RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16 Owner's Manual

Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 365, PDF Size: 2.11 MB

Page 21 of 365

13B-21

MR-372-J84-13B200$144.mif

V13

13B

DIESEL INJECTION

Fault finding – Replacement of components

COMPUTER REPLACEMENT OR REPROGRAMMING

Two operations must be performed when replacing or reprogramming the computer:

SC003 Save computer data and SC001 Enter saved data.

– Run command SC003 Save computer data before replacing or reprogramming the computer. This enables

certain data to be saved in the diagnostic tool so that the new computer* can be reconfigured like the old one.

The saved data includes: injector codes, EGR programming, specific data for particle filter operation and vehicle

options.

– Run command SC001 Write saved data after replacing or reprogramming the computer. This command

enables the data (saved by the command SC003 Save computer data) to be rewritten in the new computer*.

If you cannot establish dialogue with the computer being replaced: you will not be able to save anything.

After replacing the computer:

– Manually enter the IMA codes for each injector by reading the code on each injector (see 13B, Diesel injection,

Replacement of components, Injector replacement).

– Enter the data specific to particle filter operation by running SC036 Reinitialise programming and select After

replacing the injection computer with no save option.

Exhaust gas recirculation valve data is programmed automatically the 1st time the new computer is switched on*.

* New computer or reprogrammed computer.

Specific to the cruise control/speed limiter operation to be carried out before reprogramming of the

computer:

Before reprogramming the injection computer, move the main cruise control/speed limiter switch to the rest

position. The information about the cruise control or the speed limiter displayed on the instrument panel

disappears.

Otherwise, if the main switch remains in the cruise control or speed limiter position during and after reprogramming,

the Cruise control/Speed limiter function will not be operational.

The procedure for resetting the function is as follows:

– Vehicle ignition on.

– Position the cruise control/speed limiter switch in the rest position (the computer then detects the rest position).

– Position the cruise control/speed limiter switch in the Cruise control position to activate the Cruise control

function.

– Position the cruise control/speed limiter switch in the Speed limiter position to activate the Speed limiter function. IMPORTANT

– Switch on the diagnostic tool (mains or cigarette lighter supply).

– Connect a battery charger.

– Cut off all the electrical consumers (lights, interior lighting, air conditioning, radio CD, etc.).

– Wait for the engine to cool (engine coolant temperature < 60° and air temperature < 50°).

– For Vdiags 50, 58, 5C, during (re)programming of the computer, the engine fan assemblies are actuated

automatically.

– For Vdiags 18, 1C, 20, during (re)programming of the computer, the instrument panel screen displays

“Oil pressure fault”.

– Ignore this message and do not take any action in connection with it.

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

MR-372-J84-13B200$144.mif

Page 22 of 365

13B-22

MR-372-J84-13B200$144.mif

V13

DIESEL INJECTION

Fault finding – Replacement of components

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

PROCEDURE:

Before replacing or reprogramming the computer:

– Select command SC003 Save computer data,

– if the following message appears: backup file exists, do you want to overwrite it?:

(this file corresponds to the last save carried out on the tool)

–select YES.

When the backup is complete, replace the computer or reprogram, then proceed to the next step.

After replacing or reprogramming the computer:

– Select command SC001 Write saved data, then follow the instructions given by the diagnostic tool,

– if the VIN has not been entered (see "Computer identification" on the main screen), select VP010 Enter VIN,

When both these commands have finished:

–switch off the ignition and wait 1minute before switching the ignition on again,

– then check the system faults, and clear any stored faults,

– otherwise, deal with faults that are present and clear the faults in the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

End of operation.IMPORTANT

Thermoplunger faults are displayed during reprogramming.

– DF032 Thermoplunger 1 relay control circuit,

– DF033 Thermoplunger 2 relay control circuit,

– DF034 Thermoplunger 3 relay control circuit,

– DF238 Thermoplunger 3 relay circuit,

– DF239 Thermoplunger 2 relay circuit,

– DF240 Thermoplunger 1 relay circuit.

In this case, configure the thermoplungers using configuration CF030 Thermoplungers.

IMPORTANT

– The injection computer retains the immobiliser code for life.

– The system has no security code.

– It is forbidden to perform tests with computers borrowed from the Parts Department or from another vehicle

which must then be returned.

– These computers are hard-coded.

– If the injection computer appears to be faulty, contact the Techline and refer to the fault finding log.

Page 23 of 365

13B-23

MR-372-J84-13B200$144.mif

V13

DIESEL INJECTION

Fault finding – Replacement of components

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

REPLACING THE INJECTORS

After replacing one or more injectors, re-enter the IMA codes.

The system must be configured via the diagnostic socket using the RENAULT CLIP diagnostic tool.

PROCEDURE to be followed after replacing one or more injectors:

– make a note of the IMA code(s) engraved on the injector body,

– enter these codes in the computer using command SC002 Enter injector codes, then follow the instructions

given by the diagnostic tool,

– once the command has finished,

– switch off the ignition,

–wait 1 minute before switching on the ignition again,

– return to fault finding mode,

– select the function "Computer identification" on the main screen,

– check that the injector codes entered into the computer match those found on the bodies of the injectors:

– if the codes do not match, repeat the procedure for command SC002 Enter injector codes.

– if the codes do match, check the system faults and clear any stored faults,

– otherwise, deal with faults that are present and clear the faults in the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

End of operation.Note:

The IMA coding (individual injector correction) is a calibration made in production on each injector to adjust

the flow accurately.

These correction values are etched onto the Bakelite body of each injector (6 alphanumeric characters) and then

entered into the computer, which then controls each injector taking into account their manufacturing variance.

IMPORTANT

Cylinder no. 1 is located on the flywheel end.

IMPORTANT

Engines can only operate correctly if the correct IMA codes have been entered.

If no codes have been entered or if an invalid code has been entered, fault

DF276 Injector code programming is present and the engine will be in defect mode (significant engine

speed restriction).

If another injector’s code has been entered, the system will accept it but will make the wrong correction.

This could lead to engine damage, loss of performance and excessive pollution.

Always use the correct injector codes for the engine cylinder/computer.

Page 24 of 365

13B-24

MR-372-J84-13B200$144.mif

V13

DIESEL INJECTION

Fault finding – Replacement of components

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

REPLACING OR CLEANING THE EXHAUST GAS RECIRCULATION (EGR) VALVE

After the exhaust gas recirculation valve has been replaced, the computer must store the new valve offset and the

offset measured when the ignition was last switched off, which corresponds to the valve closing.

Using this data, the computer can detect whether the valve is clogged or seized.

When the valve is replaced or cleaned, clear the stored offsets so that the program uses the new valve's offset

value.

The data linked to this strategy is compiled in the Antipollution/OBD sub-function.

– PR128 First EGR valve offset.

– PR129 Last EGR valve offset > or = PR128 for a new valve.

The PR128 and PR129 programming must be cleared every time the exhaust gas recirculation valve is replaced.

PROCEDURE:

– Run command SC036 Reinitialise programming.

–Select EGR valve as the type of operation, then follow the instructions given by the diagnostic tool.

When the command is finished,

– switch off the ignition,

–wait 1 minute before switching on the ignition again.

When the ignition is switched on again, the new EGR valve offset is automatically reprogrammed.

– start the vehicle to enable the latest EGR valve offset to be programmed,

– switch off the ignition,

–wait 1 minute before switching on the ignition again.

Reprogramming of the last EGR valve offset is stored in the computer.

– then check the system faults, and clear any stored faults,

– otherwise, deal with the faults that are present and clear the faults in the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

End of operation.Note:

When the reinitialisation is complete, the Emission control/OBD sub-function displays:

PR128 = PR129 > 100 %

Note:

When the new EGR valve offset has been reprogrammed, the Emission control/OBD sub-function displays:

10 % < PR128 < 40 %

PR129 > 100 %

Note:

When the last EGR valve offset has been reprogrammed, the Emission control/OBD sub-function displays:

10 % < PR128 < 40 %

10% < PR129 < 40%

Page 25 of 365

13B-25

MR-372-J84-13B200$144.mif

V13

DIESEL INJECTION

Fault finding – Replacement of components

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

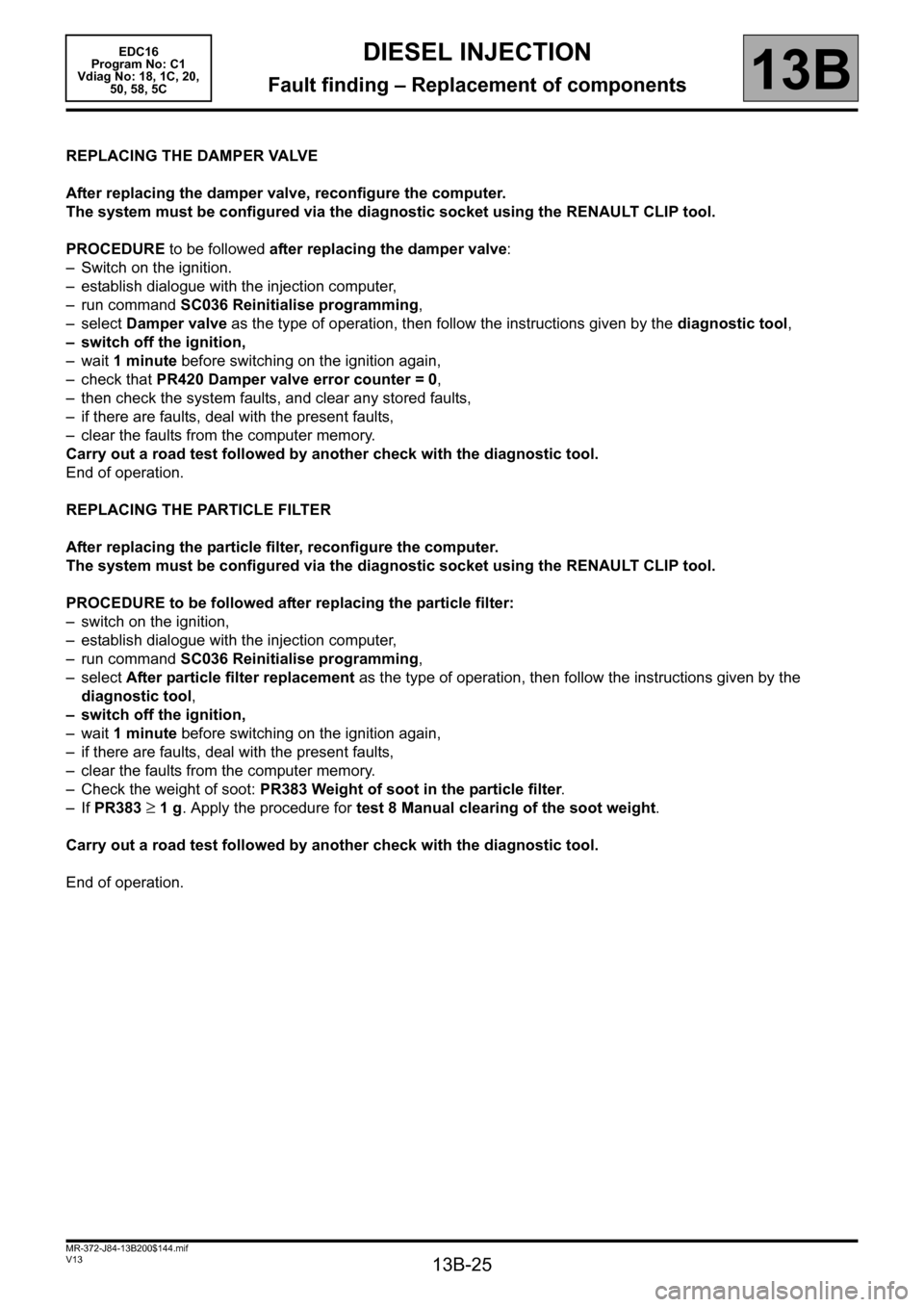

REPLACING THE DAMPER VALVE

After replacing the damper valve, reconfigure the computer.

The system must be configured via the diagnostic socket using the RENAULT CLIP tool.

PROCEDURE to be followed after replacing the damper valve:

– Switch on the ignition.

– establish dialogue with the injection computer,

– run command SC036 Reinitialise programming,

–select Damper valve as the type of operation, then follow the instructions given by the diagnostic tool,

– switch off the ignition,

–wait 1 minute before switching on the ignition again,

– check that PR420 Damper valve error counter = 0,

– then check the system faults, and clear any stored faults,

– if there are faults, deal with the present faults,

– clear the faults from the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

End of operation.

REPLACING THE PARTICLE FILTER

After replacing the particle filter, reconfigure the computer.

The system must be configured via the diagnostic socket using the RENAULT CLIP tool.

PROCEDURE to be followed after replacing the particle filter:

– switch on the ignition,

– establish dialogue with the injection computer,

– run command SC036 Reinitialise programming,

–select After particle filter replacement as the type of operation, then follow the instructions given by the

diagnostic tool,

– switch off the ignition,

–wait 1 minute before switching on the ignition again,

– if there are faults, deal with the present faults,

– clear the faults from the computer memory.

– Check the weight of soot: PR383 Weight of soot in the particle filter.

– If PR383

≥ 1 g. Apply the procedure for test 8 Manual clearing of the soot weight.

Carry out a road test followed by another check with the diagnostic tool.

End of operation.

Page 26 of 365

13B-26

MR-372-J84-13B200$180.mif

V13

13B

DIESEL INJECTION

Fault finding – Configuration and programming

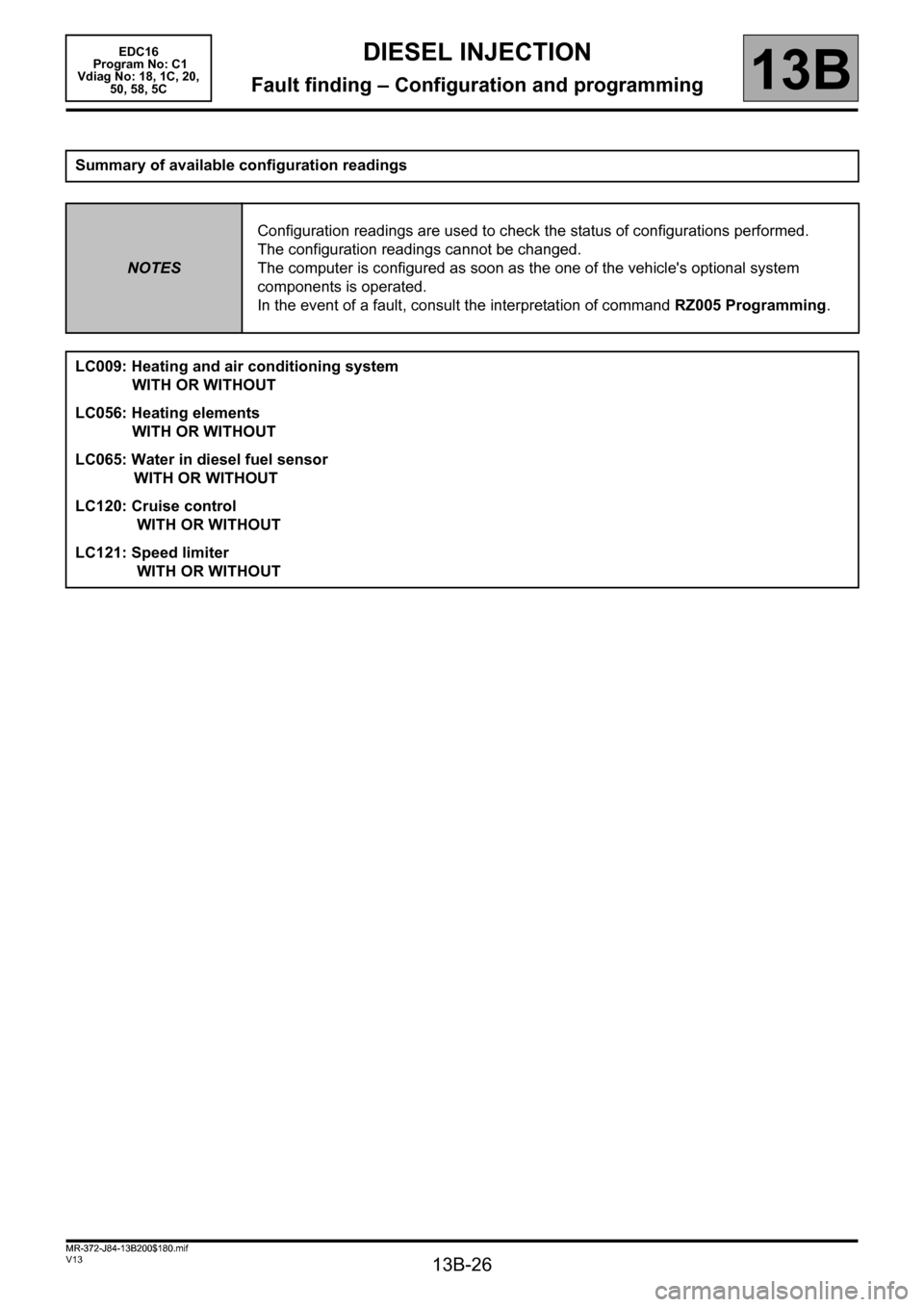

Summary of available configuration readings

NOTESConfiguration readings are used to check the status of configurations performed.

The configuration readings cannot be changed.

The computer is configured as soon as the one of the vehicle's optional system

components is operated.

In the event of a fault, consult the interpretation of command RZ005 Programming.

LC009: Heating and air conditioning system

WITH OR WITHOUT

LC056: Heating elements

WITH OR WITHOUT

LC065: Water in diesel fuel sensor

WITH OR WITHOUT

LC120: Cruise control

WITH OR WITHOUT

LC121: Speed limiter

WITH OR WITHOUT

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

MR-372-J84-13B200$180.mif

Page 27 of 365

13B-27

MR-372-J84-13B200$216.mif

V13

13B

DIESEL INJECTION

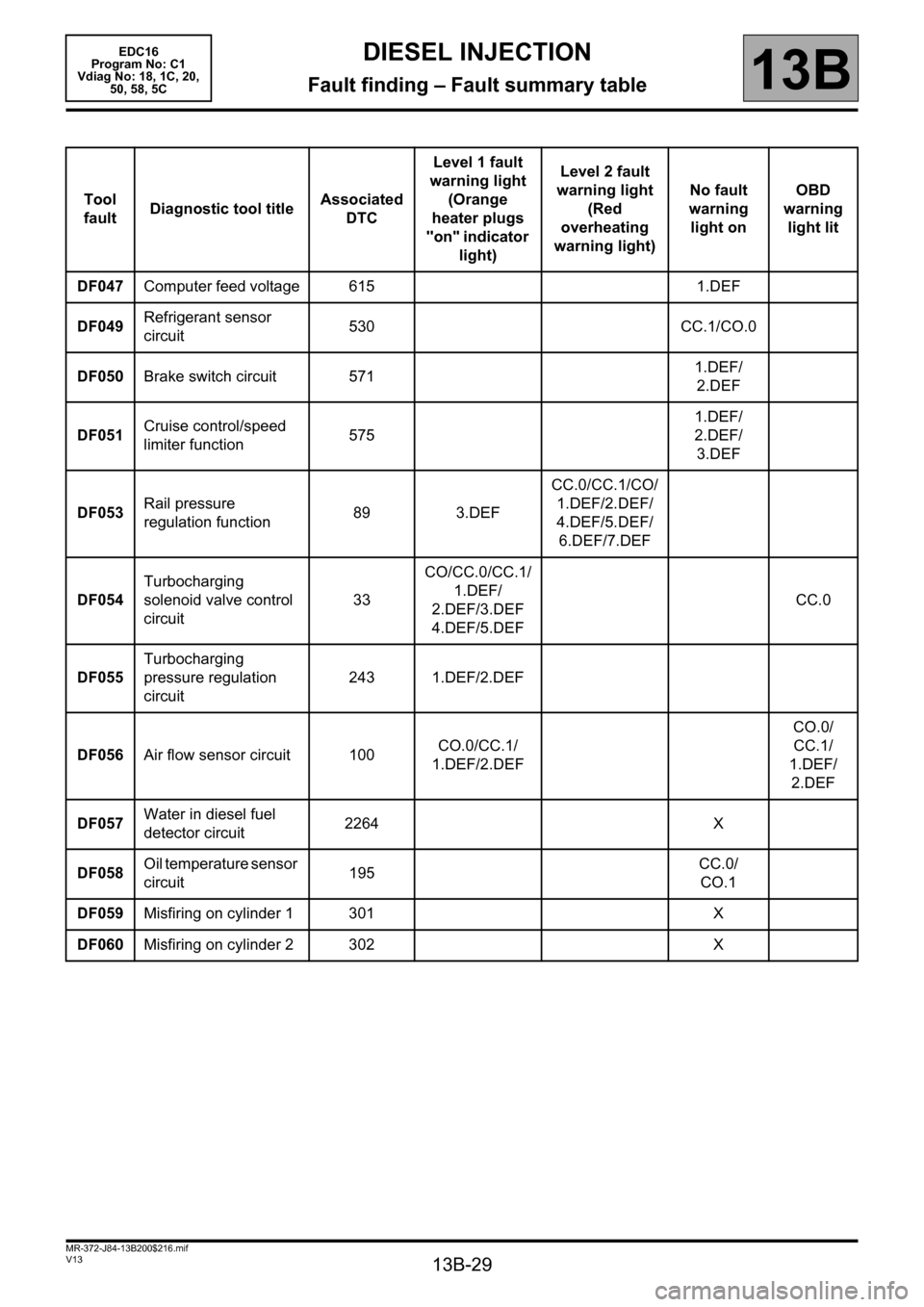

Fault finding – Fault summary table

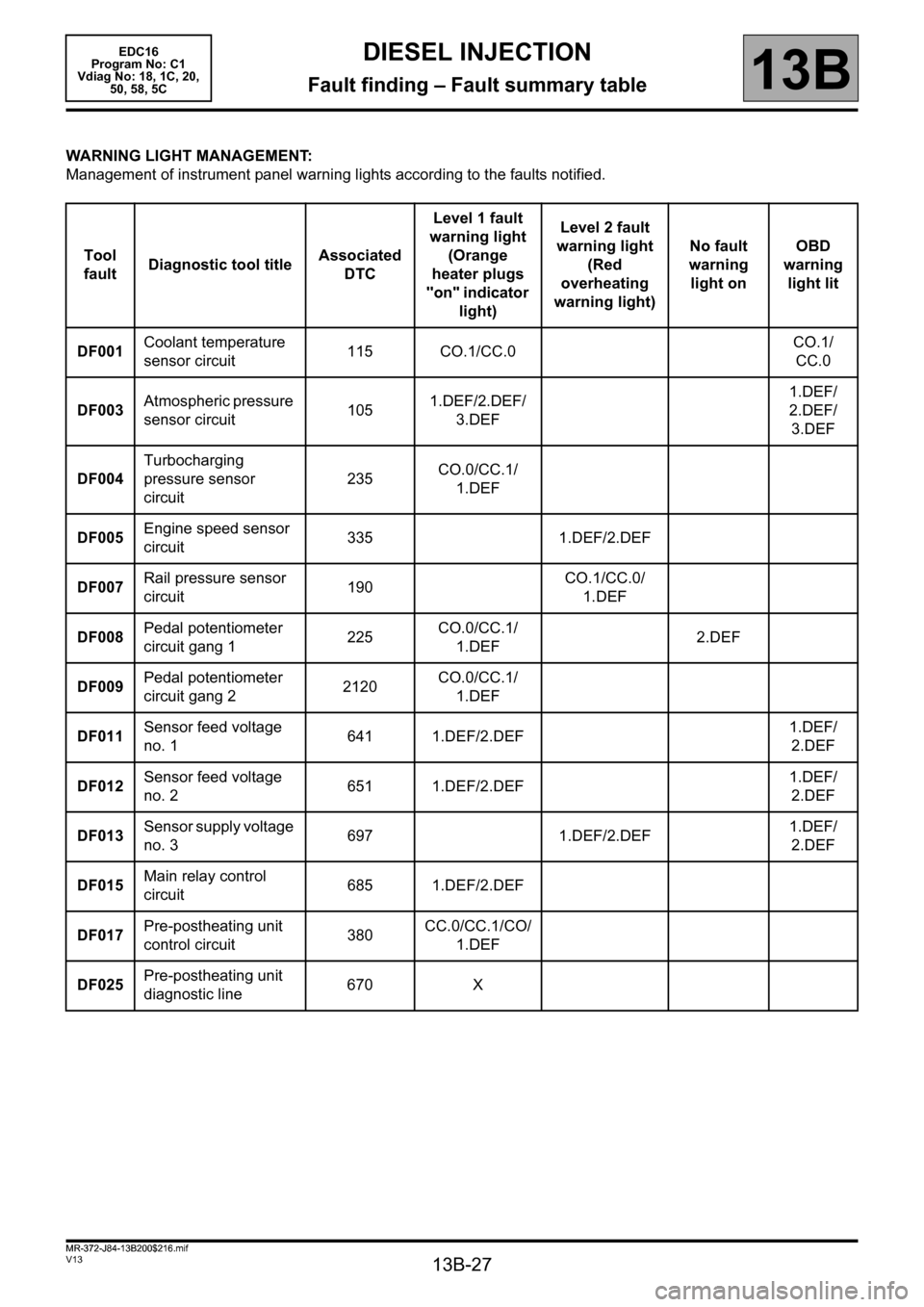

WARNING LIGHT MANAGEMENT:

Management of instrument panel warning lights according to the faults notified.

Tool

faultDiagnostic tool titleAssociated

DTCLevel 1 fault

warning light

(Orange

heater plugs

"on" indicator

light)Level 2 fault

warning light

(Red

overheating

warning light)No fault

warning

light onOBD

warning

light lit

DF001Coolant temperature

sensor circuit115 CO.1/CC.0CO.1/

CC.0

DF003Atmospheric pressure

sensor circuit1051.DEF/2.DEF/

3.DEF1.DEF/

2.DEF/

3.DEF

DF004Turbocharging

pressure sensor

circuit235CO.0/CC.1/

1.DEF

DF005Engine speed sensor

circuit335 1.DEF/2.DEF

DF007Rail pressure sensor

circuit190CO.1/CC.0/

1.DEF

DF008Pedal potentiometer

circuit gang 1225CO.0/CC.1/

1.DEF2.DEF

DF009Pedal potentiometer

circuit gang 22120CO.0/CC.1/

1.DEF

DF011Sensor feed voltage

no. 1641 1.DEF/2.DEF1.DEF/

2.DEF

DF012Sensor feed voltage

no. 2651 1.DEF/2.DEF1.DEF/

2.DEF

DF013Sensor supply voltage

no. 3697 1.DEF/2.DEF1.DEF/

2.DEF

DF015Main relay control

circuit685 1.DEF/2.DEF

DF017Pre-postheating unit

control circuit380CC.0/CC.1/CO/

1.DEF

DF025Pre-postheating unit

diagnostic line670 X

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

MR-372-J84-13B200$216.mif

Page 28 of 365

13B-28

MR-372-J84-13B200$216.mif

V13

DIESEL INJECTION

Fault finding – Fault summary table

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

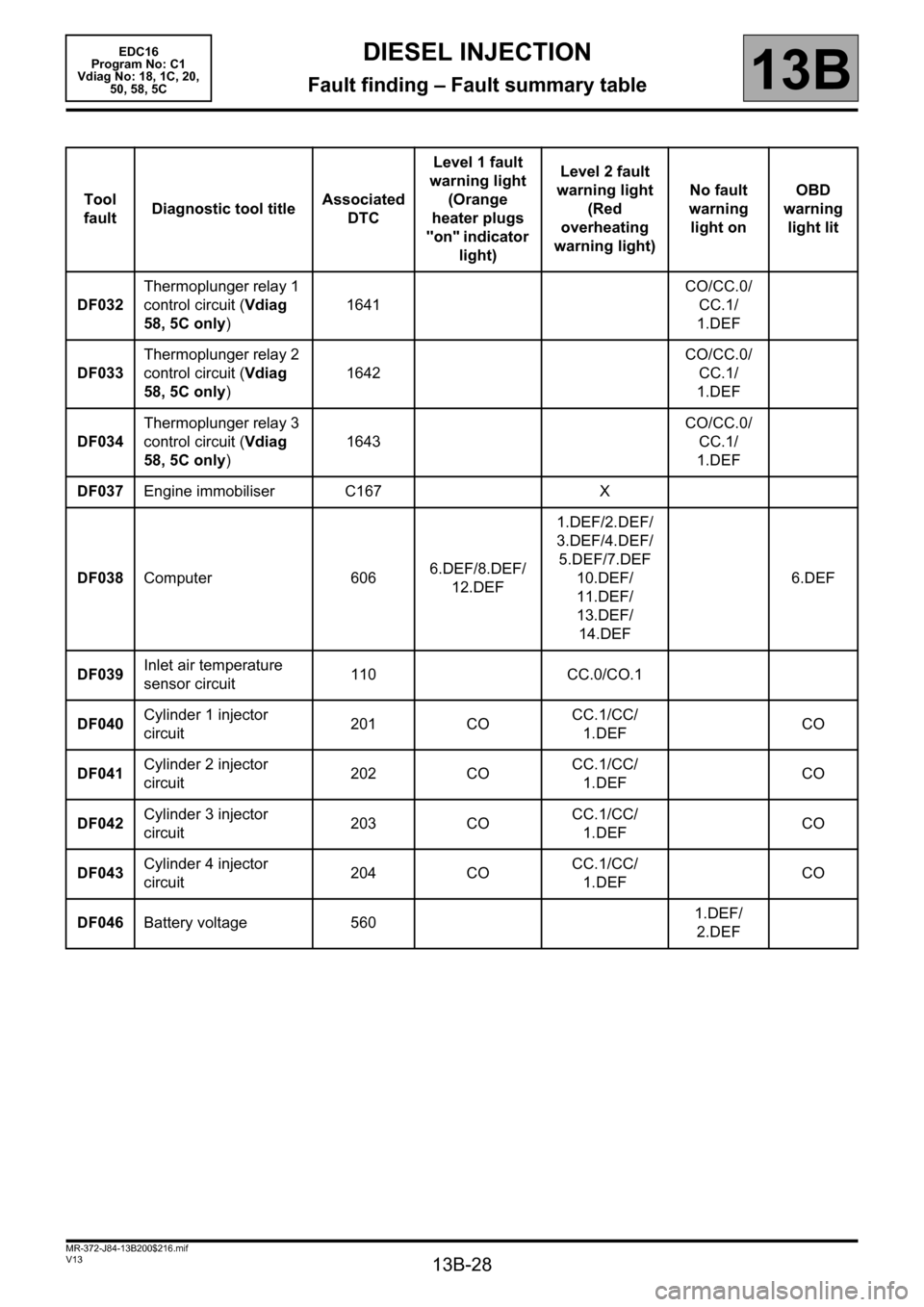

Tool

faultDiagnostic tool titleAssociated

DTCLevel 1 fault

warning light

(Orange

heater plugs

"on" indicator

light)Level 2 fault

warning light

(Red

overheating

warning light)No fault

warning

light onOBD

warning

light lit

DF032Thermoplunger relay 1

control circuit (Vdiag

58, 5C only)1641CO/CC.0/

CC.1/

1.DEF

DF033Thermoplunger relay 2

control circuit (Vdiag

58, 5C only)1642CO/CC.0/

CC.1/

1.DEF

DF034Thermoplunger relay 3

control circuit (Vdiag

58, 5C only)1643CO/CC.0/

CC.1/

1.DEF

DF037Engine immobiliser C167 X

DF038Computer 6066.DEF/8.DEF/

12.DEF1.DEF/2.DEF/

3.DEF/4.DEF/

5.DEF/7.DEF

10.DEF/

11.DEF/

13.DEF/

14.DEF6.DEF

DF039Inlet air temperature

sensor circuit110 CC.0/CO.1

DF040Cylinder 1 injector

circuit201 COCC.1/CC/

1.DEFCO

DF041Cylinder 2 injector

circuit202 COCC.1/CC/

1.DEFCO

DF042Cylinder 3 injector

circuit203 COCC.1/CC/

1.DEFCO

DF043Cylinder 4 injector

circuit204 COCC.1/CC/

1.DEFCO

DF046Battery voltage 5601.DEF/

2.DEF

Page 29 of 365

13B-29

MR-372-J84-13B200$216.mif

V13

DIESEL INJECTION

Fault finding – Fault summary table

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

Tool

faultDiagnostic tool titleAssociated

DTCLevel 1 fault

warning light

(Orange

heater plugs

"on" indicator

light)Level 2 fault

warning light

(Red

overheating

warning light)No fault

warning

light onOBD

warning

light lit

DF047Computer feed voltage 615 1.DEF

DF049Refrigerant sensor

circuit530 CC.1/CO.0

DF050Brake switch circuit 5711.DEF/

2.DEF

DF051Cruise control/speed

limiter function5751.DEF/

2.DEF/

3.DEF

DF053Rail pressure

regulation function89 3.DEFCC.0/CC.1/CO/

1.DEF/2.DEF/

4.DEF/5.DEF/

6.DEF/7.DEF

DF054Turbocharging

solenoid valve control

circuit33CO/CC.0/CC.1/

1.DEF/

2.DEF/3.DEF

4.DEF/5.DEFCC.0

DF055Turbocharging

pressure regulation

circuit243 1.DEF/2.DEF

DF056Air flow sensor circuit 100CO.0/CC.1/

1.DEF/2.DEFCO.0/

CC.1/

1.DEF/

2.DEF

DF057Water in diesel fuel

detector circuit2264 X

DF058Oil temperature sensor

circuit195CC.0/

CO.1

DF059Misfiring on cylinder 1 301 X

DF060Misfiring on cylinder 2 302 X

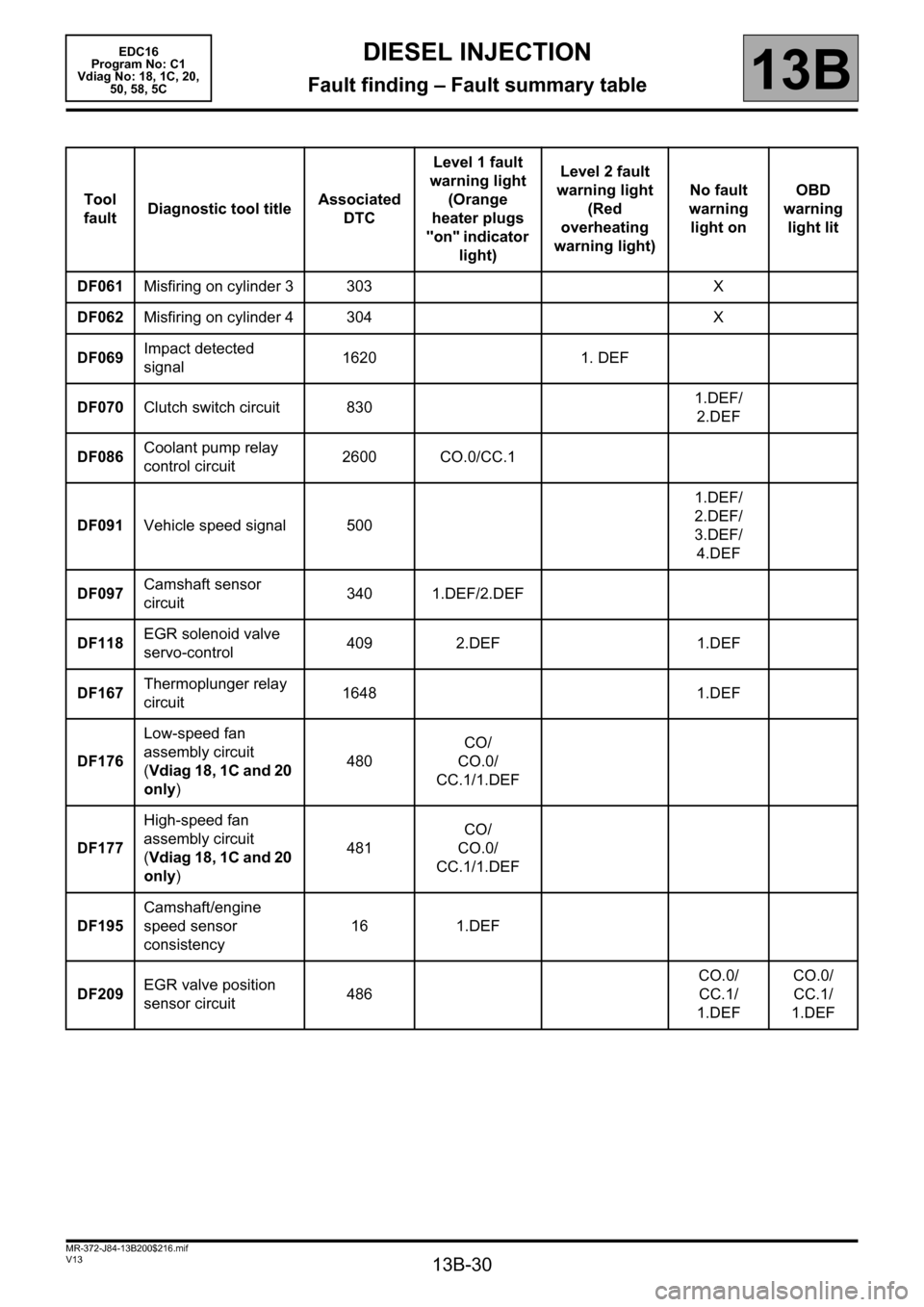

Page 30 of 365

13B-30

MR-372-J84-13B200$216.mif

V13

DIESEL INJECTION

Fault finding – Fault summary table

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

Tool

faultDiagnostic tool titleAssociated

DTCLevel 1 fault

warning light

(Orange

heater plugs

"on" indicator

light)Level 2 fault

warning light

(Red

overheating

warning light)No fault

warning

light onOBD

warning

light lit

DF061Misfiring on cylinder 3 303 X

DF062Misfiring on cylinder 4 304 X

DF069Impact detected

signal1620 1. DEF

DF070Clutch switch circuit 8301.DEF/

2.DEF

DF086Coolant pump relay

control circuit2600 CO.0/CC.1

DF091Vehicle speed signal 5001.DEF/

2.DEF/

3.DEF/

4.DEF

DF097Camshaft sensor

circuit340 1.DEF/2.DEF

DF118EGR solenoid valve

servo-control409 2.DEF 1.DEF

DF167Thermoplunger relay

circuit1648 1.DEF

DF176 Low-speed fan

assembly circuit

(Vdiag 18, 1C and 20

only)480CO/

CO.0/

CC.1/1.DEF

DF177 High-speed fan

assembly circuit

(Vdiag 18, 1C and 20

only)481CO/

CO.0/

CC.1/1.DEF

DF195Camshaft/engine

speed sensor

consistency16 1.DEF

DF209EGR valve position

sensor circuit486CO.0/

CC.1/

1.DEFCO.0/

CC.1/

1.DEF