engine RENAULT KANGOO 1997 KC / 1.G Foult Finding - Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 363

Page 233 of 363

JSA052.0

INJECTION

Fault finding - Status and parameter interpretation17

D7F 710

engine -

55 tracks

AFTER REPAIRStart the status and parameter check again from the beginning.

DIAG 10RICHNESS REGULATIONFiche n° 27

XR25 aid: Richness regulation faulty

No fault bargraphs should be illuminated.

Ignition correct (a check may be made using the OPTIMA 5800 station).

No other status bargraph should show a fault.NOTES

Check the sealing of the canister bleed valve (a leak can disrupt the richness considerably).

Check the sealing of the exhaust pipe upstream from the oxygen sensor.

Check the sealing of the inlet manifold.

If the vehicle has only been driven in town, the sensor is contaminated (try driving under load).

Check the fuel pressure.

If the idle speed is unstable, check the valve clearances.

Check the injectors (flow and shape of the jet).

If necessary, replace the oxygen sensor.

17-190

Page 234 of 363

Check the insulation and continuity of the line:

injectors 1 and 4 Computer 30 2 injectors

injectors 2 and 3 Computer 4 2 injectors

Repair if necessary.

JSA052.0

INJECTION

Fault finding - Status and parameter interpretation17

D7F 710

engine -

55 tracks

AFTER REPAIRStart the status and parameter check again from the beginning.

DIAG 11INJECTORFiche n° 27

XR25 aid : CO or CC - line 30 of the computer for injectors 1 and 4

CO or CC - line 4 of the computers for injectors 2 and 3

No fault bargraphs should be illuminated.NOTES

Check the resistance of the faulty injector.

Replace it if necessary.

During command mode operation, check for + 12 Volts on track 1 of the faulty injector.

Repair.

17-191

Page 235 of 363

JSA052.0

INJECTION

Fault finding - Status and parameter interpretation17

D7F 710

engine -

55 tracks

AFTER REPAIRStart the status and parameter check again from the beginning.

DIAG 12IMMOBILISERFiche n° 27

XR25 aid : Status BG 3RH, illuminated when ignition switched on

No fault bargraphs should be illuminated.NOTES

Check the insulation and continuity of the wiring for track 37 on the injection computer.

If the fault persists, refer to the immobiliser fault finding.

17-192

Page 236 of 363

if the value read is incoherent:

- Check that the sensor is correctly mounted and fed:

• +12 V on A1

• Earth on B2

- Check the insulation, continuity and that there is no interference resistance on the line:

Computer 12 B1 vehicle speed sensor

Repair.

JSA052.0

INJECTION

Fault finding - Status and parameter interpretation17

D7F 710

engine -

55 tracks

AFTER REPAIRStart the status and parameter check again from the beginning.

DIAG 13

Fiche n° 27

VEHICLE SPEED

XR25 aid: # 18 = Speed read on speedometer in km/h

No fault bargraphs should be illuminated. Check with a road test.NOTES

The fault persists! Replace the speed sensor.

17-193

Page 237 of 363

JSA052.0

INJECTION

Fault finding - Status and parameter interpretation17

D7F 710

engine -

55 tracks

AFTER REPAIRStart the status and parameter check again from the beginning.

DIAG 14Fiche n° 27 side 2/2

ADAPTIVE RICHNESS

XR25 aid:Minimum < # 30 < Maximum

Minimum < # 31 < Maximum

No fault bargraphs should be illuminated.Carry out the programming operations.NOTES

Ensure the canister bleed valve is sealed.

Erase the computer memory.

Engine warm , running at idle speed, check the values for # 30 and # 31.

-If # 30 or # 31 is at a MAXIMUM, there is not enough fuel.

- If # 30 or # 31 is at a MINIMUM, there is too much fuel.

Ensure the hygiene, cleanliness and correct operation of :

- filter

- fuel pump

- fuel circuit

- fuel tank.

17-194

Page 238 of 363

JSA052.0

INJECTION

Fault finding - Status and parameter interpretation17

D7F 710

engine -

55 tracks

AFTER REPAIRStart the status and parameter check again from the beginning.

NOTES

DIAG 15

Fiche n° 27

EMISSION OF POLLUTANTS

XR25 aid:

None

No fault bargraphs should be illuminated.

NOTES

0.97 ≤ λ ≤ 1.03 at 2500

rpmThe oxygen sensor loops correctly at 2500 rpm.

If CO > 0.3 % at 2500 rpm

NOTES 0.97 ≤ λ ≤ 1.03 at 2500

rpmThe oxygen sensor does not loop correctly at 2500 rpm.

It is an injection or sensor fault.

The catalytic converter is faulty.

NOTE : it is vital to determine the cause of the catalytic converter damage to

avoid a new converter also being damaged.

If λ < 0.97 or λ > 1.03 at idle speed

Check the sensor earth and heating.

Check there is no air leak at the manifold.

17-195

Page 239 of 363

JSA052.0

INJECTION

Fault finding - Status and parameter interpretation17

D7F 710

engine -

55 tracks

AFTER REPAIRStart the status and parameter check again from the beginning.

DIAG 15

Cont.Fiche n° 27

No fault bargraphs should be illuminated.

NOTES

NOTES λ > 1.03 at 2500 rpmNone

The oxygen sensor loops correctly at 2500 rpm.

NOTES λ < 0.97

at 2500 rpm.The oxygen sensor does not loop correctly at 2500 rpm, CO >

0.3 % at 2500 rpm.

Check the pressure sensor.

Check the sensor.

Check that an injector is not faulty.

Check there is no leak at the exhaust.

Check that an injector has not seized.

Check the fuel pressure is not too low.

The oxygen sensor does not loop correctly at 2500 rpm.

Check there is not an injection fault.

Check there is not an ignition fault.

Check the sensor is not faulty.

Check the fuel pressure.

17-196

Page 240 of 363

JSA052.0

INJECTION

Fault finding - Status and parameter interpretation17

D7F 710

engine -

55 tracks

AFTER REPAIRStart the status and parameter check again from the beginning.

DIAG 16AIR CONDITIONINGFiche n° 27

XR25 aid:Status BG 10LH or 10RH incorrect illumination

No fault bargraphs should be illuminated.

NOTES

Check the insulation and continuity of lines track 5 and track 51 of the injection computer.Repair if

necessary.Consult the air conditioning fault finding.

17-197

Page 241 of 363

Connect the bornier in place of the computer and

check the insulation and continuity of the line:

Bornier 10 2 Relay

Repair.

Check the insulation and continuity of the line:

Relay 5 1 Fan assembly

Fan assembly 2 Earth

Repair.

JSA052.0

INJECTION

Fault finding - Status and parameter interpretation17

D7F 710

engine -

55 tracks

AFTER REPAIRStart the status and parameter check again from the beginning.

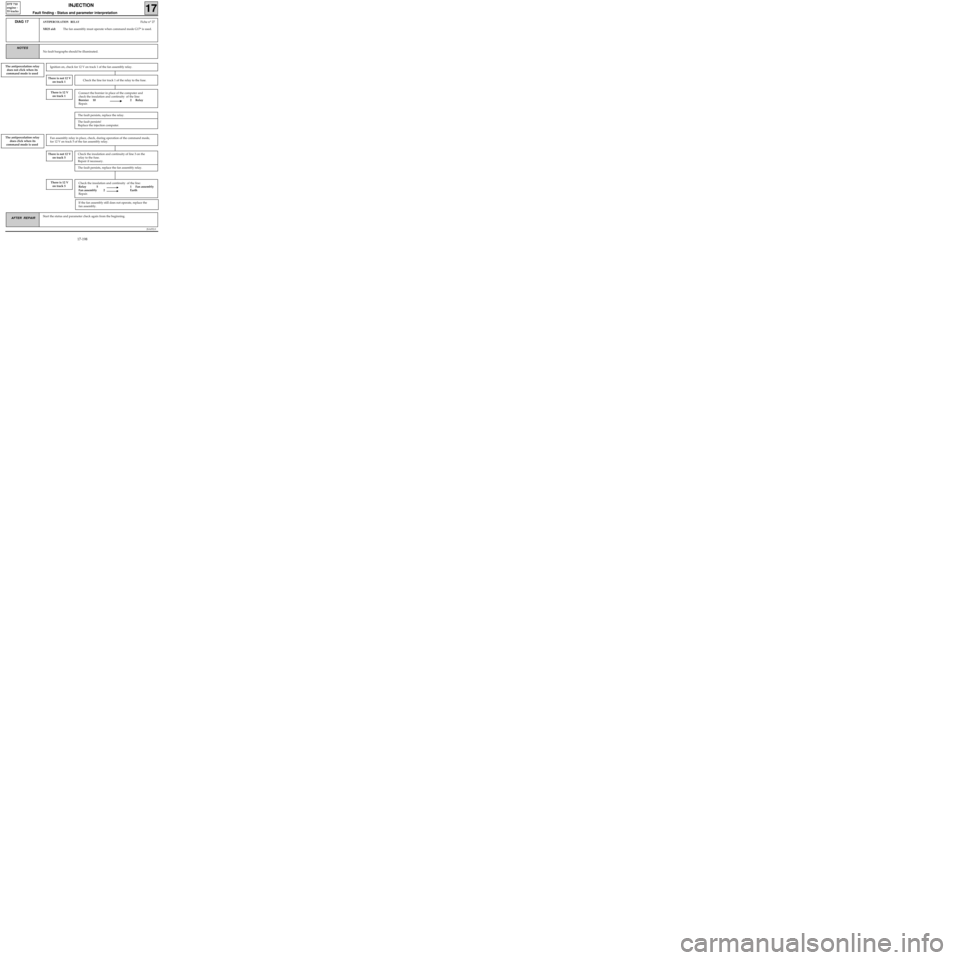

DIAG 17ANTIPERCOLATION RELAYFiche n° 27

XR25 aid:The fan assembly must operate when command mode G17* is used.

No fault bargraphs should be illuminated.

NOTES

The antipercolation relay

does not click when its

command mode is used

There is 12 V

on track 1

Ignition on, check for 12 V on track 1 of the fan assembly relay.

There is not 12 V

on track 1Check the line for track 1 of the relay to the fuse.

The antipercolation relay

does click when its

command mode is usedFan assembly relay in place, check, during operation of the command mode,

for 12 V on track 5 of the fan assembly relay.

There is not 12 V

on track 5Check the insulation and continuity of line 3 on the

relay to the fuse.

Repair if necessary.

The fault persists, replace the fan assembly relay.

There is 12 V

on track 5

If the fan assembly still does not operate, replace the

fan assembly.

The fault persists, replace the relay.

The fault persists!

Replace the injection computer.

17-198

Page 242 of 363

JSA052.0

INJECTION

Fault finding - Status and parameter interpretation17

D7F 710

engine -

55 tracks

AFTER REPAIRStart the status and parameter check again from the beginning.

DIAG 18POWER ASSISTED STEERING PRESSOSTATFiche n° 27

XR25 aid :None.

No fault bargraphs should be illuminated.

NOTES

Check the correct operation of the power assisted steering (oil level, ...).

Check the insulation and continuity of the line for track 13 on the injection computer.

Check the power assisted steering pressostat is correctly connected.

Repair if necessary.

If all these points are correct, replace the power assisted steering pressostat.

17-199