airbag RENAULT KANGOO 1997 KC / 1.G Foult Finding - Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 363

Page 1 of 363

Renault 1997

77 11 194 235JULY 1997Edition Anglaise

"The repair methods given by the manufacturer in this document are based on the

technical specifications current when it was prepared.

The methods may be modified as a result of changes introduced by the

manufacturer in the production of the various component units and accessories

from which his vehicles are constructed."All copyrights reserved by Renault.

Copying or translating, in part or in full, of this document or use of the service part

reference numbering system is forbidden without the prior written authority of

Renault.

C

Fault finding

LUCAS DIESEL INJECTION

INJECTION

IMMOBILISER

AIRBAG - SEAT BELT PRETENSIONERS ELECTRONICALLY CONTROLLED HYDRAULIC

SYSTEMS

FC0A - FC0C - FC0D - FC0E - KC0A - KC0C - KC0D - KC0E

Page 3 of 363

Contents

Page

Fault finding

BATTERIE PROJECTEURS

Introduction

XR25 fiche

Interpretation of XR25 bargraphs

Customer complaints (petrol

version)

Fault charts (petrol version)

Customer complaints (diesel

version)

Fault charts (diesel version)

Checking conformity

Aid82-1

82-2

82-4

82-14

82-15

82-25

82-26

82-34

82-39IMMOBILISER82

Introduction

Wiring

XR25 fiche

Interpretation of XR25 bargraphs

Checking conformity

Checking the pretensioners

Aid88-1

88-2

88-5

88-7

88-22

88-23

88-24

AIRBAG - PRETENSIONERS88

Page 339 of 363

AIRBAG ANDPRETENSIONERS

FAULT FINDING

SUMMARY

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 01

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 02

XR25 fiche . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 05

Interpretation of XR25 bargraphs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 07

Checking conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Checking the pretensioners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Aid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24Page

Page 340 of 363

1EC761.0

AIRBAG - SEAT BELT PRETENSIONERS

Fault finding -Introduction

CONDITIONS FOR THE APPLICATION OF THE CHECKS DEFINED IN THIS FAULT FINDING

The checks defined in this fault finding should only be applied to a vehicle when the fault bargraph is

illuminated, indicating that the fault is present on the vehicle at the time of checking. Only a computer

fault will require replacement of the computer, whether the bargraph is permanently illuminated or

flashing .

If the fault is not present but simply memorised, the bargraph flashes and application of the checks

recommended in the fault finding section will not allow the origin of the fault to be found. In this case,

only a check of the wiring and the connection of the component in question must be carried out (it is

possible to test the wiring concerned in fault finding mode to try to obtain permanent illumination of the

bargraph ).

TOOLING REQUIRED FOR OPERATIONS ON THE AIRBAG AND SEAT BELT PRETENSIONER SYSTEMS :

- XR25 (with minimum XR25 cassette N° 16).

- XRBAG the updated N° 3 version (with the new measuring lead and its adaptors as well as the 30 track

adaptor for operations on the computer connector).

REMINDER:

When carrying out an operation on the airbag/seat belt pretensioner systems , it is essential to lock the

computer with the XR25 command G80* to avoid all risk of triggering at the wrong time (all firing lines

will be inhibited). This operating mode will be indicated by illumination of the warning light on the

instrument panel.

Never carry out any measuring operations on the airbag and pretensioners trigger lines with equipment

other than the XRBAG.

Before using a dummy ignition module, ensure that its resistance is between 1.8 and 2.5 ohms.

Only 30 track connector computers with airbag(s) function are able to be tested with the XR25.

Computers with the pretensioner function only must be checked with the XRBAG by following the checks

described in the fault finding section.

The ignition must be switched off, then on again to make the warning light extinguish following erasure

of the memory using the command G0**.

88

88-1

Page 341 of 363

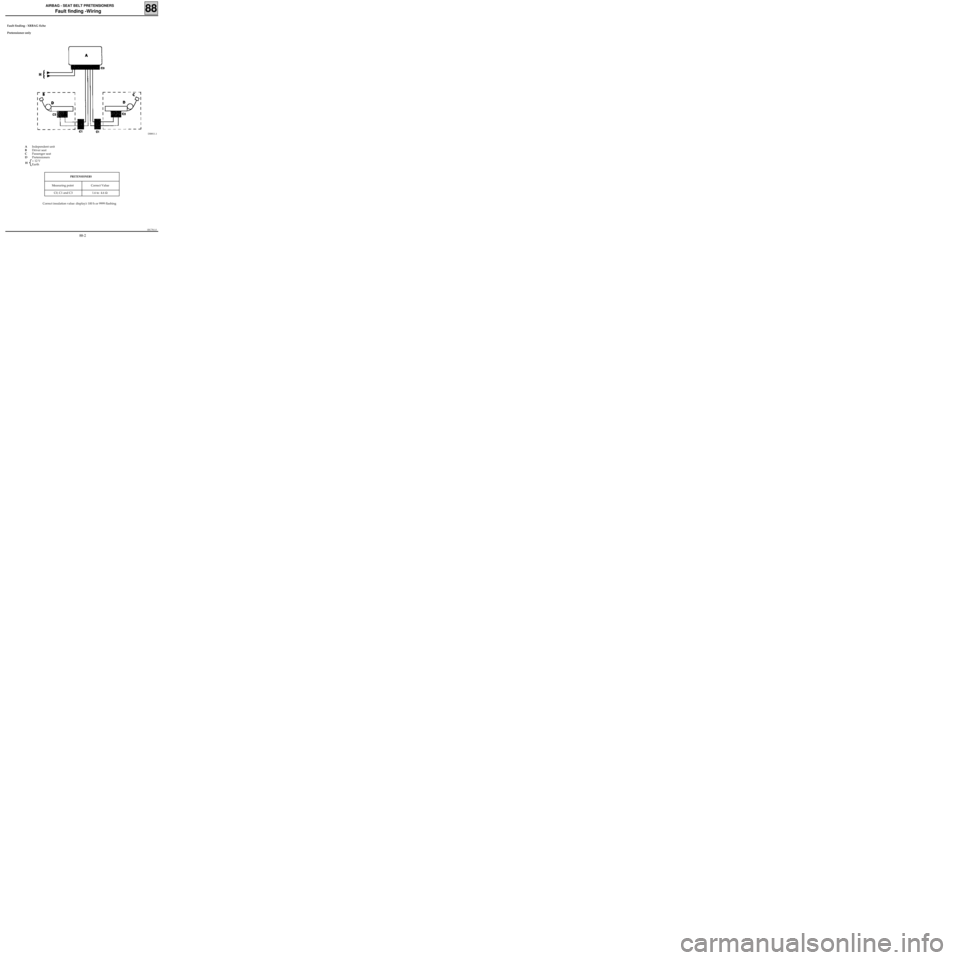

1EC761.0

AIRBAG - SEAT BELT PRETENSIONERS

Fault finding -Wiring

Fault finding - XRBAG fiche

Pretensioner only

88

DI8811.1

Correct insulation value: display≥ 100 h or 9999 flashing

PRETENSIONERS

Measuring point Correct Value

C0, C1 and C3 1.6 to 4.6 Ω

AIndependent unit

BDriver seat

CPassenger seat

DPretensioners

+ 12 V

Earth

H

88-2

Page 342 of 363

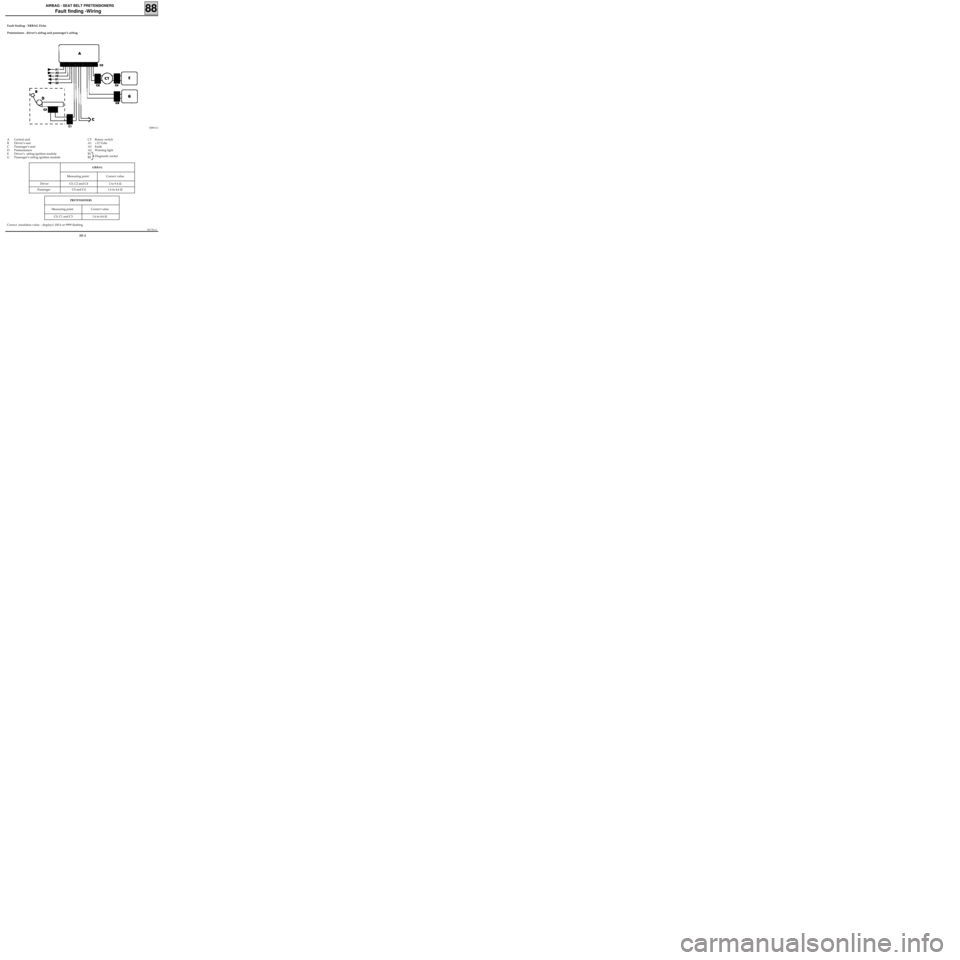

1EC761.0

AIRBAG - SEAT BELT PRETENSIONERS

Fault finding -Wiring

Fault finding - XRBAG Fiche

Pretensioner and driver airbag

88

DI8812.3

Correct insulation value : display≥ 100 h or 9999 flashing

PRETENSIONERS

Measuring point Correct value

C0, C1 and C3 1.6 to 4.6 Ω

AIRBAG

Measuring point Correct value

C0, C2 and C4 2 to 9.4 Ω

CT Rotary switch

A1 +12 Volts

A3 Earth

A2 Warning light

B1

B2Diagnostic socket A Central unit

B Driver seat

C Passenger seat

D Pretensioners

E Driver’s airbag ignition module

88-3

Page 343 of 363

1EC761.0

AIRBAG - SEAT BELT PRETENSIONERS

Fault finding -Wiring

Fault finding - XRBAG Fiche

Pretensioner , driver’s airbag and passenger’s airbag

88

DI8813.2

PRETENSIONERS

Measuring point Correct value

C0, C1 and C3 1.6 to 4.6 Ω

AIRBAG

Measuring point Correct value

Driver C0, C2 and C4 2 to 9.4 Ω

Passenger C0 and C4 1.6 to 4.6 Ω

CT Rotary switch

A1 +12 Volts

A3 Earth

A2 Warning light

B1

B2Diagnostic socket A Central unit

B Driver’s seat

C Passenger’s seat

D Pretensioners

E Driver’s airbag ignition module

G Passenger’s airbag ignition module

Correct insulation value : display≥ 100 h or 9999 flashing

88-4

Page 344 of 363

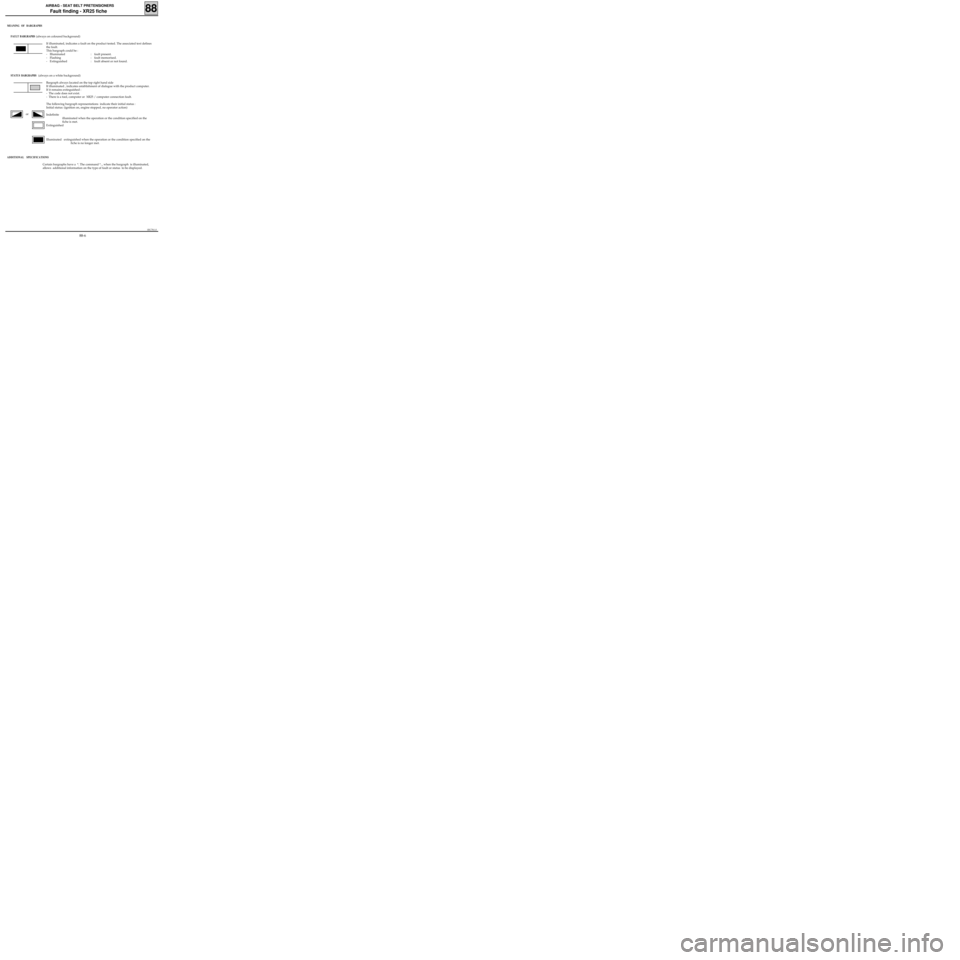

1EC761.0

AIRBAG - SEAT BELT PRETENSIONERS

Fault finding - XR25 Fiche

PRESENTATION OF XR25 FICHE N° 49

88

FI21749

88-5

Page 345 of 363

1EC761.0

AIRBAG - SEAT BELT PRETENSIONERS

Fault finding - XR25 fiche

MEANING OF BARGRAPHS

FAULT BARGRAPHS

(always on coloured background)

If illuminated, indicates a fault on the product tested. The associated text defines

the fault.

This bargraph could be :

- Illuminated : fault present.

- Flashing : fault memorised.

- Extinguished : fault absent or not found.

STATUS BARGRAPHS (always on a white background)

Bargraph always located on the top right hand side

If illuminated , indicates establishment of dialogue with the product computer.

If it remains extinguished :

- The code does not exist.

- There is a tool, computer or XR25 / computer connection fault.

The following bargraph representations indicate their initial status :

Initial status: (ignition on, engine stopped, no operator action)

Indefinite

illuminated when the operation or the condition specified on the

fiche is met.

Extinguished

Illuminated extinguished when the operation or the condition specified on the

fiche is no longer met.

ADDITIONAL SPECIFICATIONS

Certain bargraphs have a *. The command *.., when the bargraph is illuminated,

allows additional information on the type of fault or status to be displayed.

or

88

88-6

Page 346 of 363

1EC761.0

AIRBAG - SEAT BELT PRETENSIONERS

Fault finding - Interpretation of XR25 bargraphs

Bargraph 1 right hand side extinguished Fiche n° 49

Code present1

The computers which only control the operation of the seat belt pretensioners do

not have XR25 fault finding (check to be carried out with XRBAG).

When communication is established, deal with any illuminated fault bargraphs.AFTER REPAIR NOTES

Check the presence and condition of the airbag fuse .

Check the condition of the computer connector and the condition of the connections.

Check that the computer is correctly fed :

- Disconnect the airbag computer and fit the 30 track adaptor of the XRBAG.

- Check and ensure the presence + after ignition feed between the terminals marked

Earth and +after ignition feed.

Check that the diagnostic socket is correctly fed :

-+ Before ignition feed on track 16.

-Earth on track 5.

Check the continuity and insulation of the lines of the diagnostic socket / airbag computer connection:

- Between the terminal marked L and track 15 of the diagnostic socket .

- Between the terminal marked K and track 7 of the diagnostic socket .

If dialogue is still not established after these various checks, replace the airbag computer (consult the

section on "Aid" for this operation).

Ensure that the XR25 is not the cause of the fault by trying to communicate with the computer on

another vehicle .

Check that the ISO selector is in position S8, that the latest XR25 cassette and the correct access code are

being used.

Check the battery voltage and carry out the operations necessary to obtain the correct voltage (10.5 volts

< U battery< 16 volts).

88

88-7