sensor RENAULT KANGOO 1997 KC / 1.G General Information Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 37

Page 10 of 37

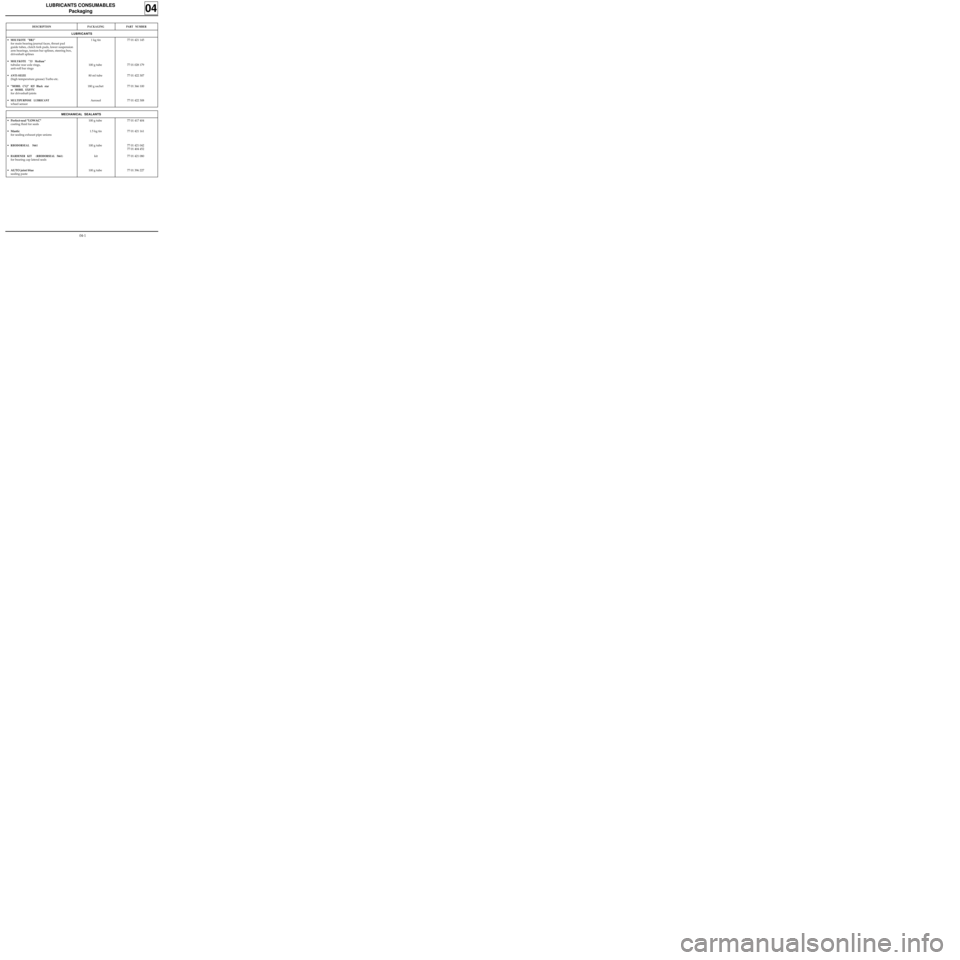

DESCRIPTIONPACKAGINGPART NUMBER

1 kg tin

100 g tube

80 ml tube

180 g sachet

Aerosol77 01 421 145

77 01 028 179

77 01 422 307

77 01 366 100

77 01 422 308

LUBRICANTS

LUBRICANTS CONSUMABLES

Packaging

04

•MOLYKOTE "BR2"

for main bearing journal faces, thrust pad

guide tubes, clutch fork pads, lower suspension

arm bearings, torsion bar splines, steering box,

driveshaft splines

•

MOLYKOTE "33 Medium"

tubular rear axle rings,

anti-roll bar rings

•

ANTI-SEIZE

(high temperature grease) Turbo etc.

•

"MOBIL CVJ" 825 Black star

or MOBIL EXF57C

for driveshaft joints

•

MULTIPURPOSE LUBRICANT

wheel sensor

• Perfect-seal "LOWAC"

coating fluid for seals

• Mastic

for sealing exhaust pipe unions

•

RHODORSEAL 5661

•HARDENER KIT (RHODORSEAL 5661)

for bearing cap lateral seals

• AUTO joint blue

sealing paste

100 g tube

1.5 kg tin

100 g tube

kit

100 g tube77 01 417 404

77 01 421 161

77 01 421 042

77 01 404 452

77 01 421 080

77 01 396 227

MECHANICAL SEALANTS

04-1

Page 21 of 37

VALUES AND SETTINGS

Belt tension

07

96601R

SPECIAL TOOLING REQUIRED

Mot. 1273 Tool for checking belt tension

A Sensor

B Display

C Connecting cable

D Calibration checking plate

Principle

The sensor, through the presser button (1), the

presser (2) and the outer pads (3), applies a

constant force to the belt.

The reaction from the belt is measured using a

test piece (4) fitted with strain gauges.

Any movement on the gauges creates a variation

in their electrical resistance. This variation, once it

has been converted by the device, is displayed on

the display in SEEM units (US).Calibrating the device

The device is set in the factory; however it must be

recalibrated every six months.

Procedure

Resetting the zero:

- switch on the device (button E) with the presser

button (1) face down,

- if 0 is displayed, do not touch anything,

- if nothing is displayed, check the condition of

the 9 volt battery in the device ,

- if a value other than 0 is displayed, adjust screw

(F) until 0 is obtained.

07-5

Page 22 of 37

VALUES AND SETTINGS

Belt tension

07

Checking the calibration

Switch on the device (button E).

Position the calibration spring plate (Z) on the sensor as shown on the diagram (control value engraved to-

wards the top, (A) minimum value, (B) maximum value).

Tighten the presser button (1) until it goes "CLICK - CLICK - CLICK".

Check that a value X between the values (A and B) (A ≤ X ≤ B) is displayed.

NOTE: it may be necessary to perform several preliminary tests in order to obtain the correct value.

If the correct value if still not obtained after several attempts, contact SEEM.

NOTE : each device has its own calibration spring plate and they are not interchangeable.

96602R

1 Knurled button (presser)

A

B

Z Calibration plate

Calibration plate control value

SEEM

Contact your After Sales Head Office for further

information.

GENERAL INSTRUCTIONS:

_ Never refit a belt which has been removed, re-

place it.

- Never retighten a belt for which the tension

reading is between the fitting value and the

minimum operating value.

- When checking, if the tension is below the mi-

nimum operating value, change the belt.

07-6

Page 23 of 37

VALUES AND SETTINGS

Accessories belt tension

07

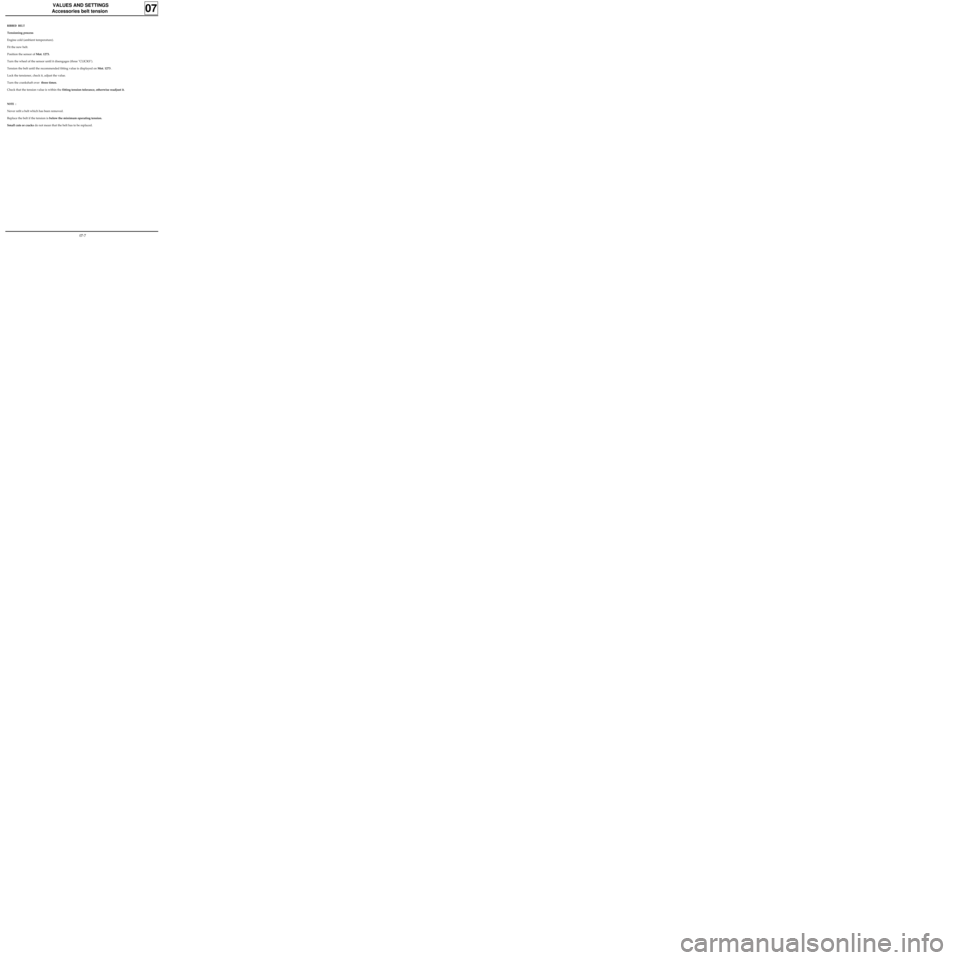

RIBBED BELT

Tensioning process

Engine cold (ambient temperature).

Fit the new belt.

Position the sensor of Mot. 1273.

Turn the wheel of the sensor until it disengages (three "CLICKS").

Tension the belt until the recommended fitting value is displayed on Mot. 1273 .

Lock the tensioner, check it, adjust the value.

Turn the crankshaft over three times.

Check that the tension value is within the fitting tension tolerance, otherwise readjust it.

NOTE :

Never refit a belt which has been removed.

Replace the belt if the tension is below the minimum operating tension.

Small cuts or cracks do not mean that the belt has to be replaced.

07-7

Page 27 of 37

VALUES AND SETTINGS

Timing belt tension

07

13361R

E7J engine Tensioning process

Engine cold (ambient temperature).

Fit the new belt.

Position the sensor of Mot. 1273.

Turn the wheel of the sensor until it disengages

(three "CLICKS").

Tension the belt until the recommended fitting

value is displayed on Mot. 1273.

Lock the tensioner, check it and adjust the value.

Turn the crankshaft over at least three times .

Check that the tension value is within the fitting

tension tolerance (± 10%), otherwise readjust it,

repeating the operations described above.

NOTE :

- For the F8Q engine, remove the pin Mot 1054

before fitting the sensor of tool Mot 1273 and

press hard on the section of belt between the

intermediate shaft sprocket (or idle sprocket)

and the tension wheel, then make the measu-

rement.

- Never refit a belt which has been removed.

- Replace the belt if the tension is below the mi-

nimum operating tension.

D7F engine

There are special features for tensioning the ti-

ming belt: refer to section 11.

Belt tension (in SEEM units)

Fitting: 30 U.S.

Minimum operating : 26 U.S.

F8Q engine

13094R

Belt tension (in SEEM units)

Fitting : 29 U.S.

Minimum operating : 25 U.S.

07-11