engine RENAULT KANGOO 1997 KC / 1.G Foult Finding - Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 363

Page 243 of 363

Connect the bornier in place of the computer and check the insulation and continuity of the line:

Computer 43 6 Instrument panel

Repair.

JSA052.0

INJECTION

Fault finding - Status and parameter interpretation17

D7F 710

engine -

55 tracks

AFTER REPAIRStart the status and parameter check again from the beginning.

DIAG 19FAULT WARNING LIGHT CIRCUITFiche n° 27

XR25 aid:None

No fault bargraphs should be illuminated.

NOTES

Check the condition of the warning light and its feed.

Repair if necessary.

17-200

Page 244 of 363

JSA052.0

INJECTION

Fault finding - Customer complaints

17

D7F 710

engine -

55 tracks

Only refer to this customer complaint after a complete check using the XR25.

NOTES

STARTING FAULTS

IDLE SPEED FAULTS

BEHAVIOUR WHILE DRIVING

Chart 1

Chart 2

Chart 3

17-201

Page 245 of 363

JSA052.0

INJECTION

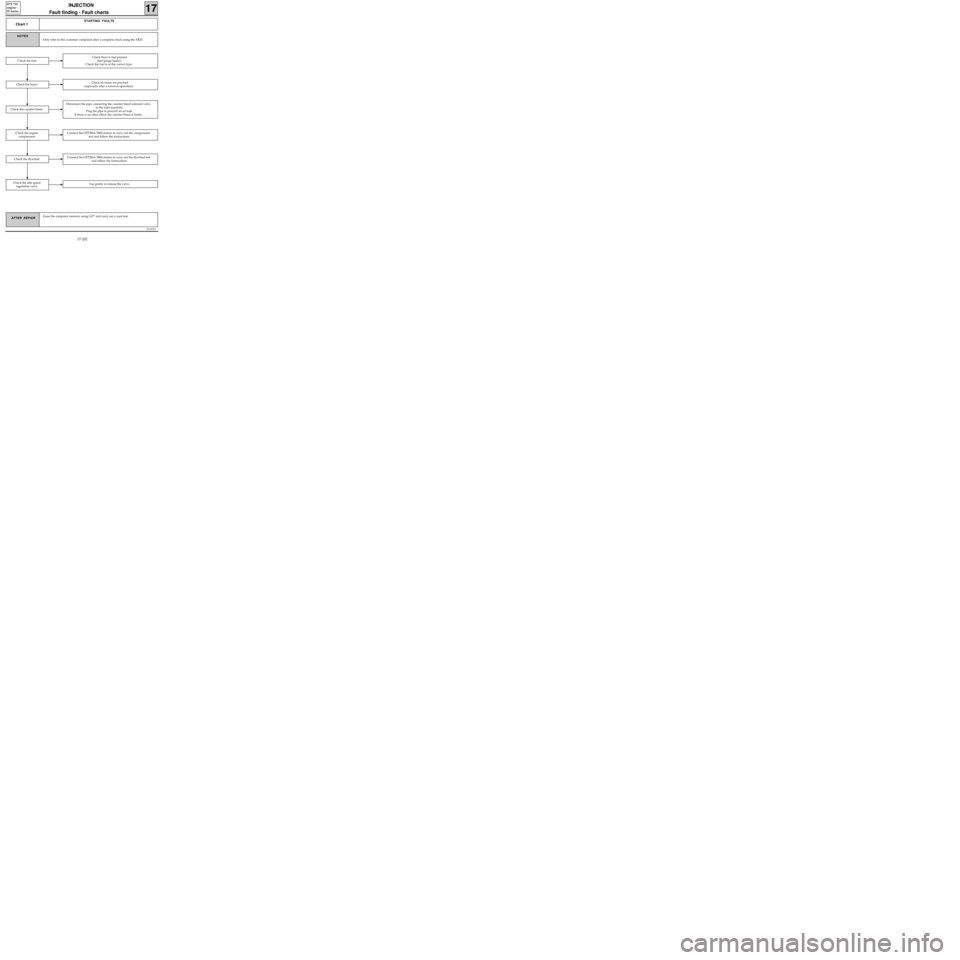

Fault finding - Fault charts

17

D7F 710

engine -

55 tracks

AFTER REPAIR

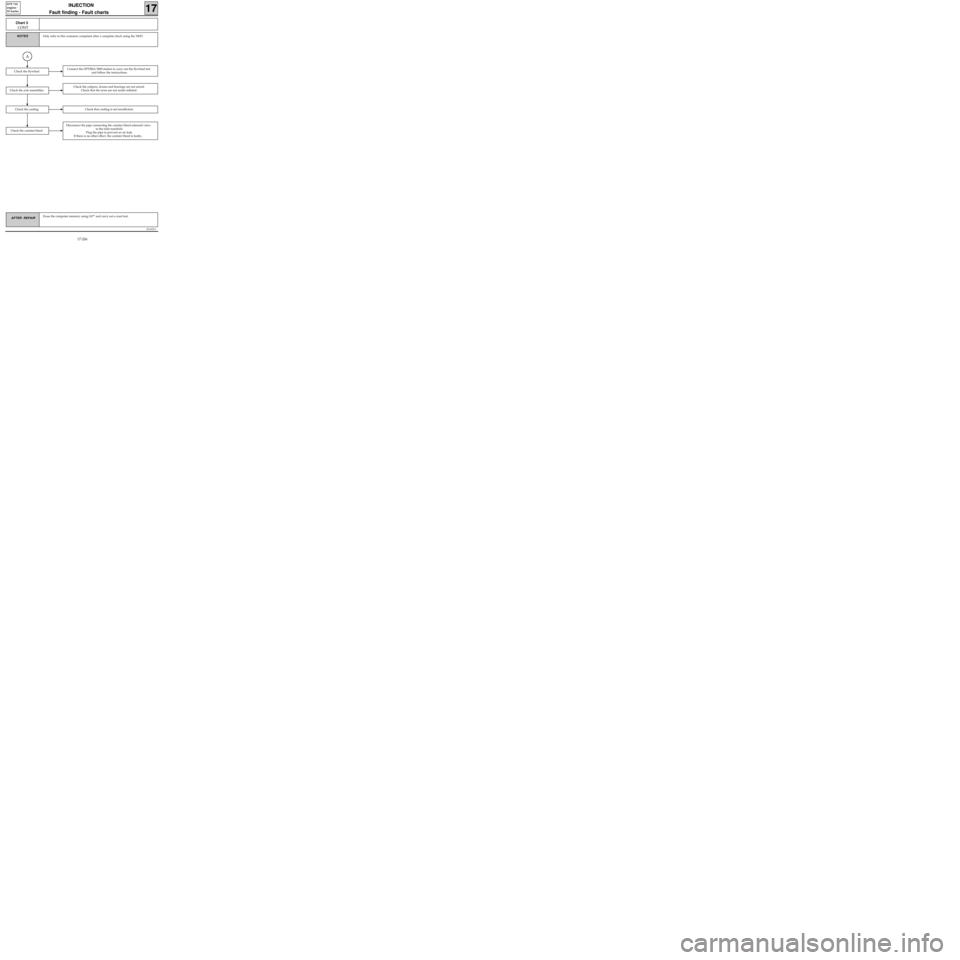

Chart 1

STARTING FAULTS

Only refer to this customer complaint after a complete check using the XR25.

NOTES

Erase the computer memory using G0** and carry out a road test.

Check there is fuel present

(fuel gauge faulty).

Check the fuel is of the correct type.

Check the hosesCheck no hoses are pinched

(especially after a removal operation).

Disconnect the pipe connecting the canister bleed solenoid valve

to the inlet manifold.

Plug the pipe to prevent an air leak.

If there is no other effect, the canister bleed is faulty.

Check the fuel

Connect the OPTIMA 5800 station to carry out the compression

test and follow the instructions.

Connect the OPTIMA 5800 station to carry out the flywheel test

and follow the instructions.

Check the idle speed

regulation valveTap gently to release the valve.

Check the flywheel

Check the engine

compression

Check the canister bleed

17-202

Page 246 of 363

JSA052.0

INJECTION

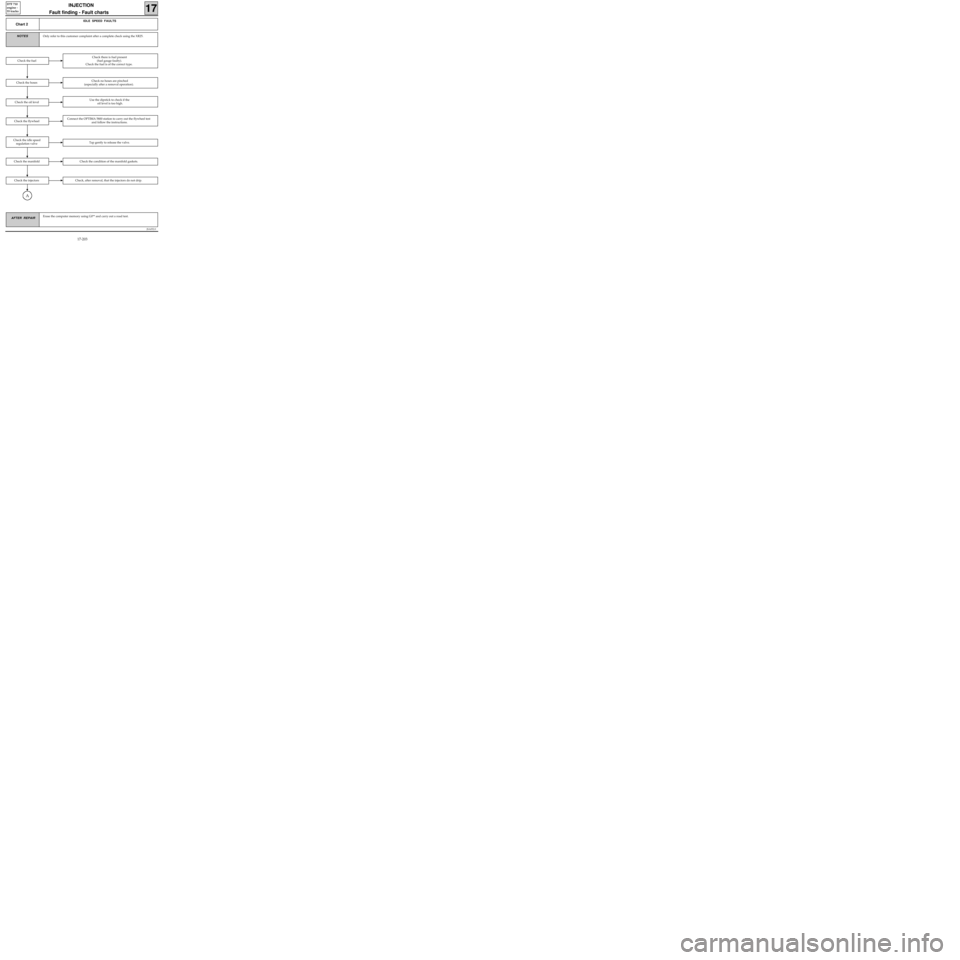

Fault finding - Fault charts

17

D7F 710

engine -

55 tracks

AFTER REPAIR

Chart 2

IDLE SPEED FAULTS

Only refer to this customer complaint after a complete check using the XR25.NOTES

Erase the computer memory using G0** and carry out a road test.

Check there is fuel present

(fuel gauge faulty).

Check the fuel is of the correct type.

Check the hosesCheck no hoses are pinched

(especially after a removal operation).

Check the oil levelUse the dipstick to check if the

oil level is too high.

Check the fuel

Check the flywheelConnect the OPTIMA 5800 station to carry out the flywheel test

and follow the instructions.

Check the idle speed

regulation valveTap gently to release the valve.

Check the manifoldCheck the condition of the manifold gaskets.

Check the injectorsCheck, after removal, that the injectors do not drip.

A

17-203

Page 247 of 363

JSA052.0

INJECTION

Fault finding - Fault charts

17

D7F 710

engine -

55 tracks

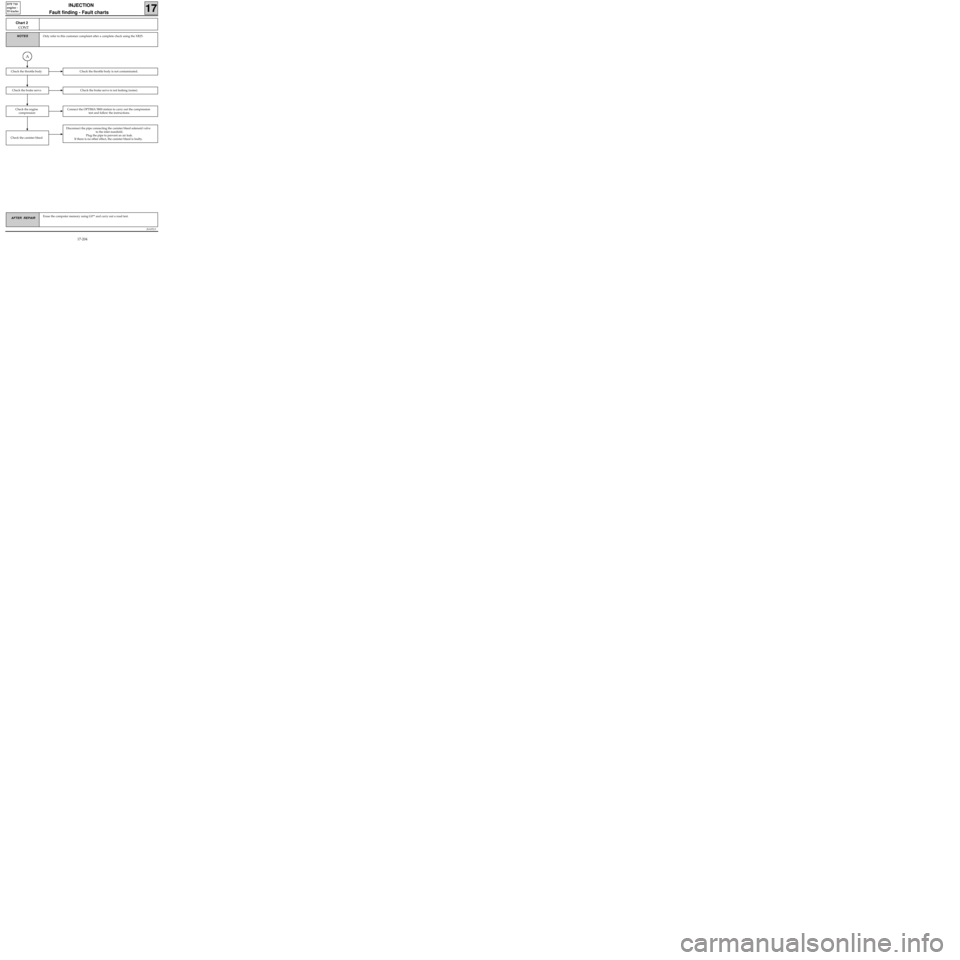

AFTER REPAIR

Chart 2

CONT

Only refer to this customer complaint after a complete check using the XR25.NOTES

A

Erase the computer memory using G0** and carry out a road test.

Check the throttle bodyCheck the throttle body is not contaminated.

Check the brake servoCheck the brake servo is not leaking (noise).

Connect the OPTIMA 5800 station to carry out the compression

test and follow the instructions.

Check the canister bleed

Disconnect the pipe connecting the canister bleed solenoid valve

to the inlet manifold.

Plug the pipe to prevent an air leak.

If there is no other effect, the canister bleed is faulty.

Check the engine

compression

17-204

Page 248 of 363

JSA052.0

INJECTION

Fault finding - Fault charts

17

D7F 710

engine -

55 tracks

AFTER REPAIRErase the computer memory using G0** and carry out a road test.

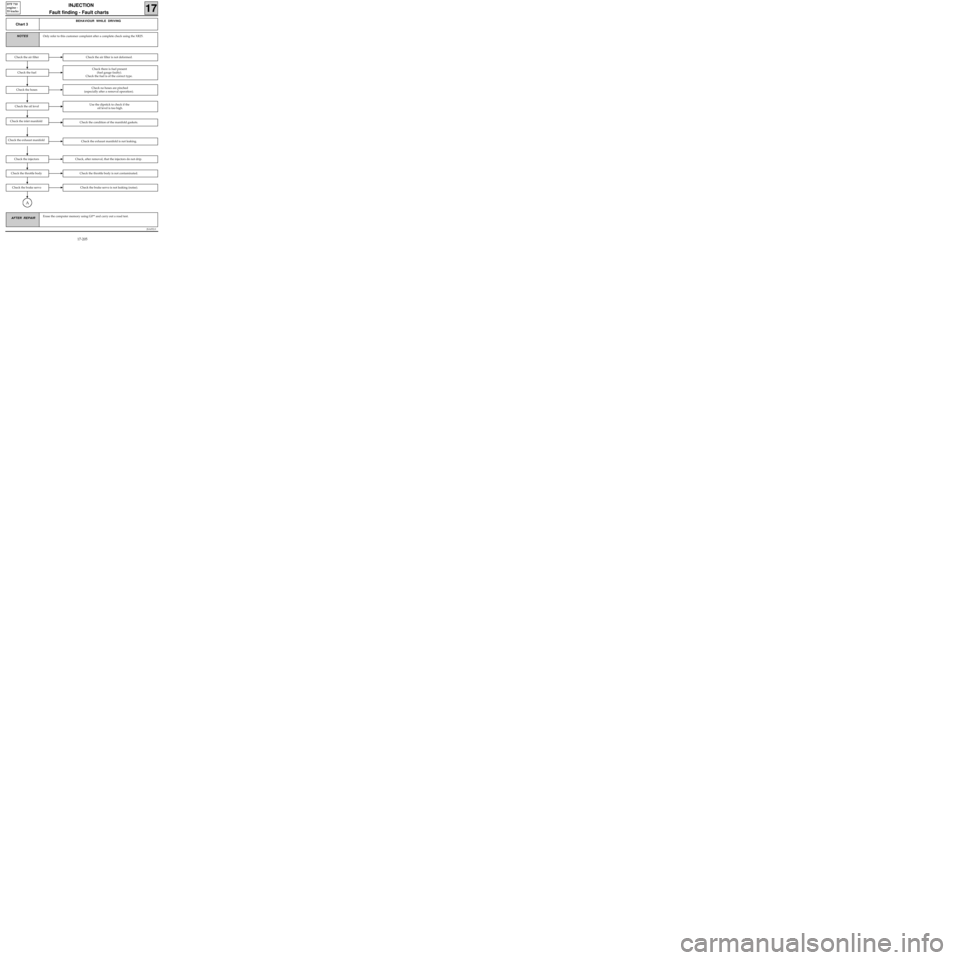

Chart 3

BEHAVIOUR WHILE DRIVING

Only refer to this customer complaint after a complete check using the XR25.NOTES

Check the air filter is not deformed.

Check the fuel

Check there is fuel present

(fuel gauge faulty).

Check the fuel is of the correct type.

Check the hosesCheck no hoses are pinched

(especially after a removal operation).

Check the air filter

Check the oil levelUse the dipstick to check if the

oil level is too high.

Check the condition of the manifold gaskets.Check the inlet manifold

Check the exhaust manifold is not leaking.Check the exhaust manifold

Check, after removal, that the injectors do not drip.Check the injectors

Check the throttle body is not contaminated.Check the throttle body

Check the brake servo is not leaking (noise).Check the brake servo

A

17-205

Page 249 of 363

JSA052.0

INJECTION

Fault finding - Fault charts

17

D7F 710

engine -

55 tracks

AFTER REPAIRErase the computer memory using G0** and carry out a road test.

Chart 3

CONT

Only refer to this customer complaint after a complete check using the XR25.NOTES

Check the calipers, drums and bearings are not seized.

Check that the tyres are not under inflated.

Check the coolingCheck that cooling is not insufficient.

Check the canister bleed

Disconnect the pipe connecting the canister bleed solenoid valve

to the inlet manifold.

Plug the pipe to prevent an air leak.

If there is no other effect, the canister bleed is faulty..

Check the axle assemblies

A

Connect the OPTIMA 5800 station to carry out the flywheel test

and follow the instructions.Check the flywheel

17-206

Page 250 of 363

JSA052.0

INJECTION Fault finding - Aid

17

D7F 710

engine -

55 tracks

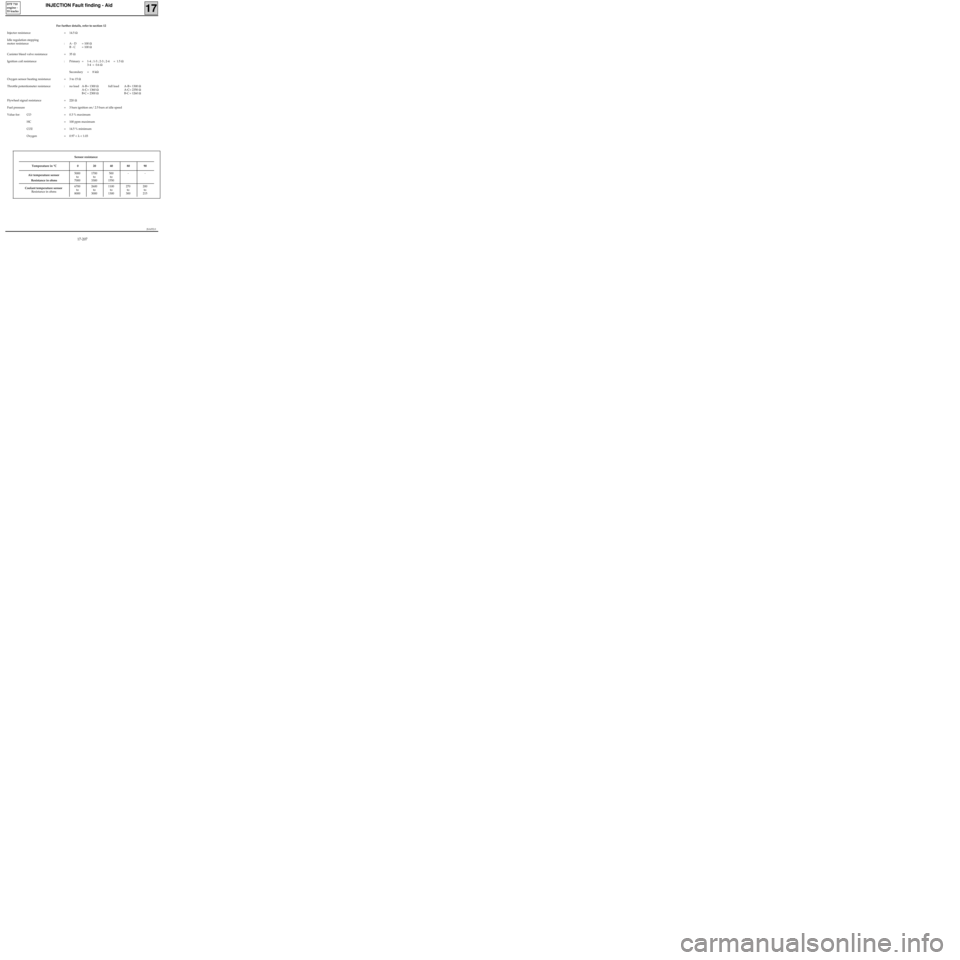

For further details, refer to section 12

Injector resistance = 14.5 Ω

Idle regulation stepping

motor resistance : A - D = 100 Ω

B - C = 100 Ω

Canister bleed valve resistance = 35 Ω

Ignition coil resistance : Primary = 1-4 ; 1-3 ; 2-3 ; 2-4 = 1.5 Ω

3-4 = 0.6 Ω

Secondary = 8 kΩ

Oxygen sensor heating resistance = 3 to 15 Ω

Throttle potentiometer resistance : no load A-B = 1300 Ωfull load A-B = 1300 Ω

A-C= 1360 ΩA-C= 2350 Ω

B-C = 2300 ΩB-C = 1260 Ω

Flywheel signal resistance = 220 Ω

Fuel pressure = 3 bars ignition on/ 2.5 bars at idle speed

Value for: CO = 0.3 % maximum

HC = 100 ppm maximum

CO2 = 14.5 % minimum

Oxygen = 0.97 < λ < 1.03

Sensor resistance

Temperature in °C 0 20 40 80 90

Air temperature sensor

Resistance in ohms5000

to

70001700

to

3300500

to

1550--

Coolant temperature sensor

Resistance in ohms6700

to

80002600

to

30001100

to

1300270

to

300200

to

215

17-207

Page 251 of 363

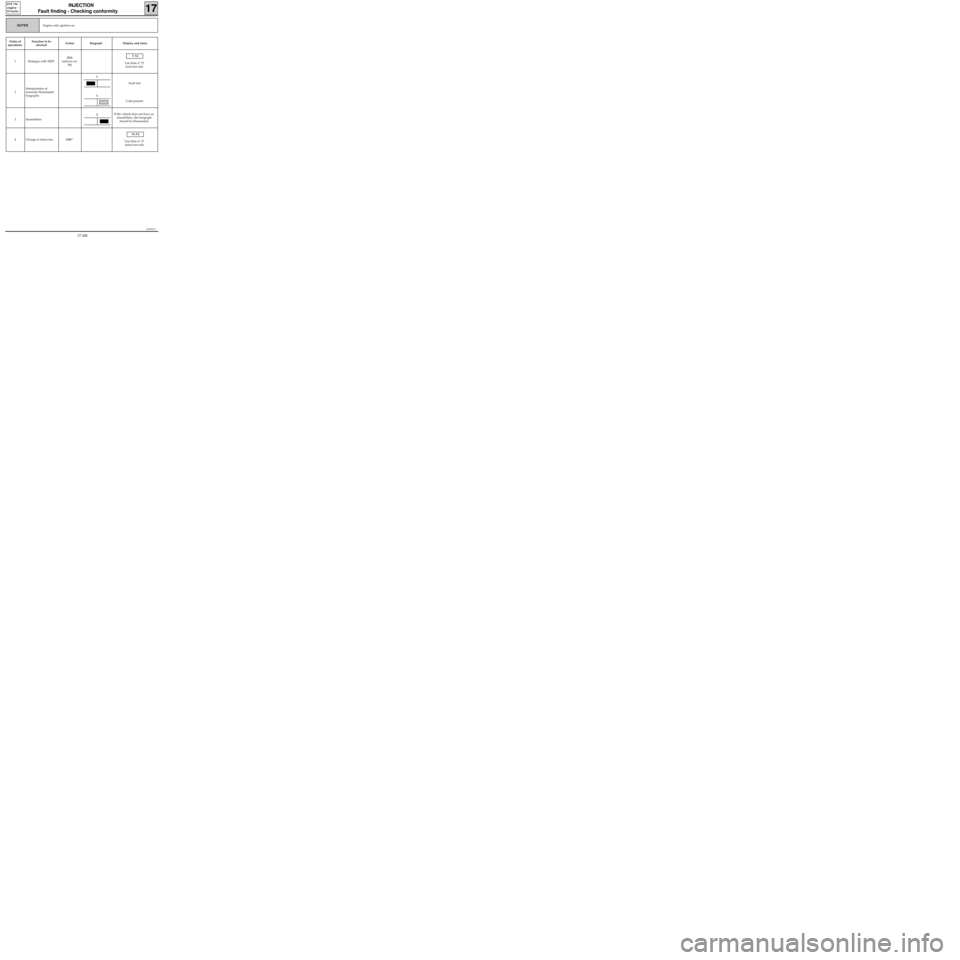

JSA051.0

INJECTION

Fault finding - Checking conformity

17

D7F 710

engine -

55 tracks

Engine cold, ignition on.NOTES

Order of

operationsFunction to be

checkedAction Bargraph Display and notes

1 Dialogue with XR25D13

(selector on

S8)

9.NJ

Use fiche n° 27

fault test side

2Interpretation of

normally illuminated

bargraphsFault test

Code present

3 ImmobiliserIf the vehicle does not have an

immobiliser, this bargraph

should be illuminated.

4 Change to status testG01*

10.NJ

Use fiche n° 27

status test side

1

1

2

17-208

Page 252 of 363

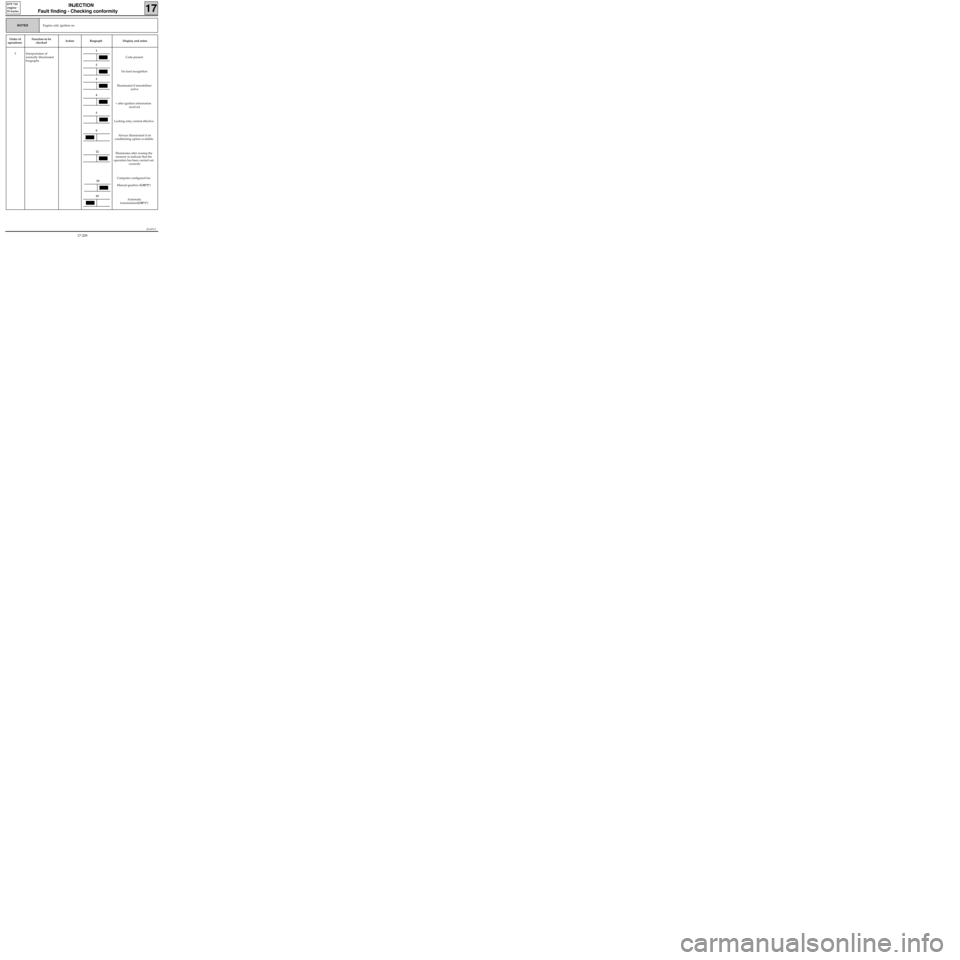

JSA051.0

INJECTION

Fault finding - Checking conformity

17

D7F 710

engine -

55 tracks

Engine cold, ignition on.NOTES

Order of

operationsFunction to be

checkedAction Bargraph Display and notes

5 Interpretation of

normally illuminated

bargraphsCode present

No load recognition

Illuminated if immobiliser

active

+ after ignition information

received

Locking relay control effective

Always illuminated if air

conditioning option available

Illuminates after erasing the

memory to indicate that the

operation has been carried out

correctly

Computer configured for:

Manual gearbox (G50*2*)

Automatic

transmission(G50*1*)

1

2

3

4

5

12

19

19

9

17-209