coolant RENAULT KANGOO 1997 KC / 1.G Engine And Peripherals Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 208

Page 156 of 208

INJECTION

General

17

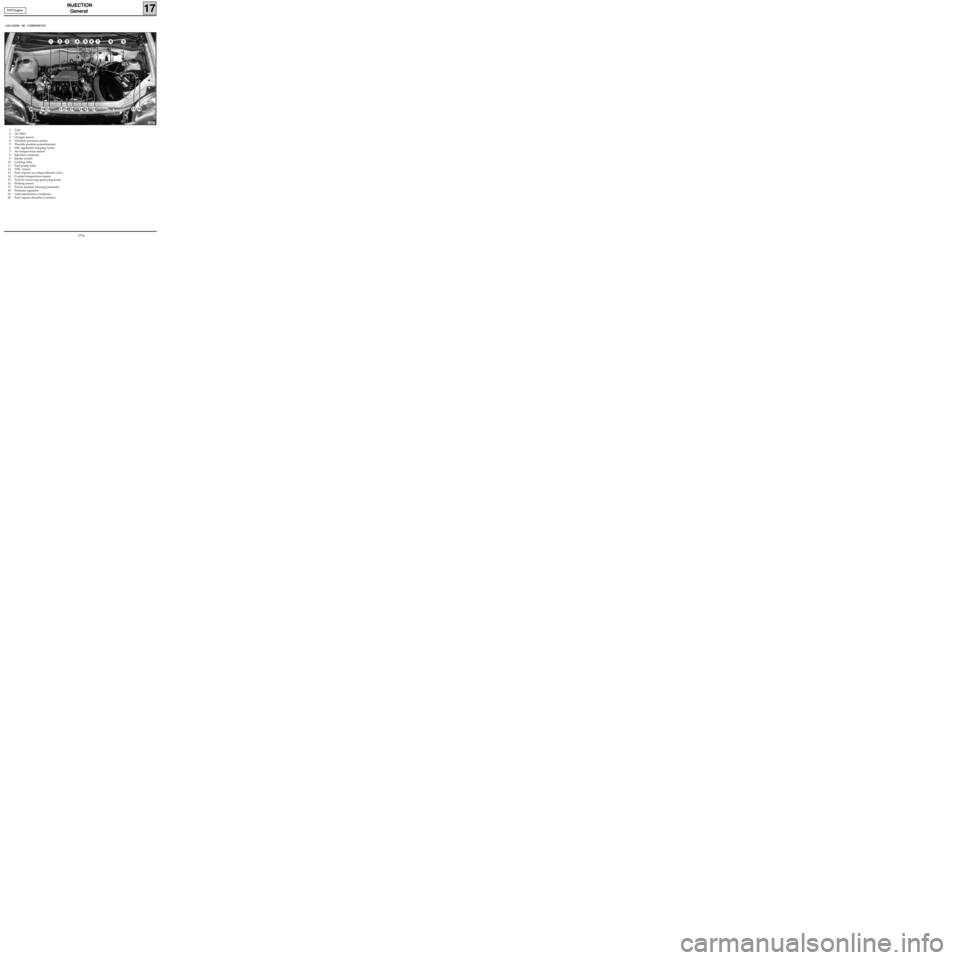

1 Coil

2 Air filter

3 Oxygen sensor

4 Absolute pressure sensor

5 Throttle position potentiometer

6 Idle regulation stepping motor

7 Air temperature sensor

8 Injection computer

9 Inertia switch

10 Locking relay

11 Fuel pump relay

12 TDC sensor

13 Fuel vapour recycling solenoid valve

14 Coolant temperature sensor

15 Tool for removing spark plug leads

16 Pinking sensor

17 Power assisted steering pressostat

18 Pressure regulator

19 Anti-interference condenser

20 Fuel vapour absorber (canister)

LOCATION OF COMPONENTS

13081

D7F Engine

17-6

Page 157 of 208

INJECTION

General

17

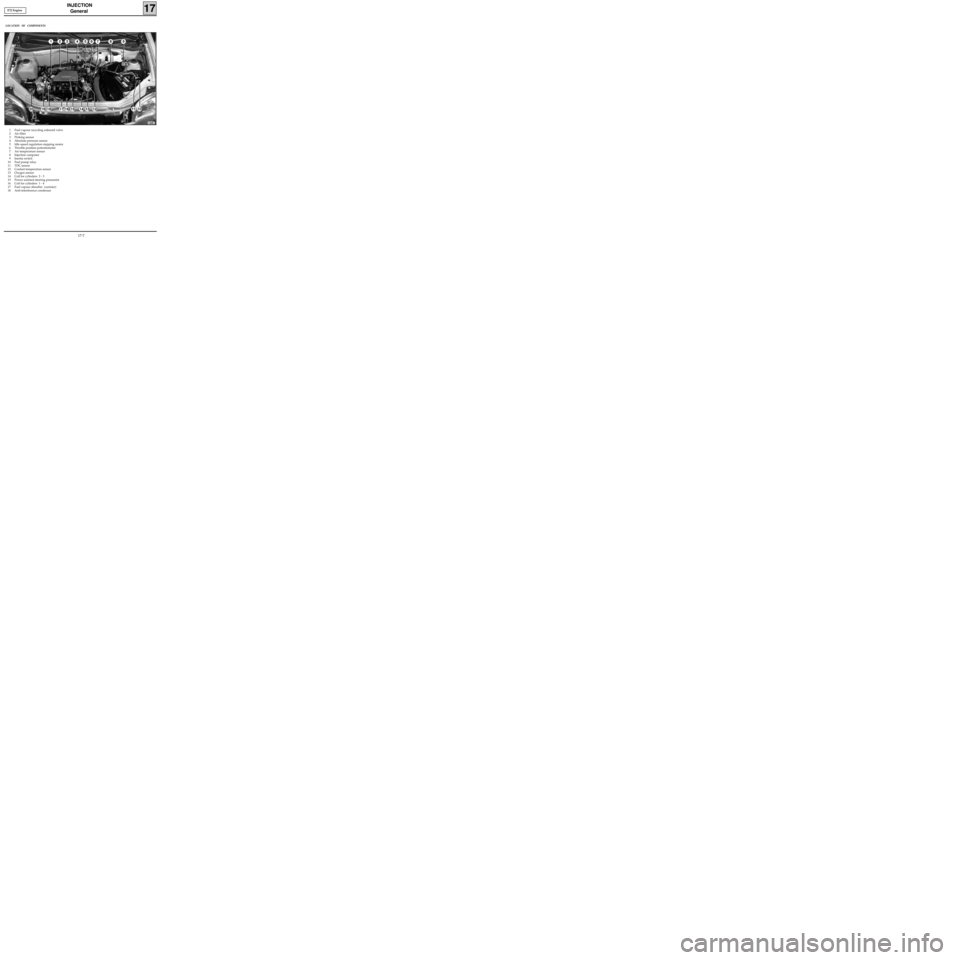

1 Fuel vapour recycling solenoid valve

2 Air filter

3 Pinking sensor

4 Absolute pressure sensor

5 Idle speed regulation stepping motor

6 Throttle position potentiometer

7 Air temperature sensor

8 Injection computer

9 Inertia switch

10 Fuel pump relay

11 TDC sensor

12 Coolant temperature sensor

13 Oxygen sensor

14 Coil for cylinders 2 - 3

15 Power assisted steering pressostat

16 Coil for cylinders 1 - 4

17 Fuel vapour absorber (canister)

18 Anti-interference condenser

LOCATION OF COMPONENTS

13082

E7J Engine

17-7

Page 158 of 208

INJECTION

Location of components

17

4 Absolute pressure sensor

5 Throttle position potentiometer

6 Idle speed regulation stepping motor

7 Air temperature sensor13 Fuel vapour recycling solenoid

14 Coolant temperature sensor 16 Pinking sensor

(tightening torque: 2.5 daN.m)

11313R4

11311R1

99939-1R2

8 Injection computer

9 Inertia switch

13051R1

D7F Engine

17-8

Page 160 of 208

INJECTION

Location of components

17

12 Coolant temperature sensor8 Injection computer

9 Inertia switch

13240R

3 Pinking sensor

(tightening torque: 2.5 daN.m)

13336R13239R

E7J Engine

17-10

Page 163 of 208

INJECTION

Coolant temperature management

244Injection coolant temperature sensor and

coolant temperature indication on

instrument panel.

3 track sensor, of which two tracks are

allocated to the injection coolant

temperature information, and one to the

indication of the coolant temperature on

the instrument panel.

259Warning coolant temperature switch for

instrument panel.

Operating principle

Sensor 244 allows :

- the coolant temperature to be shown on the

instrument panel,

- the injection computer to receive constant in-

formation on the engine coolant temperature

.

The injection computer, depending on the co-

olant temperature, controls :

- the injection system,

- the cooling fan assembly.

The engine cooling fan assembly is controlled

at fast speed (both slow and fast speeds are

controlled by the air conditioning system) if

the temperature is greater than 99°C. If the

temperature falls below 96°C, it cuts off

automatically ( if a check has to be carried out,

ensure that the air conditioning is not opera-

tional).

17

11634R2

D7F Engine

13239R1

E7J Engine

17-13

Page 167 of 208

INJECTION

Injection/air conditioning programming

17

THIS VEHICLE IS FITTED WITH A VARIABLE OUTPUT COMPRESSOR

AIR CONDITIONING/INJECTION COMPUTER CONNECTION

The electrical connection :

- between the air conditioning computer and the injection computer consists of a single wire (track 5).

This track carries two types of information :

-the fast idle speed request information . For this information to be transmitted to the injection

computer , two conditions must be fulfilled :

• the air conditioning function must have been selected on the control panel ,

• the pressure in the air conditioning circuit must be greater than a certain threshold.

If this information is transmitted, the fast idle speed is obtained (it is therefore normal that

sometimes, when the air conditioning is switched on, engine idling, there is no fast idle speed ).

-the Absorbed Power information. This information has no influence on the idle speed. It simply

informs the injection computer of the torque value taken up by the compressor; the computer, in

turn, acts on the idle speed regulation solenoid. The absorbed power may be visualised using the

XR25. When the air conditioning is switched on , #44 should be between 300 and 5 000 watts.

IMPORTANT: the value at #44 or idle speed is never equal to 0, whatever the status of the

compressor, off or on . The minimum value which may be read using #44 is approximately 300

watts.

- between the the injection computer and the air conditioning computer consists of a single wire (track

51). This track carries the information regarding the authorisation or prevention of compressor

operation.

COMPRESSOR OPERATION PROGRAMMING

During certain operating phases, the injection computer prevents the compressor from operating.

Programming when starting engine

The compressor is prevented from functioning for 10 seconds after starting the engine .

Recovery of performance ( D7F engine)

Depending on the torque required by the driver and on the power absorbed by the air conditioning

compressor, the injection computer stops or allows the operation of the compressor .

Anti-stalling function (D7F engine)

If the no load position is recognised , and the engine speed is lower than 600 rpm, and if the power absorbed

by the compressor is greater than 300 watts, the compressor disengages .

It engages again if:

- the no load position is recognised when the engine speed reaches 850 rpm.,

- if the no load position is not recognised when the engine speed reaches 1 800 rpm.

Thermal protection programming ( E7J engine )

The compressor does not engage in cases where the coolant temperature is greater than or equal to +

115°C.

Over-revving protection (E7J engine )

The compressor is prevented from operating if the engine speed is greater than 5 900 rpm.

17-17

Page 169 of 208

INJECTION

Adaptive idle speed correction

17

PRINCIPLE

Under normal warm engine operating conditions , the R.C.O. idle speed value at #12 varies between a

high value and a low value, until the nominal idle speed is obtained .

It is possible that during variations in the operation of the vehicle (running in, engine wear..), that the

R.C.O. idle speed value could become close to the highest or lowest values.

The adaptive correction (#21) of the

R.C.O. idle speed (#12) allows the slow variations in the engine air re-

quirement to be corrected, so that the

R.C.O. (#12) is recentred to an average nominal value.

This correction only becomes effective if the coolant temperature is higher than 75°C, 20 seconds after

starting the engine and if the nominal idle speed regulation phase has been reached.

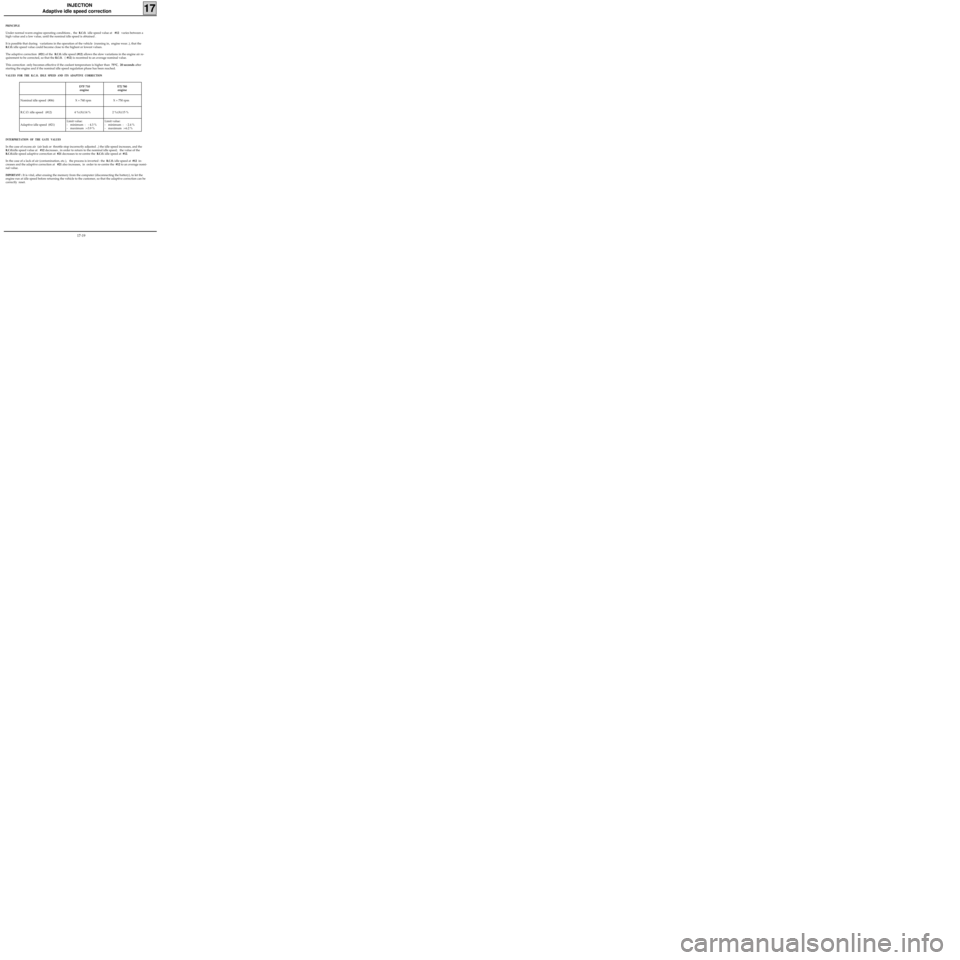

VALUES FOR THE R.C.O. IDLE SPEED AND ITS ADAPTIVE CORRECTION

D7F 710

engineE7J 780

engine

Nominal idle speed (#06) X = 740 rpm X = 750 rpm

R.C.O. idle speed (#12) 4 %≤X≤14 % 2 %≤X≤15 %

Adaptive idle speed (#21)Limit value:

- minimum : - 4.3 %

- maximum :+3.9 %Limit value:

- minimum : - 2.4 %

- maximum :+6.2 %

INTERPRETATION OF THE GATE VALUES

In the case of excess air (air leak or throttle stop incorrectly adjusted ..) the idle speed increases, and the

R.C.O.idle speed value at #12 decreases , in order to return to the nominal idle speed; the value of the

R.C.O.idle speed adaptive correction at #21 decreases to re-centre the R.C.O. idle speed at #12.

In the case of a lack of air (contamination, etc.), the process is inverted : the

R.C.O. idle speed at #12 in-

creases and the adaptive correction at #21 also increases, in order to re-centre the #12 to an average nomi-

nal value.

IMPORTANT : It is vital, after erasing the memory from the computer (disconnecting the battery), to let the

engine run at idle speed before returning the vehicle to the customer, so that the adaptive correction can be

correctly reset.

17-19

Page 170 of 208

OXYGEN SENSOR VOLTAGE (#05)

Reading #05 on the XR25 : the value read is the voltage sent to the computer by the oxygen sensor; it is ex-

pressed in volts (the value actually varies between 0 and 1 000 millivolts).

When the engine is in the loop phase, the voltage value should oscillate rapidly and should be between

50±50 mV (lean mixture) and 850 ± 50 mV (rich mixture) and vice versa.

The smaller the gap between the upper and lower values, the poorer the information from the sensor (the

gap is usually at least 500 mV).

RICHNESS CORRECTION (#35)

The value given under # 35 on the XR25 represents the average value of richness corrections made by the

computer depending on the richness of the burnt mixture as seen by the oxygen sensor (the oxygen sensor ac-

tually analyses the oxygen content of the exhaust gases directly from the richness of the burnt mixture).

The richness correction has a centre point of 128 with thresholds of 0 and 255 (experience has shown that un-

der normal operating conditions # 35 is located close to 128 with only a small amount of variation).

- Value less than 128 : request for mixture to be made leaner.

- Value greater than 128 : request for mixture to be made richer.

ENTRY INTO RICHNESS REGULATION MODE

Loop phase

Richness regulation begins after the timed starting period :

- for no load, if the coolant temperature has reached :

•46°C for the E7J engine ,

•30°C for the D7F engine.

- outside no load conditions if the coolant temperature is greater than :

•+ 20°C for the E7J, engine

•+ 20°C for the D7F engine.

The timed starting period is dependent on the coolant temperature :

- at 20°C it is a maximum of :

•3 minutes for the E7J engine,

•1 minute 20 seconds for the D7F engine,

- at 80°C it is a maximum of :

•1 minute 30 seconds for the E7J engine,

•35 seconds for the D7F engine,

If richness regulation has not yet started, #35 = 128

INJECTION

Richness regulation

17

17-20

Page 173 of 208

INJECTION

Adaptive richness correction

17

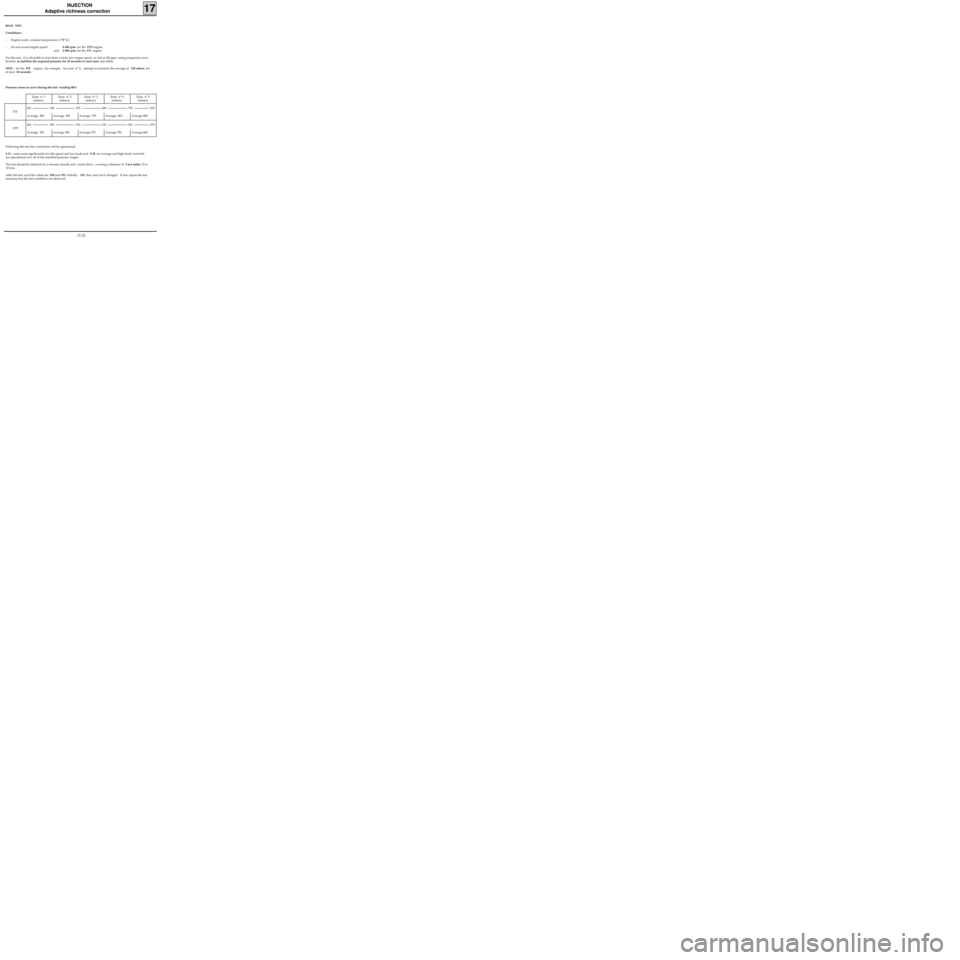

Zone n° 5

(mbars)Zone n° 4

(mbars)Zone n° 3

(mbars)Zone n° 2

(mbars)Zone n° 1

(mbars)

220340470 600 730870

Average 280 Average 405 Average 535 Average 665 Average 800

260385510 635 760970

Average 320 Average 450 Average 570 Average 700 Average 865

E7J

D7F Pressure zones to cover during the test (reading #01)

Following this test the corrections will be operational.

# 31 varies more significantly for idle speed and low loads and # 30 for average and high loads, but both

are operational over all of the manifold pressure ranges.

The test should be followed by a normal, smooth and varied drive, covering a distance of 3 to 6 miles (5 to

10 km).

After the test, read the values for #30 and #31. Initially 128, they may have changed. If not, repeat the test

ensuring that the test conditions are observed.

ROAD TEST

Conditions :

- Engine warm (coolant temperature > 75° C).

- Do not exceed engine speed 4 400 rpm. for the D7F engine.

and 4 800 rpm. for the

E7J engine.

For this test , it is advisable to start from a fairly low engine speed , in 3rd or 4th gear using progressive acce-

leration to stabilise the required pressure for 10 seconds in each zone (see table).

NOTE : for the D7F engine, for example, for zone n° 1, attempt to maintain the average of 320 mbars for

at least 10 seconds.

17-23

Page 175 of 208

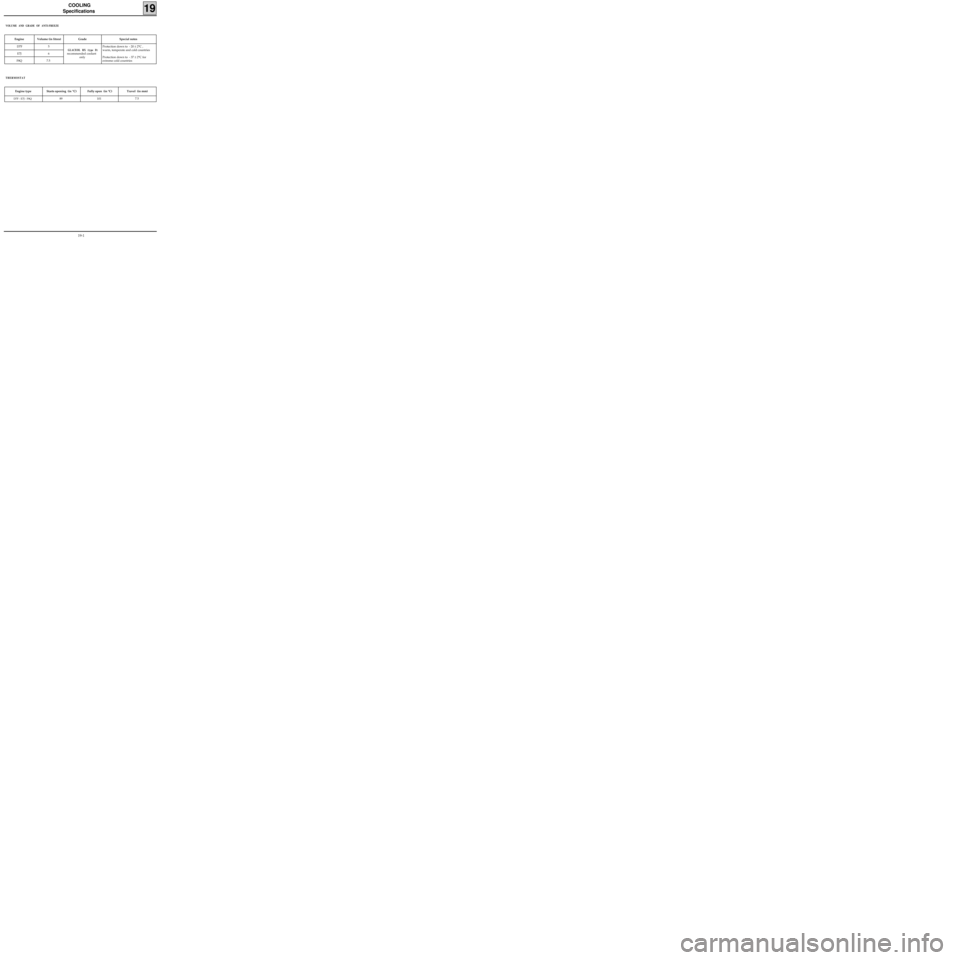

COOLING

Specifications

19

VOLUME AND GRADE OF ANTI-FREEZE

Engine Volume (in litres) Grade Special notes

D7F

E7J

F8Q5

6

7.5

GLACEOL RX (type D)

recommended coolant

onlyProtection down to - 20 ± 2°C ,

warm, temperate and cold countries

Protection down to - 37 ± 2°C for

extreme cold countries

THERMOSTAT

Engine type Starts opening (in °C) Fully open (in °C) Travel (in mm)

D7F - E7J - F8Q89 101 7.5

19-1