coolant RENAULT KANGOO 1997 KC / 1.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 208

Page 4 of 208

Page

Cooling

Specifications

Filling and bleeding

Testing

Diagram

Water pump

Exhaust

General

Exhaust pipe assembly

Fuel tank

Tank

Sender unit

Pump and sender unit assembly

Engine suspension

Suspended engine mountings19-1

19-2

19-3

19-4

19-7

19-12

19-15

19-17

19-29

19-30

19-32 COOLING - EXHAUST - FUEL TANK -

ENGINE SUSPENSION

19

16-1

16-7 STARTING - CHARGING

Alternator

Starter

16

IGNITION - INJECTION

Ignition

Static ignition

Plugs

Injection

General

Location of components

Centralised coolant temperature

management

Injection fault warning light

Immobiliser function

Computer configuration depending

on gearbox type17

14-1

14-2

14-7

14-11 ANTIPOLLUTION

Test for the presence of lead

Fuel vapour rebreathing

Oil vapour rebreathing

Exhaust gas recirculation

(EGR)

14

17-17

17-18

17-19

17-20

17-22 IGNITION - INJECTION

(continued)

Injection/air conditioning

programming

Idle speed correction

Adaptive idle speed

correction

Richness regulation

Adaptive richness correction

17

Page

17-1

17-3

17-4

17-8

17-13

17-14

17-15

17-16

Contents

Page 21 of 208

ENGINE AND ENGINE PERIPHERALS

Engine and transmission assembly

10

Fit retaining lug Mot. 1159 in place of the coolant

pipe mounting on the cylinder block.

99310R

Remove the suspended engine mounting cover.

13359R

13086R

Insert a wooden block between the gearbox and

the sub-frame.

Remove:

- the nut (1), then tap it with a copper hammer

to release the suspended engine mounting

stud.- the mounting bolts (3).

E7J engine

12993-1R3

10-17

Page 27 of 208

ENGINE AND ENGINE PERIPHERALS

Engine and transmission assembly

10

Remove the suspended engine mounting cover.

13086R1

13086R

Insert a wedge between the gearbox and the sub-

frame.

Remove:

- the nut (1), then tap it with a copper hammer

to release the suspended engine mounting

stud. F8Q engine

99024R2

Fit tool Mot. 1159 between the sub-frame and the

cylinder block.

Fit tool Mot. 1159 in place of the coolant pipe

mounting on the cylinder block.

99310R

10-23

Page 53 of 208

TOP AND FRONT OF ENGINE

Cylinder head gasket

11

13339S

- the cover on the air filter assembly,

- the air filter assembly,

13338S

99310R

Remove :

- the connector along with the pipe on the ab-

solute pressure sensor,

- the stepping motor connector, Fit the bracket Mot. 1159 in place of the coolant

pipe mounting on the cylinder block, then remove

the engine support tool.- the throttle position potentiometer connec-

tor,

- the accelerator cable

- the air intake pipe, having disconnected the

air temperature connector, E7J Engine

11-18

Page 59 of 208

TOP AND FRONT OF ENGINE

Cylinder head gasket

11

Remove :

- the exhaust downpipe,

- the hoses and connectors of the cylinder head

coolant pipe housing outlet,

- the connection at (1) using tool Mot. 1311-06,

13097R

99461R

- the air filter assembly by disconnecting the

EGR solenoid valve and the air temperature

sensor (unclip the fuel supply pipes from the

air filter housing),

- the air inlet pipe

- the accelerator cable

- the feeds for the heater plugs ,

- the connector of the injector with sensor,

along with the fast idle solenoid valve connec-

tor (5),

- the fuel supply and return unions at (A) and

(B).

Disconnect connector (6) from the diesel fuel fil-

ter, remove it from its support and move the die-

sel fuel filter pipe assembly to one side. Place bracket Mot. 1159 at the mounting of the

coolant pipe on the cylinder block, then remove

the engine support tool.

99310R

F8Q Engine

11-24

Page 66 of 208

FUEL MIXTURE

Specifications

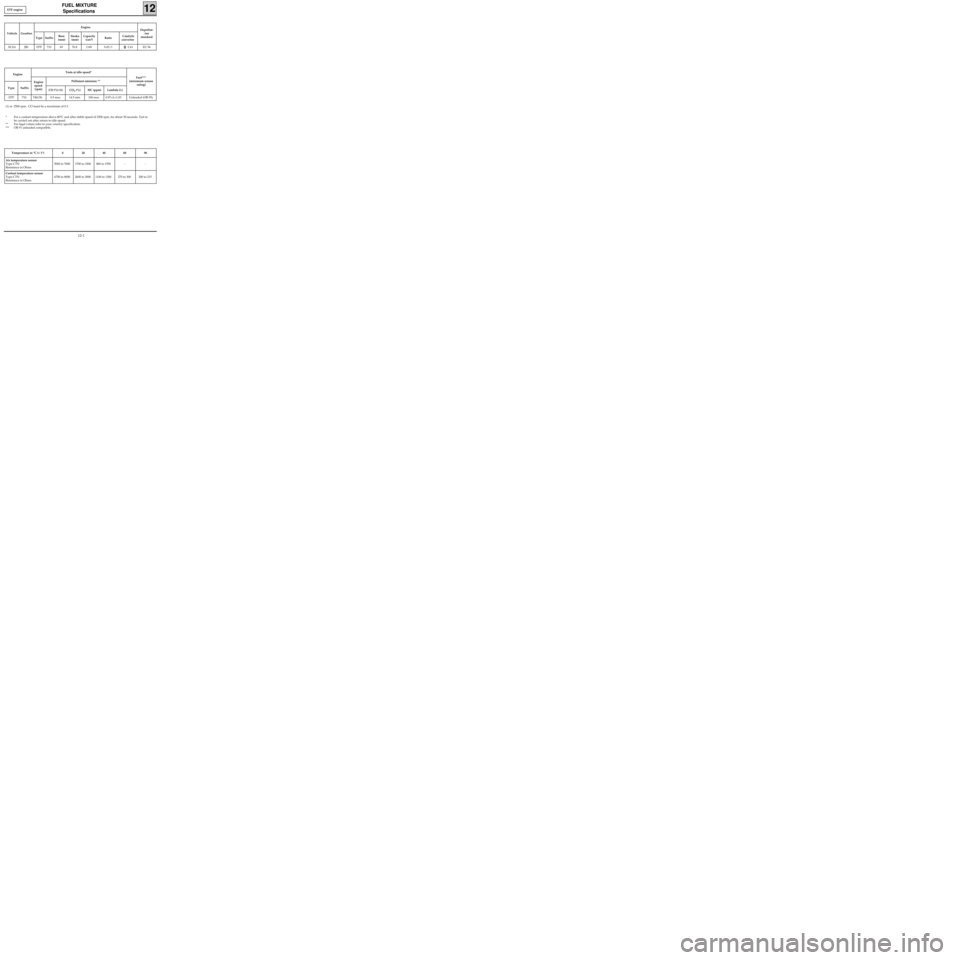

12

Vehicle GearboxEngine

Type SuffixBore

(mm)Stroke

(mm)Capacity

(cm

3)RatioCatalytic

converterDepollut-

ion

standard

XC0A JB1 D7F 710 69 76.8 1149 9.65/1 C61 EU 96

Temperature in °C (± 1°) 0 20 40 80 90

Air temperature sensor

Type CTN

Resistance in Ohms5000 to 7000 1700 to 3300 800 to 1550 - -

Coolant temperature sensor

Type CTN

Resistance in Ohms6700 to 8000 2600 to 3000 1100 to 1300 270 to 300 200 to 215

Engine

Type SuffixTests at idle speed*

Engine

speed

[rpm]Pollutant emission **

CO (%) (1) CO

2 (%) HC (ppm) Lambda (λ)Fuel***

[minimum octane

rating]

D7F 710 740±50 0.5 max 14.5 min 100 max 0.97<λ<1.03 Unleaded (OR 95)

(1) at 2500 rpm, CO must be a maximum of 0.3

* For a coolant temperature above 80°C and after stable speed of 2500 rpm, for about 30 seconds. Test to

be carried out after return to idle speed.

** For legal values refer to your country specification.

*** OR 91 unleaded compatible.D7F engine

12-1

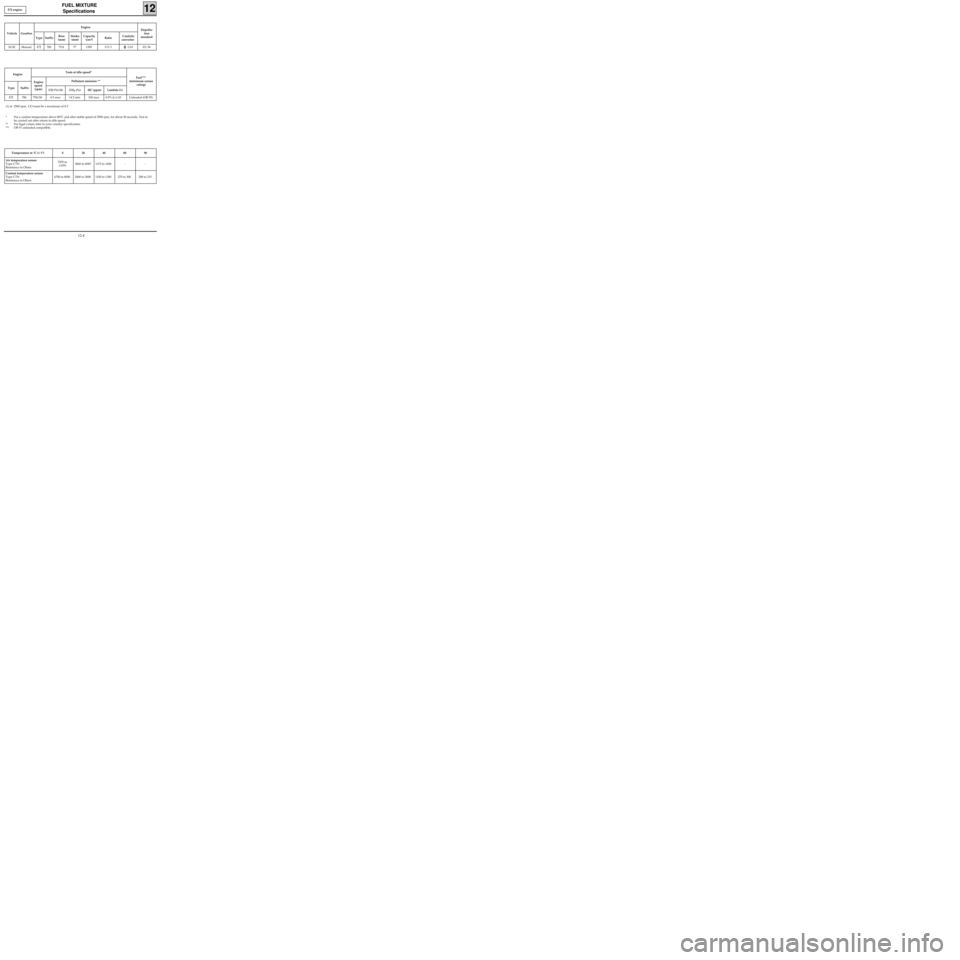

Page 69 of 208

FUEL MIXTURE

Specifications

12

Vehicle GearboxEngine

Type SuffixBore

(mm)Stroke

(mm)Capacity

(cm

3)RatioCatalytic

converterDepollu-

tion

standard

XC0C Manual E7J 780 75.8 77 1390 9.5/1 C63 EU 96

Temperature in °C (± 1°) 0 20 40 80 90

Air temperature sensor

Type CTN

Resistance in Ohms7470 to

119703060 to 4045 1315 to 1600 - -

Coolant temperature sensor

Type CTN

Resistance in Ohms6700 to 8000 2600 to 3000 1100 to 1300 270 to 300 200 to 215

Engine

Type SuffixTests at idle speed*

Engine

speed

[rpm]Pollutant emission **

CO (%) (1) CO

2 (%) HC (ppm) Lambda (λ)Fuel***

(minimum octane

rating)

E7J 780 750±50 0.5 max 14.5 min 100 max 0.97<λ<1.03 Unleaded (OR 95)

(1) at 2500 rpm, CO must be a maximum of 0.3

* For a coolant temperature above 80°C and after stable speed of 2500 rpm, for about 30 seconds. Test to

be carried out after return to idle speed.

** For legal values refer to your country specification.

*** OR 91 unleaded compatible.E7J engine

12-4

Page 92 of 208

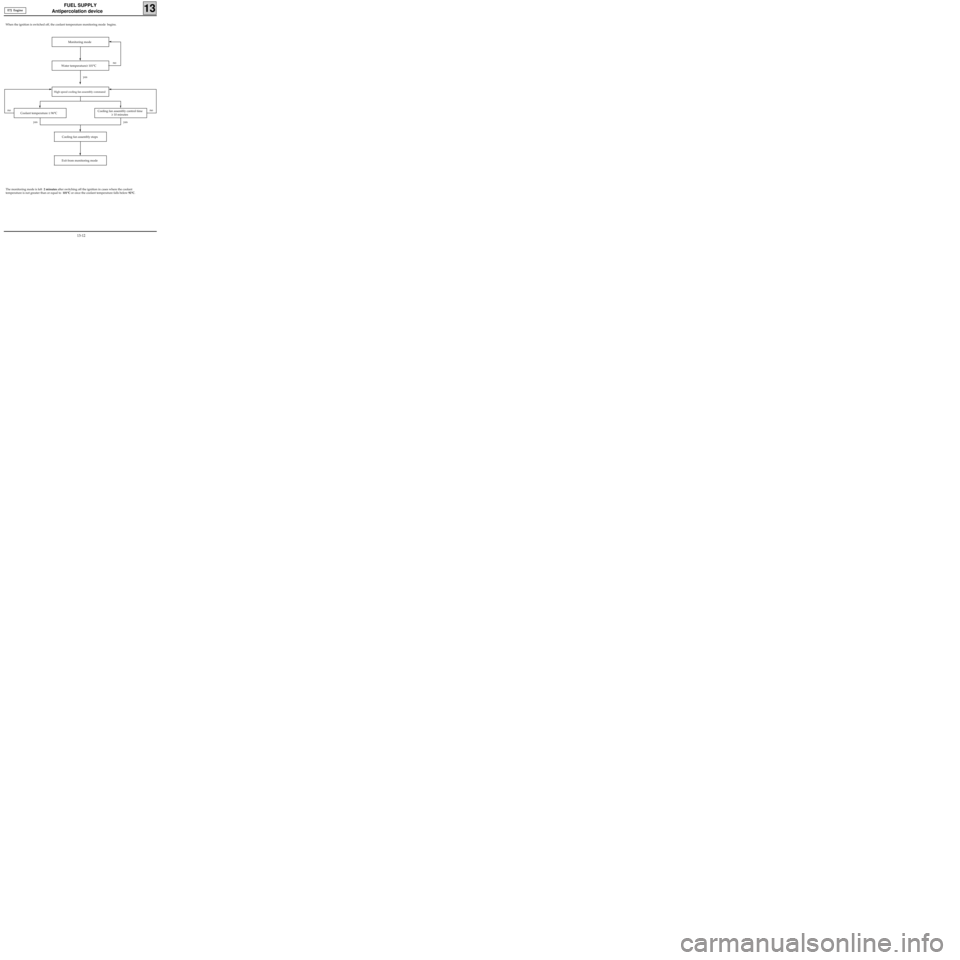

FUEL SUPPLY

Antipercolation device

13

When the ignition is switched off, the coolant temperature monitoring mode begins.

E7J Engine

Monitoring mode

Water temperature≥ 101°C

Coolant temperature ≤ 96°C Cooling fan assembly control time

≥ 10 minutes

Cooling fan assembly stops

Exit from monitoring mode

The monitoring mode is left 2 minutes after switching off the ignition in cases where the coolant

temperature is not greater than or equal to 101°C or once the coolant temperature falls below 92°C.

no

yes

nono

yes yes

High speed cooling fan assembly command

13-12

Page 93 of 208

DIESEL EQUIPMENT

General

13

The use of electronic injection in Diesel engines has allowed the operational power of these engines to be

optimised, thus reducing the emission rate of pollutant gases.

The system consists of a computer, which receives information from:

- the coolant temperature sensor,

- the air temperature sensor,

- the engine speed sensor,

- the vehicle speed sensor,

- the load potentiometer,

- the injection start sensor, which forms part of the injector of cylinder n° 3 (injector with sensor).

It controls :

- the injection pump :

• the altimetric corrector (F8Q 630) via a relay

• the advance solenoid valve.

- the cold engine starting system (heater plugs and pre-postheating unit),

- the exhaust gas recycling system (EGR),

- the diesel injection fault warning light,

- the preheating warning light,

- the solenoid valve controlling the fast idle speed LDA,

- the relay controlling the power assisted steering electric pump assembly (for vehicles with air conditio-

ning), the pump assembly is supplied once the engine speed exceeds 650 rpm.

It carries out a self diagnosis procedure which may be visualised through the

XR25.

SPECIAL FEATURES

On the injection pump it is possible to replace:

- the load potentiometer,

- the advance solenoid valve,

- the altimetric corrector,

- the electrical solenoid.

13-13

Page 94 of 208

DIESEL EQUIPMENT

Specifications

13

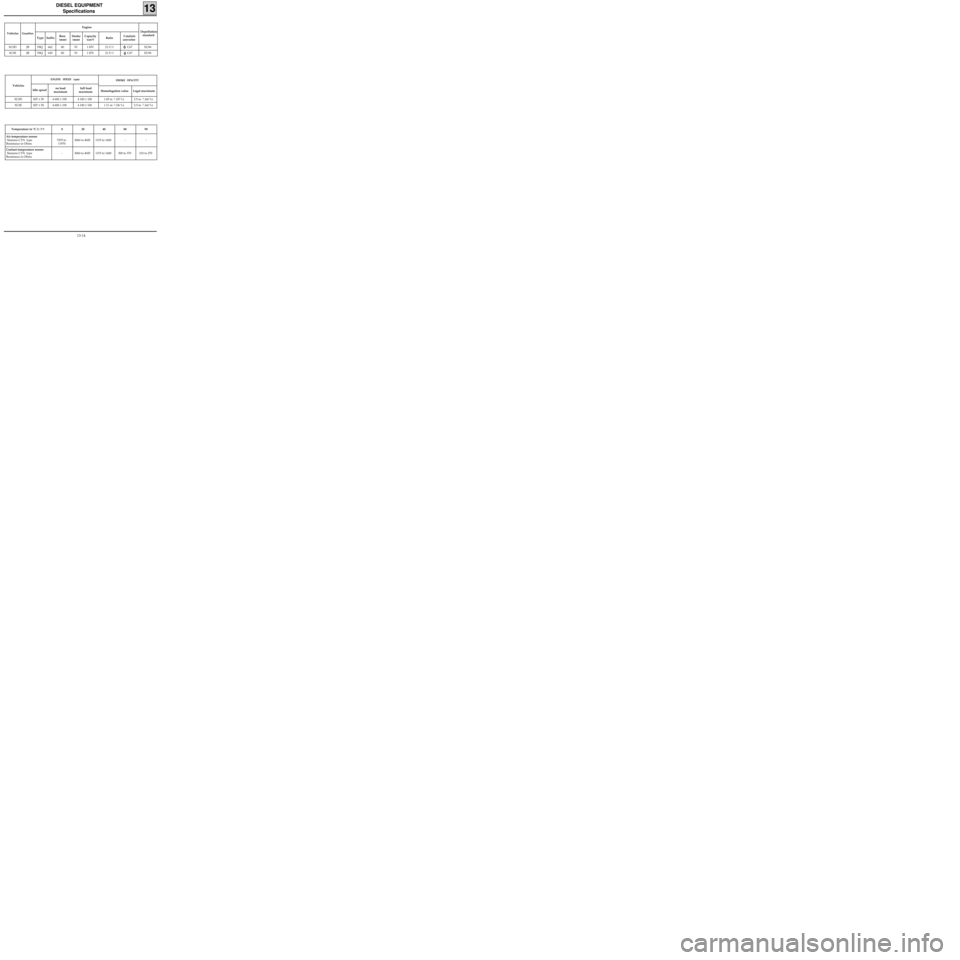

Vehicles GearboxEngine

Type SuffixBore

(mm)Stroke

(mm)Capacity

(cm

3)RatioCatalytic

converterDepollution

standard

XC0D JB F8Q 662 80 93 1 870 21.5/1 C67 EU96

XC0E JB F8Q 630 80 93 1 870 21.5/1 C67 EU96

Vehicles

ENGINE SPEED (rpm)

Idle speedno load

maximumfull load

maximum

SMOKE OPACITY

Homologation value Legal maximum

XC0D 825 ± 50 4 600 ± 100 4 100 ± 100 1.05 m

-1 (35 %) 2.5 m -1 (64 %)

XC0E 825 ± 50 4 600 ± 100 4 100 ± 100 1.11 m

-1 (36 %) 2.5 m -1 (64 %)

Temperature in °C (± 1°) 0 20 40 80 90

Air temperature sensor

Siemens CTN type

Resistance in Ohms7470 to

119703060 to 4045 1315 to 1600 - -

Coolant temperature sensor

Siemens CTN type

Resistance in Ohms- 3060 to 4045 1315 to 1600 300 to 370 210 to 270

13-14