RENAULT SCENIC 2000 J64 / 1.G Technical Note 3426A Repair Manual

Manufacturer: RENAULT, Model Year: 2000, Model line: SCENIC, Model: RENAULT SCENIC 2000 J64 / 1.GPages: 118, PDF Size: 1.5 MB

Page 61 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Location of components

13

13-10

16192R

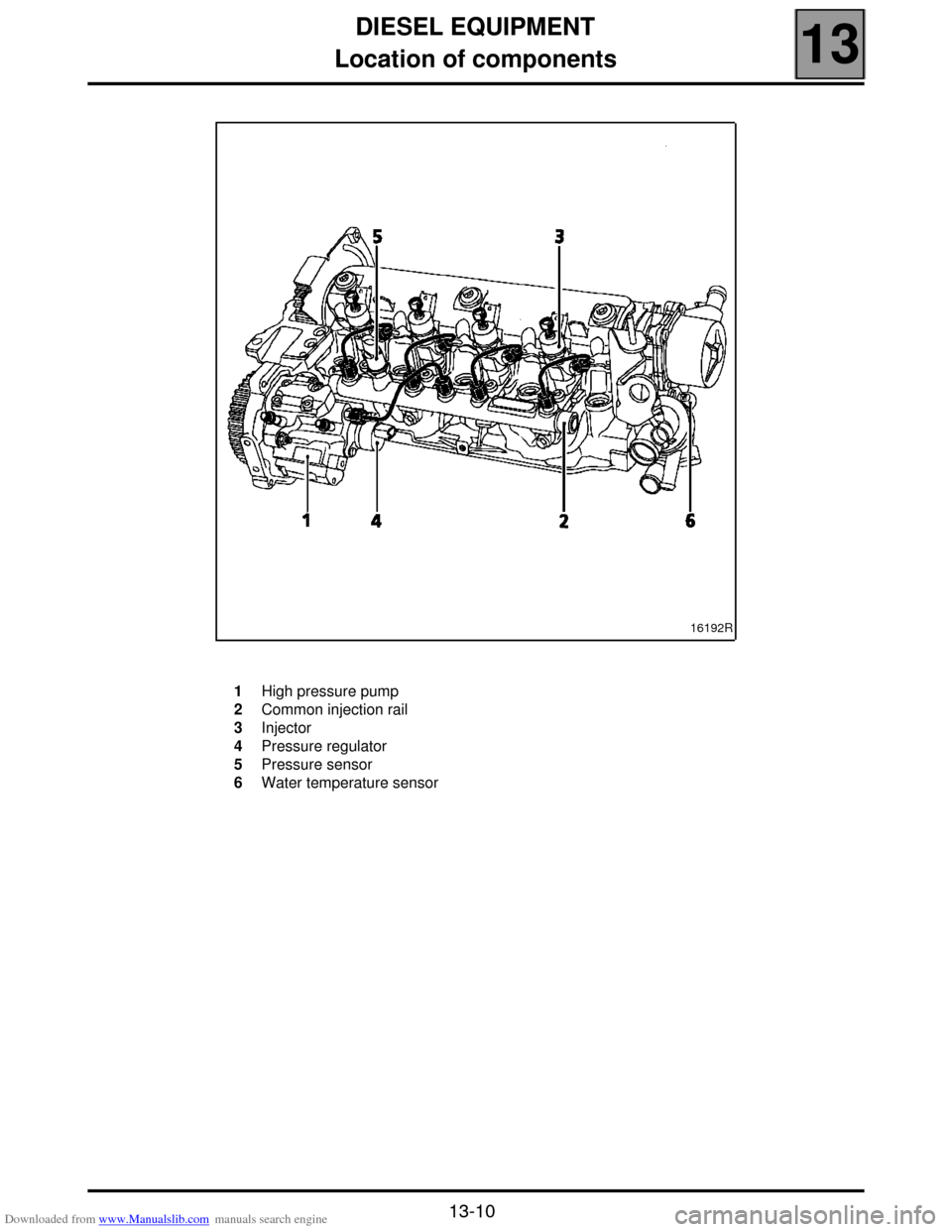

1

2

3

4

5

6High pressure pump

Common injection rail

Injector

Pressure regulator

Pressure sensor

Water temperature sensor

Page 62 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Location of components

13

13-11

16181R

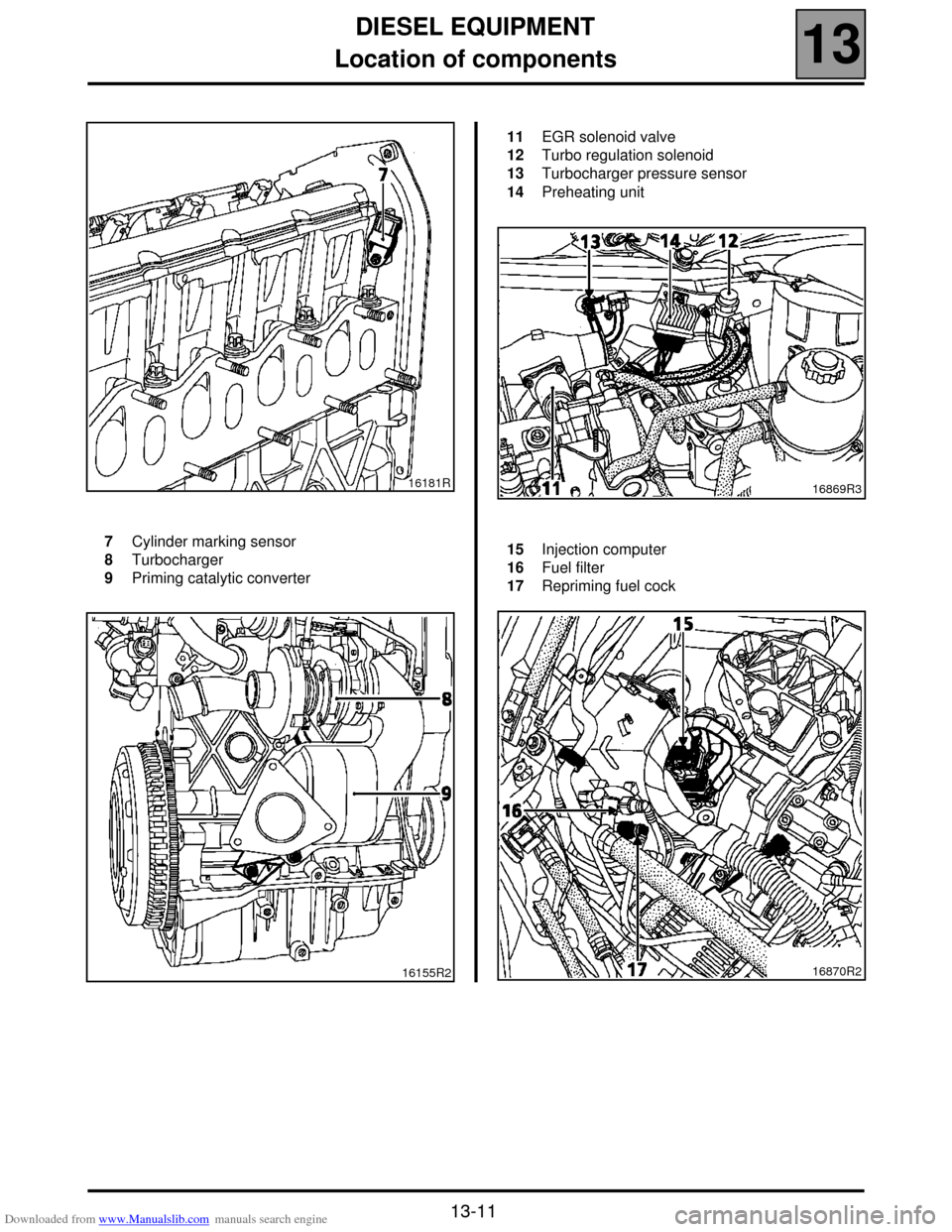

7

8

9Cylinder marking sensor

Turbocharger

Priming catalytic converter

16155R2

11

12

13

14EGR solenoid valve

Turbo regulation solenoid

Turbocharger pressure sensor

Preheating unit

16869R3

15

16

17Injection computer

Fuel filter

Repriming fuel cock

16870R2

Page 63 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Injection warning light

13

13-12

Injection warning light

Vehicles using the high pressure diesel system are fitted with two injection warning lights used during the preheating

phase and in case of an injection fault (or engine overheating).

WARNING LIGHT PRINCIPLE

!When ignition is switched on, the preheating light is lit during the preheating phase and then goes out (see section

13 "Pre-postheating control").

!When there is a fault on the injection system the "fault" warning light lights up. These faults are:

– internal computer fault,

– engine speed fault (the vehicle doesn't start),

– main relay or low pressure fault (the vehicle doesn't start),

– injector fault,

–TDC sensor coherence fault and camshaft sensor,

– rail pressure sensor fault,

– rail pressure regulator fault,

– accelerator potentiometer fault,

– engine immobiliser fault,

– computer supply voltage fault,

– engine overheating.

NOTE: the OBD warning light (symbolised by an engine), visible when the ignition is switched on, is never visible

when the engine is running.

Page 64 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Immobiliser function

13

13-13

Immobiliser function

This vehicle is fitted with an engine immobiliser controlled by a random rolling code key recognition system.

REPLACING AN INJECTION COMPUTER

The injection computers are supplied without a code but they must all be programmed with one.

When the computer is replaced, the vehicle code must be programmed in and then a check must be made to ensure

that the immobiliser system is operational.

To do this, simply switch on the ignition for a few seconds without starting the engine then switch it of f. When the

ignition is off, the engine immobiliser function will be activated after approximately 10 seconds (red engine

immobiliser warning light flashes).

IMPORTANT:

With this engine immobiliser, the computer keeps its immobiliser code for life.

In addition, this system does not have a security code.

Consequently, it is forbidden to perform tests with computers borrowed from the stores or from another

vehicle which must then be returned.

It will no longer be possible to decode them.

Page 65 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Injection/air conditioning programming

13

13-14

Injection/air conditioning programming

INJECTION COMPUTER/AC COMPUTER CONNECTION

The compressor is of the variable cubic capacity type.

The injection calculator and the air conditioning calculator are linked by two leads:

– The power absorbed information tells the injection computer the output absorbed by the compressor. It is possible

to see the output absorbed using the diagnostic tool. When air conditioning is engaged the reading should be

between 250 and 5000 Watts.

– The connection from the injection computer to the air conditioning computer. This lead carries information on

whether starting the compressor is authorized or forbidden.

When the air conditioning function is selected, idling speed is modified to reach a maximum of 875 rpm.

IMPORTANT: the absorbed output is never equal to 0, whatever the status of the compressor, engaged or not. The

minimum value read is approximately 250 Watts.

Page 66 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Injection/air conditioning programming

13

13-15

COMPRESSOR OPERATION PROGRAMMING

During certain stages of operation, the diesel injection computer stops the compressor from functioning.

Engine start programming

The compressor is prevented from operating for 5 seconds after the engine has started.

Recovery of performance

When the position of the accelerator pedal is changed significantly and if the engine speed is less than 3000 rpm,

the compressor is prevented from operation for 5 seconds.

Recovery of output when the vehicle starts moving

If the position of the potentiometer is more than 50 % the engine speed is less than 2250 rpm and the vehicle speed

is below 20 km/h, the compressor is cut for 5 seconds.

Anti-stall protection

If the no load position is not detected, and the engine speed is less than 675 rpm. the compressor is disengaged. It

is engaged again after 5 seconds if the engine speed is increased.

Thermal protection programming

The compressor does not engage in cases where the coolant temperature is greater than + 112 °C.

Page 67 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Idle speed correction

13

13-16

Idle speed correction

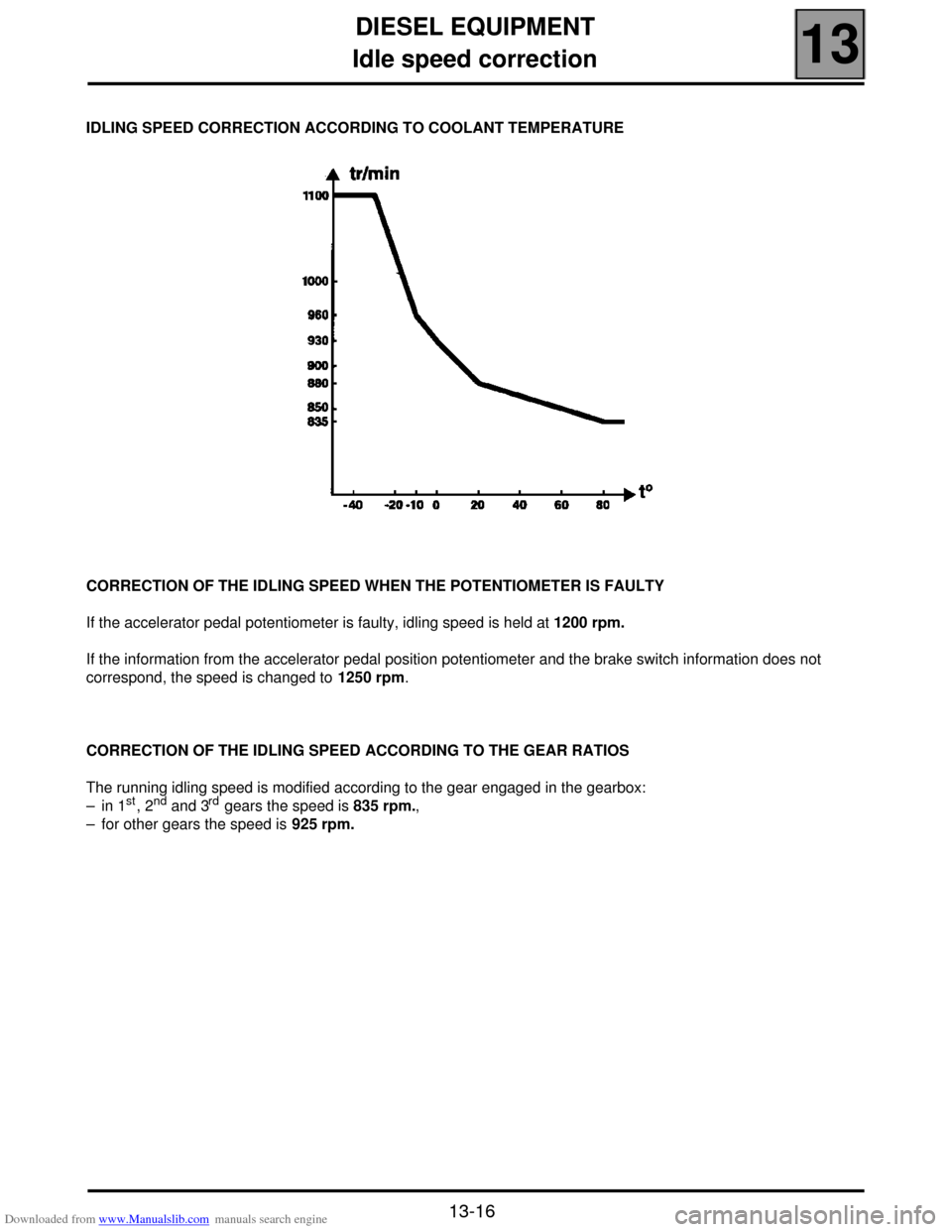

IDLING SPEED CORRECTION ACCORDING TO COOLANT TEMPERATURE

CORRECTION OF THE IDLING SPEED WHEN THE POTENTIOMETER IS FAULTY

If the accelerator pedal potentiometer is faulty, idling speed is held at 1200 rpm.

If the information from the accelerator pedal position potentiometer and the brake switch information does not

correspond, the speed is changed to 1250 rpm.

CORRECTION OF THE IDLING SPEED ACCORDING TO THE GEAR RATIOS

The running idling speed is modified according to the gear engaged in the gearbox:

– in 1

st, 2nd and 3rd gears the speed is 835 rpm.,

– for other gears the speed is 925 rpm.

Page 68 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Pre-postheating control

13

13-17

Pre-postheating control

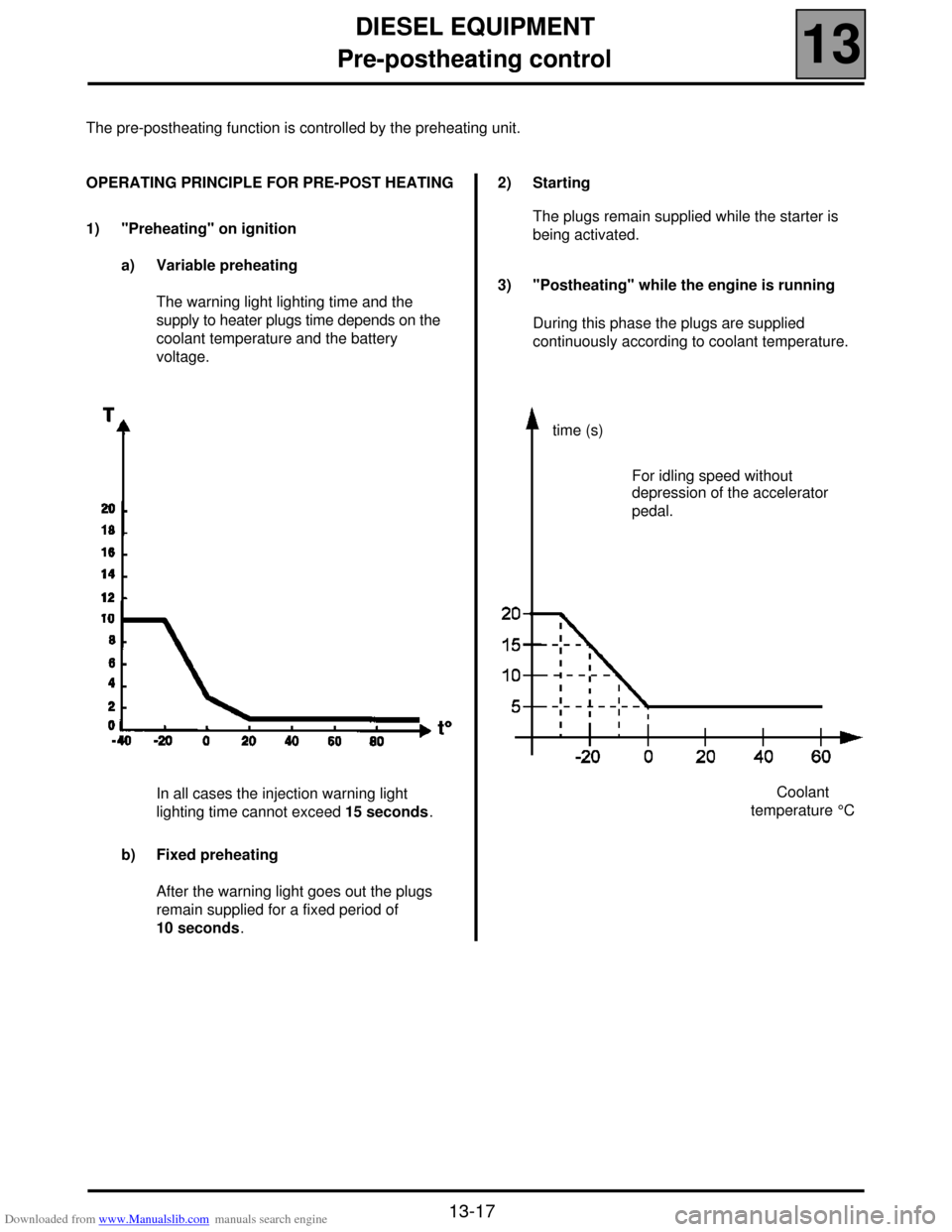

The pre-postheating function is controlled by the preheating unit.

OPERATING PRINCIPLE FOR PRE-POST HEATING

1) "Preheating" on ignition

a) Variable preheating

The warning light lighting time and the

supply to heater plugs time depends on the

coolant temperature and the battery

voltage.

In all cases the injection warning light

lighting time cannot exceed 15 seconds.

b) Fixed preheating

After the warning light goes out the plugs

remain supplied for a fixed period of

10 seconds.2) Starting

The plugs remain supplied while the starter is

being activated.

3) "Postheating" while the engine is running

During this phase the plugs are supplied

continuously according to coolant temperature.

time (s)

Coolant

temperature °C For idling speed without

depression of the accelerator

pedal.

Page 69 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Heater plugs

13

13-18

Heater plugs

The resistance of a heater plug is 0.6 Ω.

Plugs may be removed without having to open the

high pressure circuit.

REMOVAL

Unclip the plug connector.

Clean the plug exterior to avoid any dirt entering the

cylinder.

Undo and then remove the plugs.

To undo the plug on cylinder 4 use a 10 mm long radio

socket attached to a universal joint. Once the plug is

loosened use a pipe socket to unscrew it completely.

REFITTING

Proceed in the reverse order to removal.TIGHTENING TORQUES (in daN.m)

Heater plug 1.5

15762S

Page 70 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Thermal plunger

13

13-19

Thermal plunger

The three thermal plungers are located on a water unit

fixed under the manifold at the engine - gearbox joint.

The objective of the system is to reheat the coolant.

The thermal plungers are supplied with 12 volts by

two relays. One relay controls two thermal plungers,

and the other relay controls one thermal plunger. This

enables control of one, two or three thermal plungers

as required.

The resistance of the thermal plungers is:

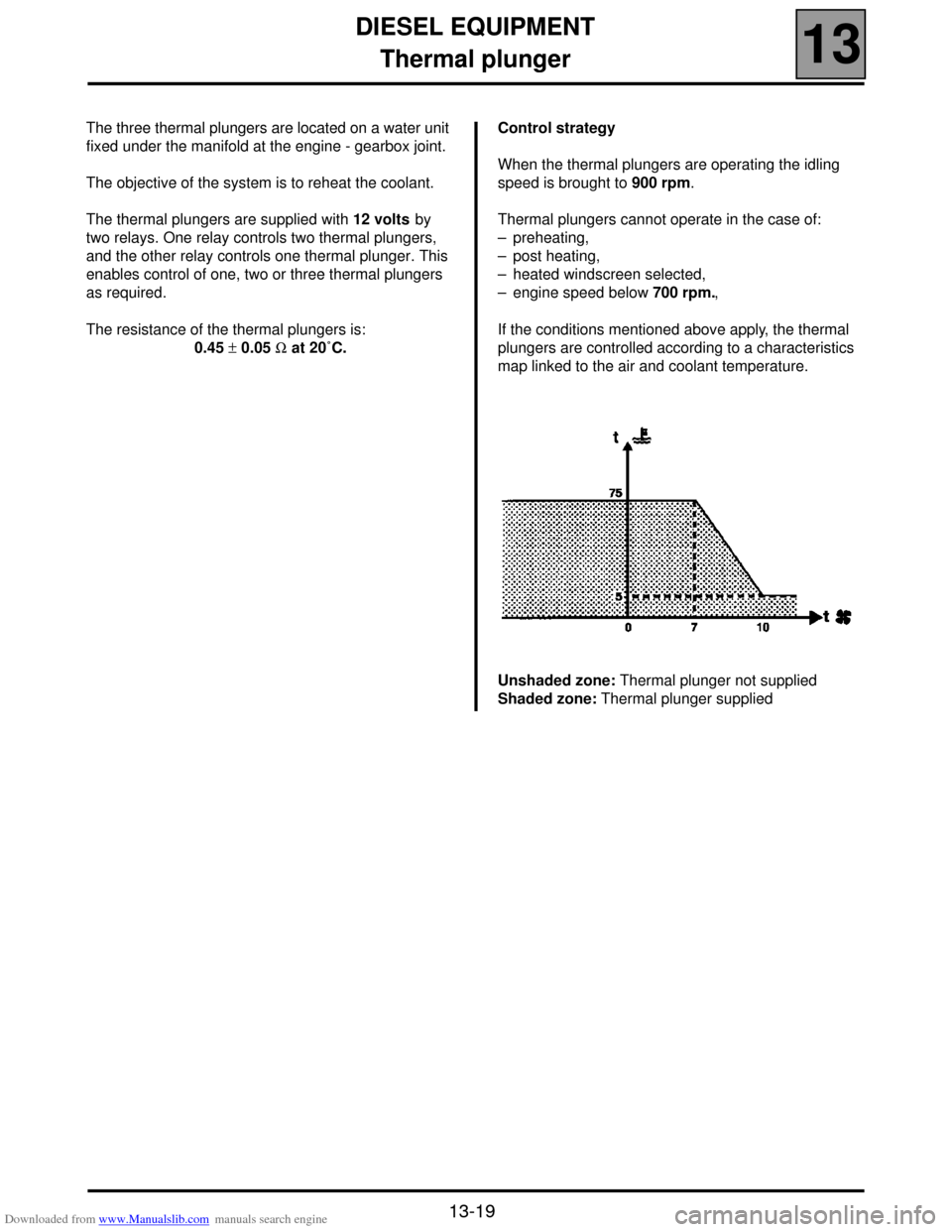

0.45 ± 0.05 Ω at 20˚C. Control strategy

When the thermal plungers are operating the idling

speed is brought to 900 rpm.

Thermal plungers cannot operate in the case of:

– preheating,

– post heating,

– heated windscreen selected,

– engine speed below 700 rpm.,

If the conditions mentioned above apply, the thermal

plungers are controlled according to a characteristics

map linked to the air and coolant temperature.

Unshaded zone: Thermal plunger not supplied

Shaded zone: Thermal plunger supplied