engine coolant RENAULT KANGOO 1997 KC / 1.G Foult Finding - Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 363

Page 11 of 363

DPCF01 1.0

LUCAS DIESEL INJECTION

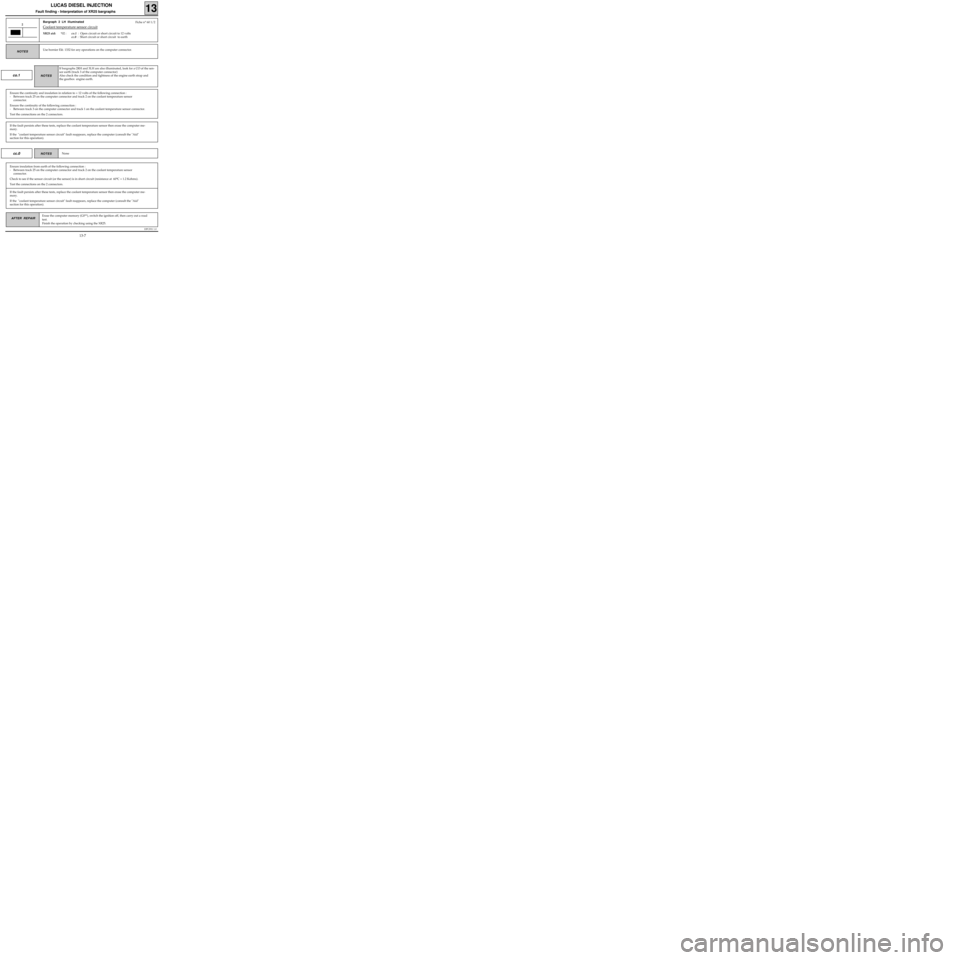

Fault finding - Interpretation of XR25 bargraphs13

AFTER REPAIRErase the computer memory (G0**), switch the ignition off, then carry out a road

test.

Finish the operation by checking using the XR25.

Bargraph 2 LH illuminated

Coolant temperature sensor circuit

XR25 aid:*02 :co.1 : Open circuit or short circuit to 12 volts

cc.0 : Short circuit or short circuit to earth

2

Use bornier Elé. 1332 for any operations on the computer connector.NOTES

Fiche n° 60 1/2

co.1

Ensure the continuity and insulation in relation to + 12 volts of the following connection :

- Between track 25 on the computer connector and track 2 on the coolant temperature sensor

connector.

Ensure the continuity of the following connection :

- Between track 3 on the computer connector and track 1 on the coolant temperature sensor connector.

Test the connections on the 2 connectors.

If bargraphs 2RH and 3LH are also illuminated, look for a CO of the sen-

sor earth (track 3 of the computer connector)

Also check the condition and tightness of the engine earth strap and

the gearbox engine earth.

NOTES

If the fault persists after these tests, replace the coolant temperature sensor then erase the computer me-

mory.

If the "coolant temperature sensor circuit" fault reappears, replace the computer (consult the "Aid"

section for this operation).

cc.0None NOTES

Ensure insulation from earth of the following connection :

- Between track 25 on the computer connector and track 2 on the coolant temperature sensor

connector.

Check to see if the sensor circuit (or the sensor) is in short circuit (resistance at 60°C = 1.2 Kohms).

Test the connections on the 2 connectors.

If the fault persists after these tests, replace the coolant temperature sensor then erase the computer me-

mory.

If the "coolant temperature sensor circuit" fault reappears, replace the computer (consult the "Aid"

section for this operation).

13-7

Page 37 of 363

DPCF01 1.0

LUCAS DIESEL INJECTION

Fault finding - Checking conformity

13

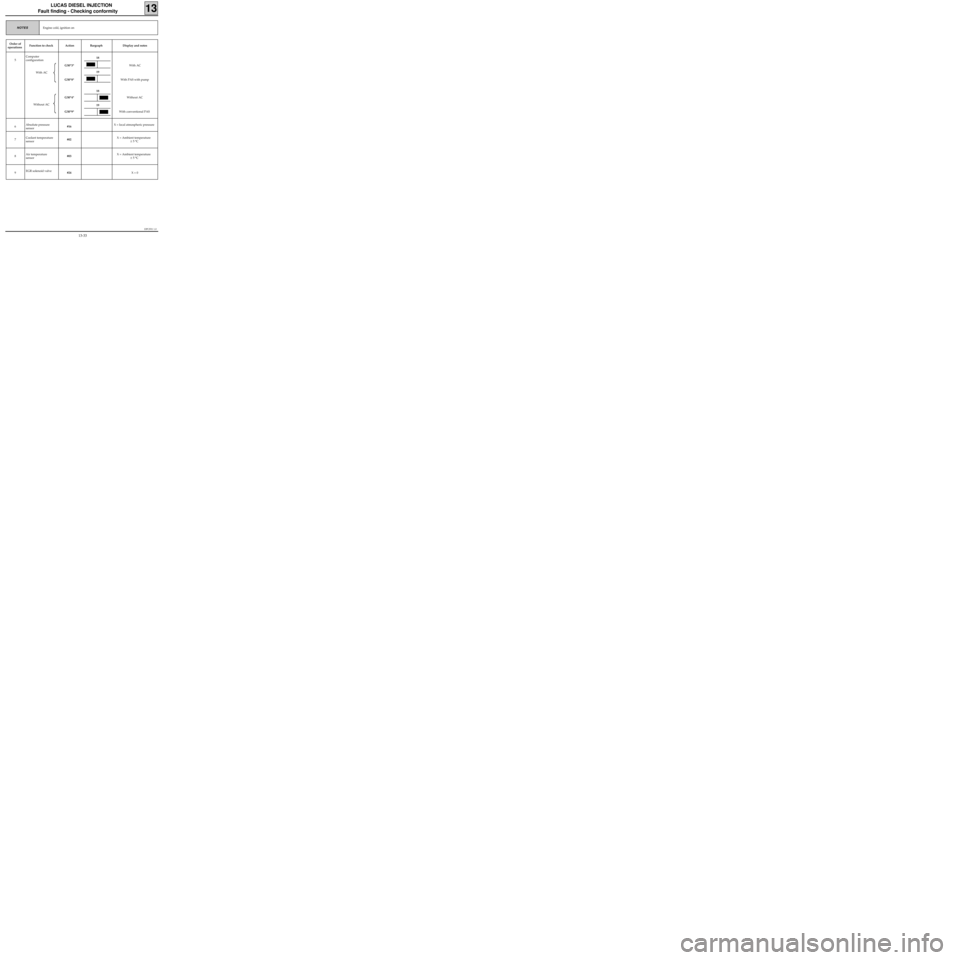

Engine cold, ignition onNOTES

Order of

operationsFunction to check Action Bargraph Display and notes

5Computer

configuration

With AC

Without ACG50*3*

G50*8*

G50*4*

G50*9*With AC

With PAS with pump

Without AC

With conventional PAS

6Absolute pressure

sensor#16 X = local atmospheric pressure

7Coolant temperature

sensor#02 X = Ambient temperature

± 5 °C

8Air temperature

sensor#03 X = Ambient temperature

± 5 °C

9EGR solenoid valve

#24 X = 0

18

18

19

19

13-33

Page 53 of 363

JF5111.0

INJECTION

Fault finding - Introduction

17

E7J 780

engine

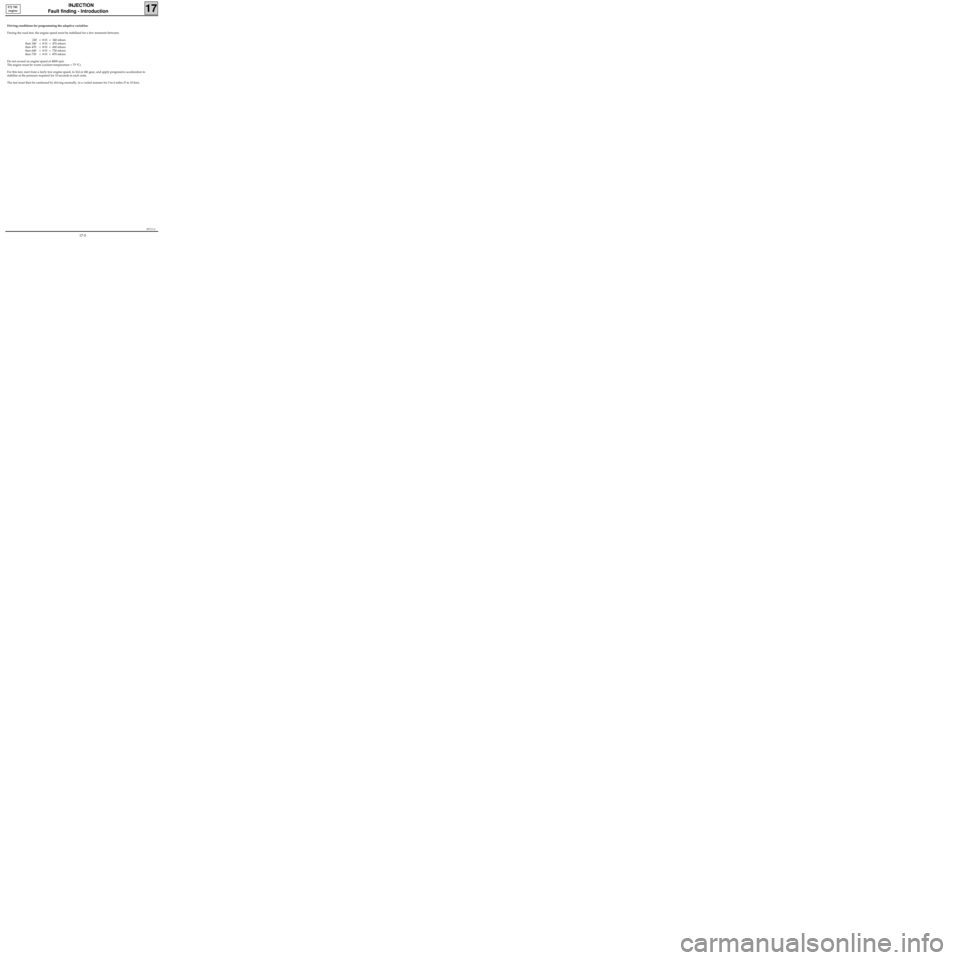

Driving conditions for programming the adaptive variables:

During the road test, the engine speed must be stabilised for a few moments between:

220 < # 01 < 340 mbars

then 340 < # 01 < 470 mbars

then 470 < # 01 < 600 mbars

then 600 < # 01 < 730 mbars

then 730 < # 01 < 870 mbars

Do not exceed an engine speed of 4800 rpm

The engine must be warm (coolant temperature > 75 °C).

For this test, start from a fairly low engine speed, in 3rd or 4th gear, and apply progressive acceleration to

stabilise at the pressure required for 10 seconds in each zone.

The test must then be continued by driving normally, in a varied manner for 3 to 6 miles (5 to 10 km).

17-5

Page 62 of 363

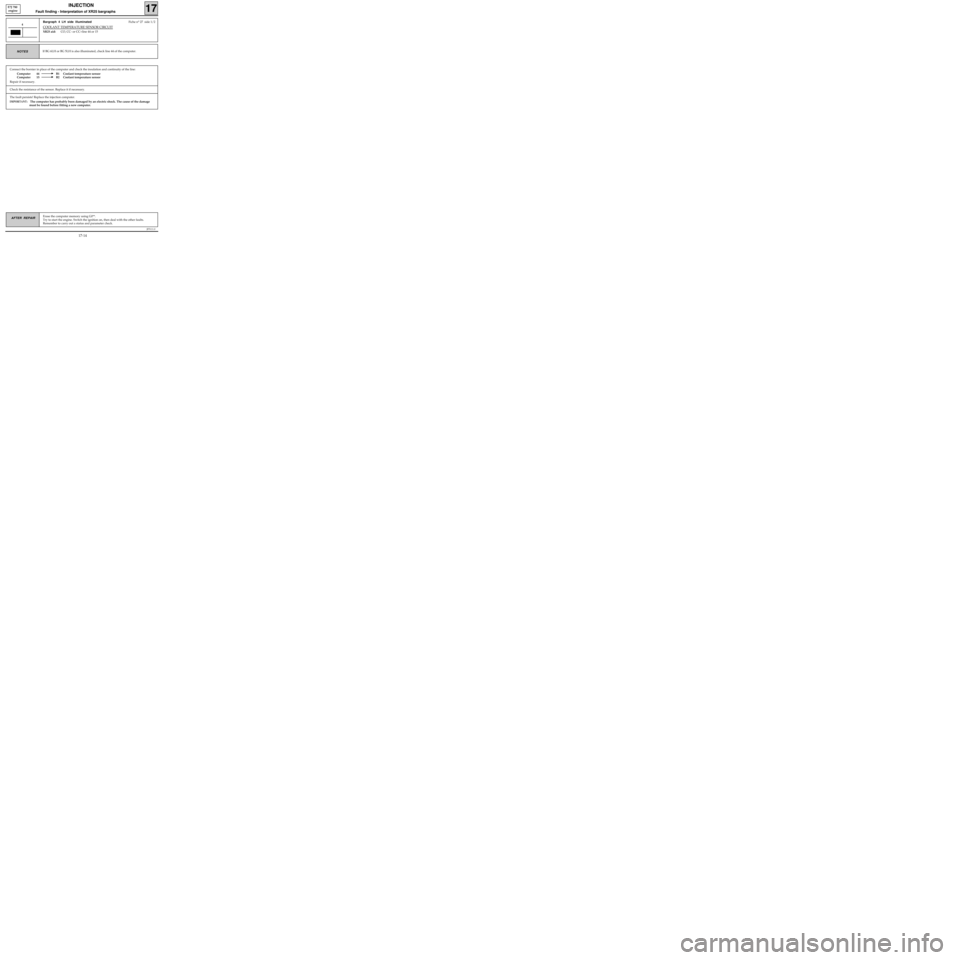

Connect the bornier in place of the computer and check the insulation and continuity of the line:

Computer 44 B1 Coolant temperature sensor

Computer 15 B2 Coolant temperature sensor

Repair if necessary.

JF5111.0

INJECTION

Fault finding - Interpretation of XR25 bargraphs17

E7J 780

engine

Erase the computer memory using G0**.

Try to start the engine. Switch the ignition on, then deal with the other faults.

Remember to carry out a status and parameter check.AFTER REPAIR

Bargraph 4 LH side illuminatedFiche n° 27 side 1/2

COOLANT TEMPERATURE SENSOR CIRCUIT

XR25 aid:CO, CC- or CC+line 44 or 15

4

If BG 6LH or BG 5LH is also illuminated, check line 44 of the computer.NOTES

The fault persists! Replace the injection computer.

IMPORTANT: The computer has probably been damaged by an electric shock. The cause of the damage

must be found before fitting a new computer.

Check the resistance of the sensor. Replace it if necessary.

17-14

Page 79 of 363

JF5111.0

INJECTION

Fault finding - Status and parameter checks

17

E7J 780

engine

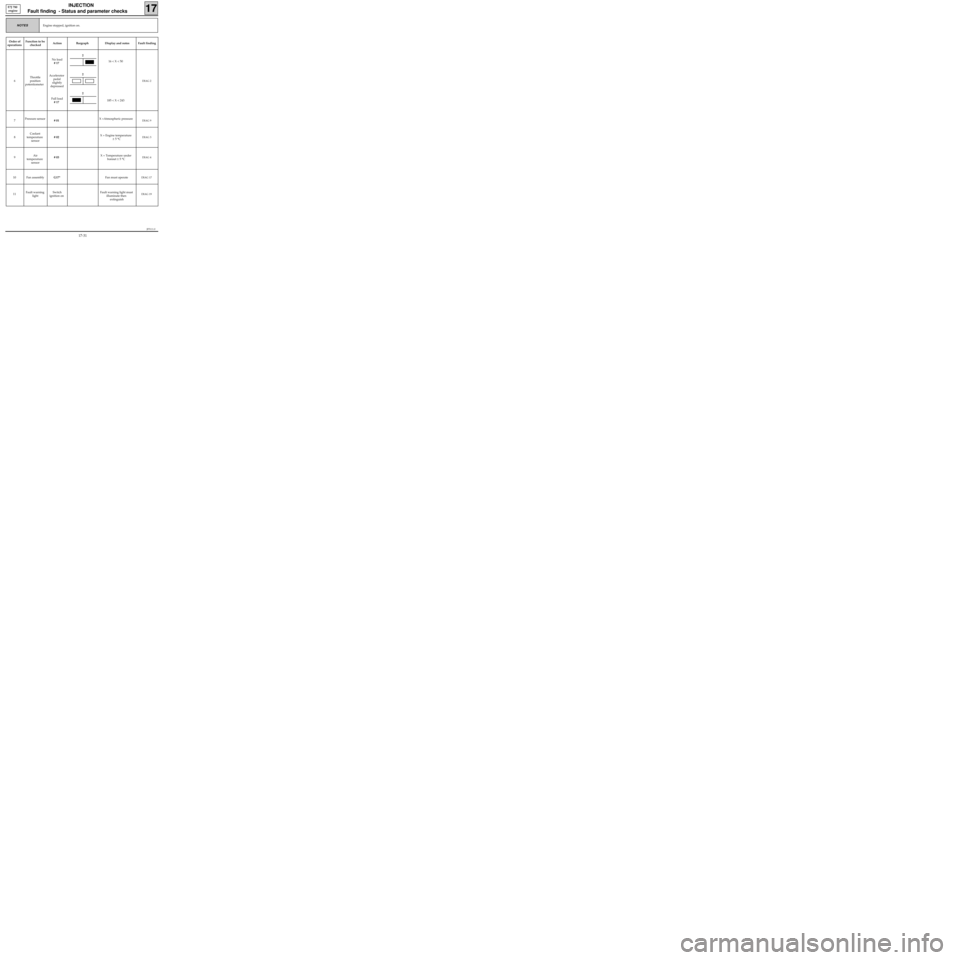

Engine stopped, ignition on.NOTES

Order of

operationsFunction to be

checkedAction Bargraph Display and notes Fault finding

6Throttle

position

potentiometer

.No load

# 17

Accelerator

pedal

slightly

depressed

Full load

# 1716 < X < 50

185 < X < 243

DIAG 2

7Pressure sensor

# 01X =Atmospheric pressureDIAG 9

8Coolant

temperature

sensor# 02X = Engine temperature

± 5 °CDIAG 3

9Air

temperature

sensor# 03X = Temperature under

bonnet ± 5 °CDIAG 4

10 Fan assemblyG17*Fan must operateDIAG 17

11Fault warning

lightSwitch

ignition onFault warning light must

illuminate then

extinguishDIAG 19

2

2

2

17-31

Page 86 of 363

Check the insulation, continuity and that there is no interference resistance on the electrical line :

Computer 15 B2 Coolant temperature sensor

Computer 44 B1 Coolant temperature sensor

Repair.

JF5111.0

INJECTION

Fault finding - Status and parameter interpretation17

E7J 780

engine

AFTER REPAIRStart the status and parameter check again from the beginning.

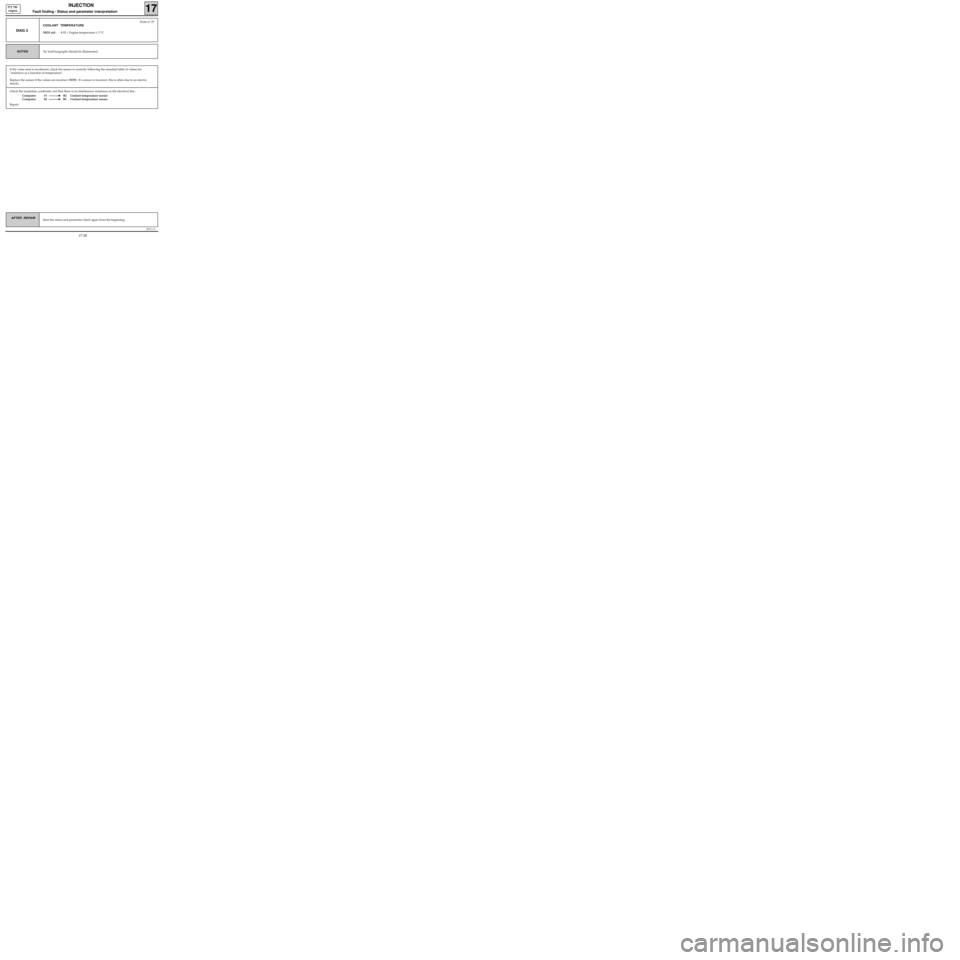

DIAG 3

Fiche n° 27

COOLANT TEMPERATURE

XR25 aid: # 02 = Engine temperature ± 5 °C

No fault bargraphs should be illuminated.NOTES

If the value read is incoherent, check the sensor is correctly following the standard table of values for

"resistance as a function of temperature".

Replace the sensor if the values are incorrect (

NOTE : If a sensor is incorrect, this is often due to an electric

shock).

17-38

Page 110 of 363

JF5111.0

INJECTION

Fault finding -Aid

17

E7J 780

engine

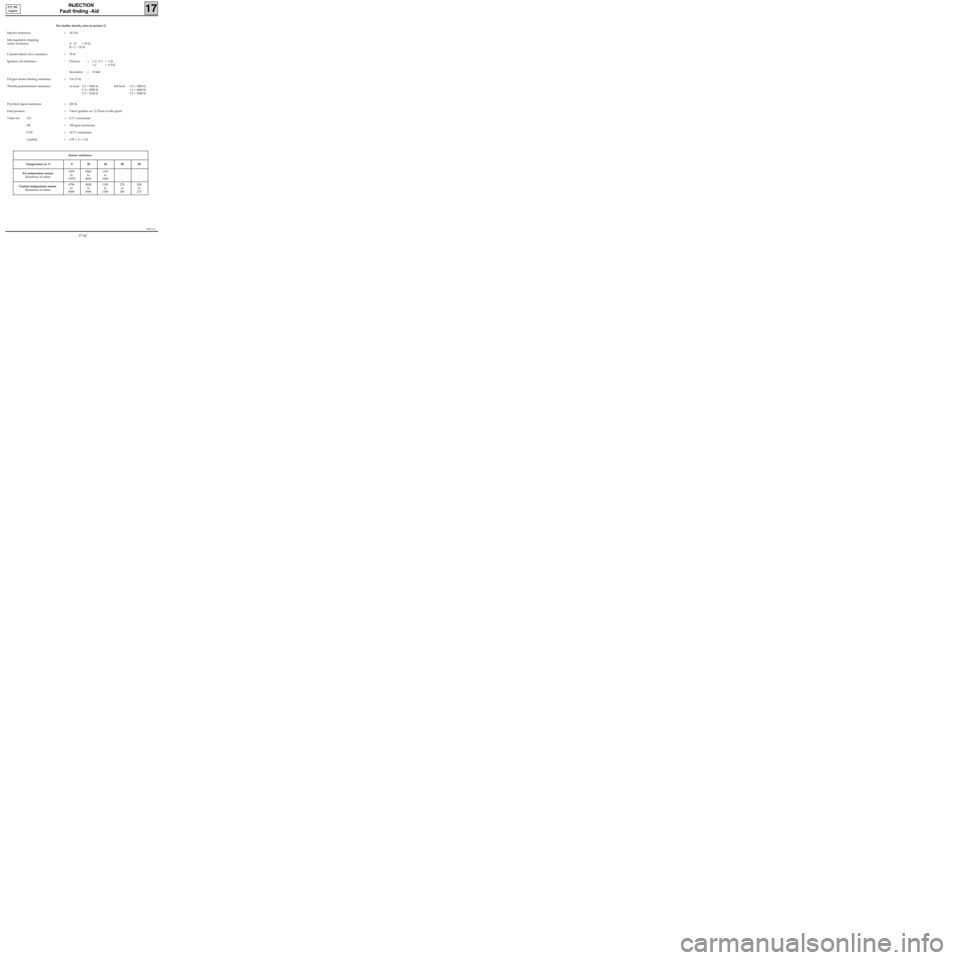

For further details, refer to section 12

Injector resistance = 14.5 Ω

Idle regulation stepping

motor resistance : A - D = 52 Ω

B - C = 52 Ω

Canister bleed valve resistance = 35 Ω

Ignition coil resistance : Primary = 1-3 ; 2-3 = 1 Ω

1-2 = 0.5 Ω

Secondary = 10 kΩ

Oxygen sensor heating resistance = 3 to 15 Ω

Throttle potentiometer resistance : no load 1-2 = 5440 Ωfull load 1-2 = 2200 Ω

1-3 = 4500 Ω1-3 = 4460 Ω

2-3 = 2160 Ω2-3 = 5340 Ω

Flywheel signal resistance = 220 Ω

Fuel pressure = 3 bars ignition on/ 2.5 bars at idle speed

Value for: CO = 0.3 % maximum

HC = 100 ppm maximum

CO2 = 14.5 % minimum

Lambda = 0.97 < λ < 1.03

Sensor resistance

Temperature in °C 0 20 40 80 90

Air temperature sensor

Resistance in ohms7470

to

119703060

to

40451315

to

1600--

Coolant temperature sensor

Resistance in ohms6700

to

80002600

to

30001100

to

1300270

to

300200

to

215

17-62

Page 113 of 363

JF5111.0

INJECTION

Fault finding - Checking conformity

17

E7J 780

engine

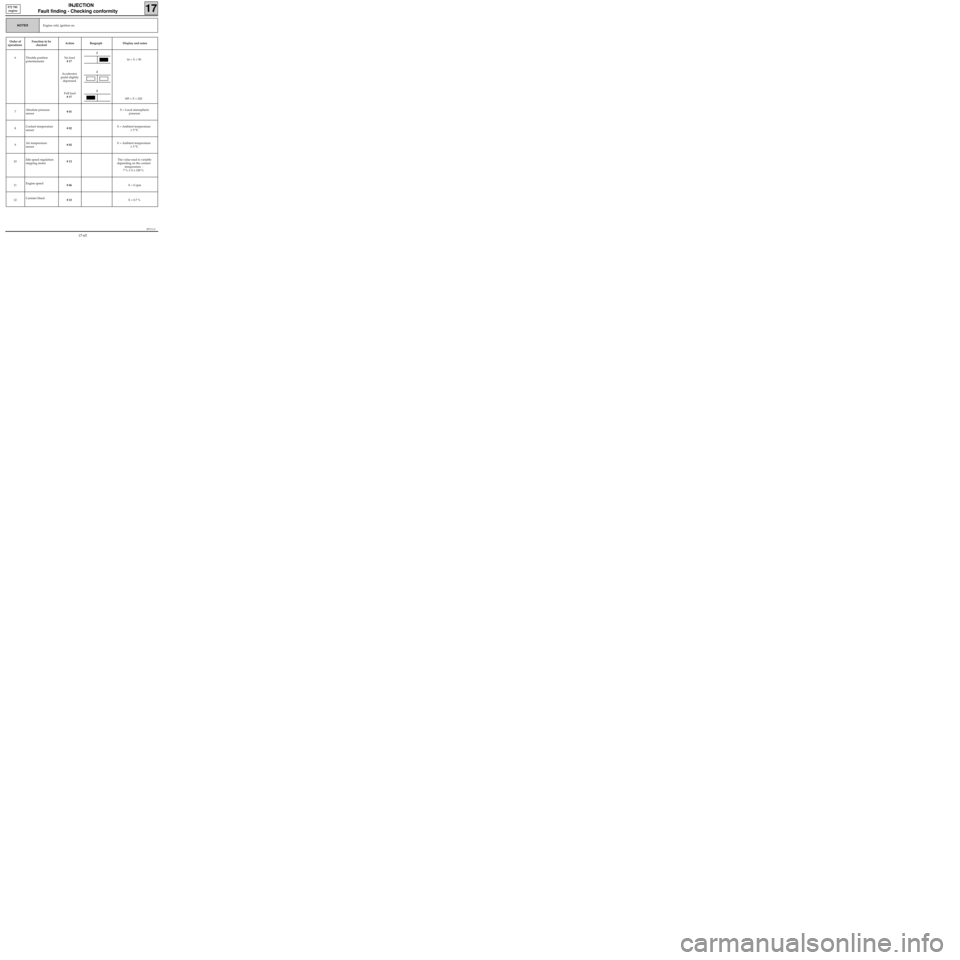

Engine cold, ignition on.NOTES

Order of

operationsFunction to be

checkedAction Bargraph Display and notes

6 Throttle position

potentiometerNo load

# 17

Accelerator

pedal slightly

depressed

Full load

# 17 16 < X < 50

185 < X < 243

7Absolute pressure

sensor# 01 X = Local atmospheric

pressure

8Coolant temperature

sensor# 02 X = Ambient temperature

± 5 °C

9Air temperature

sensor# 03 X = Ambient temperature

± 5 °C

10Idle speed regulation

stepping motor# 12The value read is variable

depending on the coolant

temperature :

7 % ≤ X ≤ 100 %

11Engine speed

# 06 X = 0 rpm

12Canister bleed

# 23 X = 0.7 %

2

2

2

17-65

Page 124 of 363

JSA051.0

INJECTION

Fault finding - Introduction

17

D7F 710

engine -

35 tracks

Driving conditions for programming the adaptive variables:

During the road test, the engine speed must be stabilised for a few moments between:

260 < # 01 < 385 mbars

then 385 < # 01 < 510 mbars

then 510 < # 01 < 635 mbars

then is 635 < # 01 < 760 mbars

then 760 < # 01 < 970 mbars

Do not exceed an engine speed of 4400 rpm

The engine must be warm (coolant temperature > 75 °C).

For this test, start from a fairly low engine speed, in 3rd or 4th gear, and apply progressive acceleration to

stabilise at the pressure required for 10 seconds in each zone.

The test must then be continued by driving normally, in a varied manner for 3 to 6 miles (5 to 10 km).

17-79

Page 133 of 363

Connect the bornier in place of the computer and check the insulation and continuity of the line:

Computer 15 1 Coolant temperature sensor

Computer 6 2 Coolant temperature sensor

Repair if necessary.

JSA051.0

INJECTION

Fault finding - Interpretation of XR25 bargraphs17

D7F 710

engine -

35 tracks

Erase the computer memory using G0**.

Try to start the engine. Switch the ignition on, then deal with the other faults.

Remember to carry out a status and parameter check.AFTER REPAIR

Bargraph 4 LH side illuminatedFiche n° 27 side 1/2

COOLANT TEMPERATURE SENSOR CIRCUIT

XR25 aid:CO, CC- or CC+line 15 or 6

4

If BG 3LH or BG 5LH or BG 6LH or BG 6RH is also illuminated, check line 15 on the

computer. For certain faults, BG 4LH is only permanently illuminated when the

engine is running.

NOTES

The fault persists! Replace the injection computer.

IMPORTANT: The computer has probably been damaged by an electric shock. The cause of the damage

must be found before fitting a new computer.

Check the resistance of the sensor. Replace it if necessary.

17-88