reset RENAULT KANGOO 1997 KC / 1.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 208

Page 81 of 208

FUEL SUPPLY

Fuel cut off in case of an impact

13

OBJECTIVE

The main function of this feature is to avoid any

fires that may result from the leakage of fuel du-

ring an accident. In order to achieve this, all

components pumping fuel from the fuel tank will

automatically stop functioning during and imme-

diately after the impact. They can then only be

made to operate again by a mechanical action car-

ried out by the driver or the repairer.

DESCRIPTION

The system consists simply of an inertia switch (1),

which:

- detects the impact,

- and thus cuts off the electrical circuit.

13051R

This is fitted:

• in petrol engines, between track 1 of the

pump relay (236) and the + 12 V supply ,

• in diesel engines, between the + supply and

the electrical solenoid (or the coded solenoid

valve if the vehicle is fitted with an engine im-

mobiliser).

OPERATING PRINCIPLE

During the impact, the ball of the inertia switch

moves up and interrupts the electrical connec-

tion.

In petrol engines, the + supply of the pump relay

control circuit (236) is cut. Neither the pump or

the injectors will receive any further supply of

electricity .

The fuel contained in the tank is actually isolated.

In diesel engines, the + supply of the electrical

solenoid or of the coded solenoid is cut off.

The pump can no longer take in fuel, and there is

no longer any high pressure. All risk of fire due to

the outlet of diesel fuel at high pressure onto the

engine is removed.

RESETTING AND OPERATING THE SWITCH

In order to reset the inertia switch, it is sufficient

to press it down in order to replace the ball bea-

ring in its original position .

IMPORTANT: for petrol engines, , having reset

the switch, it is

VITAL to erase the memory of the

computer, using the

XR25. The injection compu-

ter will memorise a pump relay fault once the

system has gone into operation .

13-1

Page 169 of 208

INJECTION

Adaptive idle speed correction

17

PRINCIPLE

Under normal warm engine operating conditions , the R.C.O. idle speed value at #12 varies between a

high value and a low value, until the nominal idle speed is obtained .

It is possible that during variations in the operation of the vehicle (running in, engine wear..), that the

R.C.O. idle speed value could become close to the highest or lowest values.

The adaptive correction (#21) of the

R.C.O. idle speed (#12) allows the slow variations in the engine air re-

quirement to be corrected, so that the

R.C.O. (#12) is recentred to an average nominal value.

This correction only becomes effective if the coolant temperature is higher than 75°C, 20 seconds after

starting the engine and if the nominal idle speed regulation phase has been reached.

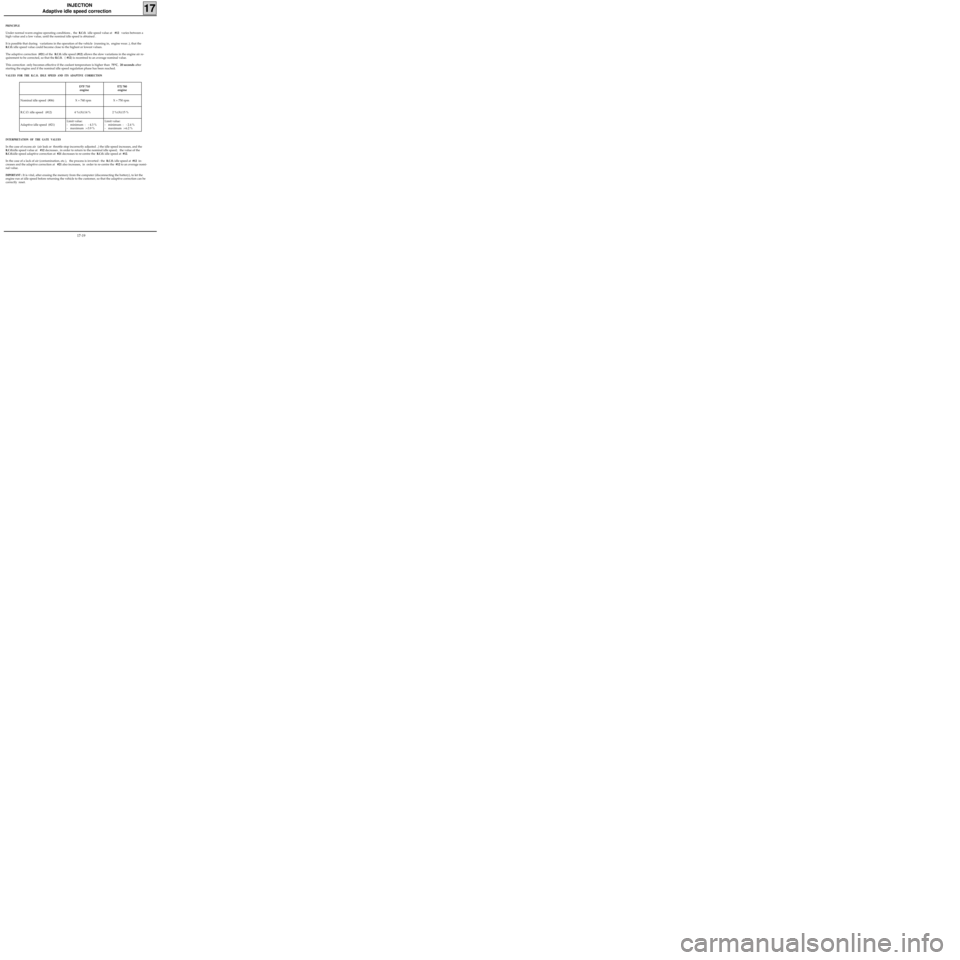

VALUES FOR THE R.C.O. IDLE SPEED AND ITS ADAPTIVE CORRECTION

D7F 710

engineE7J 780

engine

Nominal idle speed (#06) X = 740 rpm X = 750 rpm

R.C.O. idle speed (#12) 4 %≤X≤14 % 2 %≤X≤15 %

Adaptive idle speed (#21)Limit value:

- minimum : - 4.3 %

- maximum :+3.9 %Limit value:

- minimum : - 2.4 %

- maximum :+6.2 %

INTERPRETATION OF THE GATE VALUES

In the case of excess air (air leak or throttle stop incorrectly adjusted ..) the idle speed increases, and the

R.C.O.idle speed value at #12 decreases , in order to return to the nominal idle speed; the value of the

R.C.O.idle speed adaptive correction at #21 decreases to re-centre the R.C.O. idle speed at #12.

In the case of a lack of air (contamination, etc.), the process is inverted : the

R.C.O. idle speed at #12 in-

creases and the adaptive correction at #21 also increases, in order to re-centre the #12 to an average nomi-

nal value.

IMPORTANT : It is vital, after erasing the memory from the computer (disconnecting the battery), to let the

engine run at idle speed before returning the vehicle to the customer, so that the adaptive correction can be

correctly reset.

17-19