check engine RENAULT SCENIC 2000 J64 / 1.G Technical Note 3426A Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2000, Model line: SCENIC, Model: RENAULT SCENIC 2000 J64 / 1.GPages: 118, PDF Size: 1.5 MB

Page 2 of 118

Downloaded from www.Manualslib.com manuals search engine Contents

Page

07

10

11

12

VALUES AND SETTINGS

Capacities - Grades 07-1

Accessories belt tension 07-2

Checking the accessories belt tension 07-3

Tightening the cylinder head 07-5

Tyres and wheels 07-6

Brakes 07-7

Brake compensator 07-8

Underbody height 07-9

Front axle angle checking values 07-11

Rear axle angle checking values 07-13

ENGINE AND PERIPHERALS

Identification 10-1

Oil pressure 10-2

Engine and transmission assembly 10-3

Sump 10-8

TOP AND FRONT OF ENGINE

Timing belt 11-1

Cylinder head gasket 11-6

FUEL MIXTURE

Air inlet 12-1

TURBOCHARGING

Pressure regulating valve 12-2

Pressure adjustment 12-3

Turbocharger 12-4

Air-air exchanger 12-7

Manifolds 12-9

Priming catalytic converter 12-12Page

13

14

DIESEL EQUIPMENT

Technical specifications 13-1

Special features 13-3

Cleanliness 13-6

Location of components 13-9

Injection warning light 13-12

Immobiliser function 13-13

Injection programming/ air conditioning 13-14

Idle speed correction13-16

Pre-postheating control 13-17

Heater plugs 13-18

Thermoplunger 13-19

Low pressure pump (supercharging

pump)13-21

Fuel filter 13-22

High pressure pump 13-23

Injector gallery 13-27

Injectors 13-32

Checking diesel pressure and flow 13-37

Pressure sensor 13-38

Pressure regulator 13-39

Accelerator potentiometer 13-40

Centralised coolant temperature

management 13-41

Computer 13-42

ANTIPOLLUTION

Oil vapour rebreathing 14-1

Exhaust gas recirculation 14-2

Page 5 of 118

Downloaded from www.Manualslib.com manuals search engine VALUES AND SETTINGS

Accessories belt tensioning

07

07-2

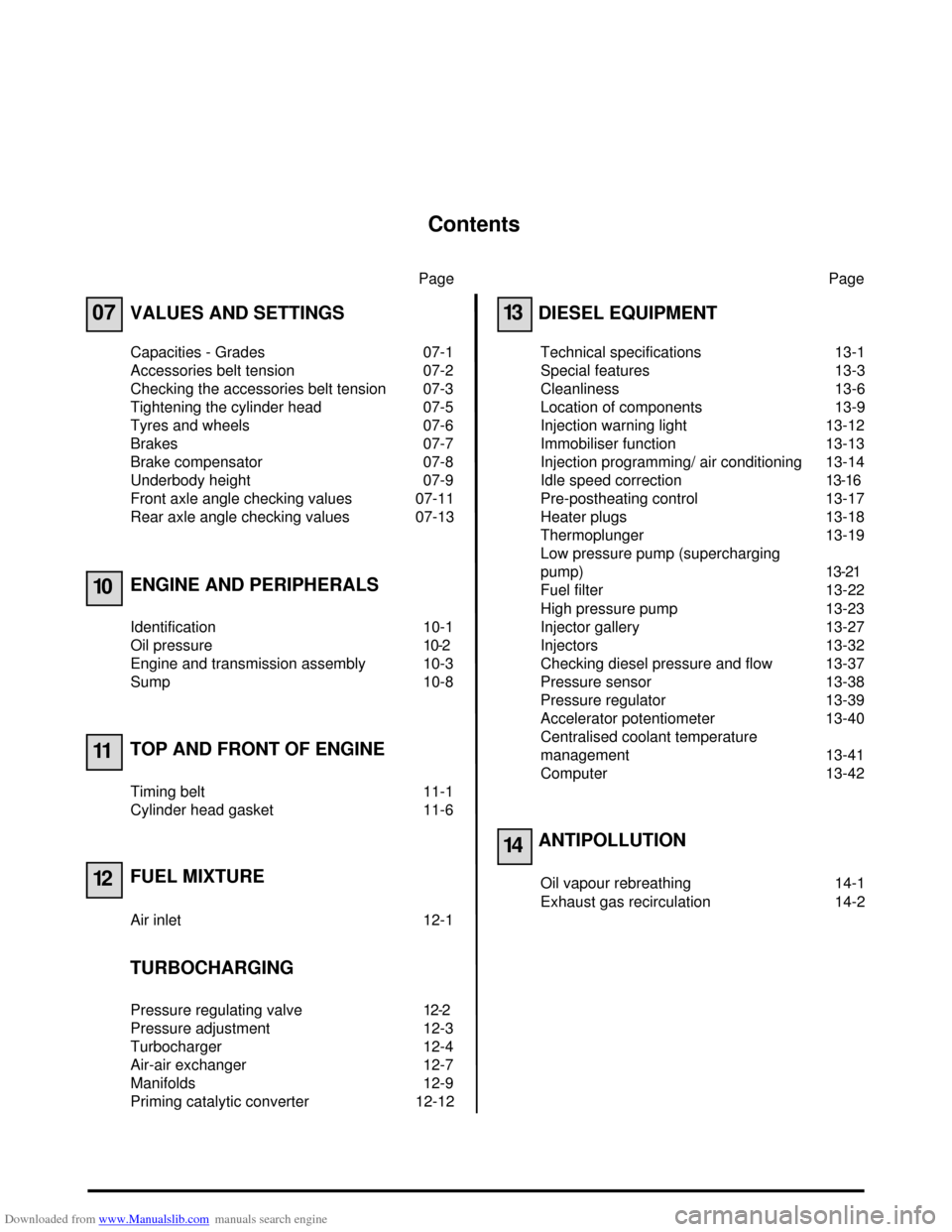

WITHOUT AIR

CONDITIONING

Accessories belt tensioning

ALTERNATOR AND POWER ASSISTED STEERING

Fitting tension (in Hertz): 188 ± 5

See Technical Note 3247A for the procedure for using

the tension measuring tool Mot. 1505.

A Crankshaft

B Alternator

C Power assisted steering pump

E Water pump

→ Tension checking point

98751R1

Page 6 of 118

Downloaded from www.Manualslib.com manuals search engine VALUES AND SETTINGS

Checking the accessories belt tension

07

07-3

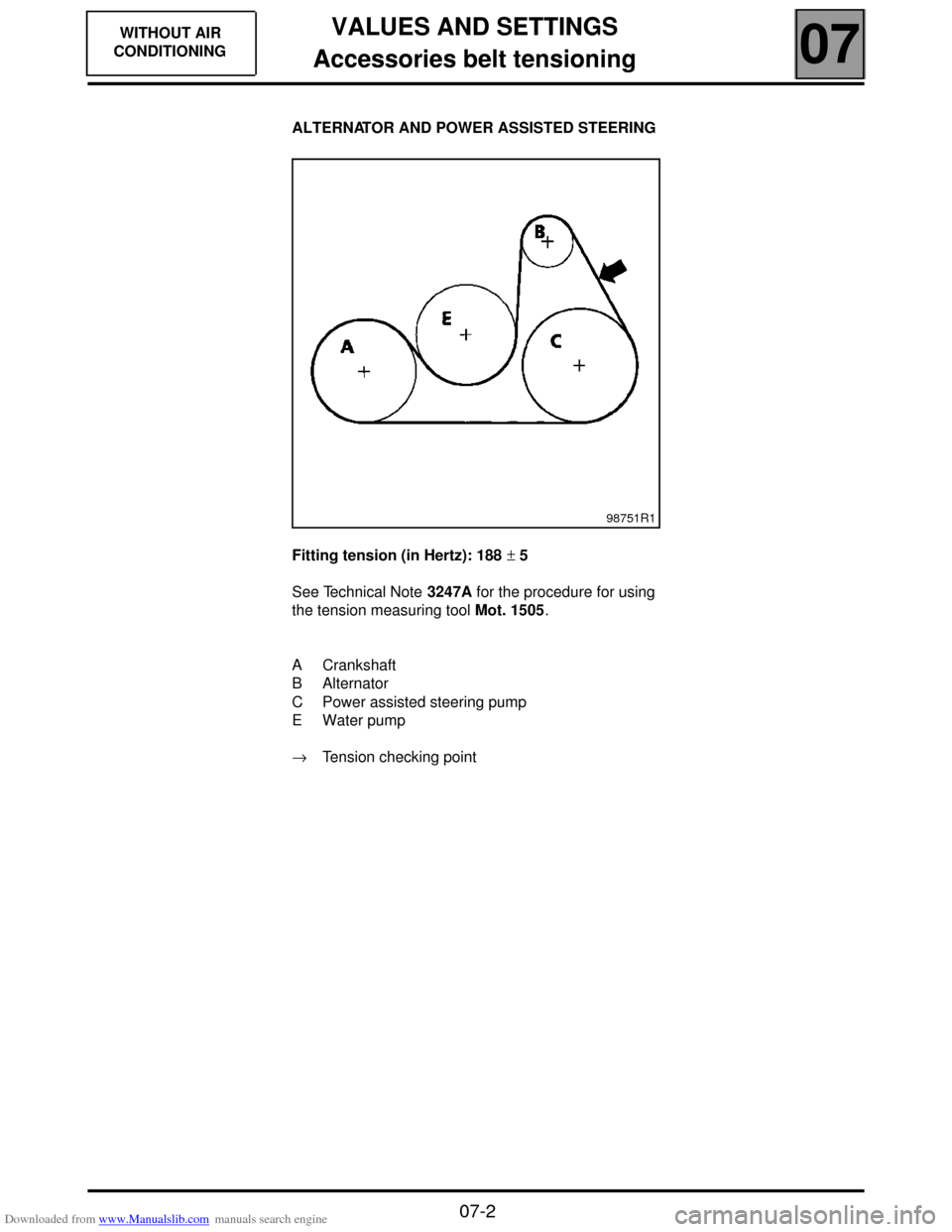

WITH AIR

CONDITIONING

Checking the accessories belt tension

SPECIAL TOOLING REQUIRED

Mot. 1387 Tool for checking the automatic

tension wheel centreline

Checking the automatic tension wheel centre line

Before removing the accessories belt, check the

centreline (A) on the automatic tension wheel using

Mot. 1387.Methods for using Mot. 1387

Loosen knurled bolt (1) so that the arms (2) and (3)

can slide against each other.

Position Mot. 1387 on the two mountings for the

tensioner component, then lock the arms (2) and (3)

by turning the knurled bolt (1).

11234R

12205G

Page 7 of 118

Downloaded from www.Manualslib.com manuals search engine VALUES AND SETTINGS

Checking the accessories belt tension

07

07-4

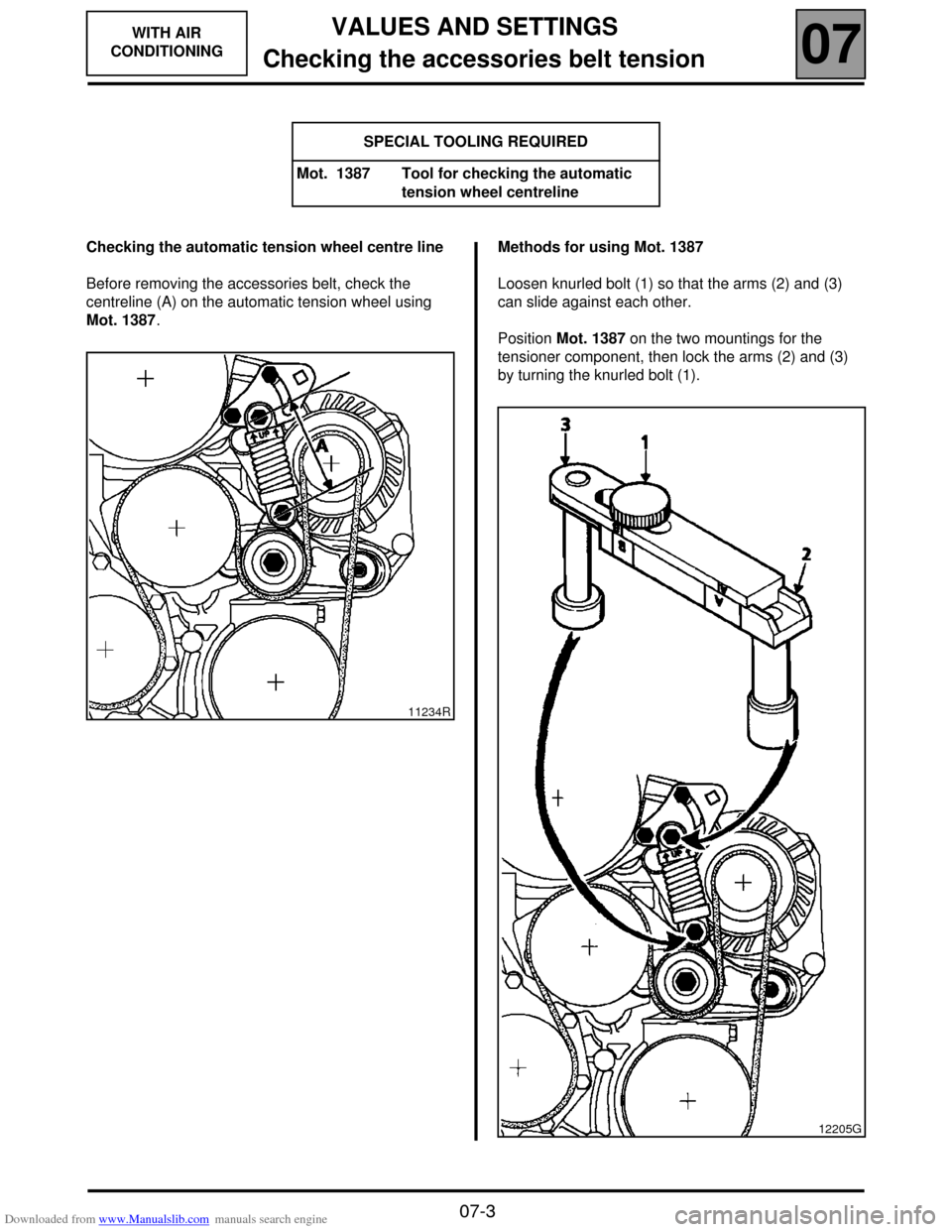

WITH AIR

CONDITIONING

Checking the accessories belt tension

Using Mot. 1387 check that you are well within

tolerance (zone B).

NOTE:

Min. tolerance = Mark (4)

Max. tolerance = Mark (5)Checking the centreline allows you to check if the

automatic tension system is working correctly.

If the centreline is outside permitted tolerance values,

check the following points:

12205R3

ENGINE

CENTRELINEF9Q

Centreline less

than minimum– Check that the eccentric plate

is positioned correctly (at the

base of the opening).

– Incorrect belt (too short).

– Incorrect belt passage.

Centreline

greater than

maximum– Check that the eccentric plate

is positioned correctly (at the

base of the opening).

– Incorrect belt (too long).

– Incorrect belt passage.

Page 11 of 118

Downloaded from www.Manualslib.com manuals search engine VALUES AND SETTINGS

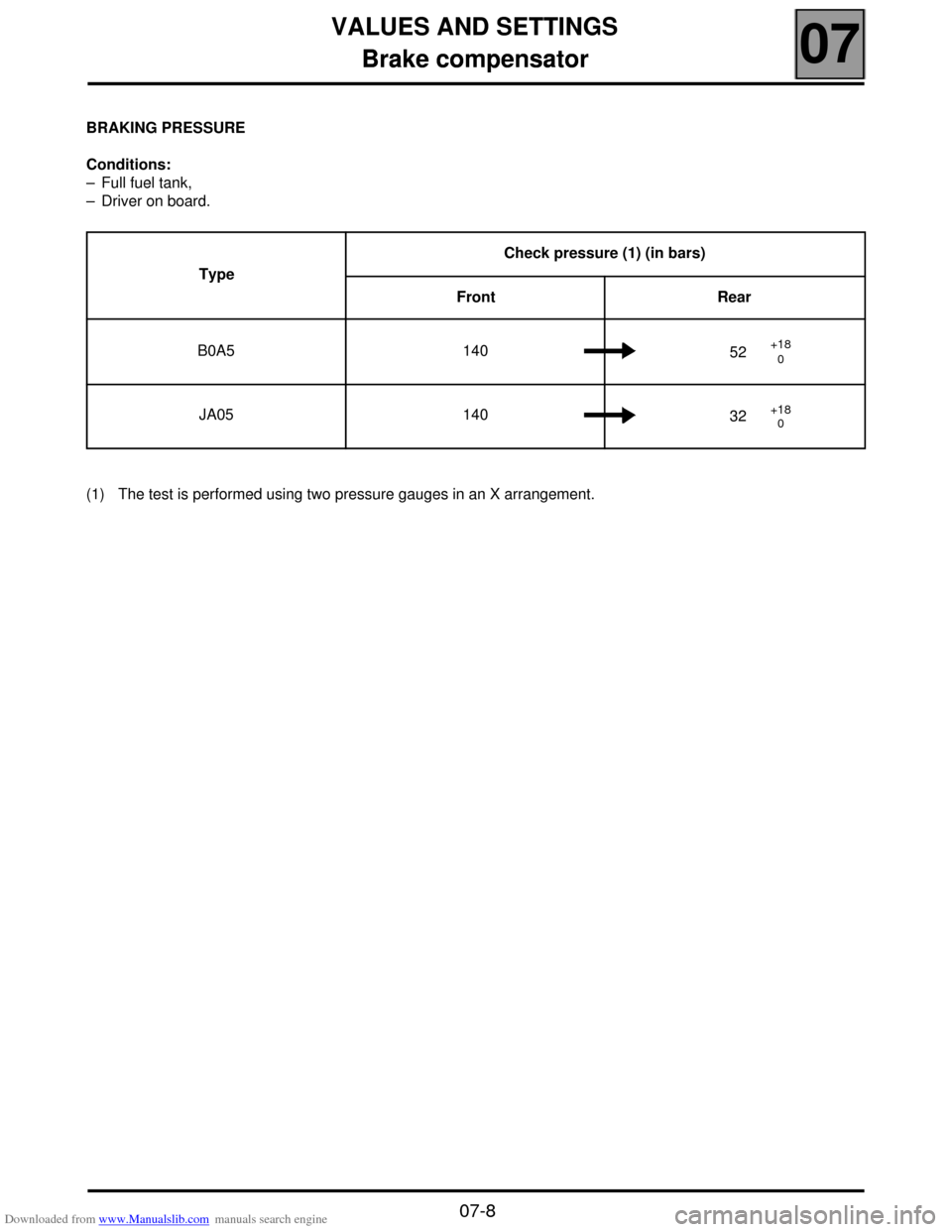

Brake compensator

07

07-8

Brake compensator

BRAKING PRESSURE

Conditions:

– Full fuel tank,

– Driver on board.

(1) The test is performed using two pressure gauges in an X arrangement.TypeCheck pressure (1) (in bars)

Front Rear

B0A5 140

+18 52 0

JA05 140 +18 32 0

Page 14 of 118

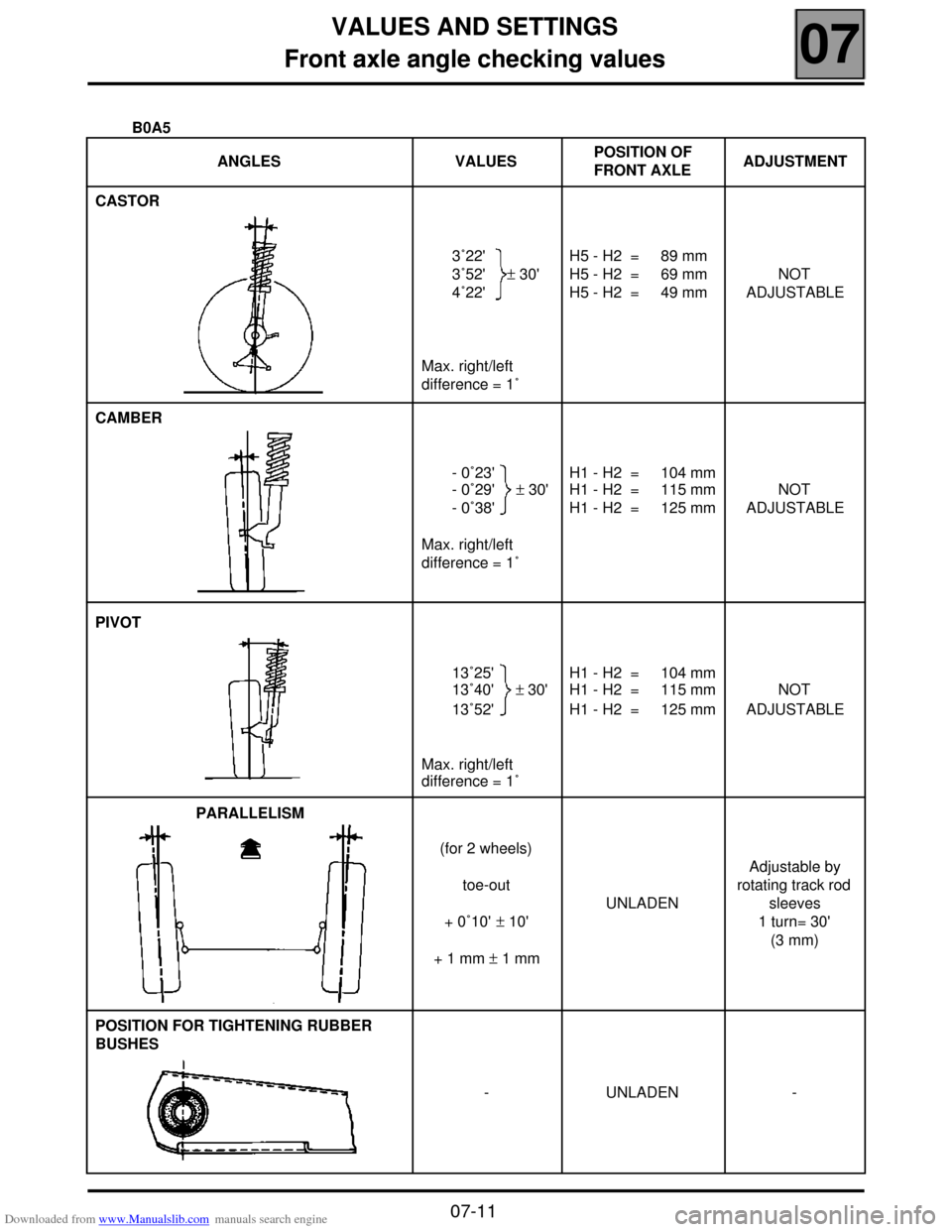

Downloaded from www.Manualslib.com manuals search engine VALUES AND SETTINGS

Front axle angle checking values

07

07-11

Front axle angle checking values

B0A5

ANGLES VALUESPOSITION OF

FRONT AXLEADJUSTMENT

CASTOR

3˚22'

3˚52' ± 30'

4˚22'

Max. right/left

difference = 1˚

H5 - H2 = 89 mm

H5 - H2 = 69 mm

H5 - H2 = 49 mmNOT

ADJUSTABLE

CAMBER

- 0˚23'

- 0˚29' ± 30'

- 0˚38'

Max. right/left

difference = 1˚

H1 - H2 = 104 mm

H1 - H2 = 115 mm

H1 - H2 = 125 mmNOT

ADJUSTABLE

PIVOT

13˚25'

13˚40' ± 30'

13˚52'

Max. right/left

difference = 1˚

H1 - H2 = 104 mm

H1 - H2 = 115 mm

H1 - H2 = 125 mmNOT

ADJUSTABLE

PARALLELISM

(for 2 wheels)

toe-out

+ 0˚10' ± 10'

+ 1 mm ± 1 mmUNLADENAdjustable by

rotating track rod

sleeves

1 turn= 30'

(3 mm)

POSITION FOR TIGHTENING RUBBER

BUSHES

- UNLADEN -

Page 15 of 118

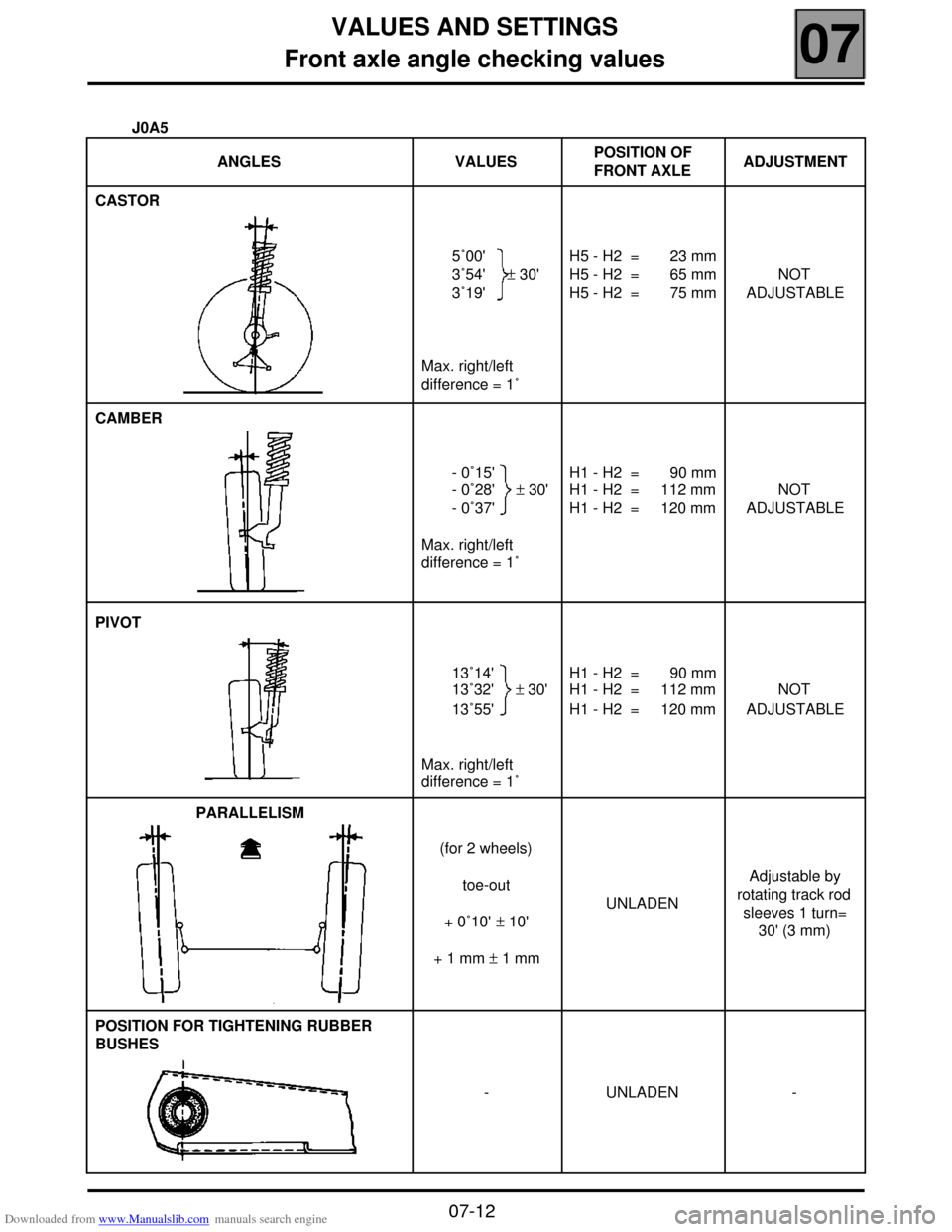

Downloaded from www.Manualslib.com manuals search engine VALUES AND SETTINGS

Front axle angle checking values

07

07-12

J0A5

ANGLES VALUESPOSITION OF

FRONT AXLEADJUSTMENT

CASTOR

5˚00'

3˚54' ± 30'

3˚19'

Max. right/left

difference = 1˚

H5 - H2 = 23 mm

H5 - H2 = 65 mm

H5 - H2 = 75 mmNOT

ADJUSTABLE

CAMBER

- 0˚15'

- 0˚28' ± 30'

- 0˚37'

Max. right/left

difference = 1˚

H1 - H2 = 90 mm

H1 - H2 = 112 mm

H1 - H2 = 120 mmNOT

ADJUSTABLE

PIVOT

13˚14'

13˚32' ± 30'

13˚55'

Max. right/left

difference = 1˚

H1 - H2 = 90 mm

H1 - H2 = 112 mm

H1 - H2 = 120 mmNOT

ADJUSTABLE

PARALLELISM

(for 2 wheels)

toe-out

+ 0˚10' ± 10'

+ 1 mm ± 1 mmUNLADENAdjustable by

rotating track rod

sleeves 1 turn=

30' (3 mm)

POSITION FOR TIGHTENING RUBBER

BUSHES

- UNLADEN -

Page 16 of 118

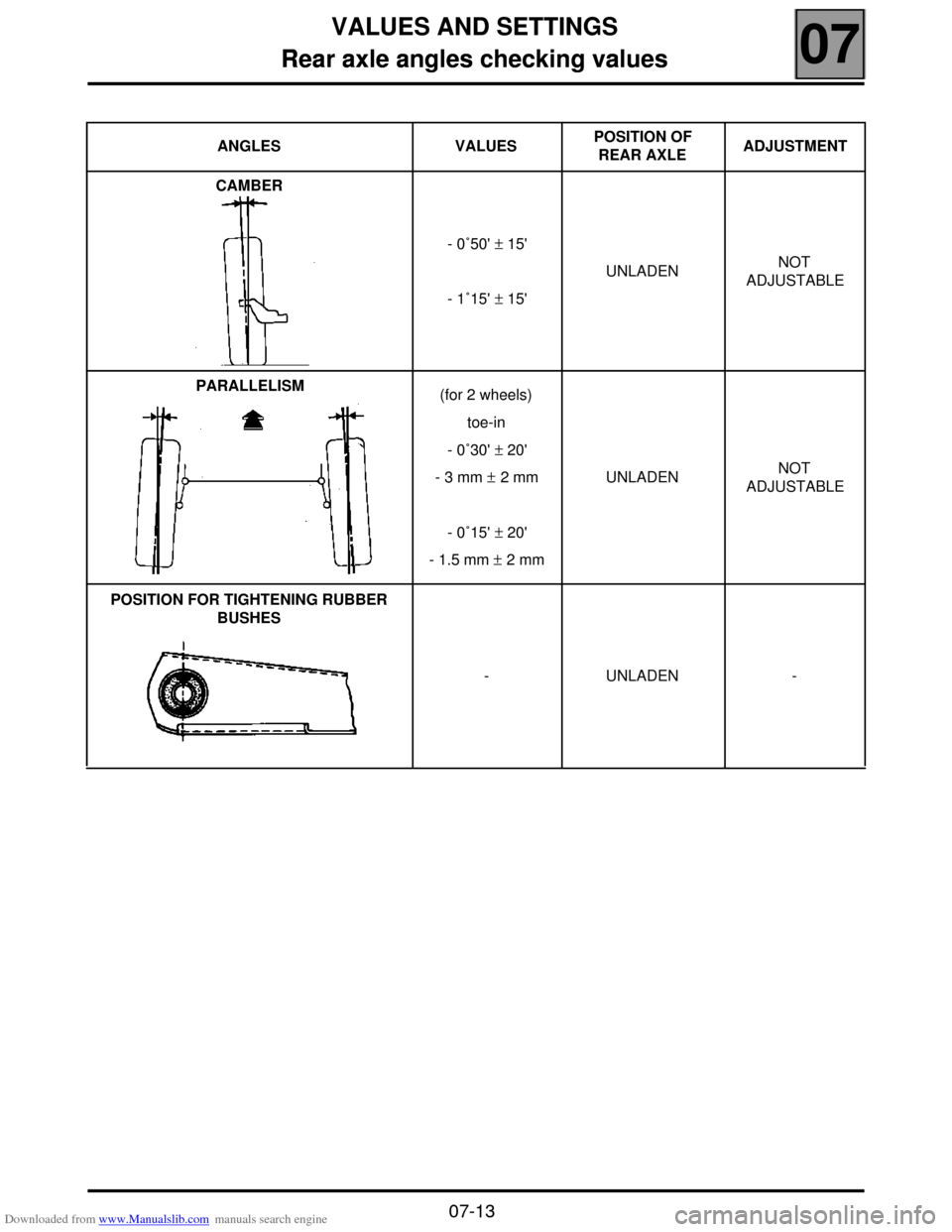

Downloaded from www.Manualslib.com manuals search engine VALUES AND SETTINGS

Rear axle angles checking values

07

07-13

Rear axle angles checking values

ANGLES VALUESPOSITION OF

REAR AXLEADJUSTMENT

CAMBER

- 0˚50' ± 15'

- 1˚15' ± 15'UNLADENNOT

ADJUSTABLE

PARALLELISM

(for 2 wheels)

toe-in

- 0˚30' ± 20'

- 3 mm ± 2 mm

- 0˚15' ± 20'

- 1.5 mm ± 2 mmUNLADENNOT

ADJUSTABLE

POSITION FOR TIGHTENING RUBBER

BUSHES

- UNLADEN -

Page 18 of 118

Downloaded from www.Manualslib.com manuals search engine ENGINE AND PERIPHERALS

Oil pressure

10

10-2

Oil pressure

CHECKING

The oil pressure should be checked when the engine

is warm (approximately 80 °C).

Contents of kit Mot. 836-05.

USE

C + F

Connect the pressure gauge in place of the oil

pressure switch.

Oil pressure

1000 rpm 1.2 bar

3000 rpm 3.5 barsSPECIAL TOOLING REQUIRED

Mot. 836-05 Boxed kit for measuring oil

pressure

ESSENTIAL SPECIAL TOOLING

22 mm long socket

87363R1

Page 27 of 118

Downloaded from www.Manualslib.com manuals search engine TOP AND FRONT OF ENGINE

Timing belt

11

11 - 1

111TOP AND FRONT OF ENGINE

Timing belt

SPECIAL TOOLING REQUIRED

Mot. 1054 TDC setting pin

Mot. 1387 Tool for checking the automatic

tensioner centreline

Mot. 1453 Engine support tool

Mot. 1505 Tool for measuring belt tension

Mot. 1543 Timing belt pretensioning torque

tool

Mot. 1294-01 Tool for removing windscreen

wiper arms

ESSENTIAL SPECIAL TOOLING

14 torx socket

REMOVAL

Put the vehicle on a 2 post lift.

Disconnect the battery.

Remove (for the SCENIC):

– the windscreen wiper arms,

– the front grilles,– the closure panel of the plenum chamber.

Remove (all types):

– the engine cover,

– the front right wheel as well as the mudguard,

– the accessories belt,

– the crankshaft accessories pulley. TIGHTENING TORQUES (in daN.m and/or ˚)

Tension roller nut 5

Crankshaft pulley bolt 2 + 115˚ ± 15˚

Suspended mounting limiter bolt 6.2

Suspended mounting cover bolt 6.2

Wheel bolts 9

11020R

11036R2