fuel pressure RENAULT KANGOO 1997 KC / 1.G Engine And Peripherals Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 208

Page 172 of 208

INJECTION

Adaptive richness correction

17

D7F

Engine

E7J

Engine

106 ≤ #30 ≤ 150 40 ≤ #30 ≤ 192

106 ≤ #31 ≤ 150 40 ≤ #31 ≤ 192

PRINCIPLE

In the loop mode (see section 17 "Richness regulation"), richness regulation (# 35), corrects the injection ti-

ming to give fuel metering which is as close as possible to richness 1. The correction value is close to 128, with

limit values of 0 and 255.

Variations may affect the components of the injection system and the correction may drift towards 0 or 255,

to ensure richness 1 is obtained.

Adaptive correction allows the injection mapping to be adjusted to recentre the richness regulation to 128

and to ensure a constant authority of correction to make the mixture leaner or richer.

Adaptive correction to richness regulation has two parts:

- Adaptive correction for average and high engine loads (#30)

- Adaptive correction for idle speed and low engine loads (#31).

Adaptive corrections take 128 as the average value after initialisation (erasing the memory) and have the

following threshold values:

Adaptive correction only takes place when the engine is warm, in the loop phase (#35 variable) and for a

specified manifold pressure range.

The engine must have operated in the loop mode for several pressure zones in order that adaptive correc-

tion begins to change to compensate for the variations in engine operating richness.

Following reinitialisation of the computer (return to 128 for # 30 and # 31) a special road test must therefore

be carried out.

17-22

Page 174 of 208

INJECTION

Adaptive richness correction

17

INTERPRETATION OF INFORMATION GATHERED DURING A ROAD TEST

If there is a lack of fuel (injectors dirty, fuel pressure and flow too low...), richness regulation # 35 increases to

obtain the richness as close as possible to richness 1 and adaptive correction # 30 and # 31 increases until the

richness correction returns to oscillate around 128.

If there is an excess of fuel, the situation is reversed : Richness regulation # 35 reduces and adaptive

correction # 30 and # 31 also reduces to recentre the richness correction (# 35) around 128.

NOTE : the analysis which may be made using # 31 remains difficult since this correction mainly operates for

idle speed and low loads and is also very sensitive.

Hasty conclusions should not therefore be drawn from this gate value, rather the position of # 30 should be

examined.

The information from these two gates gives an idea about the engine operation richness, and may be used as

a guide for fault finding. In order for these to be put to good use during fault finding, no conclusion may be

drawn from their value unless they are at the minimum or maximum correction limit, and if both gate values

were offset in the same direction.

IMPORTANT : # 30 and # 31 should only be examined and analysed after a customer complaint, an opera-

ting fault and if they are at the threshold with the value for # 35 also offset (# 35 varies above 175 or be-

low 80).

17-24

Page 201 of 208

FUEL TANK

Fuel tank

19

Components

1 Tank

2 Bolt

3 Filler neck

4 Filler neck bowl

5 Rivet

6 Sleeve mounting clip

7 Fuel cap

8 Fuel supply pipe

9 Fuel return pipe

10 Clip

13 Cup

14 Canister pipe

15 Canister pipe

18 Canister

19 Bolt

20 Clip

21 Clip

22 Damper pad

23 Captive nut

24 Connection between filler neck outlet and

fuel passage pipe

25 Degassing - filling

27 Canister connection (fuel vapours)

28 Over-filling prevention valve

29 Excess pressure-under-pressure safety valve

30 Restriction valve

31 Leak prevention valve in case vehicle turns

over

32 Over-filling prevention valve and leak pre-

vention valve in case vehicle turns over.

A Quick-release union

B Snap-fit union

C Quick release union

D Sleeve (not snap-fit)

E Opening for air outlet during filling

F Air volume allowing the fuel to expand

R Fuel inlet for filling

V Maximum fuel volume allowed.

19-27

Page 202 of 208

FUEL TANK

Fuel tank

19

PURPOSE OF THE VALVES

28 Overfill prevention valve

When the filler cap is removed the valve is

closed, trapping a volume of air within the

breather volume. This prevents fuel from fil-

ling this volume.

When the filler cap is replaced, the valve

opens allowing the tank to breathe through

the canister

29 Excess - vacuum safety valve

If the fuel vapour recirculation circuit is

blocked, this valve prevents the fuel tank

being subject to excess pressure (the tank

would inflate) or vacuum (as fuel is used, the

tank would be crushed).

30 Restriction valve

This valve prevents the introduction of leaded

fuel into the tank.

31 Leak prevention valve in case vehicle turns

over

If the vehicle turns over, this valve prevents

the tank from emptying, either through the

pipe leading to the canister, or through the

breather pipe (in Diesel versions).

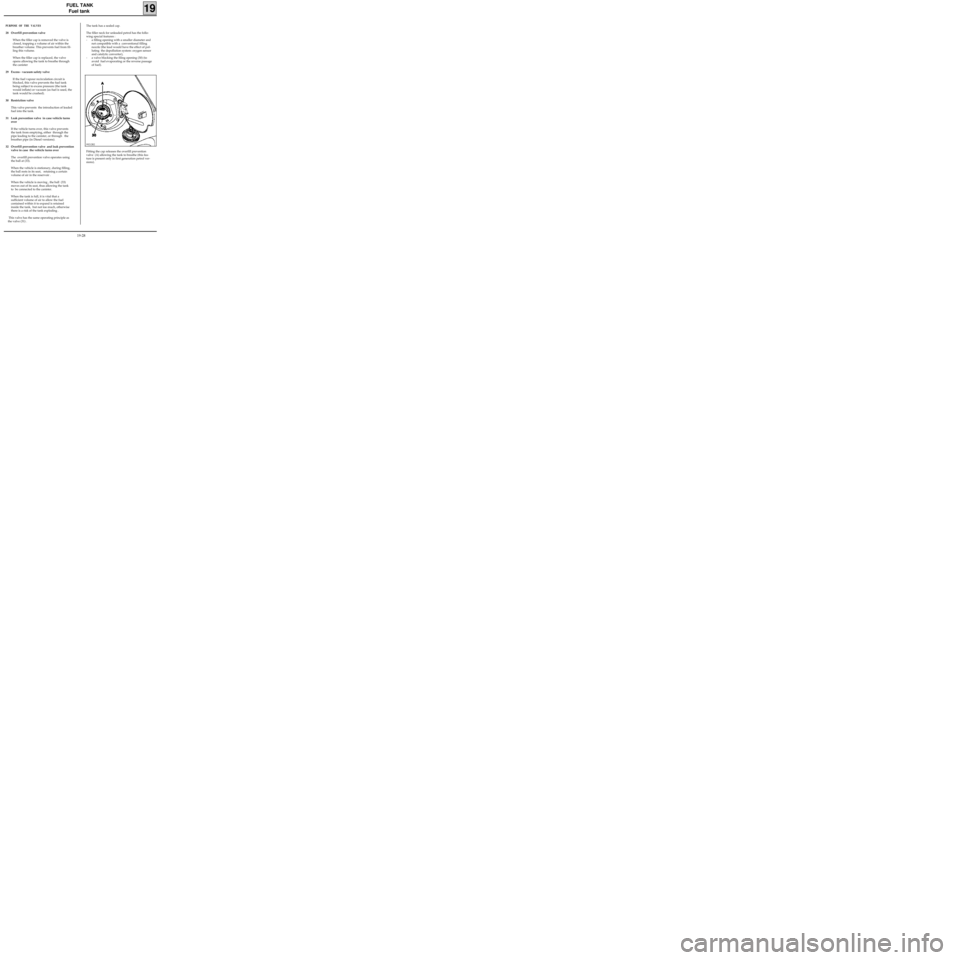

32 Overfill prevention valve and leak prevention

valve in case the vehicle turns over

The overfill prevention valve operates using

the ball at (33).

When the vehicle is stationary, during filling,

the ball rests in its seat, retaining a certain

volume of air in the reservoir .

When the vehicle is moving , the ball (33)

moves out of its seat, thus allowing the tank

to be connected to the canister.

When the tank is full, it is vital that a

sufficient volume of air to allow the fuel

contained within it to expand is retained

inside the tank, but not too much, otherwise

there is a risk of the tank exploding .

This valve has the same operating principle as

the valve (31) .

The tank has a sealed cap.

The filler neck for unleaded petrol has the follo-

wing special features :

- a filling opening with a smaller diameter and

not compatible with a conventional filling

nozzle (the lead would have the effect of pol-

luting the depollution system: oxygen sensor

and catalytic converter),

- a valve blocking the filing opening (30) (to

avoid fuel evaporating or the reverse passage

of fuel).

Fitting the cap releases the overfill prevention

valve (A) allowing the tank to breathe (this fea-

ture is present only in first generation petrol ver-

sions).

99212R2

19-28

Page 204 of 208

Mot. 1264 Wrench for removing

Mot. 1264-01 pump-sender unit assembly nut

Mot. 1265 Pliers for removing

Mot. 1265-01 quick release unions

FUEL TANK

Pump- sender unit

19

SPECIAL TOOLING REQUIRED

IMPORTANT :

During all operations on the fuel tank or on the

fuel supply circuit , it is vital :

- to refrain from smoking and handling incan-

descent objects in the vicinity of the working

area,

- to avoid fuel projections, due to the residual

pressure present in the pipes during removal .

REMOVAL

To remove the pump-sender unit assembly, it is

not necessary to remove the tank, as it is accessi-

ble through the inside of the vehicle. To do this :

- disconnect the battery,

- lift the rear bench seat ,

- remove the steel access cover,

- remove the electrical connection at (1),

- remove the clips at (2).

97163R5

Nut for pump - sender unit assembly 7

TIGHTENING TORQUES (in daN.m)Disconnect, using tool Mot. 1265 or Mot. 1265-

01:

- the fuel supply pipe (3) (which is marked by a

green quick release union),

- the fuel return pipe (4) (marked by a red quick

release union and by an arrow (B)).

96420R1

19-30