RENAULT KANGOO 1997 KC / 1.G Transmission User Guide

Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 22, PDF Size: 0.17 MB

Page 11 of 22

MECHANICAL GEARBOX

Consumables

21

TYPEPACKAGING

Loctite 518

LOCTITE FRENBLOC

(locking and sealing

resin)

24 ml syringe

100 g tube

24 cc bottle

PART NUMBER

77 01 404 452

77 01 394 071

COMPONENT

77 01 421 162Housing assembling faces

Threaded plugs and switches

Bearing plugs

Ends of roll pins on driveshafts

Primary and secondary shaft nuts

Fixed gear and 5th gear hub

Rear differential lock drive stud

Splines of the right - hand sunwheel

Fork pivot

Thrust bearing guide

Fork pads

MOLYKOTE BR277 01 421 1451 kg tinClutch

Parts to be systematically replaced

After they have been removed :

- the lip seals,

- the O-ring seals,

- the clutch thrust bearing guide tubes,

- the secondary and differential shaft nuts,

- the speedometer drive gear and its shaft,

- the speedometer ring gear,

- the roll pins,

- the gear supporting rings.

RHODORSEAL 5661

Eg : CAF 4/60 THIXO

21-4

Page 12 of 22

MANUAL GEARBOX

Gearbox (removal - refitting)

21

SPECIAL TOOLING REQUIRED

B. Vi. 31-01Set of punches

Mot. 1040-01Engine sub-frame carrier

T. Av. 476Ball joint extractor

Brake calliper bolt 4

Driveshaft gaiter bolt 2.5

Lower ball joint nut 5.5

Shock absorber base bolt 18

Engine tie-bar bolt 6.5

Gearbox edge and starter motor bolt 4.5

Suspended mounting bolt on gearbox 4

Wheel bolts 9

Track rod end nut 4

TIGHTENING TORQUES (In daN.m)

REMOVAL

Place the vehicle onto a two post lift.

Disconnect the battery.

Remove :

- the engine cover,

- the battery.

Disconnect the connectors on:

- the injection computer (petrol version),

- the preheating unit (diesel version),

_ the diesel fuel filter (diesel version),

- the impact sensor.

Remove the air filter sleeve.

13083S

EQUIPMENT REQUIRED

Engine support tool

Component jack

Remove the bolts (A) of the battery protective

screen.

13088R

21-5

Page 13 of 22

MANUAL GEARBOX

Gearbox (Removal - Refitting)

21

Remove :

- the two mounting bolts (B),

13119R

Disconnect the clutch cable.

Remove :

- the upper bolts at the gearbox edge and on

the starter motor (slacken the bolt (D) as far

as possible)

- the earth strap bolts on the gearbox,

- the two bolts of the

TDC sensor.

13097-2R

- the front wheels,

- the oil collector under the gearbox.

On the right-hand side of the vehicle, remove the

driveshaft pins using tool B. Vi. 31-01.

91755-1R2

Remove on both sides :

- the brake callipers and attach them together

- the mudguards,

- the track rod ends (T. Av. 476),

- the shock absorber base bolts,

- the sub-frame side member tie-rods (A),

- the stub axle carrier-driveshaft by disconnec-

ting it from the lower ball joint

99070R1

21-6

Page 14 of 22

MANUAL GEARBOX

Gearbox (Removal - Refitting)

21

Ensure that the rollers of the left driveshaft can-

not be removed by hand. If they can, check if any

of the needles have fallen into the gearbox.

Disconnect and remove the starter motor.

Disconnect:

- the reversing light connector,

- the speedometer connector and remove the

gearbox sensor.

Remove :

- the exhaust downpipe,

- the entire gear control lever by removing the

bolt (E) and the three bolts of the heat shield

for access to the base of the gear lever

- the engine tie-bar bolt,

- the rear support on the gearbox.

12993-1R2

Remove the engine-gearbox tie-rod.

To aid the removal of the steering box, fit, if ne-

cessary, a shim, in order to tilt the engine for-

ward.

Remove the steering box and secure it.

Fit the engine support and take the weight of

the engine and transmission assembly.

Positioning on F8Q engine

13120S

13121S

21-7

Page 15 of 22

MANUAL GEARBOX

Gearbox (Removal - Refitting)

21

Positioning on petrol engines

13122S

Remove the three mounting bolts for the support

on the gearbox.

Remove the engine sub-frame by slackening the

four mounting bolts.

Fit the component jack under the gearbox wi-

thout lifting it.

Separate the gearbox from the engine having re-

moved the nut (E) and the engine-gearbox moun-

ting stud.

98755R1

85812-1R

12924R

Lower the engine as far as possible.

Remove :

- the last gearbox edge bolt at the top,

- the bumper.

Fit the sub-frame support (Mot. 1040-01) and lo-

wer the vehicle.

21-8

Page 16 of 22

MANUAL GEARBOX

Gearbox (Removal - Refitting)

21

REFITTING

Coat the walls of the guide tube and the fork pads

with

MOLIKOTE BR2 grease.

Place the fork onto the slots of the clutch thrust

bearing.

Assemble the gearbox on the engine taking care

not to alter the height of the engine.

Ensure the presence and correct positioning of

the engine- gearbox centering rings .

The presence of the stud (C) aids assembly.

86308R2

Refit:

- the engine sub-frame,

- the steering,

- the exhaust downpipe,

- the engine tie-bar.

SPECIAL NOTE FOR THE E7J ENGINE

Refit the exhaust downpipe before the right-

hand driveshaft.

Refit the other components by proceeding in the

reverse order to removal.

21-9

Page 17 of 22

DRIVESHAFTS

General

29

SPECIFICATION

NOTE : the replacement of the NYLSTOP nut with the ENKO driveshaft nut means that the splines of the

stub axles must no longer be coated with

Loctite SCELBLOC.

Vehicle type Engines

GearboxesDriveshaft seal

Left Right

F8Q JB1

D7F JB1

E7J

JB1 / JB3

FC0X

KC0XGE 86 + GI 69GE 86 + RC 462

CONSUMABLES

Type Quantity Component concerned

RHODORSEAL 5661Coat Gearbox side driveshaft roll pin

MOBIL K 575 GS180 g GE 86

ELF GMPT89 or

MOBIL CVJ 825 BLACK STAR110 cm3RC 462

29-1

Page 18 of 22

DRIVESHAFTS

Front driveshafts

REFITTING

Left side :

Fit the driveshaft as horizontally as possible.

Right side :

Coat the splines of the joint on the gearbox side

with

MOLYKOTE BR2 grease.

Fit the driveshaft and check its positioning : an-

gled pin B. Vi. 31-01.

Fit two new roll pins : B. Vi. 31-01. Seal the roll pin

holes using

RHODORSEAL 5661.

On both sides :

Fit the driveshaft stub axle into the hub, it should

go in easily.

Refitting is the reverse of removal. Observe the

tightening torques.

Top up the gearbox oil.

Press the brake pedal several times in order to

bring the piston into contact with the pads.

29

REMOVAL

Vehicle on a two post lift.

Drain the gearbox.

Remove :

- the brake assembly (suspend it from the

chassis),

- the driveshaft nut : tool Rou. 604-01.

Left side :

Remove the three bolts on the gearbox.

Right side :

Remove the roll pin : tool B. Vi. 31-01.

On both sides :

Remove :

- The track rod end nut and extract the shaft :

tool T. Av. 476,

- the upper bolt of the shock absorber base.

Push back the driveshaft : tool T. Av. 1050-02.

Remove the lower bolt of the shock absorber

base and extract the driveshaft.

99544R

SPECIAL TOOLING REQUIRED

B. Vi. 31-01Roll pin punch

Rou. 604-01Hub locking tool

T. Av. 476Ball joint extractor

T. Av. 1050-02Driveshaft extractor

Driveshaft nut 28

Mounting bolt of gaiter on gearbox. 2.5

Wheel bolts 9

Shock absorber base nuts 18

Brake caliper mounting bolts 10

Track rod end nut 3.7

TIGHTENING TORQUES (in daN.m)

29-2

Page 19 of 22

DRIVESHAFTS

Front driveshafts

REFITTING

For its correct positioning on the shaft, the

bearing must be pressed on to obtain a distance

of L = 118 ± 0.2 mm between the rear part of

the bearing and the end of the shaft.

This measurement is obtained using the tool T.

Av. 1331 when its extremity is level with the

shaft.

29

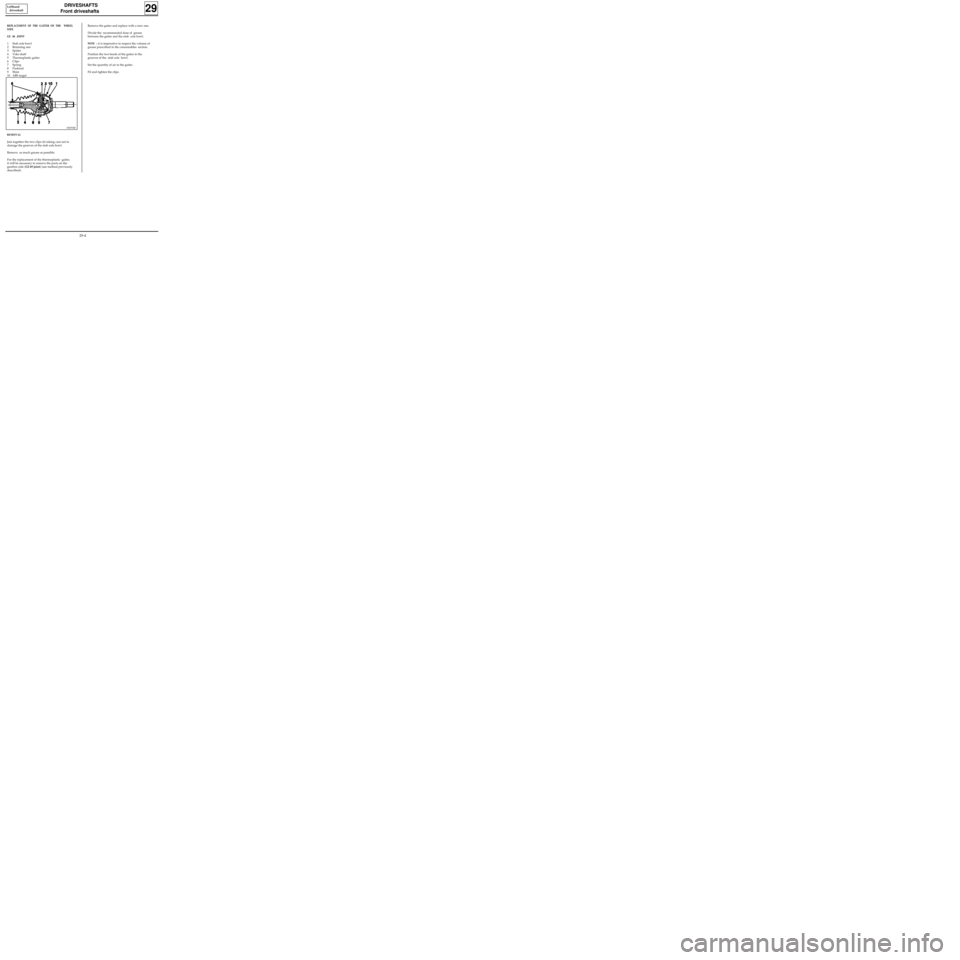

REPLACEMENT OF THE GAITER ON THE GEARBOX

SIDE

GI 69 JOINT

1 Spider

2 Rubber gaiter

3 Bearing guide

4 Retainer

5 Deflector

6 Circlip

7 Driveshaft

85884-1R1

Lefthand

driveshaft

SPECIAL TOOLING REQUIRED

T. Av. 1168 CAILLAU clip pliers

T. Av. 1256 OETIKER crimping pliers

T. Av. 1331 Tool for holding driveshaft bearing gai-

ter in position

DI2935R

REMOVAL

Remove the circlip.

On the press, remove the spider using an

extractor.

NOTE : mark the position of the spider before

extracting it.

Remove the gaiter and deflector - bearing

assembly in the same way as for the spider.

NOTE : in order to avoid deformation of the bea-

ring with a lip seal, and therefore any risk of lea-

kage, do not press it on using a hammer, but using

a press, in order to apply progressive pressure.

The driveshaft is held in the press using the slot

(G) with an extractor.

Replace the spider in the position marked on

removal and refit the retaining circlip.

29-3

Page 20 of 22

DRIVESHAFTS

Front driveshafts

Remove the gaiter and replace with a new one.

Divide the recommended dose of grease

between the gaiter and the stub axle bowl.

NOTE : it is imperative to respect the volume of

grease prescribed in the consumables section.

Position the two beads of the gaiter in the

grooves of the stub axle bowl.

Set the quantity of air in the gaiter.

Fit and tighten the clips.

29

REPLACEMENT OF THE GAITER ON THE WHEEL

SIDE

GE 86 JOINT

1 Stub axle bowl

2 Retaining star

3 Spider

4 Yoke shaft

5 Thermoplastic gaiter

6 Clips

7 Spring

8 Pushrod

9 Shim

10 ABS target

Lefthand

driveshaft

DI2934R

REMOVAL

Join together the two clips (6) taking care not to

damage the grooves of the stub axle bowl.

Remove as much grease as possible.

For the replacement of the thermoplastic gaiter,

it will be necessary to remove the parts on the

gearbox side (GI 69 joint) (see method previously

described).

29-4