RENAULT SCENIC 2000 J64 / 1.G Technical Note 3426A Owners Manual

Manufacturer: RENAULT, Model Year: 2000, Model line: SCENIC, Model: RENAULT SCENIC 2000 J64 / 1.GPages: 118, PDF Size: 1.5 MB

Page 91 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Accelerator potentiometer

13

13-40

Accelerator potentiometer

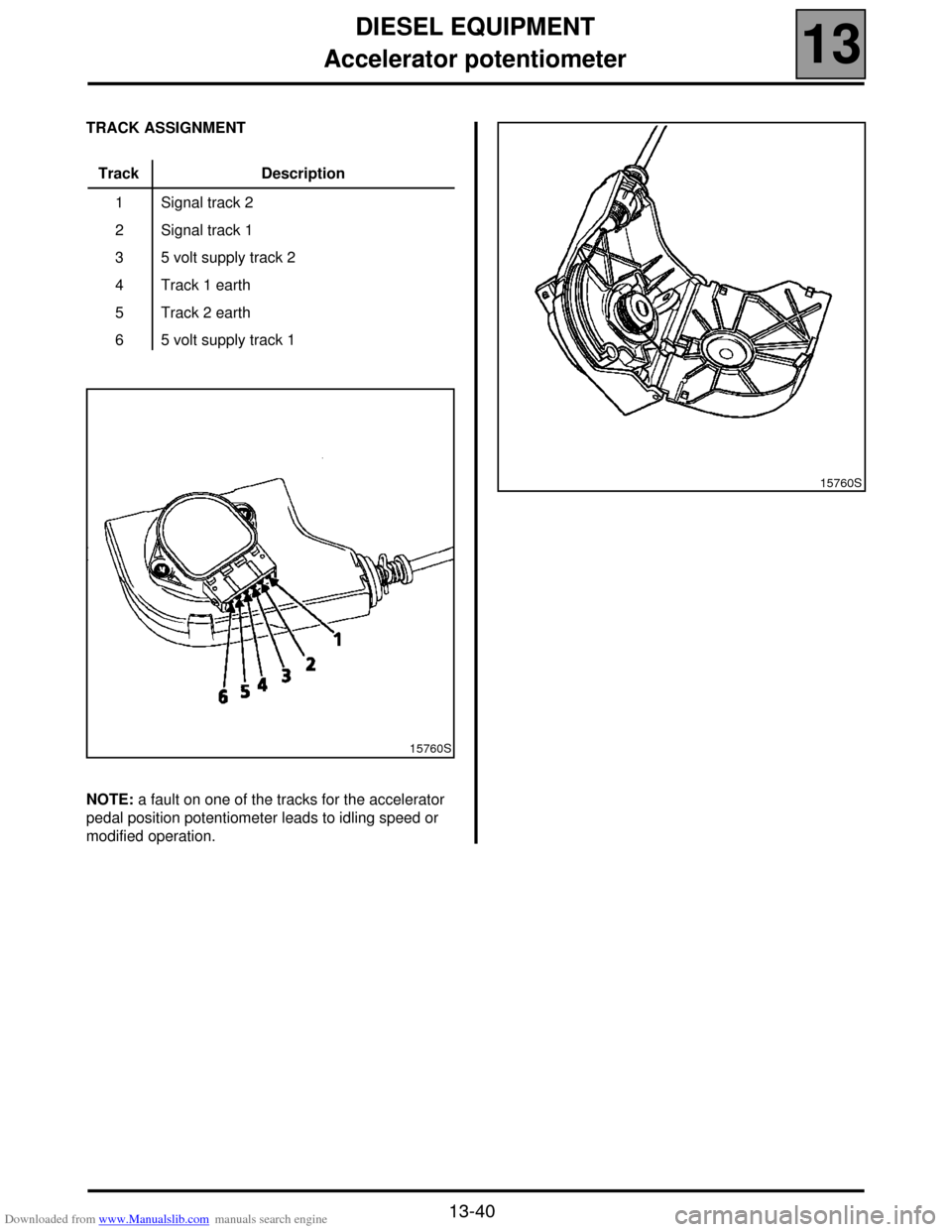

TRACK ASSIGNMENT

NOTE: a fault on one of the tracks for the accelerator

pedal position potentiometer leads to idling speed or

modified operation.Track Description

1

2

3

4

5

6 Signal track 2

Signal track 1

5 volt supply track 2

Track 1 earth

Track 2 earth

5 volt supply track 1

15760S

15760S

Page 92 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Coolant temperature management

13

13-41

Coolant temperature management

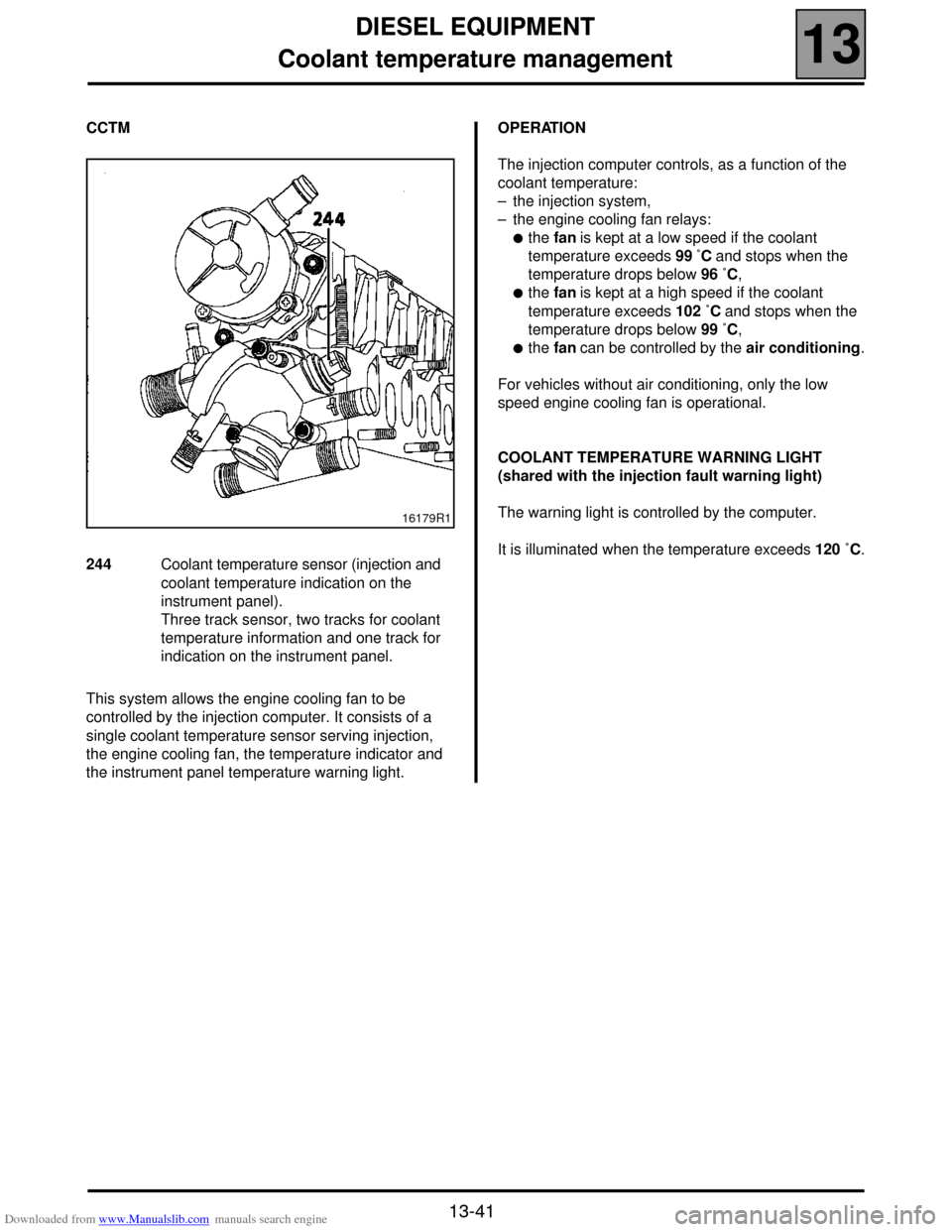

CCTM

This system allows the engine cooling fan to be

controlled by the injection computer. It consists of a

single coolant temperature sensor serving injection,

the engine cooling fan, the temperature indicator and

the instrument panel temperature warning light.OPERATION

The injection computer controls, as a function of the

coolant temperature:

– the injection system,

– the engine cooling fan relays:

!the fan is kept at a low speed if the coolant

temperature exceeds 99 ˚C and stops when the

temperature drops below 96 ˚C,

!the fan is kept at a high speed if the coolant

temperature exceeds 102 ˚C and stops when the

temperature drops below 99 ˚C,

!the fan can be controlled by the air conditioning.

For vehicles without air conditioning, only the low

speed engine cooling fan is operational.

COOLANT TEMPERATURE WARNING LIGHT

(shared with the injection fault warning light)

The warning light is controlled by the computer.

It is illuminated when the temperature exceeds 120 ˚C.

16179R1

244 Coolant temperature sensor (injection and

coolant temperature indication on the

instrument panel).

Three track sensor, two tracks for coolant

temperature information and one track for

indication on the instrument panel.

Page 93 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Computer

13

13-42

Computer

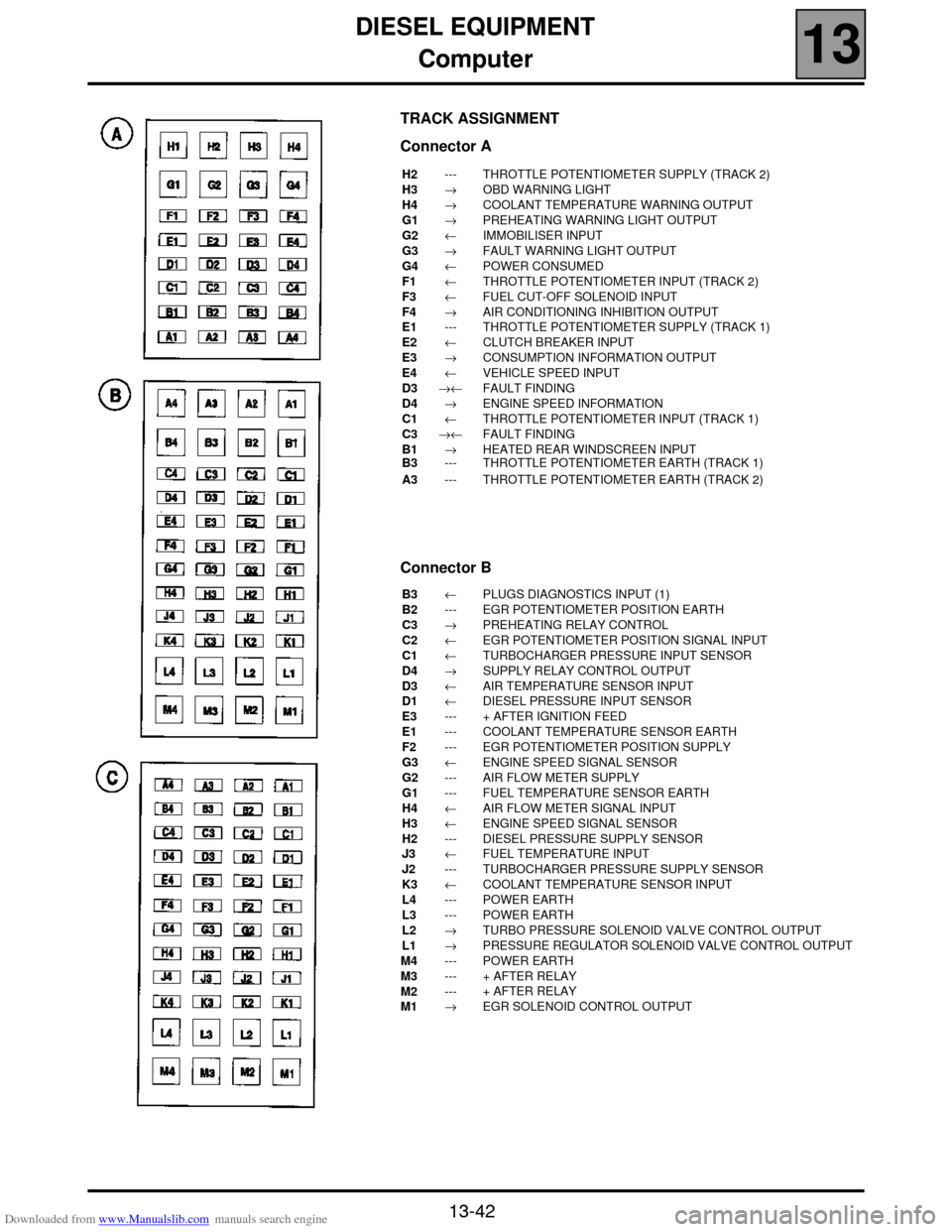

TRACK ASSIGNMENT

Connector A

H2

H3

H4

G1

G2

G3

G4

F1

F3

F4

E1

E2

E3

E4

D3

D4

C1

C3

B1

B3

A3---

→

→

→

←

→

←

←

←

→

---

←

→

←

→←

→

←

→←

→

---

---THROTTLE POTENTIOMETER SUPPLY (TRACK 2)

OBD WARNING LIGHT

COOLANT TEMPERATURE WARNING OUTPUT

PREHEATING WARNING LIGHT OUTPUT

IMMOBILISER INPUT

FAULT WARNING LIGHT OUTPUT

POWER CONSUMED

THROTTLE POTENTIOMETER INPUT (TRACK 2)

FUEL CUT-OFF SOLENOID INPUT

AIR CONDITIONING INHIBITION OUTPUT

THROTTLE POTENTIOMETER SUPPLY (TRACK 1)

CLUTCH BREAKER INPUT

CONSUMPTION INFORMATION OUTPUT

VEHICLE SPEED INPUT

FAULT FINDING

ENGINE SPEED INFORMATION

THROTTLE POTENTIOMETER INPUT (TRACK 1)

FAULT FINDING

HEATED REAR WINDSCREEN INPUT

THROTTLE POTENTIOMETER EARTH (TRACK 1)

THROTTLE POTENTIOMETER EARTH (TRACK 2)

Connector B

B3

B2

C3

C2

C1

D4

D3

D1

E3

E1

F2

G3

G2

G1

H4

H3

H2

J3

J2

K3

L4

L3

L2

L1

M4

M3

M2

M1←

---

→

←

←

→

←

←

---

---

---

←

---

---

←

←

---

←

---

←

---

---

→

→

---

---

---

→PLUGS DIAGNOSTICS INPUT (1)

EGR POTENTIOMETER POSITION EARTH

PREHEATING RELAY CONTROL

EGR POTENTIOMETER POSITION SIGNAL INPUT

TURBOCHARGER PRESSURE INPUT SENSOR

SUPPLY RELAY CONTROL OUTPUT

AIR TEMPERATURE SENSOR INPUT

DIESEL PRESSURE INPUT SENSOR

+ AFTER IGNITION FEED

COOLANT TEMPERATURE SENSOR EARTH

EGR POTENTIOMETER POSITION SUPPLY

ENGINE SPEED SIGNAL SENSOR

AIR FLOW METER SUPPLY

FUEL TEMPERATURE SENSOR EARTH

AIR FLOW METER SIGNAL INPUT

ENGINE SPEED SIGNAL SENSOR

DIESEL PRESSURE SUPPLY SENSOR

FUEL TEMPERATURE INPUT

TURBOCHARGER PRESSURE SUPPLY SENSOR

COOLANT TEMPERATURE SENSOR INPUT

POWER EARTH

POWER EARTH

TURBO PRESSURE SOLENOID VALVE CONTROL OUTPUT

PRESSURE REGULATOR SOLENOID VALVE CONTROL OUTPUT

POWER EARTH

+ AFTER RELAY

+ AFTER RELAY

EGR SOLENOID CONTROL OUTPUT

Page 94 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Computer

13

13-43

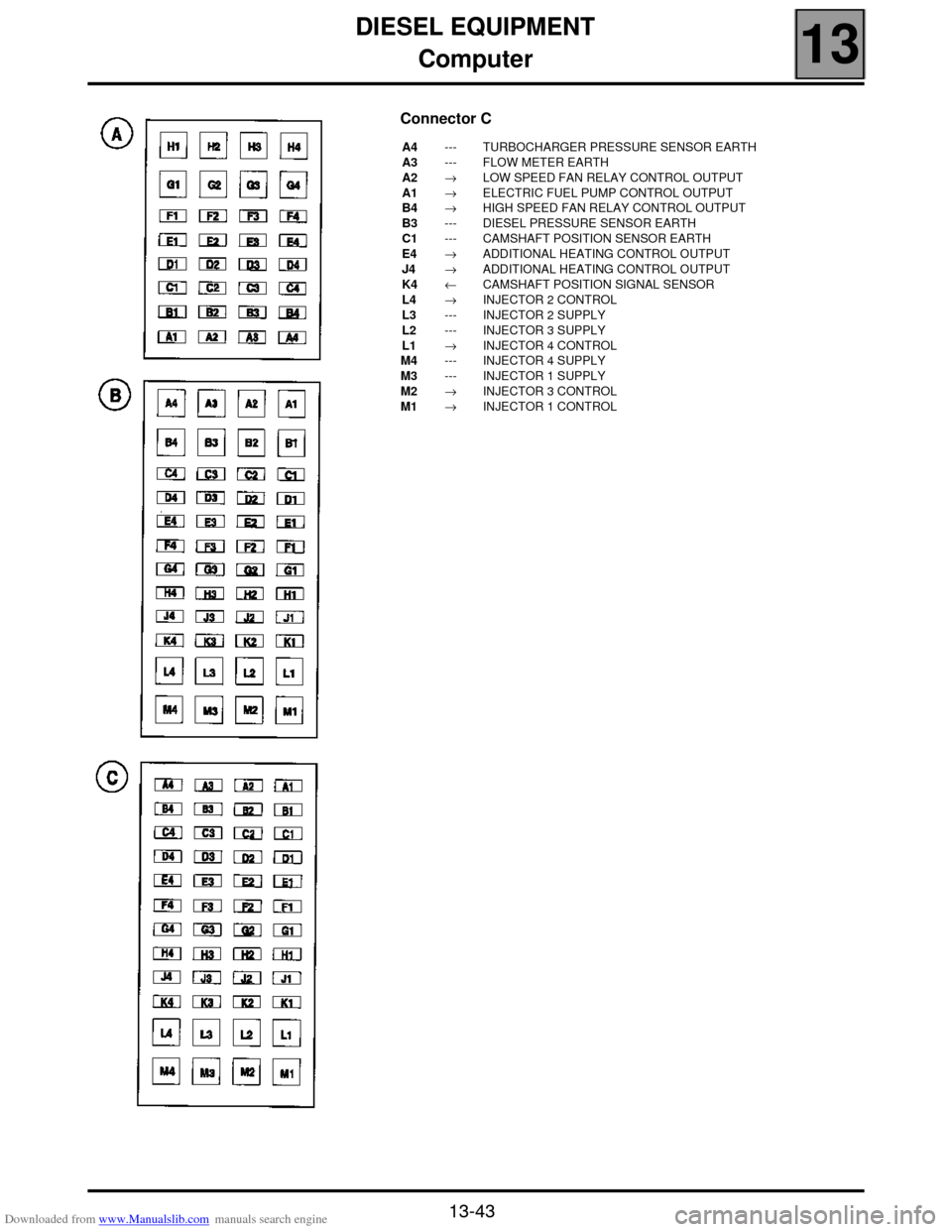

Connector C

A4

A3

A2

A1

B4

B3

C1

E4

J4

K4

L4

L3

L2

L1

M4

M3

M2

M1---

---

→

→

→

---

---

→

→

←

→

---

---

→

---

---

→

→TURBOCHARGER PRESSURE SENSOR EARTH

FLOW METER EARTH

LOW SPEED FAN RELAY CONTROL OUTPUT

ELECTRIC FUEL PUMP CONTROL OUTPUT

HIGH SPEED FAN RELAY CONTROL OUTPUT

DIESEL PRESSURE SENSOR EARTH

CAMSHAFT POSITION SENSOR EARTH

ADDITIONAL HEATING CONTROL OUTPUT

ADDITIONAL HEATING CONTROL OUTPUT

CAMSHAFT POSITION SIGNAL SENSOR

INJECTOR 2 CONTROL

INJECTOR 2 SUPPLY

INJECTOR 3 SUPPLY

INJECTOR 4 CONTROL

INJECTOR 4 SUPPLY

INJECTOR 1 SUPPLY

INJECTOR 3 CONTROL

INJECTOR 1 CONTROL

Page 95 of 118

Downloaded from www.Manualslib.com manuals search engine ANTIPOLLUTION

Oil vapour rebreathing

14

14-1

114ANTIPOLLUTION

Oil vapour rebreathing

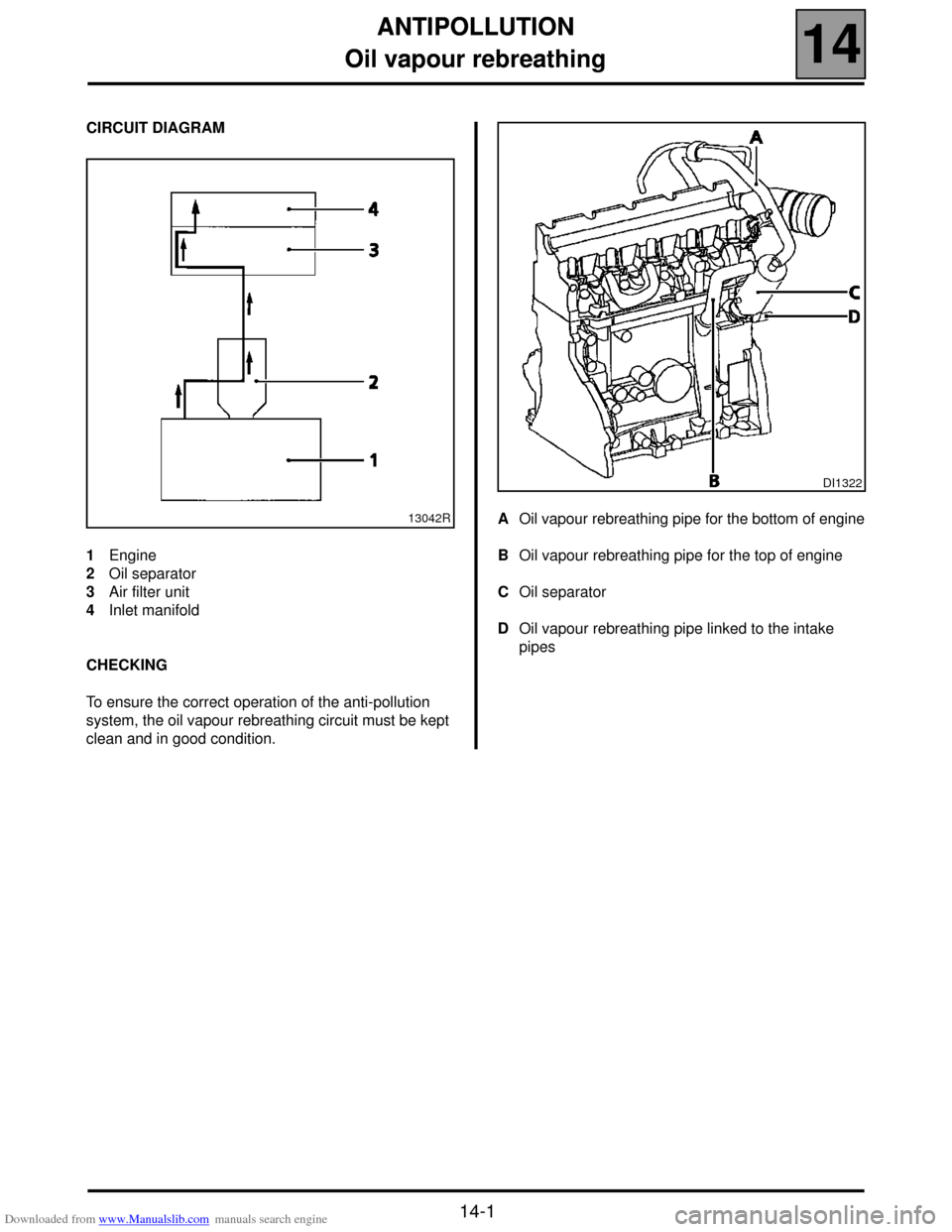

CIRCUIT DIAGRAM

1Engine

2Oil separator

3Air filter unit

4Inlet manifold

CHECKING

To ensure the correct operation of the anti-pollution

system, the oil vapour rebreathing circuit must be kept

clean and in good condition.AOil vapour rebreathing pipe for the bottom of engine

BOil vapour rebreathing pipe for the top of engine

COil separator

DOil vapour rebreathing pipe linked to the intake

pipes

13042R

DI1322

Page 96 of 118

Downloaded from www.Manualslib.com manuals search engine ANTIPOLLUTION

Exhaust gas recirculation

14

14-2

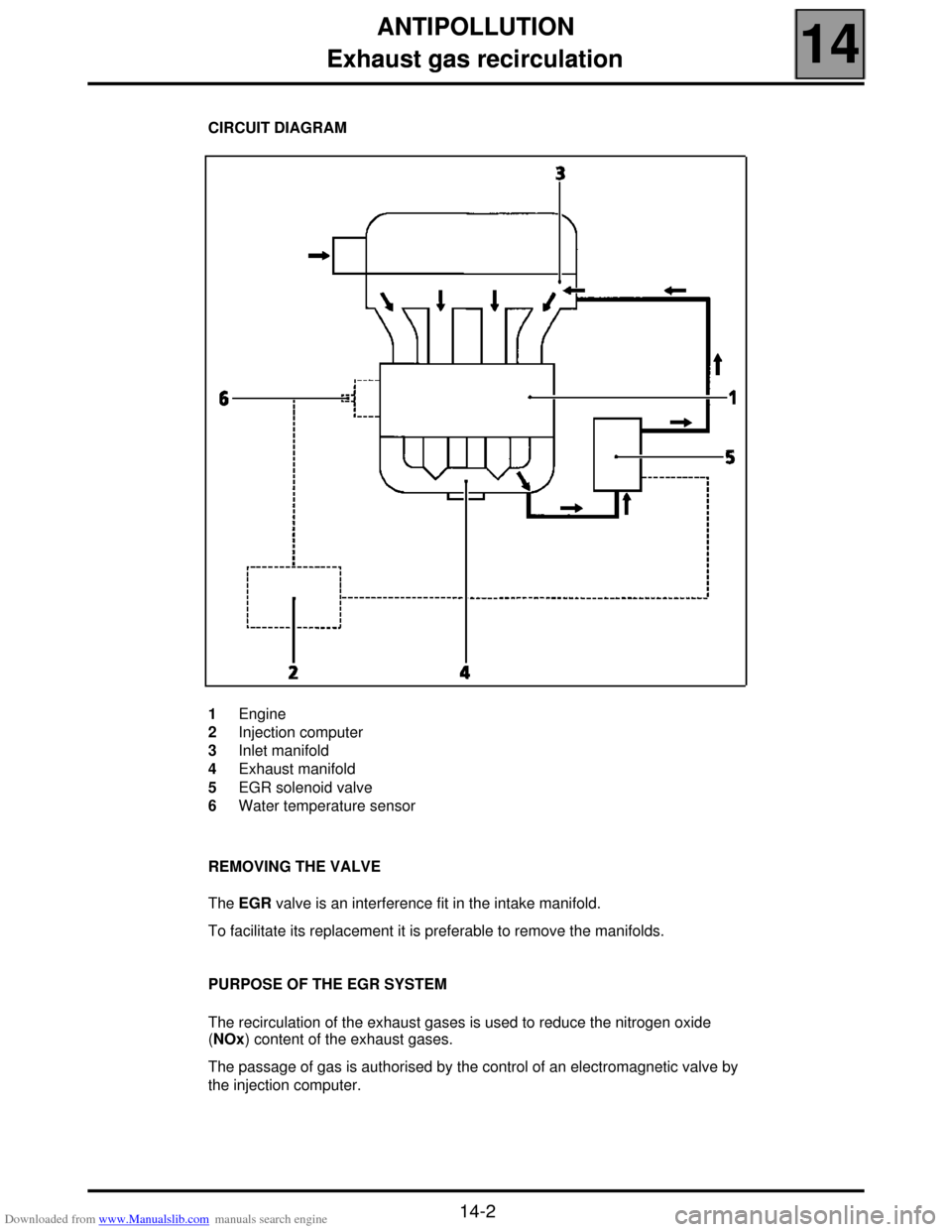

Exhaust gas recirculation

CIRCUIT DIAGRAM

1Engine

2Injection computer

3Inlet manifold

4Exhaust manifold

5EGR solenoid valve

6Water temperature sensor

REMOVING THE VALVE

The EGR valve is an interference fit in the intake manifold.

To facilitate its replacement it is preferable to remove the manifolds.

PURPOSE OF THE EGR SYSTEM

The recirculation of the exhaust gases is used to reduce the nitrogen oxide

(NOx) content of the exhaust gases.

The passage of gas is authorised by the control of an electromagnetic valve by

the injection computer.

Page 97 of 118

Downloaded from www.Manualslib.com manuals search engine ANTIPOLLUTION

Exhaust gas recirculation

14

14-3

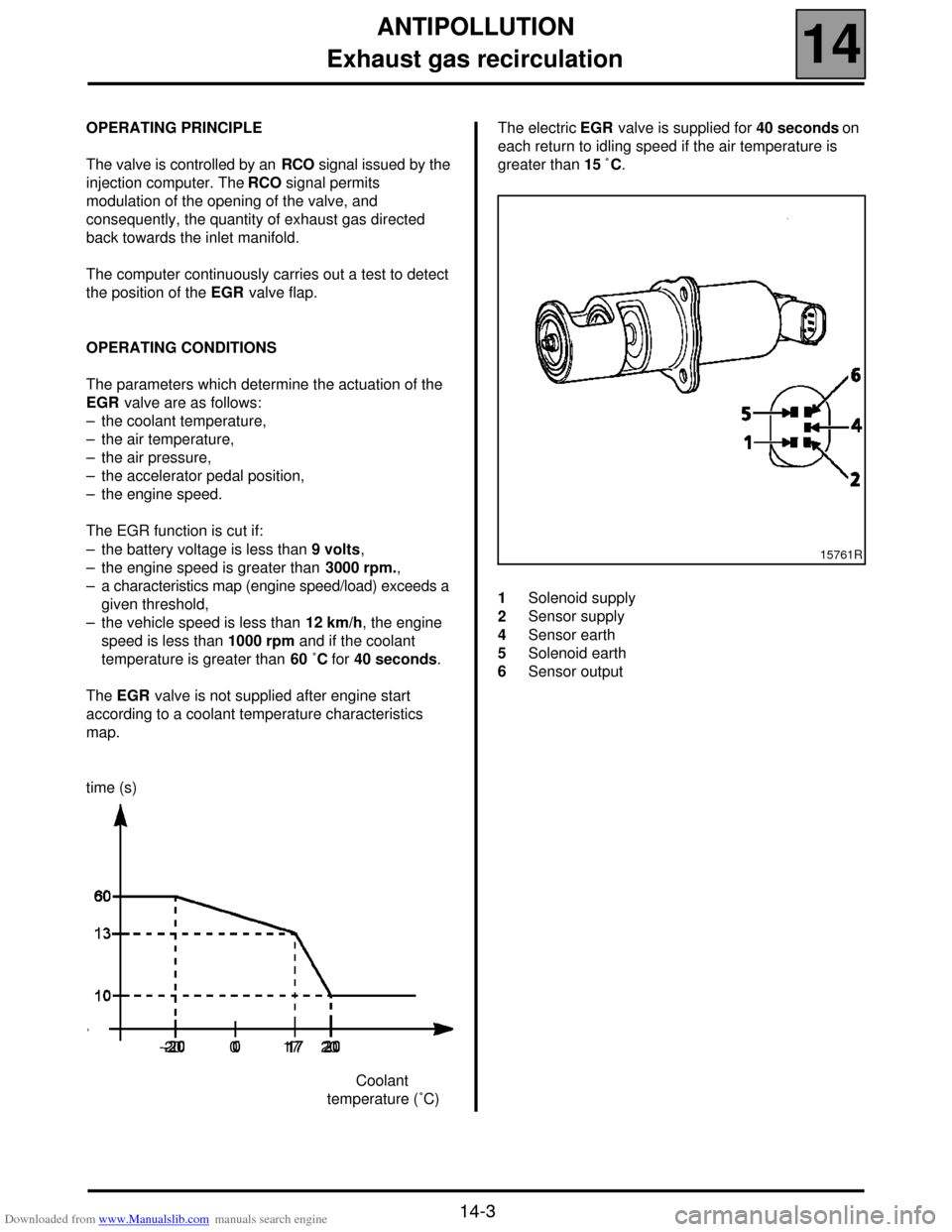

OPERATING PRINCIPLE

The valve is controlled by an RCO signal issued by the

injection computer. The RCO signal permits

modulation of the opening of the valve, and

consequently, the quantity of exhaust gas directed

back towards the inlet manifold.

The computer continuously carries out a test to detect

the position of the EGR valve flap.

OPERATING CONDITIONS

The parameters which determine the actuation of the

EGR valve are as follows:

– the coolant temperature,

– the air temperature,

– the air pressure,

– the accelerator pedal position,

– the engine speed.

The EGR function is cut if:

– the battery voltage is less than 9 volts,

– the engine speed is greater than 3000 rpm.,

– a characteristics map (engine speed/load) exceeds a

given threshold,

– the vehicle speed is less than 12 km/h, the engine

speed is less than 1000 rpm and if the coolant

temperature is greater than 60 ˚C for 40 seconds.

The EGR valve is not supplied after engine start

according to a coolant temperature characteristics

map.

time (s)The electric EGR valve is supplied for 40 seconds on

each return to idling speed if the air temperature is

greater than 15 ˚C.

Coolant

temperature (˚C)

15761R

1

2

4

5

6Solenoid supply

Sensor supply

Sensor earth

Solenoid earth

Sensor output

-20 0 17 20

Page 98 of 118

Downloaded from www.Manualslib.com manuals search engine STARTING - CHARGING

Alternator

16

116STARTING - CHARGING

Alternator

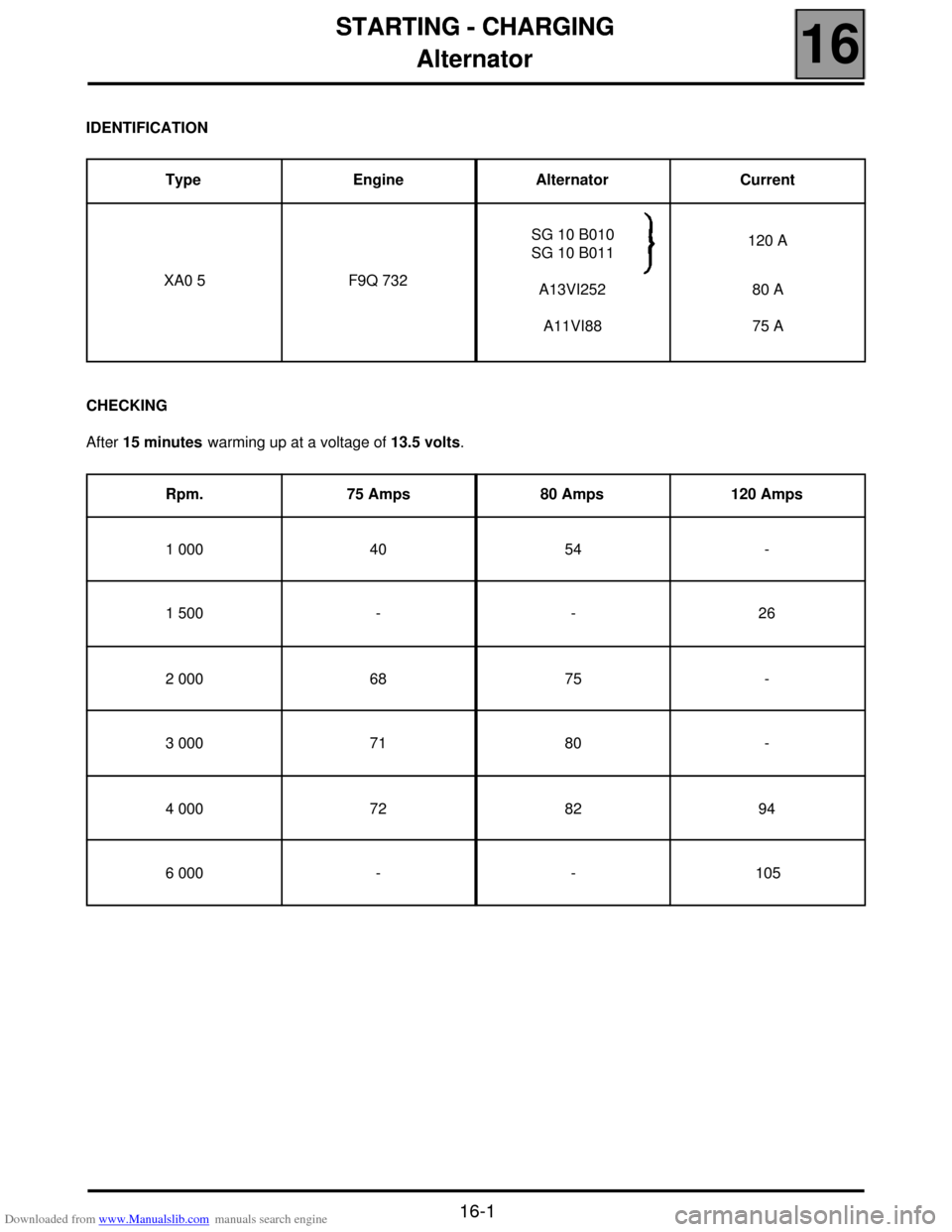

IDENTIFICATION

CHECKING

After 15 minutes warming up at a voltage of 13.5 volts. Type Engine Alternator Current

XA0 5 F9Q 732

SG 10 B010

SG 10 B011

A13VI252

A11VI88120 A

80 A

75 A

Rpm. 75 Amps 80 Amps 120 Amps

1 000 40 54 -

1 500 - - 26

2 000 68 75 -

3 000 71 80 -

4 000 72 82 94

6 000 - - 105

16-1

Page 99 of 118

Downloaded from www.Manualslib.com manuals search engine STARTING - CHARGING

Alternator

16

16-2

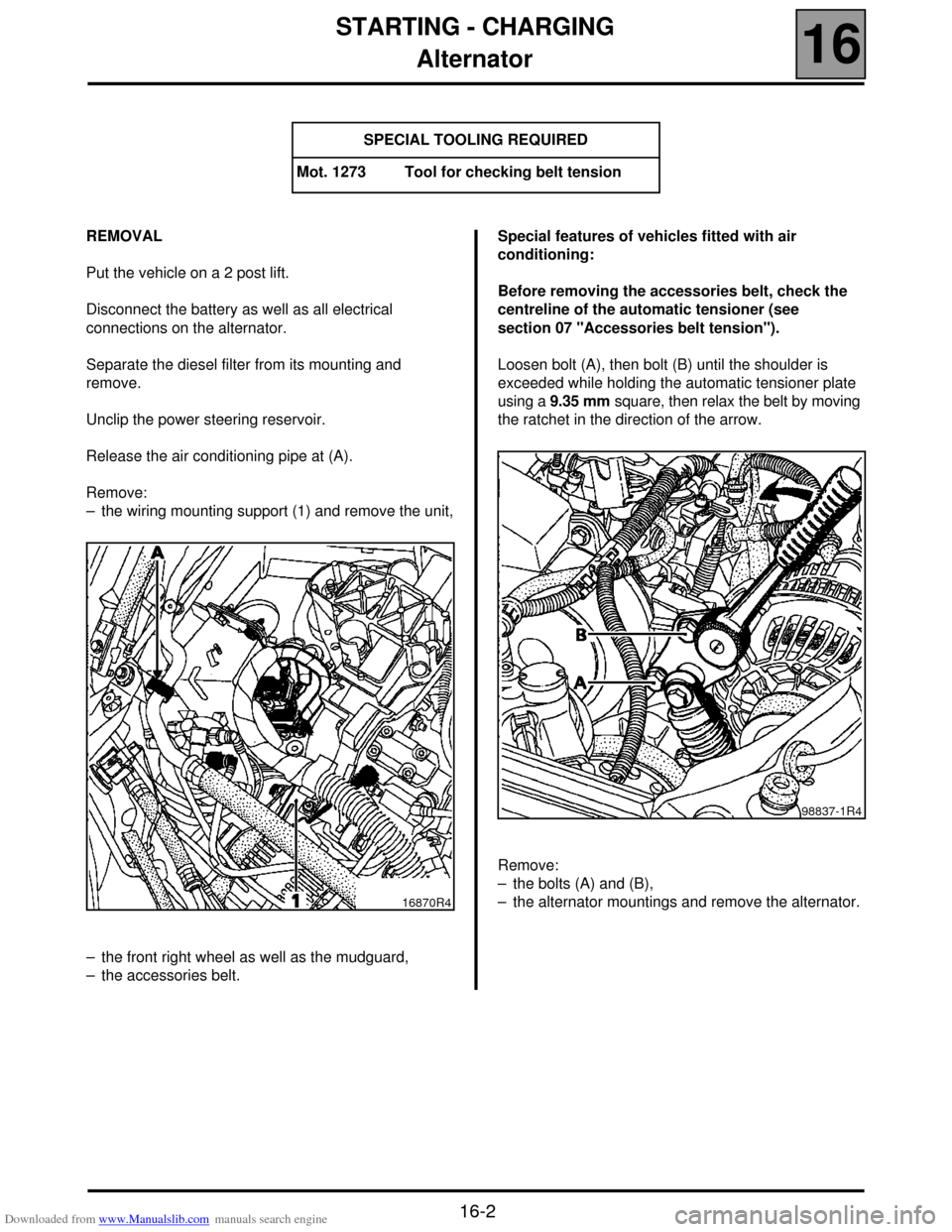

REMOVAL

Put the vehicle on a 2 post lift.

Disconnect the battery as well as all electrical

connections on the alternator.

Separate the diesel filter from its mounting and

remove.

Unclip the power steering reservoir.

Release the air conditioning pipe at (A).

Remove:

– the wiring mounting support (1) and remove the unit,

– the front right wheel as well as the mudguard,

– the accessories belt.Special features of vehicles fitted with air

conditioning:

Before removing the accessories belt, check the

centreline of the automatic tensioner (see

section 07 "Accessories belt tension").

Loosen bolt (A), then bolt (B) until the shoulder is

exceeded while holding the automatic tensioner plate

using a 9.35 mm square, then relax the belt by moving

the ratchet in the direction of the arrow.

Remove:

– the bolts (A) and (B),

– the alternator mountings and remove the alternator. SPECIAL TOOLING REQUIRED

Mot. 1273 Tool for checking belt tension

16870R4

98837-1R4

Page 100 of 118

Downloaded from www.Manualslib.com manuals search engine STARTING - CHARGING

Alternator

16

16-3

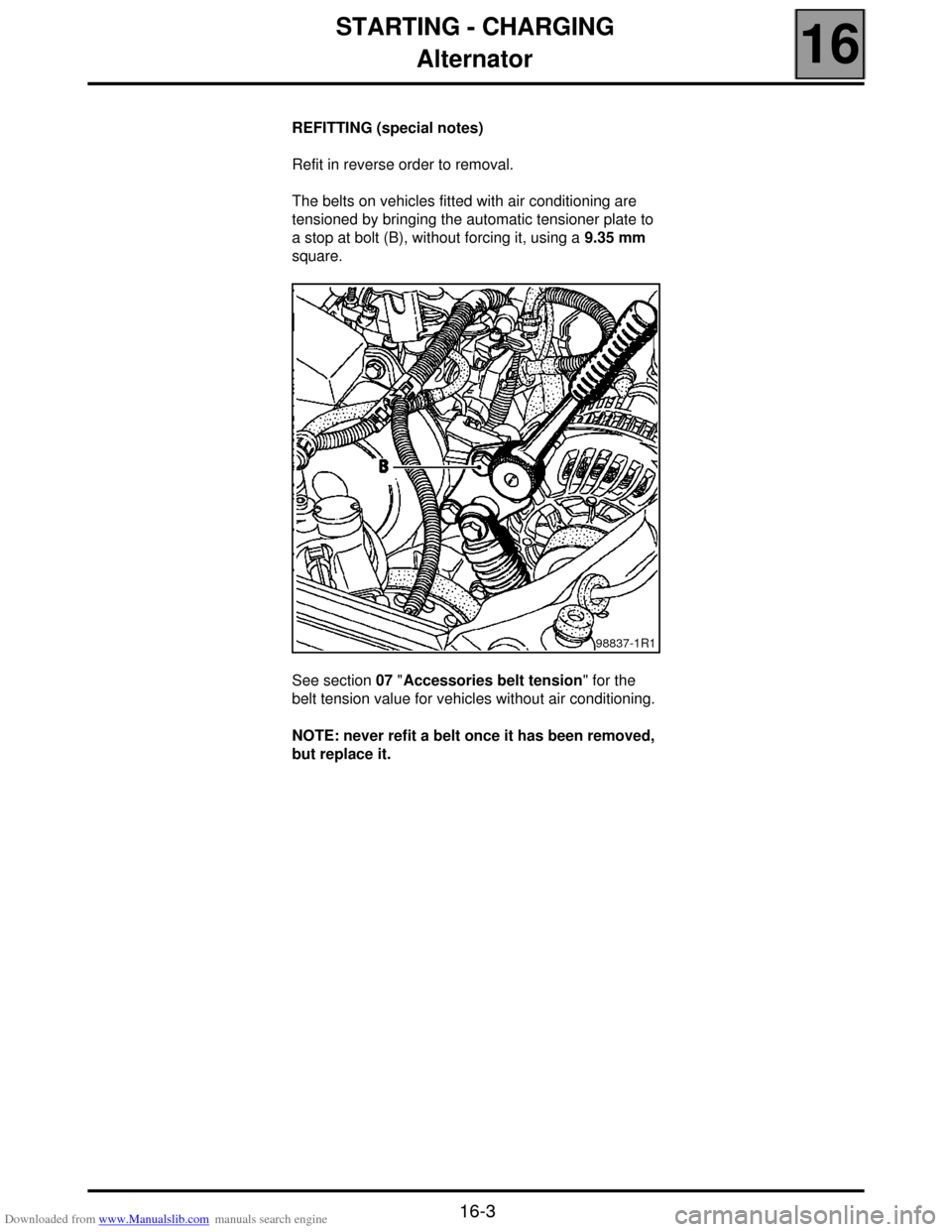

REFITTING (special notes)

Refit in reverse order to removal.

The belts on vehicles fitted with air conditioning are

tensioned by bringing the automatic tensioner plate to

a stop at bolt (B), without forcing it, using a 9.35 mm

square.

See section 07 "Accessories belt tension" for the

belt tension value for vehicles without air conditioning.

NOTE: never refit a belt once it has been removed,

but replace it.

98837-1R1