonline.info/img/7/1731/w960_1731-0.png

RENAULT KANGOO 1997 KC / 1.G Engine And Peripherals User Guide

Page 98 of 208

DIESEL EQUIPMENT

Location of components

13

20 EGR valve

13047-1R

7Engine speed sensor

13048R

87970R

17Diesel injection fault warning light

18Preheating warning light

Warning light illuminates when ignition is

switched on during preheating phase.

12839S

C Power assisted steering pump assembly relay

HAltimetric corrector relay

LInjection locking relay

MDiesel heating relay

13-18

Page 117 of 208

DIESEL EQUIPMENT

Computer

13

PRM1316

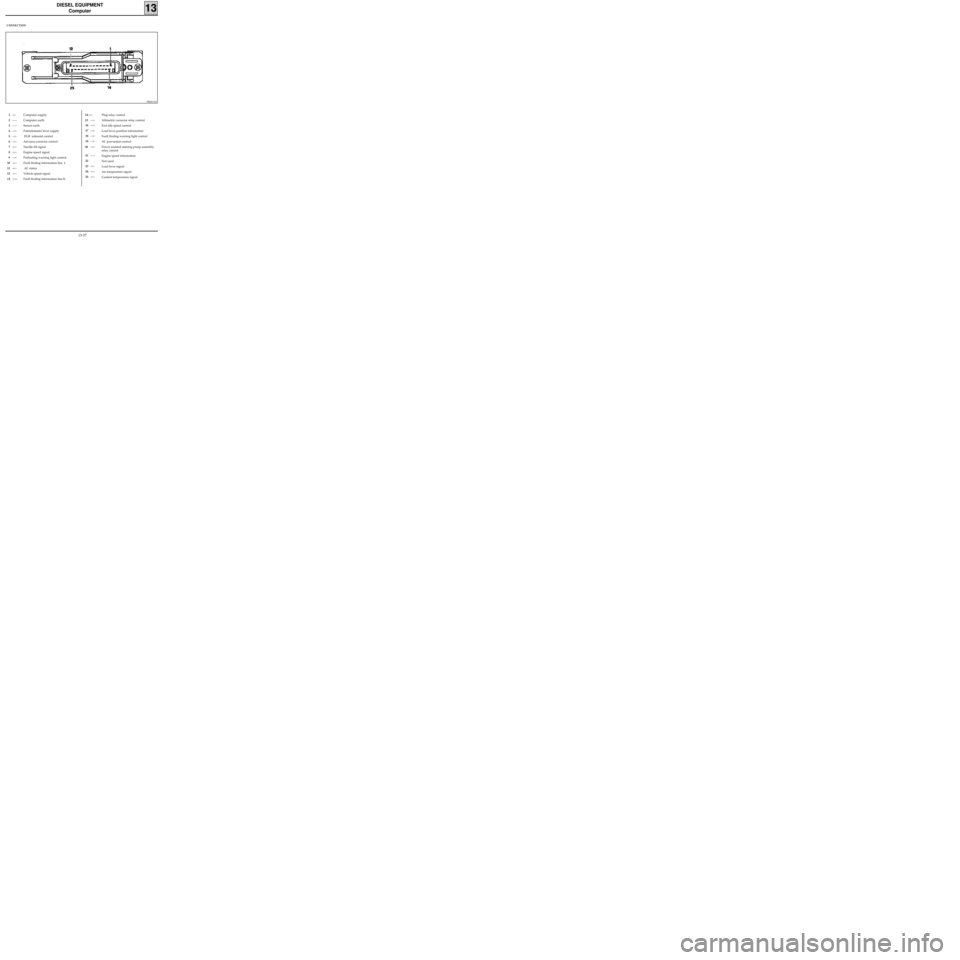

CONNECTION

1-<-

2-----

3-----

4-->-

5-->-

6-->-

7-<--

8-<--

9-->-

10-<--

11-<--

12-<--

13-><-Computer supply

Computer earth

Sensor earth

Potentiometer lever supply

EGR solenoid control

Advance corrector control

Needle lift signal

Engine speed signal

Preheating warning light control

Fault finding information line L

AC status

Vehicle speed signal

Fault finding information line KPlug relay control

Altimetric corrector relay control

Fast idle speed control

Load lever position information

Fault finding warning light control

AC prevention control

Power assisted steering pump assembly

relay control

Engine speed information

Not used

Load lever signal

Air temperature signal

Coolant temperature signal14-->-

15-->-

16-->-

17-->-

18-->-

19-->-

20 -->-

21-----

22

23-<--

24-<--

25-<--

13-37

Page 118 of 208

DIESEL EQUIPMENT

Defect modes

13

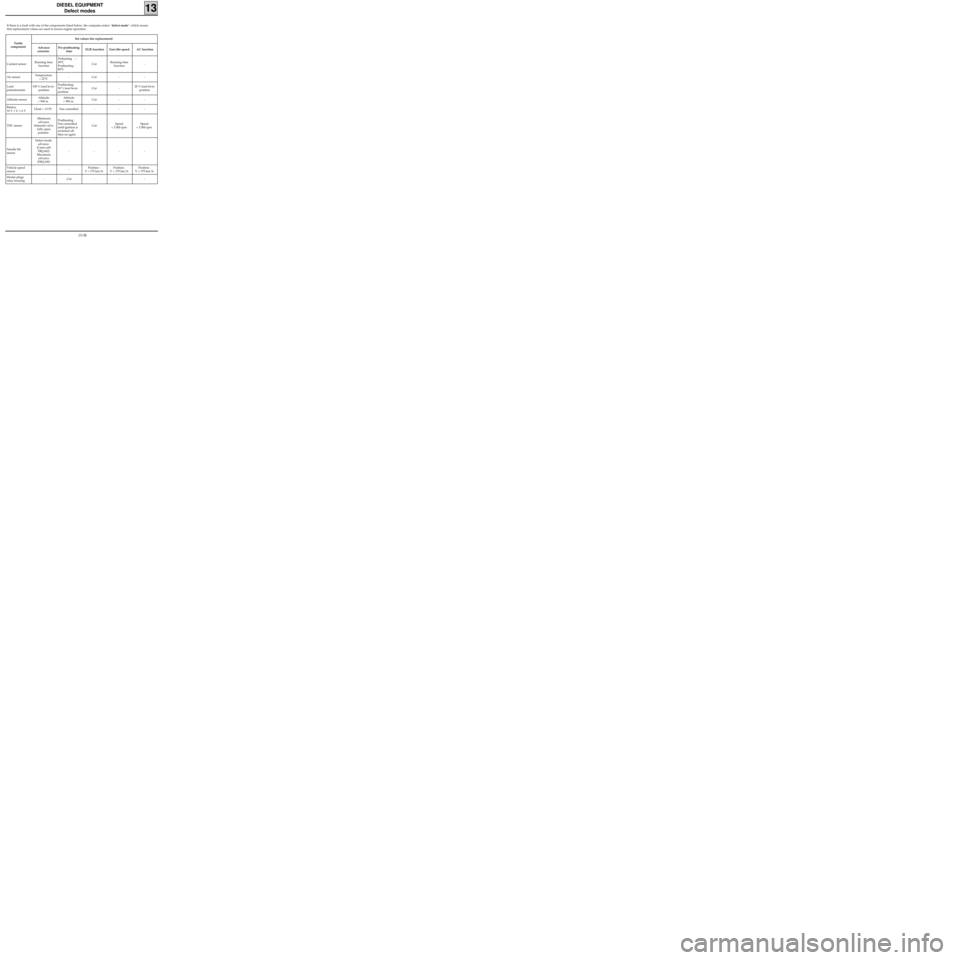

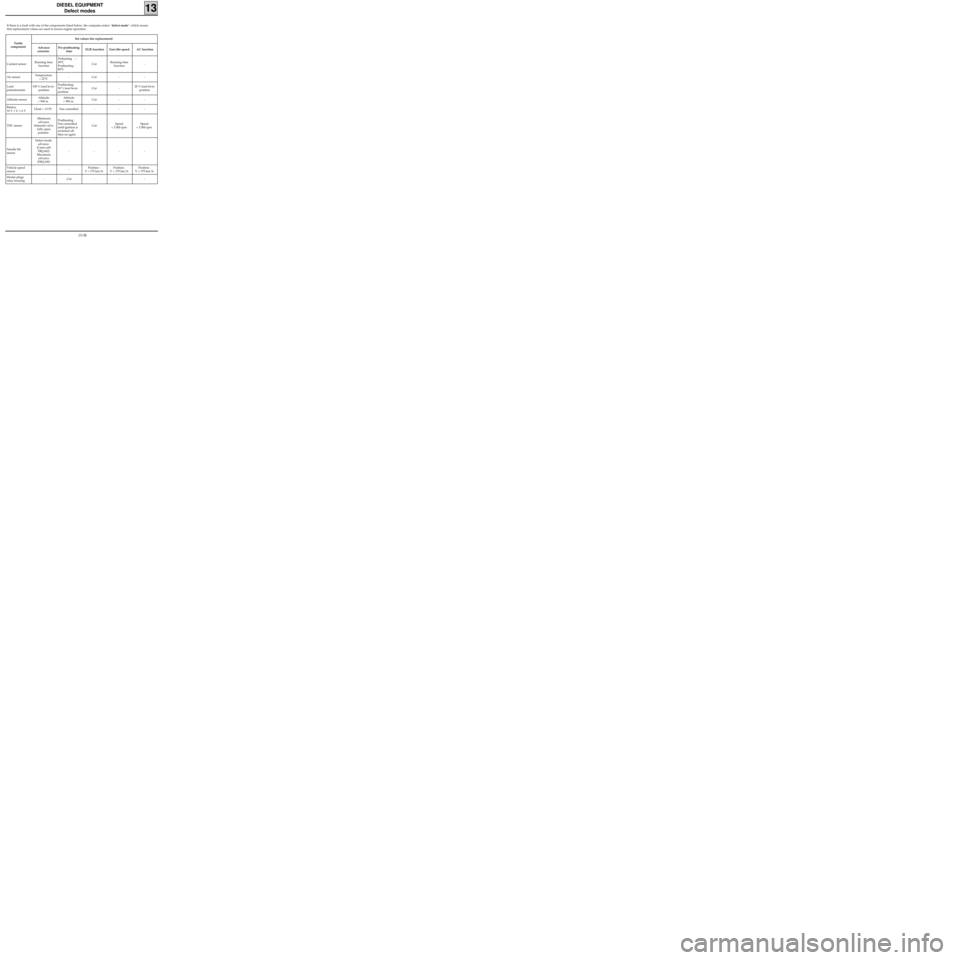

If there is a fault with one of the components listed below, the computer enters "defect mode", which means

that replacement values are used to ensure engine operation.

Faulty

componentSet values (for replacement)

Advance

corrector Pre-postheating

timeEGR function Fast idle speed AC function

Coolant sensorRunning time

functionPreheating : -

30°C

Postheating :

80°CCutRunning time

function-

Air sensorTemperature

= 22°C- Cut - -

Load

potentiometer100 % load lever

positionPostheating:

30 % load lever

position Cut - 20 % load lever

position

Altitude sensorAltitude

= 900 mAltitude

= 900 mCut - -

Battery

16 V < U < 6 VUbatt = 13.5V Not controlled - - -

TDC sensorMinimum

advance

Solenoid valve

fully open

position Postheating :

Not controlled

until ignition is

switched off

then on againCutSpeed

= 2 000 rpmSpeed

= 2 000 rpm

Needle lift

sensorDefect mode

advance

(Carto soft

F8Q 662)

Maximum

advance

(F8Q 630)----

Vehicle speed

sensor--Position :

V = 175 km/hPosition :

V = 175 km/hPosition :

V = 175 km/h

Heater plugs

relay housing- Cut - - -

13-38

Page 156 of 208

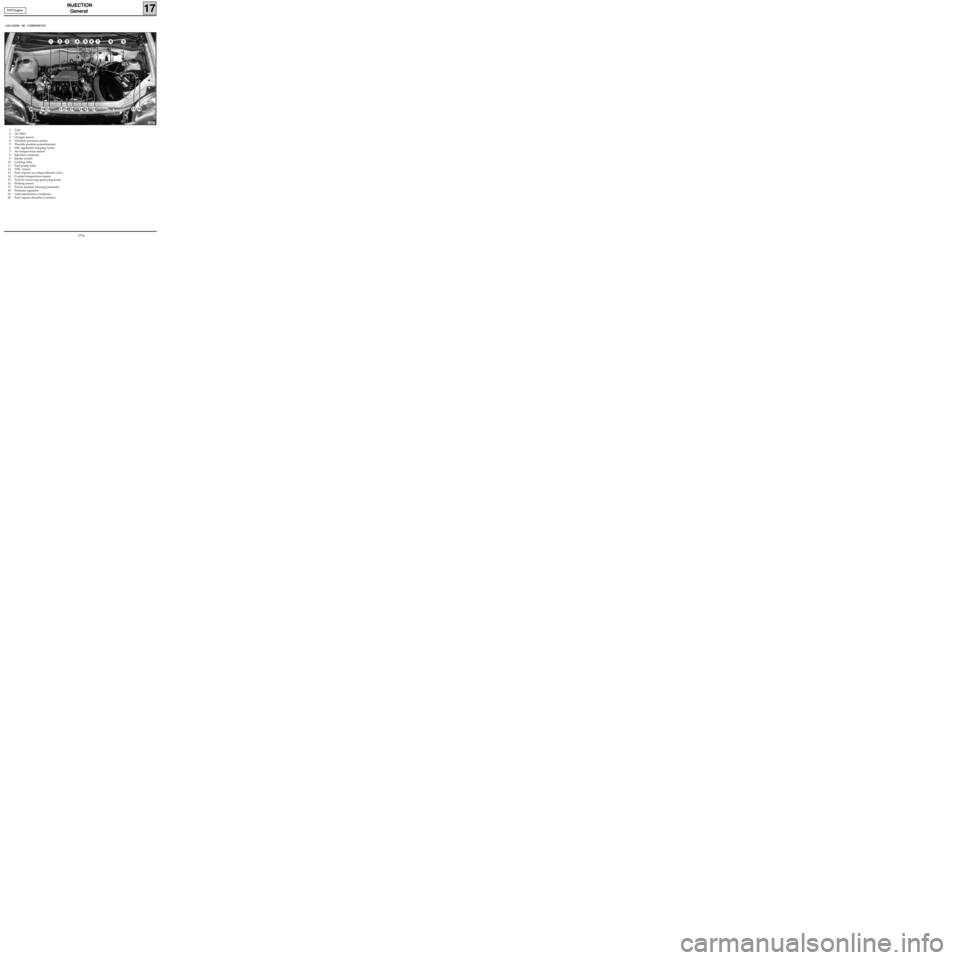

INJECTION

General

17

1 Coil

2 Air filter

3 Oxygen sensor

4 Absolute pressure sensor

5 Throttle position potentiometer

6 Idle regulation stepping motor

7 Air temperature sensor

8 Injection computer

9 Inertia switch

10 Locking relay

11 Fuel pump relay

12 TDC sensor

13 Fuel vapour recycling solenoid valve

14 Coolant temperature sensor

15 Tool for removing spark plug leads

16 Pinking sensor

17 Power assisted steering pressostat

18 Pressure regulator

19 Anti-interference condenser

20 Fuel vapour absorber (canister)

LOCATION OF COMPONENTS

13081

D7F Engine

17-6

Page 157 of 208

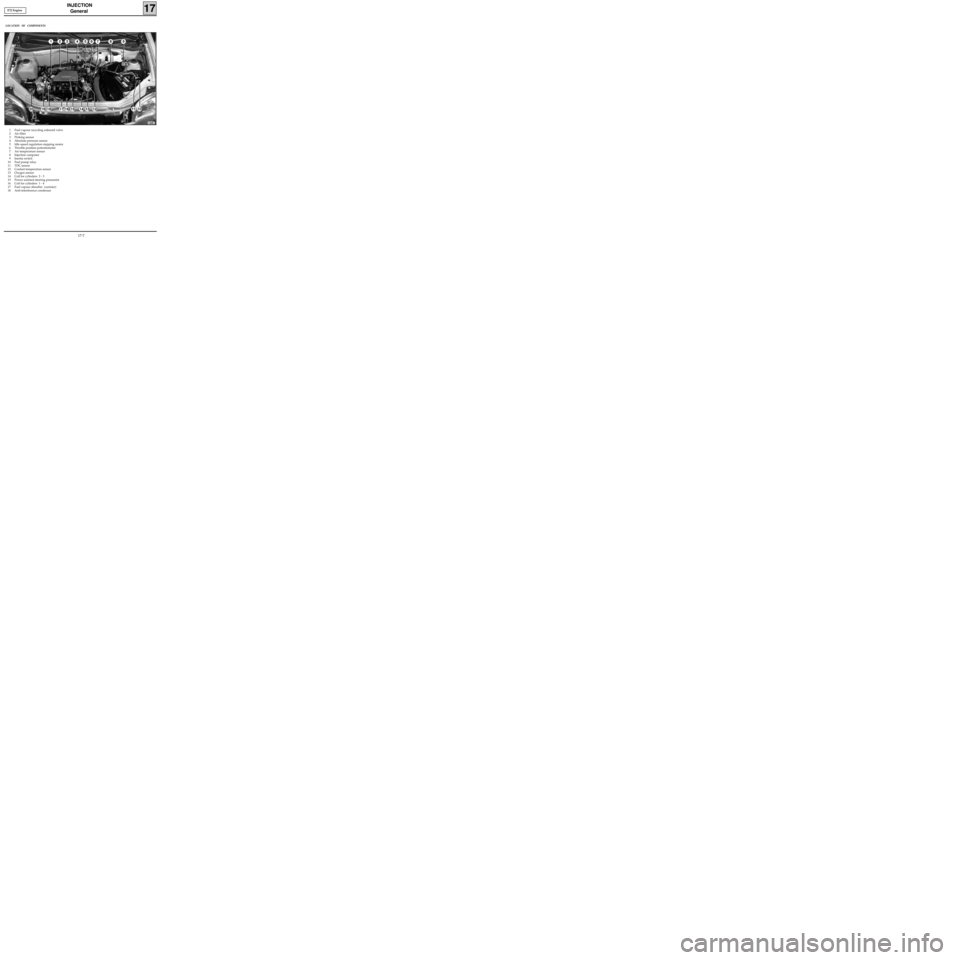

INJECTION

General

17

1 Fuel vapour recycling solenoid valve

2 Air filter

3 Pinking sensor

4 Absolute pressure sensor

5 Idle speed regulation stepping motor

6 Throttle position potentiometer

7 Air temperature sensor

8 Injection computer

9 Inertia switch

10 Fuel pump relay

11 TDC sensor

12 Coolant temperature sensor

13 Oxygen sensor

14 Coil for cylinders 2 - 3

15 Power assisted steering pressostat

16 Coil for cylinders 1 - 4

17 Fuel vapour absorber (canister)

18 Anti-interference condenser

LOCATION OF COMPONENTS

13082

E7J Engine

17-7

Page 159 of 208

INJECTION

Location of components

17

H Locking relay

K Fuel pump relay

3 Oxygen sensor

(tightening torque : 5 daN.m)

12993R

1 Coil

19 Anti-interference condenser

99931-1R1

12839S

17 Power assisted steering pressostat

13050R

D7F Engine

17-9

Page 162 of 208

INJECTION

Location of components

17

K Fan assembly relay (for versions with air

conditioning)

L Fuel pump relay

M Fan assembly relay (for versions without air

conditioning) slow speed fan assembly (with

air conditioning) 15 Power assisted steering pressostat

13241R

12839S

E7J engine

17-12

Page 192 of 208

FUEL TANK

Fuel tank

19

In the engine compartment, disconnect the fuel

pump relay at (K) , which is located in the engine

connection unit.

12839S

DRAINING THE FUEL TANK ( Diesel version)

Since Diesel versions are not fitted with an electri-

cal fuel pump, a manual pump must be used to

drain the tank.

For example, the

INTAIRCO pneumatic siphoning

pump is suitable for this operation (see

EQUIPMENT catalogue),

Shunt tracks 3 and 5 and let the fuel flow until it

runs out in intermittent jets.

Disconnect the shunt.

Reconnect the relay.

Disconnect the battery.Remove the pump-sender unit steel access cover.

Remove the clip which shows if the assembly has

been pushed in (if fitted).

Disconnect the quick release union at (1), tool

Mot. 1265.

99641S

97163R2

Connect the pneumatic pump rubber tube to the

outlet union at (A).

Drain the tank.

19-18