RENAULT SCENIC 2000 J64 / 1.G Technical Note 3426A Owner's Manual

Manufacturer: RENAULT, Model Year: 2000, Model line: SCENIC, Model: RENAULT SCENIC 2000 J64 / 1.GPages: 118, PDF Size: 1.5 MB

Page 21 of 118

Downloaded from www.Manualslib.com manuals search engine ENGINE AND PERIPHERALS

Engine and transmission assembly

10

10-5

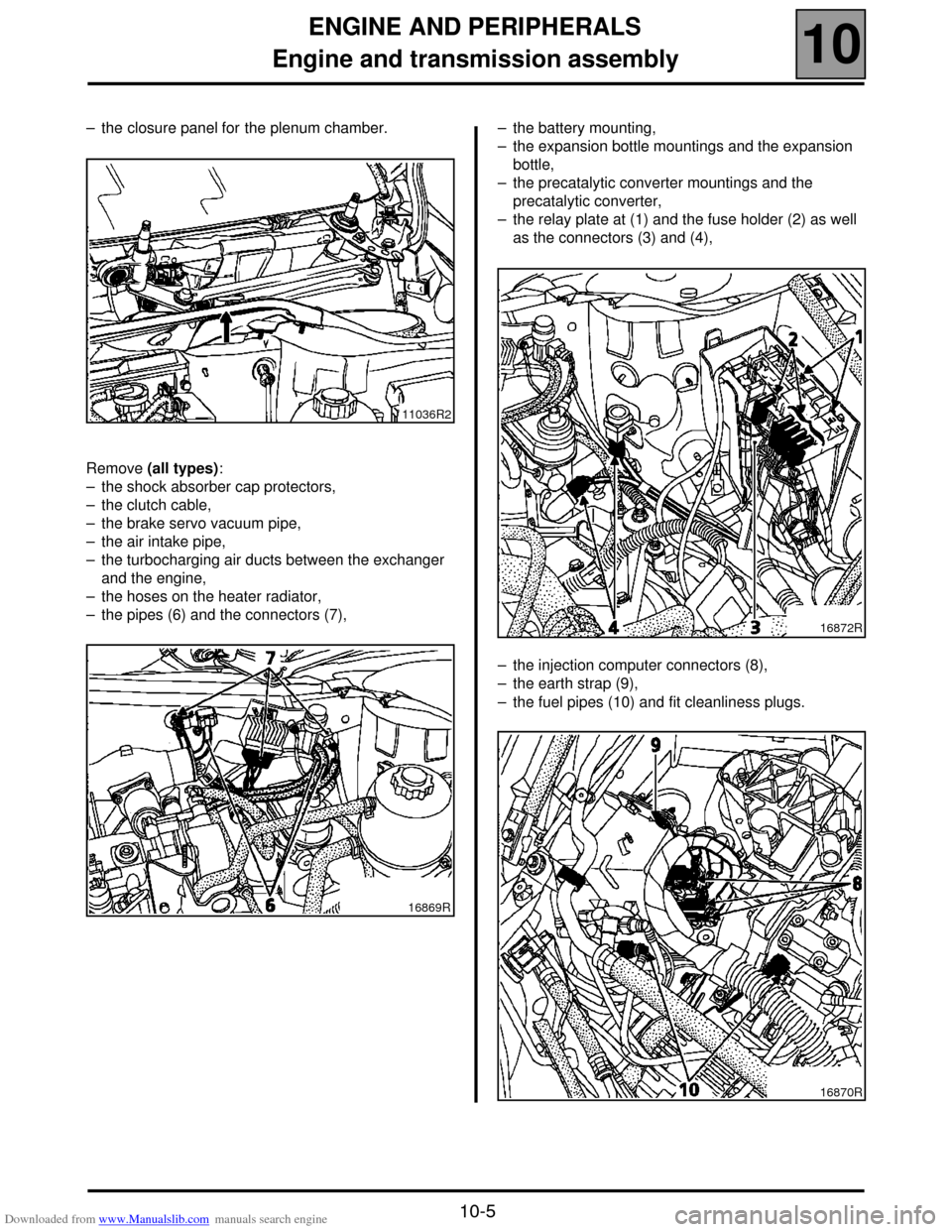

– the closure panel for the plenum chamber.

Remove (all types):

– the shock absorber cap protectors,

– the clutch cable,

– the brake servo vacuum pipe,

– the air intake pipe,

– the turbocharging air ducts between the exchanger

and the engine,

– the hoses on the heater radiator,

– the pipes (6) and the connectors (7),– the battery mounting,

– the expansion bottle mountings and the expansion

bottle,

– the precatalytic converter mountings and the

precatalytic converter,

– the relay plate at (1) and the fuse holder (2) as well

as the connectors (3) and (4),

– the injection computer connectors (8),

– the earth strap (9),

– the fuel pipes (10) and fit cleanliness plugs.

11036R2

16869R

16872R

16870R

Page 22 of 118

Downloaded from www.Manualslib.com manuals search engine ENGINE AND PERIPHERALS

Engine and transmission assembly

10

10-6

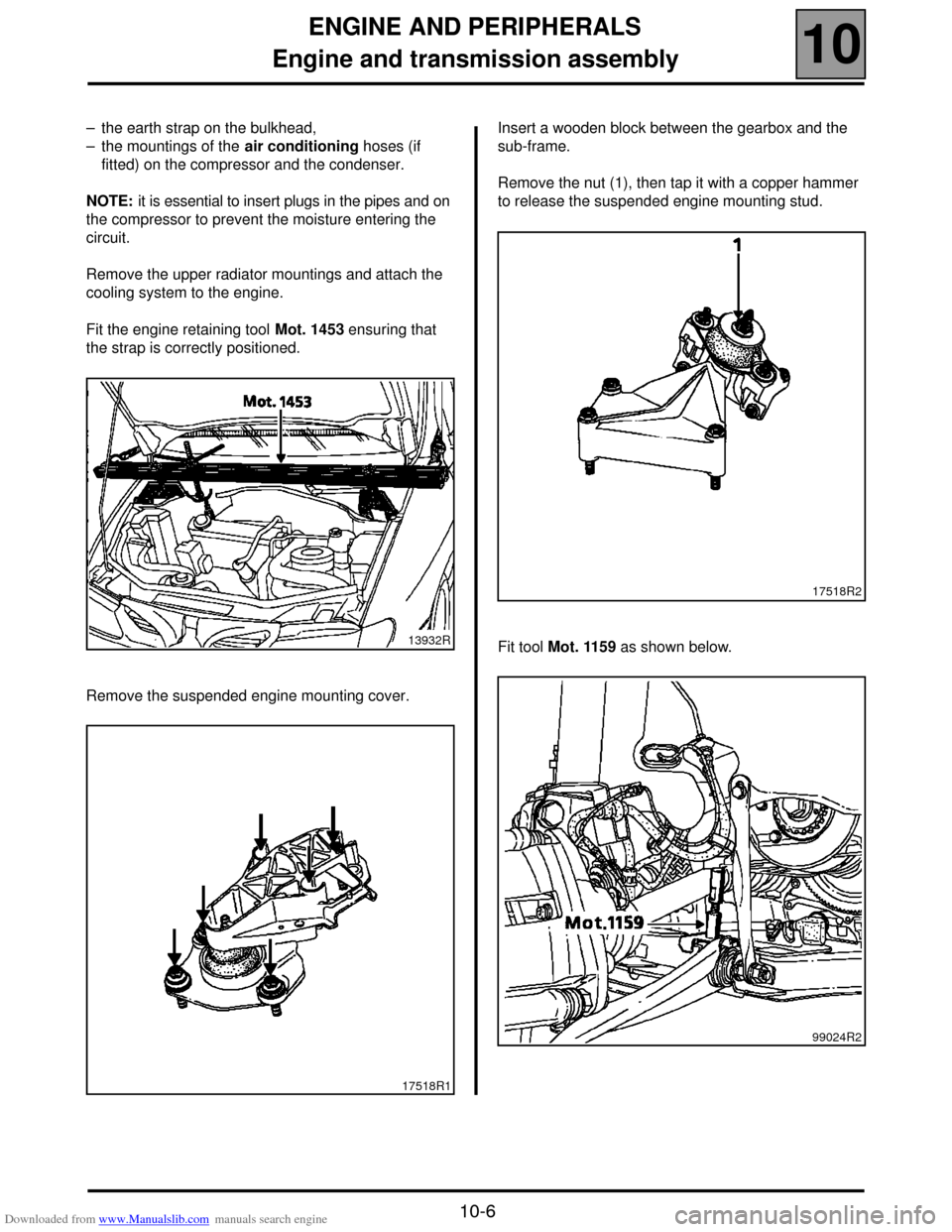

– the earth strap on the bulkhead,

– the mountings of the air conditioning hoses (if

fitted) on the compressor and the condenser.

NOTE: it is essential to insert plugs in the pipes and on

the compressor to prevent the moisture entering the

circuit.

Remove the upper radiator mountings and attach the

cooling system to the engine.

Fit the engine retaining tool Mot. 1453 ensuring that

the strap is correctly positioned.

Remove the suspended engine mounting cover.Insert a wooden block between the gearbox and the

sub-frame.

Remove the nut (1), then tap it with a copper hammer

to release the suspended engine mounting stud.

Fit tool Mot. 1159 as shown below.

13932R

17518R1

17518R2

99024R2

Page 23 of 118

Downloaded from www.Manualslib.com manuals search engine ENGINE AND PERIPHERALS

Engine and transmission assembly

10

10-7

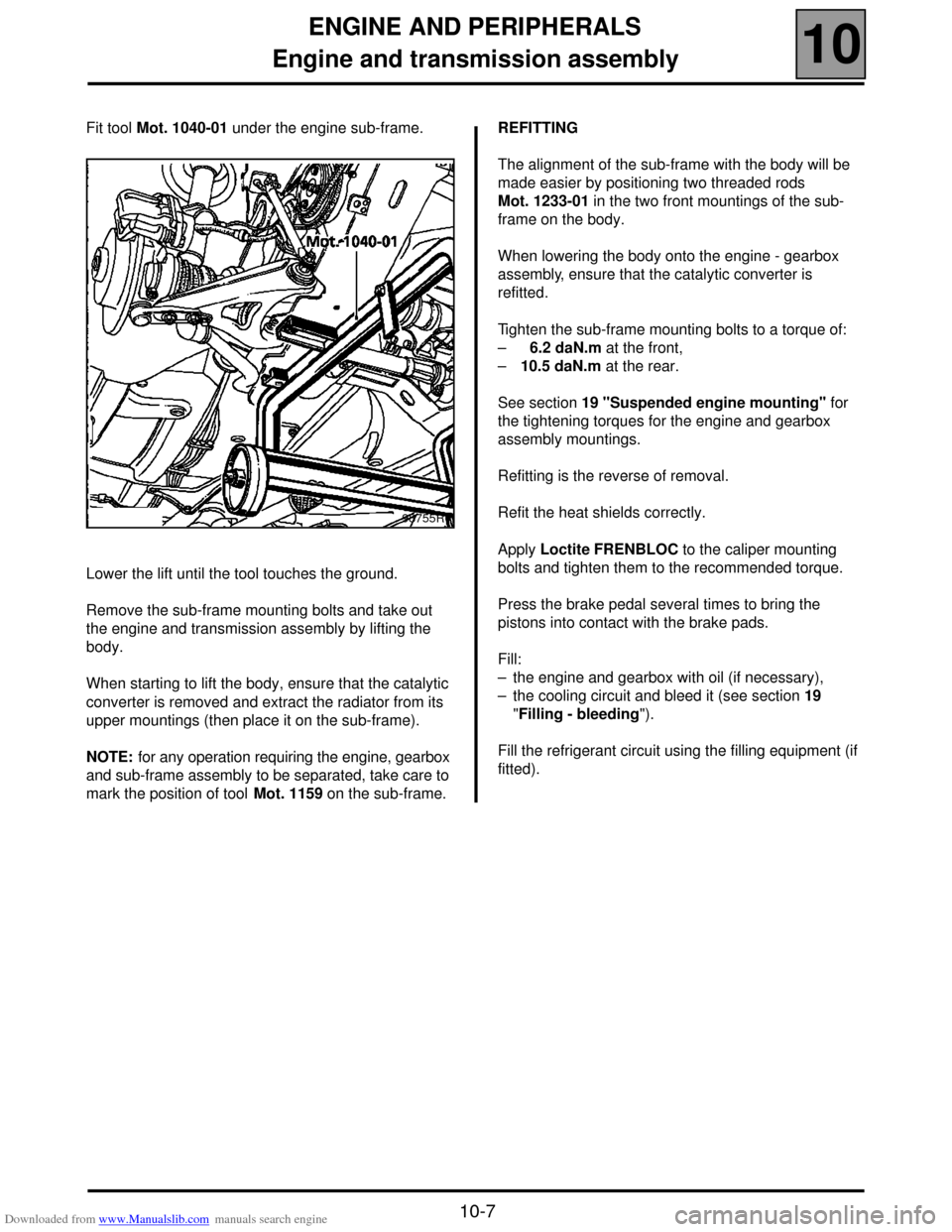

Fit tool Mot. 1040-01 under the engine sub-frame.

Lower the lift until the tool touches the ground.

Remove the sub-frame mounting bolts and take out

the engine and transmission assembly by lifting the

body.

When starting to lift the body, ensure that the catalytic

converter is removed and extract the radiator from its

upper mountings (then place it on the sub-frame).

NOTE: for any operation requiring the engine, gearbox

and sub-frame assembly to be separated, take care to

mark the position of tool Mot. 1159 on the sub-frame.REFITTING

The alignment of the sub-frame with the body will be

made easier by positioning two threaded rods

Mot. 1233-01 in the two front mountings of the sub-

frame on the body.

When lowering the body onto the engine - gearbox

assembly, ensure that the catalytic converter is

refitted.

Tighten the sub-frame mounting bolts to a torque of:

– 6.2 daN.m at the front,

–10.5 daN.m at the rear.

See section 19 "Suspended engine mounting" for

the tightening torques for the engine and gearbox

assembly mountings.

Refitting is the reverse of removal.

Refit the heat shields correctly.

Apply Loctite FRENBLOC to the caliper mounting

bolts and tighten them to the recommended torque.

Press the brake pedal several times to bring the

pistons into contact with the brake pads.

Fill:

– the engine and gearbox with oil (if necessary),

– the cooling circuit and bleed it (see section 19

"Filling - bleeding").

Fill the refrigerant circuit using the filling equipment (if

fitted).

98755R1

Page 24 of 118

Downloaded from www.Manualslib.com manuals search engine ENGINE AND PERIPHERALS

Sump

10

10-8

Sump

SPECIAL TOOLING REQUIRED

Mot. 1233-01 Threaded rods for lowering the

sub-frame

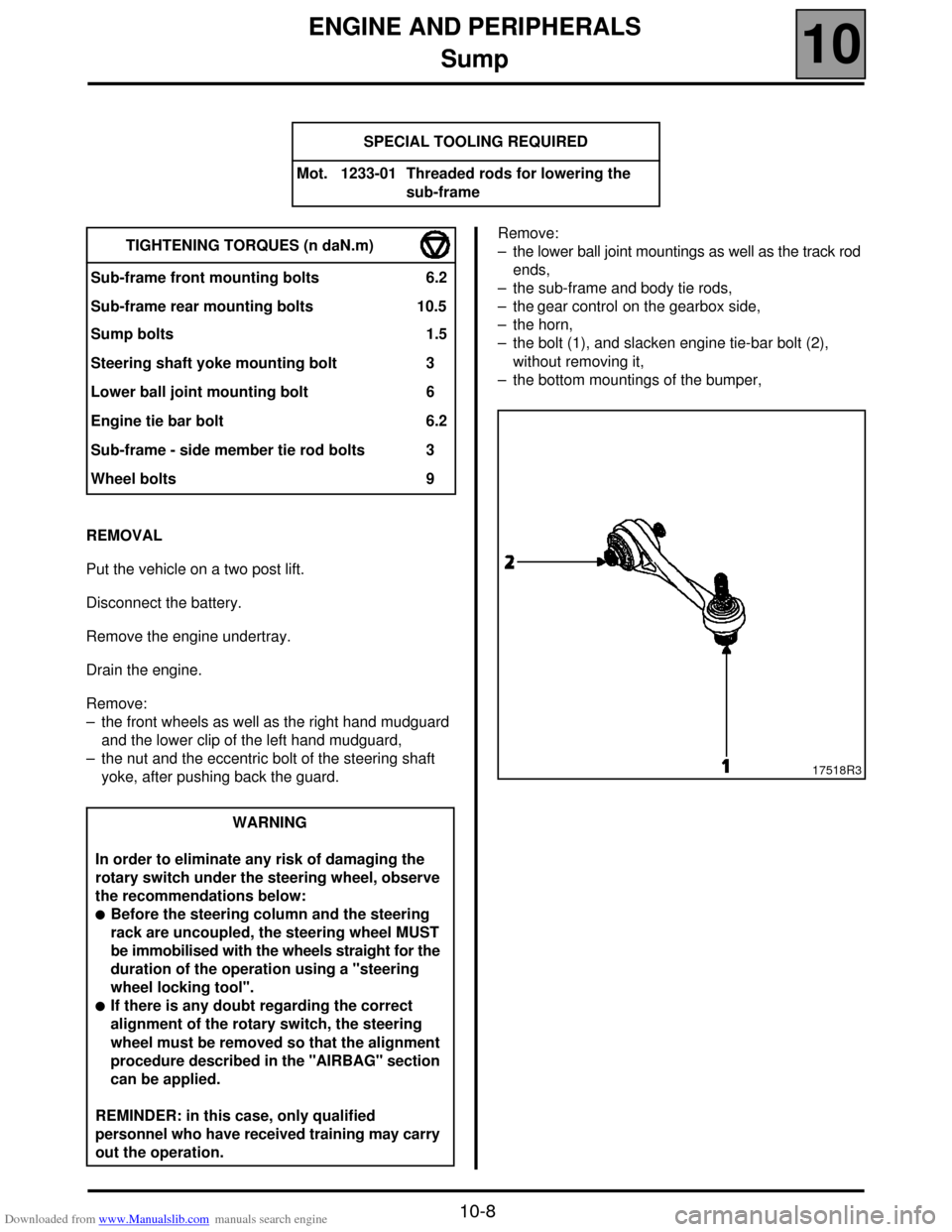

REMOVAL

Put the vehicle on a two post lift.

Disconnect the battery.

Remove the engine undertray.

Drain the engine.

Remove:

– the front wheels as well as the right hand mudguard

and the lower clip of the left hand mudguard,

– the nut and the eccentric bolt of the steering shaft

yoke, after pushing back the guard.Remove:

– the lower ball joint mountings as well as the track rod

ends,

– the sub-frame and body tie rods,

– the gear control on the gearbox side,

– the horn,

– the bolt (1), and slacken engine tie-bar bolt (2),

without removing it,

– the bottom mountings of the bumper, TIGHTENING TORQUES (n daN.m)

Sub-frame front mounting bolts 6.2

Sub-frame rear mounting bolts 10.5

Sump bolts 1.5

Steering shaft yoke mounting bolt 3

Lower ball joint mounting bolt 6

Engine tie bar bolt 6.2

Sub-frame - side member tie rod bolts 3

Wheel bolts 9

WARNING

In order to eliminate any risk of damaging the

rotary switch under the steering wheel, observe

the recommendations below:

!Before the steering column and the steering

rack are uncoupled, the steering wheel MUST

be immobilised with the wheels straight for the

duration of the operation using a "steering

wheel locking tool".

!If there is any doubt regarding the correct

alignment of the rotary switch, the steering

wheel must be removed so that the alignment

procedure described in the "AIRBAG" section

can be applied.

REMINDER: in this case, only qualified

personnel who have received training may carry

out the operation.

17518R3

Page 25 of 118

Downloaded from www.Manualslib.com manuals search engine ENGINE AND PERIPHERALS

Sump

10

10-9

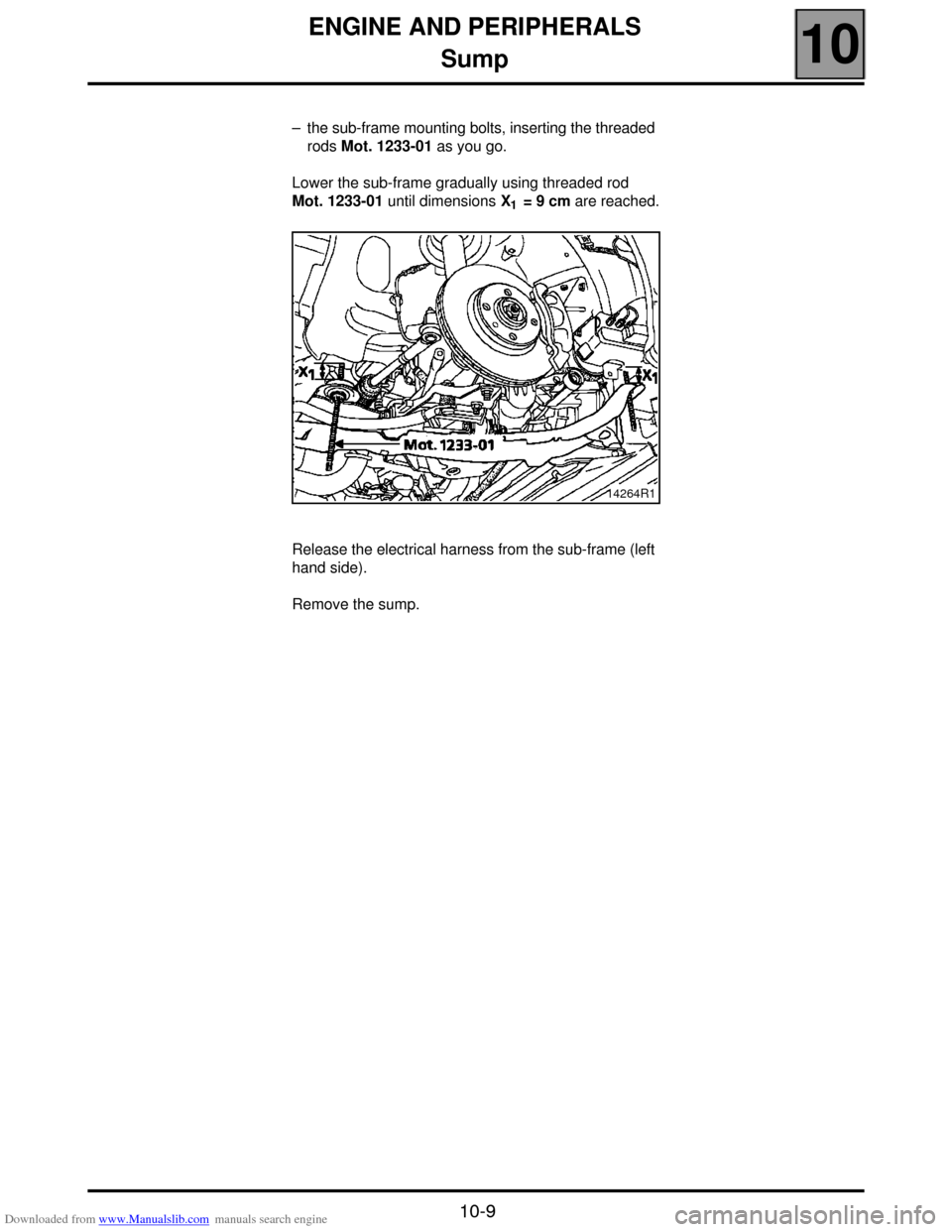

– the sub-frame mounting bolts, inserting the threaded

rods Mot. 1233-01 as you go.

Lower the sub-frame gradually using threaded rod

Mot. 1233-01 until dimensions X = 9 cm are reached.

Release the electrical harness from the sub-frame (left

hand side).

Remove the sump.

14264R1

1

Page 26 of 118

Downloaded from www.Manualslib.com manuals search engine ENGINE AND PERIPHERALS

Sump

10

10-10

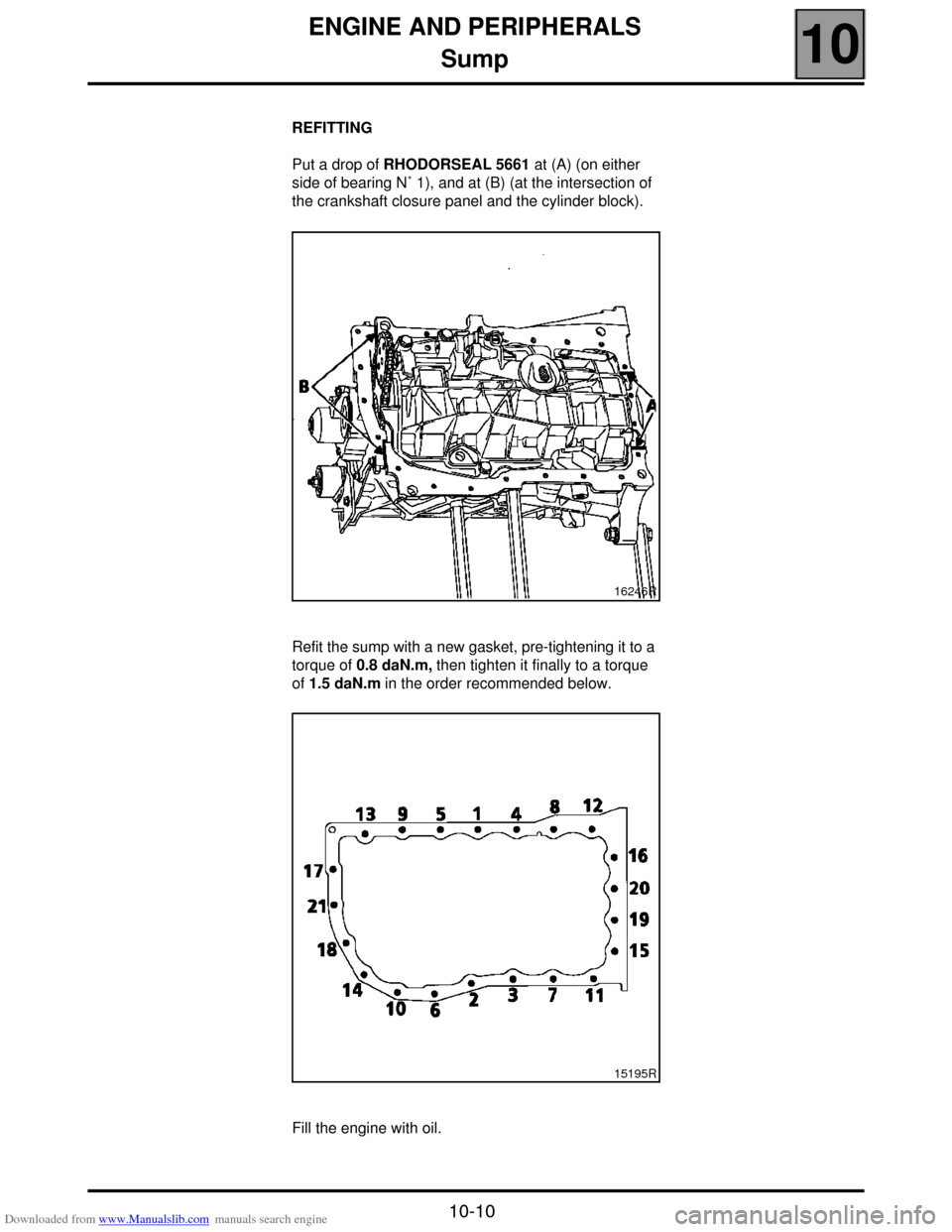

REFITTING

Put a drop of RHODORSEAL 5661 at (A) (on either

side of bearing N˚ 1), and at (B) (at the intersection of

the crankshaft closure panel and the cylinder block).

Refit the sump with a new gasket, pre-tightening it to a

torque of 0.8 daN.m, then tighten it finally to a torque

of 1.5 daN.m in the order recommended below.

Fill the engine with oil.

16246R

15195R

Page 27 of 118

Downloaded from www.Manualslib.com manuals search engine TOP AND FRONT OF ENGINE

Timing belt

11

11 - 1

111TOP AND FRONT OF ENGINE

Timing belt

SPECIAL TOOLING REQUIRED

Mot. 1054 TDC setting pin

Mot. 1387 Tool for checking the automatic

tensioner centreline

Mot. 1453 Engine support tool

Mot. 1505 Tool for measuring belt tension

Mot. 1543 Timing belt pretensioning torque

tool

Mot. 1294-01 Tool for removing windscreen

wiper arms

ESSENTIAL SPECIAL TOOLING

14 torx socket

REMOVAL

Put the vehicle on a 2 post lift.

Disconnect the battery.

Remove (for the SCENIC):

– the windscreen wiper arms,

– the front grilles,– the closure panel of the plenum chamber.

Remove (all types):

– the engine cover,

– the front right wheel as well as the mudguard,

– the accessories belt,

– the crankshaft accessories pulley. TIGHTENING TORQUES (in daN.m and/or ˚)

Tension roller nut 5

Crankshaft pulley bolt 2 + 115˚ ± 15˚

Suspended mounting limiter bolt 6.2

Suspended mounting cover bolt 6.2

Wheel bolts 9

11020R

11036R2

Page 28 of 118

Downloaded from www.Manualslib.com manuals search engine TOP AND FRONT OF ENGINE

Timing belt

11

11 - 2

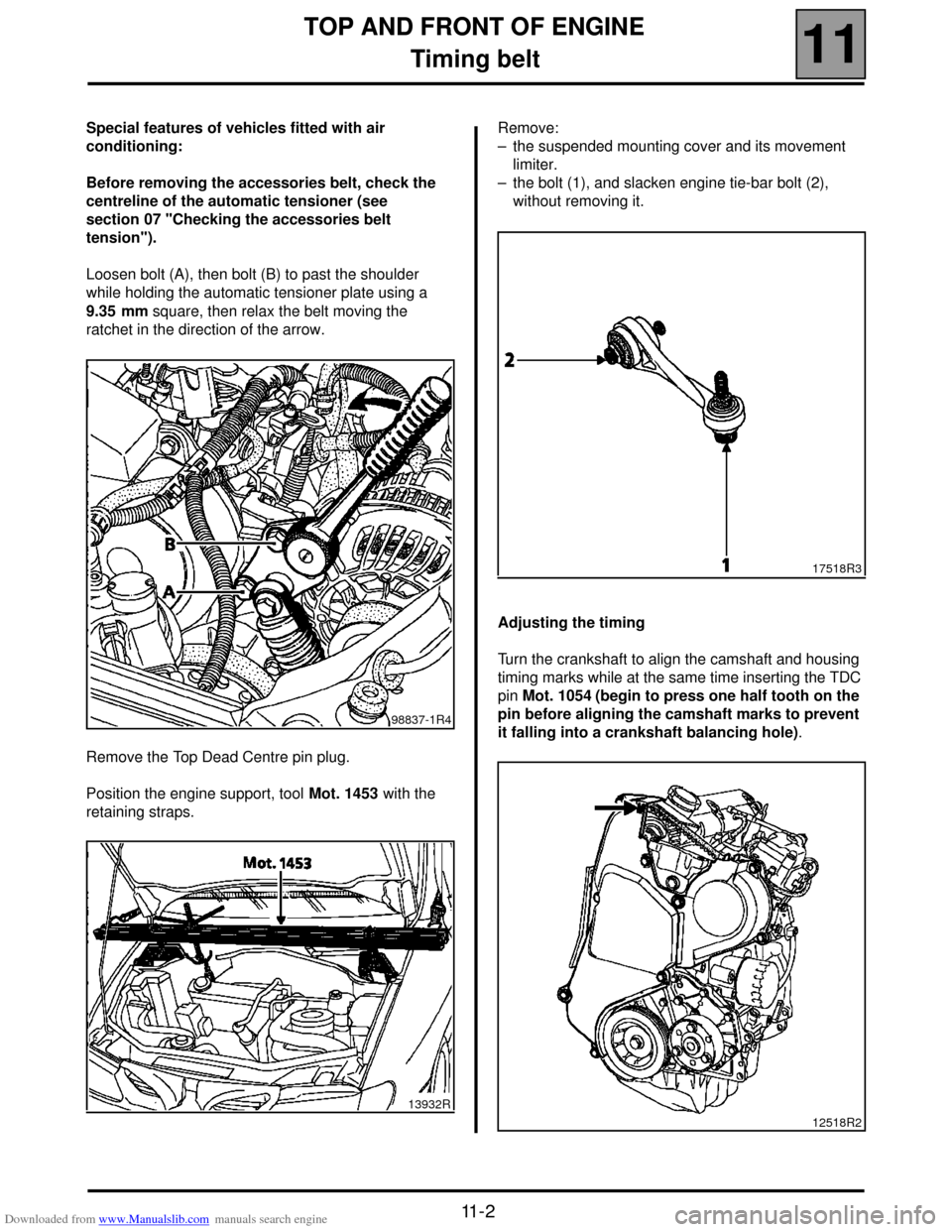

Special features of vehicles fitted with air

conditioning:

Before removing the accessories belt, check the

centreline of the automatic tensioner (see

section 07 "Checking the accessories belt

tension").

Loosen bolt (A), then bolt (B) to past the shoulder

while holding the automatic tensioner plate using a

9.35 mm square, then relax the belt moving the

ratchet in the direction of the arrow.

Remove the Top Dead Centre pin plug.

Position the engine support, tool Mot. 1453 with the

retaining straps.Remove:

– the suspended mounting cover and its movement

limiter.

– the bolt (1), and slacken engine tie-bar bolt (2),

without removing it.

Adjusting the timing

Turn the crankshaft to align the camshaft and housing

timing marks while at the same time inserting the TDC

pin Mot. 1054 (begin to press one half tooth on the

pin before aligning the camshaft marks to prevent

it falling into a crankshaft balancing hole).

98837-1R4

13932R

17518R3

12518R2

Page 29 of 118

Downloaded from www.Manualslib.com manuals search engine TOP AND FRONT OF ENGINE

Timing belt

11

11 - 3

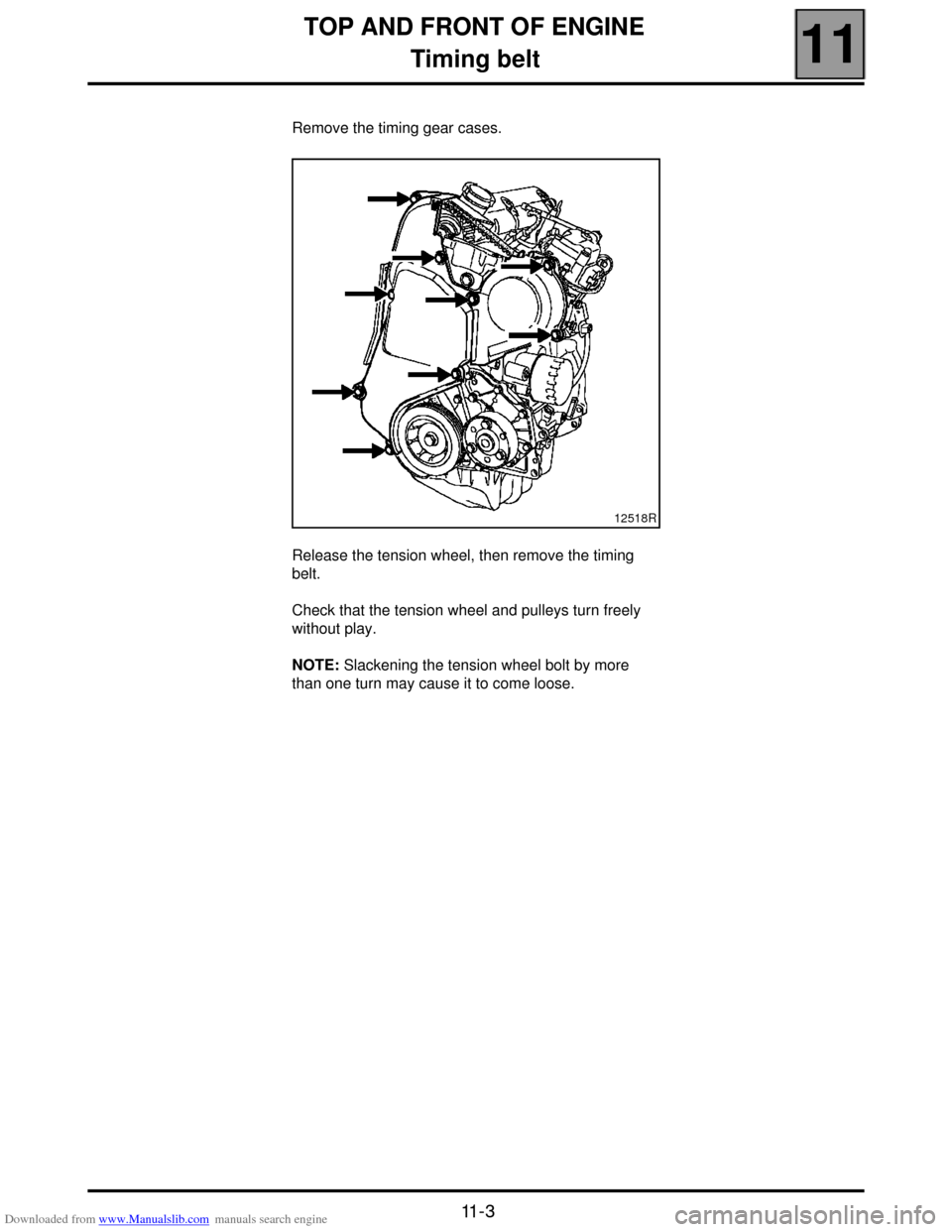

Remove the timing gear cases.

Release the tension wheel, then remove the timing

belt.

Check that the tension wheel and pulleys turn freely

without play.

NOTE: Slackening the tension wheel bolt by more

than one turn may cause it to come loose.

12518R

Page 30 of 118

Downloaded from www.Manualslib.com manuals search engine TOP AND FRONT OF ENGINE

Timing belt

11

11 - 4

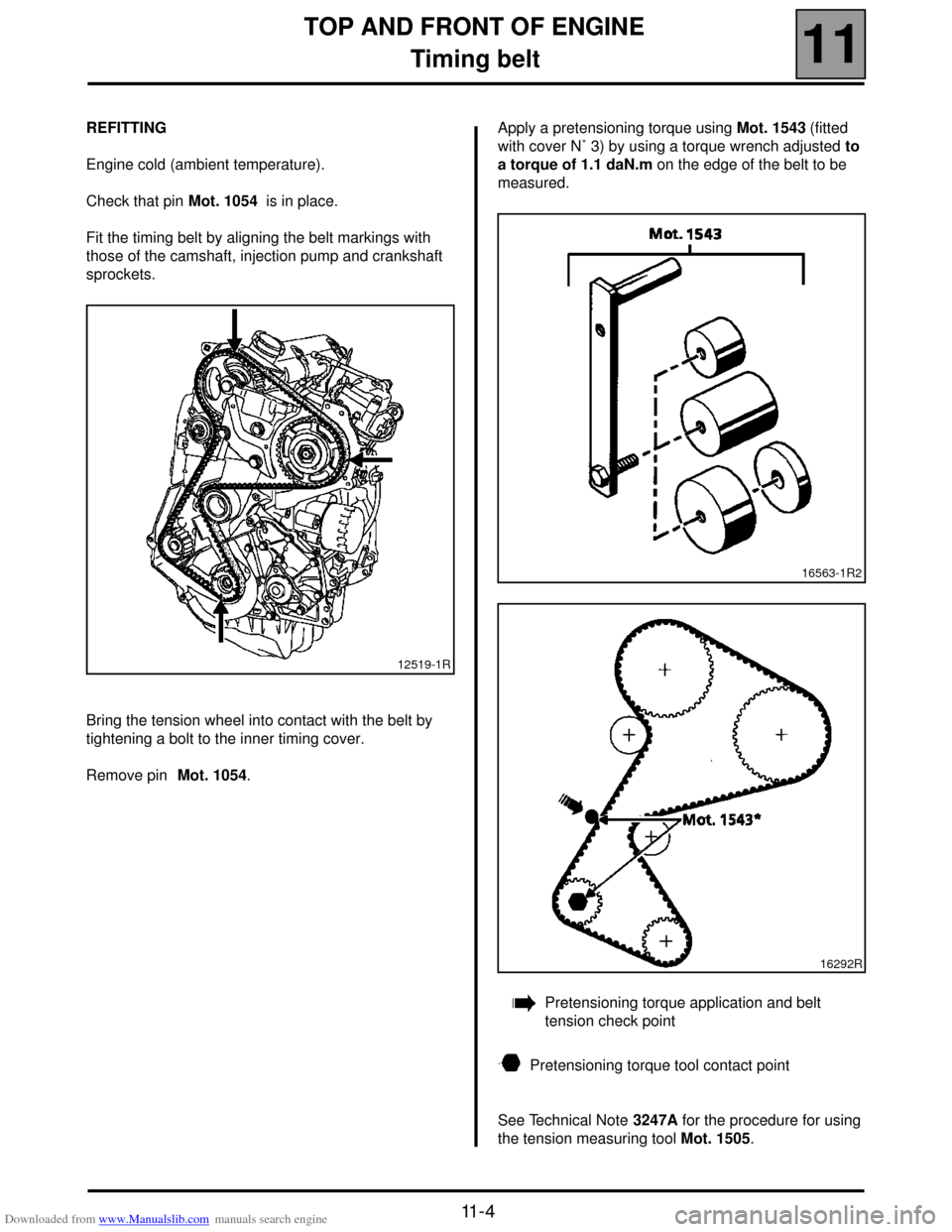

REFITTING

Engine cold (ambient temperature).

Check that pin Mot. 1054 is in place.

Fit the timing belt by aligning the belt markings with

those of the camshaft, injection pump and crankshaft

sprockets.

Bring the tension wheel into contact with the belt by

tightening a bolt to the inner timing cover.

Remove pin Mot. 1054.Apply a pretensioning torque using Mot. 1543 (fitted

with cover N˚ 3) by using a torque wrench adjusted to

a torque of 1.1 daN.m on the edge of the belt to be

measured.

Pretensioning torque application and belt

tension check point

Pretensioning torque tool contact point

See Technical Note 3247A for the procedure for using

the tension measuring tool Mot. 1505.

12519-1R

16563-1R2

16292R