engine RENAULT KANGOO 1997 KC / 1.G Sheet Metal Work Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 255

Page 3 of 255

Contents

GENERAL

Dimensions

Engine and equipment

Identification

Means of lifting

Towing

Using symbols

Key to symbols

Description of Parts (exploded)

Opening clearances

Collision fault finding

Sub- frame dimensions

Repair bench

Special tooling

Part Number of special tooling40-1

40-2

40-4

40-6

40-8

40-9

40-11

40-12

40-15

40-22

40-25

40-27

40-38

40-38

LOWER STRUCTURE

41- 1

41- 5

41-10

41-13

41-17

41-21

41-26

41-29

41-33

41-36

41-39

41-41

41-44

41-51

41-53

41-55

41-58

41-60

41-62

41-63

41-67

41-68

41-71UPPER FRONT STRUCTUREPage Page40

41

42

Sheet metal work

UPPER SIDE STRUCTURE43

AFront end lower cross member

BFront side member, front section

CFront side member closure panel

DFront half unit

EFront side cross member

FFront side member, rear section

GFront mounting of sub frame

HSill panel closure panel

ICross member under front seat

JSide floor

KTunnel

LRear floor, front section

MRear floor, rear section (part

section)

NFront cross member of rear floor,

front section

ORear floor stiffener

PRear end cross member

QRear absorber reinforcement

RRear side member extension

SRear side member, part section

TComplete rear side member

URear floor centre cross member

VSeat anchoring reinforcement

WRear floor unit42-1

42-2

42-5

42-8

42-12

42-17

42-24

42-28

42-32

42-34 AFront wing

BHeadlight carrier panel

CCowl side panel (pillar lining)

part section

DUpper reinforcement of cowl side

panel

EWheel arch, front section

FWheel arch

GPlenum chamber

HWindscreen aperture lower cross

member

ISteering column mounting

JBulkhead

43-1

43-6

43-9

43-14

43-19

43-23

43-25 AFront pillar

BWindscreen pillar

C Front pillar lining/Cowl side panel

DCentre pillar / sill panel

ECentre pillar lower reinforcement /

door pillar

FSill panel reinforcement

GLeft hand side sill panel

UPPER REAR STRUCTURE

44

44-1

44-9

44-17

44-26

44-30

44-33

44-38

44-41 ARear wing panel

BSide panel

CSide panel lining

DRoof stretcher lining

ERear inner wheel arch

FLights mounting side panel rain

channel

GRear wing panel extension

HRear end panel

Page 6 of 255

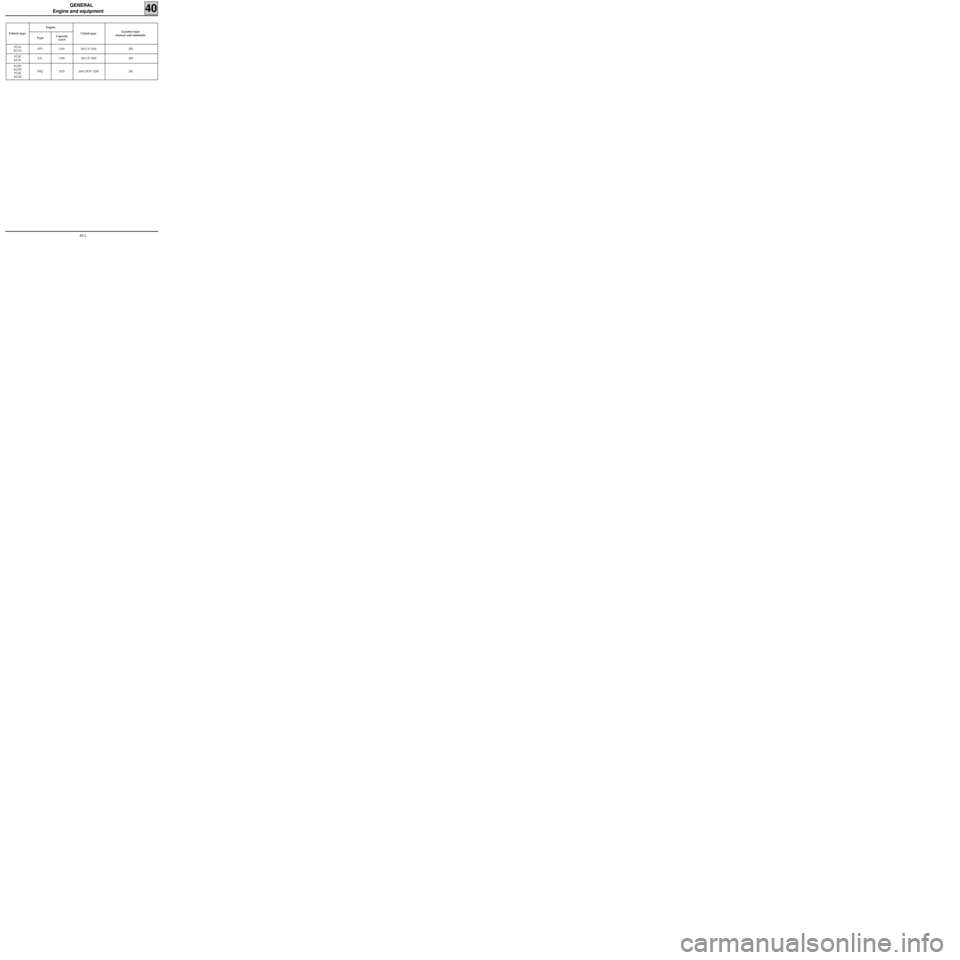

GENERAL

Engine and equipment

40

Vehicle type Engine

TypeCapacity

(cm

3)Clutch type Gearbox type

manual and automatic

FC0A

KC0AD7F 1149 180 CP 3300 JB1

FC0C

KC0CE7J 1390 180 CP 3300 JB3

FC0D

KC0D

FC0E

KC0EF8Q 1870 200 CPOV 3250 JB1

40-2

Page 7 of 255

GENERAL

Engine and equipment

40

SPECIFIC BODYWORK FEATURES

Driver’s airbag

Passenger’s and driver’s airbag

Height adjustable front head restraint

Height adjustable and tiltable front head restraint

Rear parcel shelf

Luggage compartment net

Electric one touch windows

Heated electric rear view mirrors

Heated screen + timed windscreen wiper

Heated front seats

Front seat driver emergency exit

Rear bench seat 1/1

Rear bench seat 1/3 - 2/3

Cabin rack without stop

Headlining

Boot carpet

Parcel shelf luggage cover

Two front fog lights in bumper

(excluding F8 AC PAS)Pay load 600 kg

Pay load 625 to 710 kg depending on

engine/equipment

Pay load 800 kg

Glazed, sliding side door and rear opening doors

or glazed tailgate

Sliding side door (reflective glass)

Sliding side door (panel)

Rear door, panel

Rear door, glazed

Opening doors, panels

Opening doors, glazed

Tailgate

Opaque roof flap (excluding tailgate)

Glazed roof flap (excluding tailgate)

Fixed side window (meaning glazed side door)

Sliding side window

Fixed rear quarter panel (meaning the glazed

sliding side door )

Heat insulating windscreen (with air conditioning)

2 point rear centre seat belt

3 point rear centre seat belt

40-3

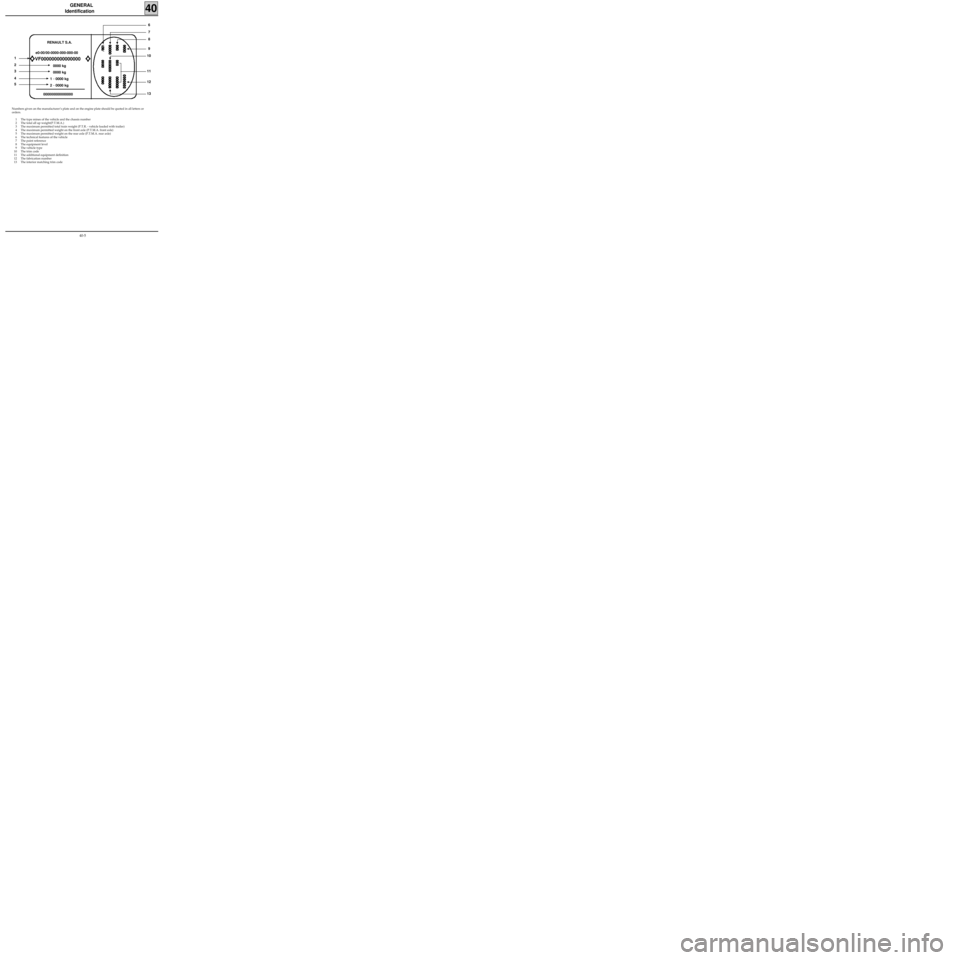

Page 9 of 255

GENERAL

Identification

40

Numbers given on the manufacturer’s plate and on the engine plate should be quoted in all letters or

orders.

1 The type mines of the vehicle and the chassis number

2 The total all up weight(P.T.M.A.)

3 The maximum permitted total train weight (P.T.R. - vehicle loaded with trailer)

4 The maximum permitted weight on the front axle (P.T.M.A. front axle)

5 The maximum permitted weight on the rear axle (P.T.M.A. rear axle)

6 The technical features of the vehicle

7 The paint reference

8 The equipment level

9 The vehicle type

10 The trim code

11 The additional equipment definition

12 The fabrication number

13 The interior matching trim code

e0-00/00-0000-000-000-00

VF000000000000000

0000 kg

0000 kg

1

- 0000 kg

2

- 0000 kg

000000000000000RENAULT S.A.

1

2

3

4

5

8 7

6

9

10

13

12 11

40-5

Page 11 of 255

GENERAL

Means of lifting

40

SAFETY SYMBOL

There are several examples :

1 - WHEN REMOVING PARTS

Generally speaking, never use a 2 post lift if a

four post lift would be more suitable.

If this is not possible, position the lifting pads

below the body flange at the jacking points for

the jack supplied with the vehicle.

98703S

FRONT

98704S

REAR

These absolutely MUST be placed to the right of

the jacking points. They must be clipped into the

sill panel flange openings.

2 -

SPECIAL CASE OF THE REMOVAL - REFITTING

OF THE ENGINE AND TRANSMISSION

ASSEMBLY

In this specific case, the body of the vehicle must

be attached to the arms of the two post lift with

special pads.

FOG Company

Part number FOG 449 8111 - 449 8411

or

CHEMICO Company

Part number 39 2550 0001

or

SCHENCH Company

Part number 776 684

40-7

Page 29 of 255

GENERAL

Sub-frame dimensions

40

DESCRIPTION X Y ZDIAMETER SLOPE %

A Front sub-frame rear mounting 205 402.5 71 18.5 0

B Rear axle assembly front mounting 1 999.3 657 71.3 20×20 X : 8°20

C Front left sub-frame front mounting - 418 447 13010×10

(squared)0

Front right sub-frame front mounting - 418 465 13010×10

(squared)0

E Rear shock absorber upper mounting 2 333.13 545.75 184 12.5 0

F Front shock absorber upper mounting 18.5 545.50 657 48X : 3°02

Y : 1°

G1 Rear section of front left side member 600 - 375 020×20

(squared)0

Rear section of front right side member 600 351.6 020×20

(squared)0

J Rear point of rear side member 2 918 497.5 151 12.2×16.2 X : 3°

K Front end cross member 575 315 280 14.25X : 4°30

Z : 5°

L Rear end cross member (end panel) 3 121 - 497.5 151 M8 0

P Front engine mounting - 247 483.5 514 M10 0

Rear engine mounting - 113 483.5 514 M10 0

40-25

Page 37 of 255

GENERAL

Repair Bench

40

12667R

The bracket touches below the side member and

is centred in the pilot hole (slot).

It may be used for a slight rear impact without re-

moving the rear axle, but requires the removal of

the exhaust mounting.

P - FRONT AND REAR ENGINE MOUNTINGIII - REFERENCE POINTS FOR POSITIONING REPLACED PARTS (cont)

12841S

The bracket is positioned from above the engine

mounting, and is centred in the mounting holes of

the engine mounting.

It is used with the mechanical units removed for

replacing a front half unit.

J - REAR SIDE MEMBER REAR END

40-33

Page 38 of 255

GENERAL

Repair Bench

40

12668R1

The bracket helps with the fitting of the cross

member and rests vertically against the front end

cross member, then it is centred by a centring bolt

at (K).

1 - Front mechanical units removed

It is used for replacing the front end cross mem-

ber, with or without mechanical units.

NOTE : The operation for replacing the front end

cross member can be carried out without the re-

moval of the engine and transmission assembly,

but requires the removal of the radiator.

2 - Front mechanical units in place

The bracket helps with fault finding on the front

cross member.

III - REFERENCE POINTS FOR POSITIONING REPLACED PARTS (cont)

L - REAR END CROSS MEMBER (REAR END)

12667R1

The bracket helps with the fitting of the cross

member and rests vertically against the rear end

cross member, then centres itself in the mounting

hole of the absorber mounting.

It is used for replacing the whole rear end, with or

without mechanical units.

K - FRONT END CROSS MEMBER

40-34

Page 47 of 255

LOWER STRUCTURE

Front side member, front section

41B

PRB4122

INTRODUCTION

The replacement of this part can be done in two

ways :

A Front side member, complete front section .

B Front side member, partial front section (cut

to be made in front of the front mounting of

the sub-frame), see the following diagram.

In the two cases these are complementary opera-

tions to the replacement of the front end lower

cross member and the headlight carrier panel. As

a result, the joints with these parts will not be

considered here, they will be dealt with in the res-

pective sections.

The repair bench must be used.

The replacement of this part also requires the re-

placement of the side member closure panel

which will have to be ordered separately.

COMPOSITION OF THE PART FROM THE PARTS

DEPARTMENT

1 -Side member

Part assembled with:

- engine mounting height adjuster (only on the

right hand side),

- sub-frame front mounting.

2 - Front side member closure panel

Part on its own.

JOINTS WITH:

Side member closure panel

Front side member, rear section

Front wheel arch

Shock absorber cup height adjuster

Engine mounting *

PARTS CONCERNED (thickness in mm) :

1Front side member, front section 1.5

2Front side member, rear section 2.5

3Front wheel arch 0.8

4Shock absorber cup height adjuster 0.8

5Side member closure panel 1.2

6Engine mounting height adjuster* 1.8

7Engine mounting reinforcement * 1.5

* Only the right hand side.or

41-5

Page 55 of 255

LOWER STRUCTURE

Front half unit

41D

PRB4124

INTRODUCTION

The operation for the replacement of this part is

complementary to :

- the front end lower cross member,

- the headlight panel

- the cowl side panel.

This operation requires the replacement of the

cowl side panel (pillar lining) and of the cowl side

panel upper reinforcements, which have to be or-

dered separately.

In the operation described below there are only

descriptions of the specific joints to the part

concerned, information concerning the parts to

be ordered separately is not considered here. This

will be dealt with in the respective sections.

The repair bench must be used.

COMPOSITION OF THE PART FROM THE PARTS

DEPARTMENT

Part assembled with:

1 Front side member , rear section

- engine mounting height adjuster (right

hand side)

- engine mounting reinforcement (right

hand side),

- engine mounting plate (right hand side),

- sub-frame front mounting,

- front side member closure panel ,

- wheel arch,

- shock absorber cup,

- shock absorber cup height adjuster,

- ABS mounting (right hand side),

- injection unit mounting and impact sensor

(left hand side).

2 Cowl side panel (pillar lining)

3 Cowl side panel upper reinforcementJOINTS WITH:

Plenum chamber

Injection unit mounting and impact sensor (left

hand side)

Front side member, rear section

Shock absorber cup height adjuster

PARTS CONCERNED (thickness in mm) :

1Plenum chamber 1

2Injection unit mounting and impact

sensor (left hand side) 2

3Front side member, front section 1.5

4Front side member, rear section 1.8

5Shock absorber cup height adjuster 1

6Shock absorber cup 2

7Cowl side panel (pillar lining) 1.5or

41-13