engine RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals Siemens Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 329, PDF Size: 1.71 MB

Page 302 of 329

13B-302

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests13B

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

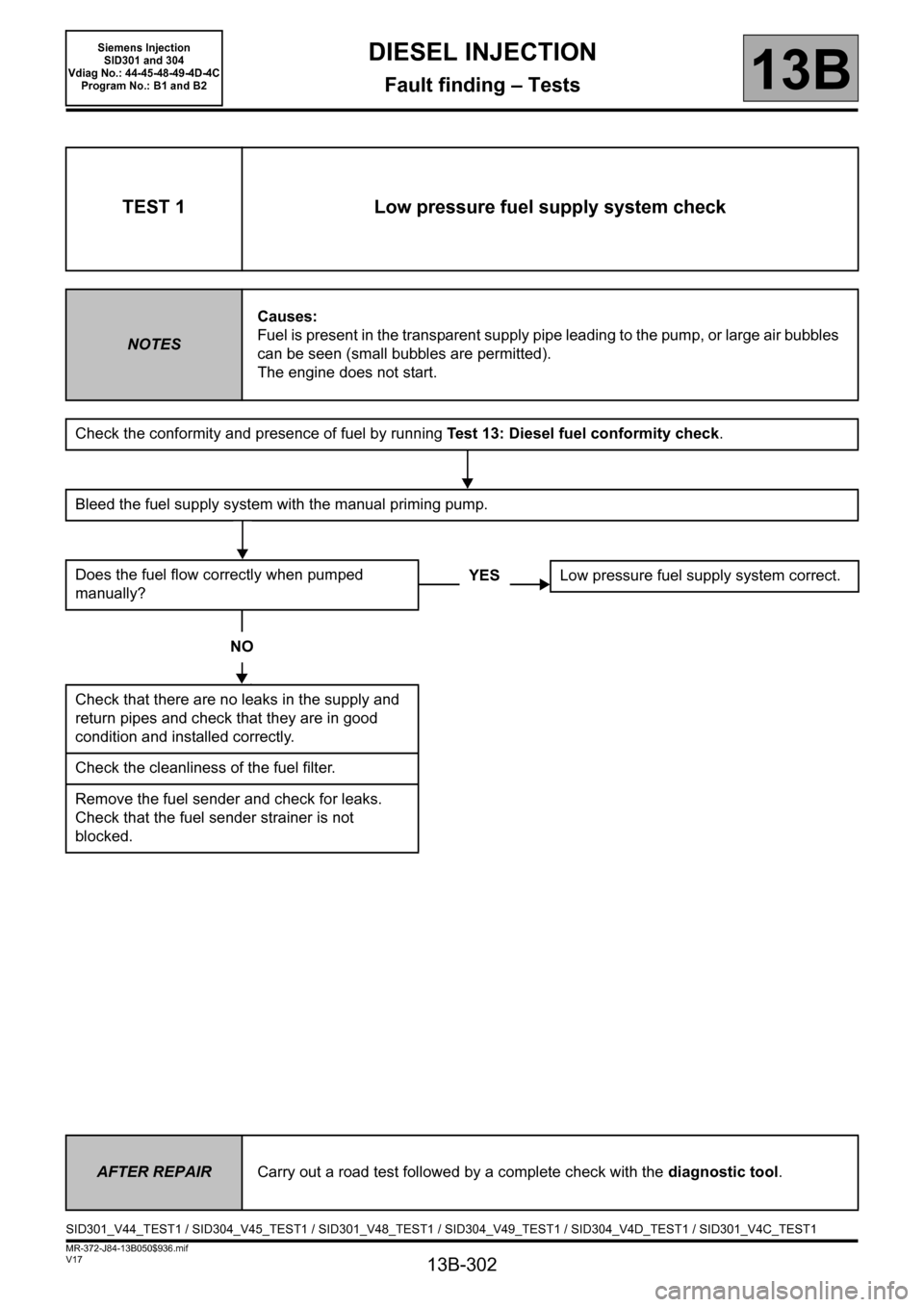

TEST 1 Low pressure fuel supply system check

NOTESCauses:

Fuel is present in the transparent supply pipe leading to the pump, or large air bubbles

can be seen (small bubbles are permitted).

The engine does not start.

Check the conformity and presence of fuel by running Test 13: Diesel fuel conformity check.

Bleed the fuel supply system with the manual priming pump.

Does the fuel flow correctly when pumped

manually?

NO

Check that there are no leaks in the supply and

return pipes and check that they are in good

condition and installed correctly.

Check the cleanliness of the fuel filter.

Remove the fuel sender and check for leaks.

Check that the fuel sender strainer is not

blocked.

YESLow pressure fuel supply system correct.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

SID301_V44_TEST1 / SID304_V45_TEST1 / SID301_V48_TEST1 / SID304_V49_TEST1 / SID304_V4D_TEST1 / SID301_V4C_TEST1

Page 307 of 329

13B-307

MR-372-J84-13B050$936.mif

V17

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2DIESEL INJECTION

Fault finding – Tests13B

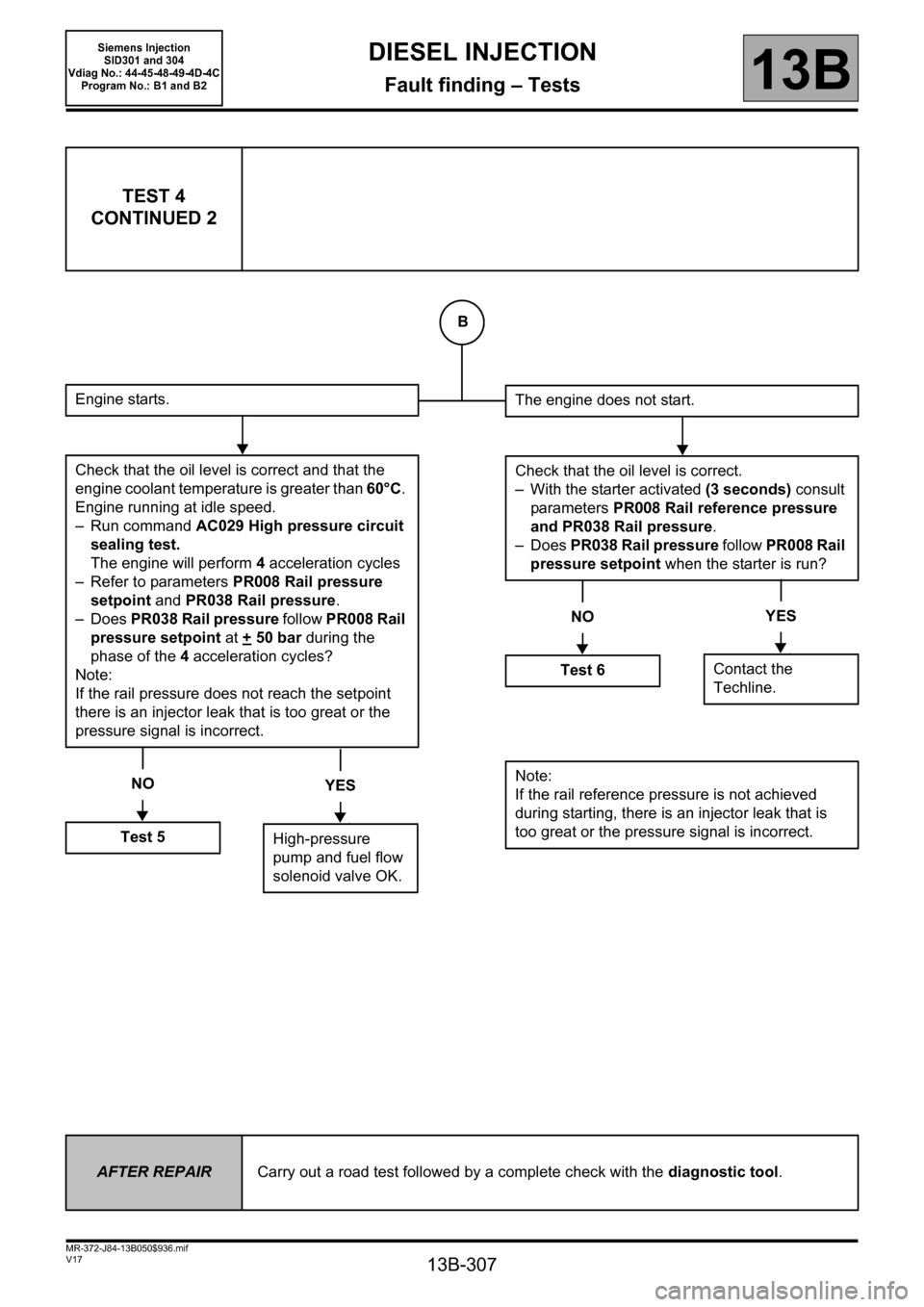

TEST 4

CONTINUED 2

Engine starts.

Check that the oil level is correct and that the

engine coolant temperature is greater than 60°C.

Engine running at idle speed.

– Run command AC029 High pressure circuit

sealing test.

The engine will perform 4acceleration cycles

– Refer to parameters PR008 Rail pressure

setpoint and PR038 Rail pressure.

–Does PR038 Rail pressure follow PR008 Rail

pressure setpoint at +

50 bar during the

phase of the 4 acceleration cycles?

Note:

If the rail pressure does not reach the setpoint

there is an injector leak that is too great or the

pressure signal is incorrect.

NO

Test 5

YES

High-pressure

pump and fuel flow

solenoid valve OK.

The engine does not start.

Check that the oil level is correct.

– With the starter activated (3 seconds) consult

parameters PR008 Rail reference pressure

and PR038 Rail pressure.

–Does PR038 Rail pressure follow PR008 Rail

pressure setpoint when the starter is run?

NO

Test 6

YES

Contact the

Techline.

Note:

If the rail reference pressure is not achieved

during starting, there is an injector leak that is

too great or the pressure signal is incorrect.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

B

Page 308 of 329

13B-308

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests13B

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

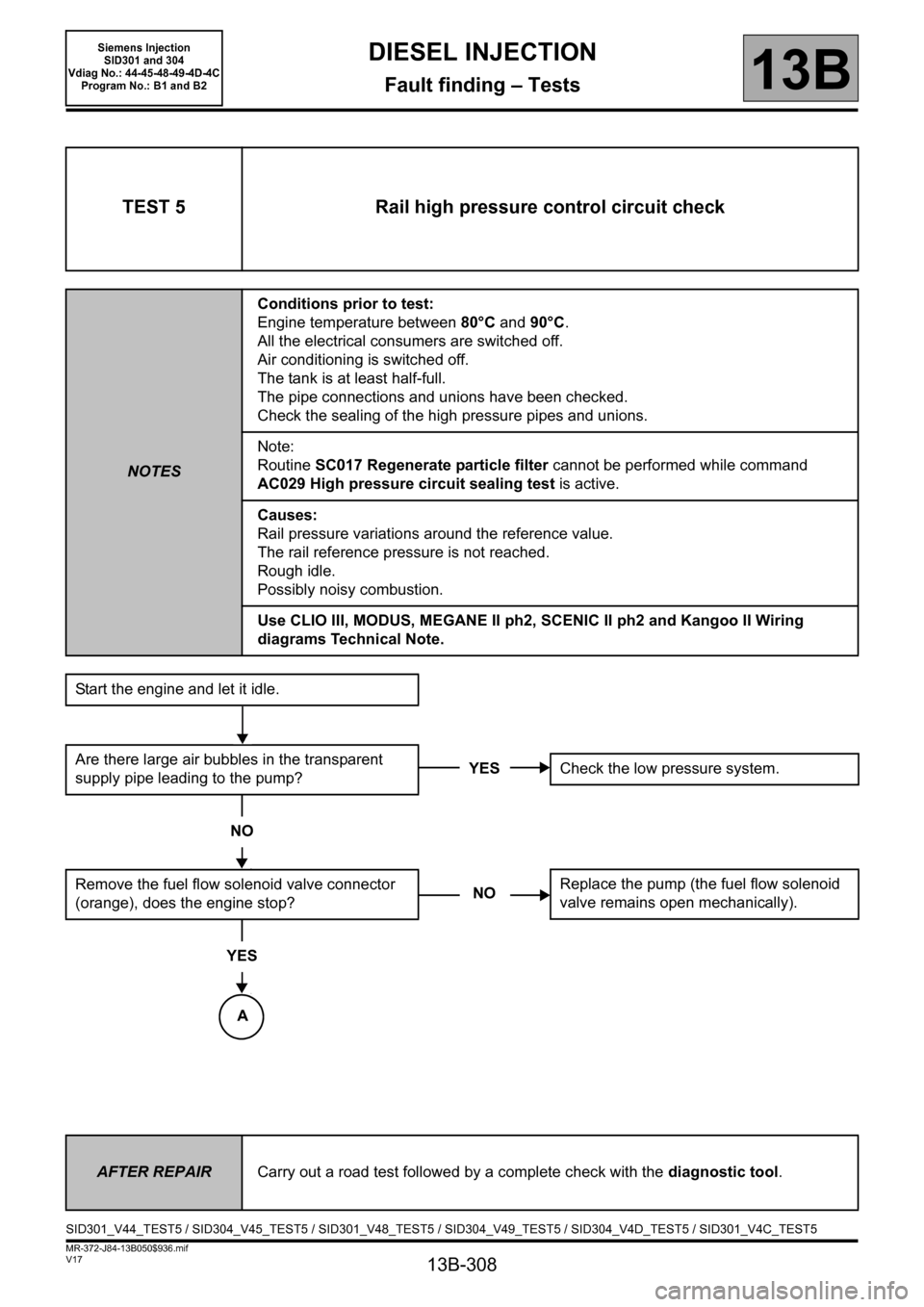

TEST 5 Rail high pressure control circuit check

NOTESConditions prior to test:

Engine temperature between 80°C and 90°C.

All the electrical consumers are switched off.

Air conditioning is switched off.

The tank is at least half-full.

The pipe connections and unions have been checked.

Check the sealing of the high pressure pipes and unions.

Note:

Routine SC017 Regenerate particle filter cannot be performed while command

AC029 High pressure circuit sealing test is active.

Causes:

Rail pressure variations around the reference value.

The rail reference pressure is not reached.

Rough idle.

Possibly noisy combustion.

Use CLIO III, MODUS, MEGANE II ph2, SCENIC II ph2 and Kangoo II Wiring

diagrams Technical Note.

Start the engine and let it idle.

Are there large air bubbles in the transparent

supply pipe leading to the pump?

NO

Remove the fuel flow solenoid valve connector

(orange), does the engine stop?

YES

YESCheck the low pressure system.

NOReplace the pump (the fuel flow solenoid

valve remains open mechanically).

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

SID301_V44_TEST5 / SID304_V45_TEST5 / SID301_V48_TEST5 / SID304_V49_TEST5 / SID304_V4D_TEST5 / SID301_V4C_TEST5

A

Page 309 of 329

13B-309

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests13B

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

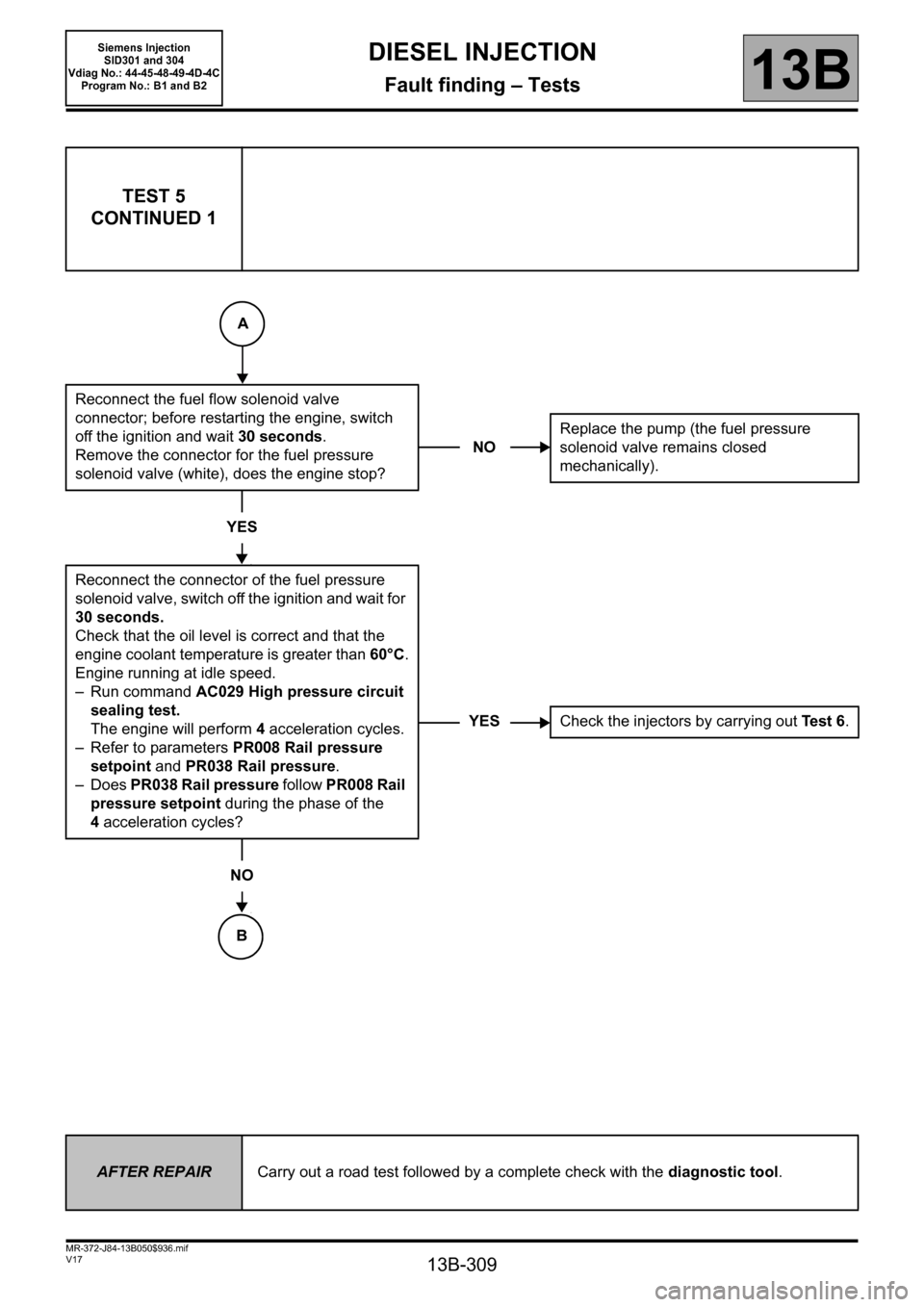

TEST 5

CONTINUED 1

Reconnect the fuel flow solenoid valve

connector; before restarting the engine, switch

off the ignition and wait 30 seconds.

Remove the connector for the fuel pressure

solenoid valve (white), does the engine stop?

YES

Reconnect the connector of the fuel pressure

solenoid valve, switch off the ignition and wait for

30 seconds.

Check that the oil level is correct and that the

engine coolant temperature is greater than 60°C.

Engine running at idle speed.

– Run command AC029 High pressure circuit

sealing test.

The engine will perform 4acceleration cycles.

– Refer to parameters PR008 Rail pressure

setpoint and PR038 Rail pressure.

–Does PR038 Rail pressure follow PR008 Rail

pressure setpoint during the phase of the

4acceleration cycles?

NO

NOReplace the pump (the fuel pressure

solenoid valve remains closed

mechanically).

YESCheck the injectors by carrying out Te s t 6.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

A

B

Page 310 of 329

13B-310

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests13B

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

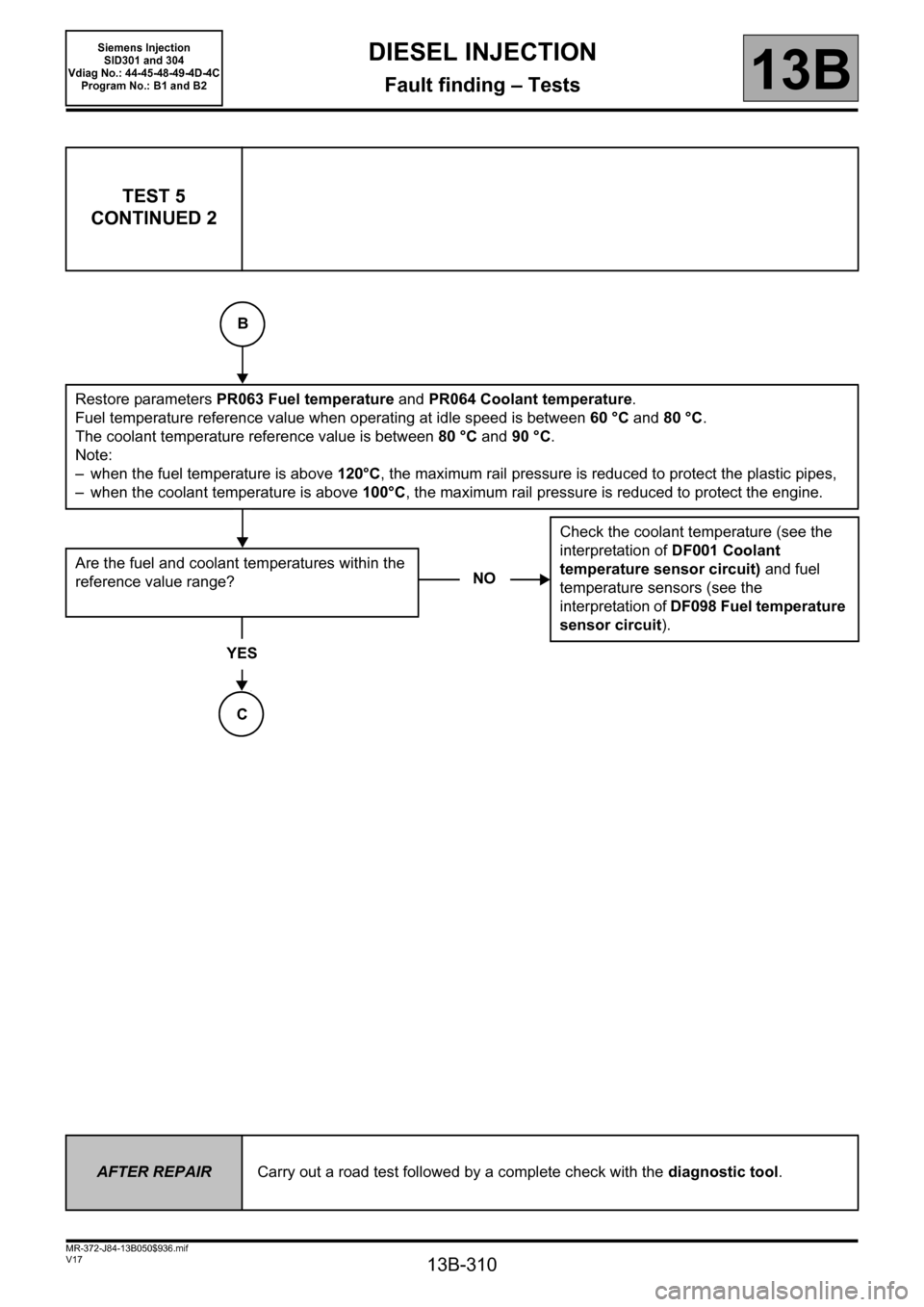

TEST 5

CONTINUED 2

Restore parameters PR063 Fuel temperature and PR064 Coolant temperature.

Fuel temperature reference value when operating at idle speed is between 60 °C and 80 °C.

The coolant temperature reference value is between 80 °C and 90 °C.

Note:

– when the fuel temperature is above 120°C, the maximum rail pressure is reduced to protect the plastic pipes,

– when the coolant temperature is above 100°C, the maximum rail pressure is reduced to protect the engine.

Are the fuel and coolant temperatures within the

reference value range?

YES

NOCheck the coolant temperature (see the

interpretation of DF001 Coolant

temperature sensor circuit) and fuel

temperature sensors (see the

interpretation of DF098 Fuel temperature

sensor circuit).

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

B

C

Page 312 of 329

13B-312

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests13B

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

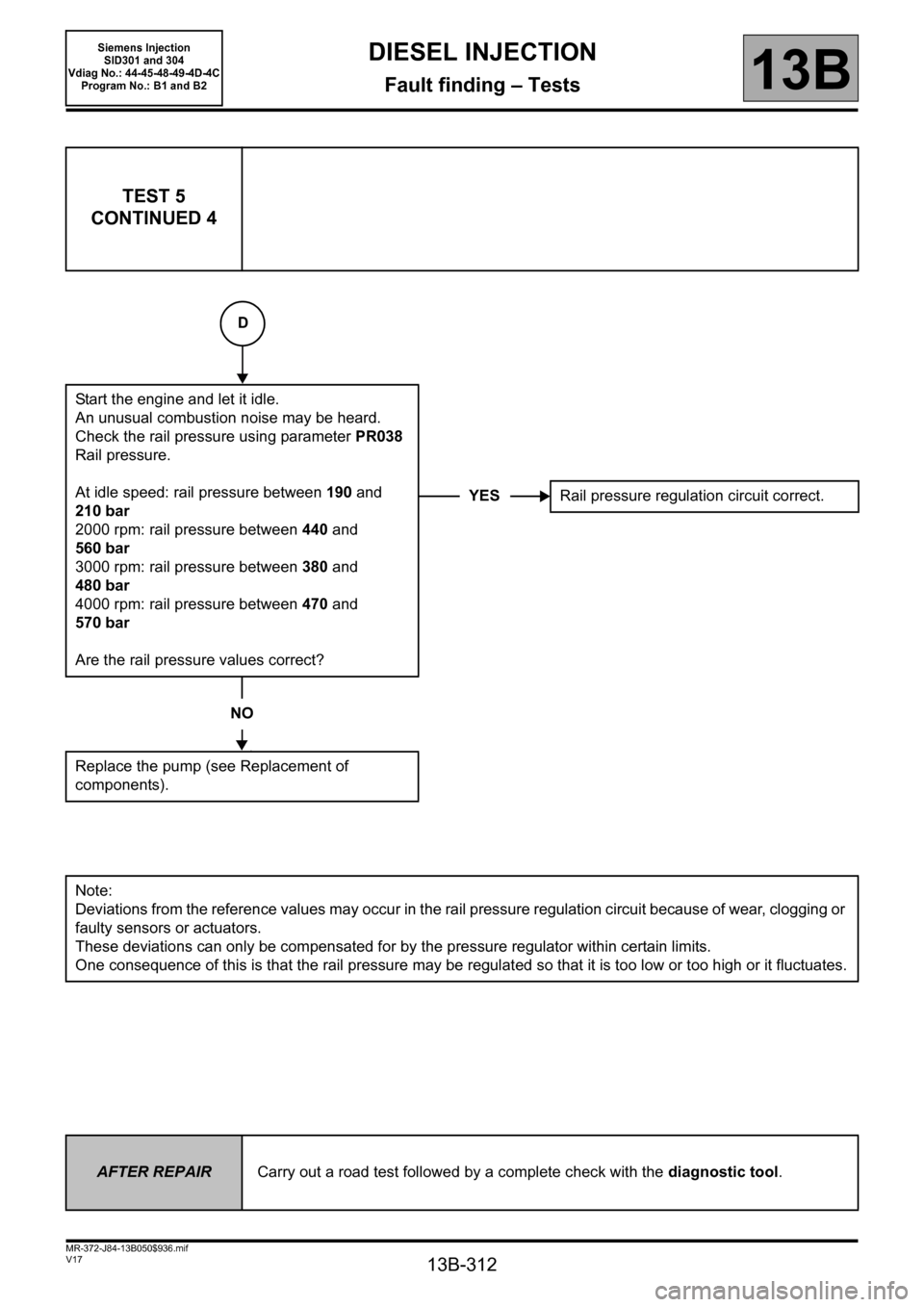

TEST 5

CONTINUED 4

Start the engine and let it idle.

An unusual combustion noise may be heard.

Check the rail pressure using parameter PR038

Rail pressure.

At idle speed: rail pressure between 190 and

210 bar

2000 rpm: rail pressure between 440 and

560 bar

3000 rpm: rail pressure between 380 and

480 bar

4000 rpm: rail pressure between 470 and

570 bar

Are the rail pressure values correct?

NO

Replace the pump (see Replacement of

components).

Note:

Deviations from the reference values may occur in the rail pressure regulation circuit because of wear, clogging or

faulty sensors or actuators.

These deviations can only be compensated for by the pressure regulator within certain limits.

One consequence of this is that the rail pressure may be regulated so that it is too low or too high or it fluctuates.

YESRail pressure regulation circuit correct.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

D

Page 313 of 329

13B-313

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests13B

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

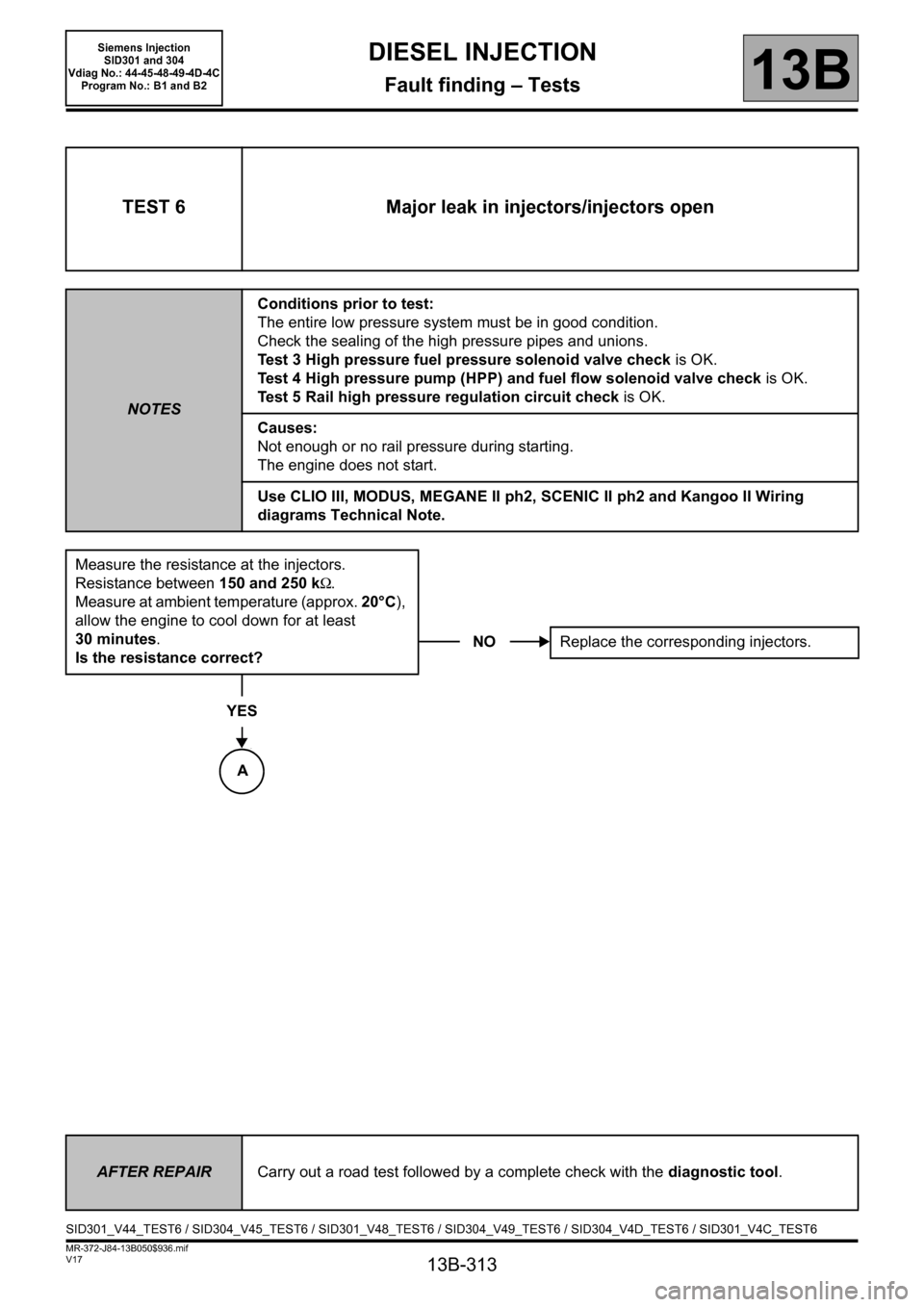

TEST 6 Major leak in injectors/injectors open

NOTESConditions prior to test:

The entire low pressure system must be in good condition.

Check the sealing of the high pressure pipes and unions.

Te s t 3 High pressure fuel pressure solenoid valve check is OK.

Test 4 High pressure pump (HPP) and fuel flow solenoid valve check is OK.

Te s t 5 Rail high pressure regulation circuit check is OK.

Causes:

Not enough or no rail pressure during starting.

The engine does not start.

Use CLIO III, MODUS, MEGANE II ph2, SCENIC II ph2 and Kangoo II Wiring

diagrams Technical Note.

Measure the resistance at the injectors.

Resistance between 150 and 250 kΩ.

Measure at ambient temperature (approx. 20°C),

allow the engine to cool down for at least

30 minutes.

Is the resistance correct?

YES

NOReplace the corresponding injectors.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

SID301_V44_TEST6 / SID304_V45_TEST6 / SID301_V48_TEST6 / SID304_V49_TEST6 / SID304_V4D_TEST6 / SID301_V4C_TEST6

A

Page 314 of 329

13B-314

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests13B

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

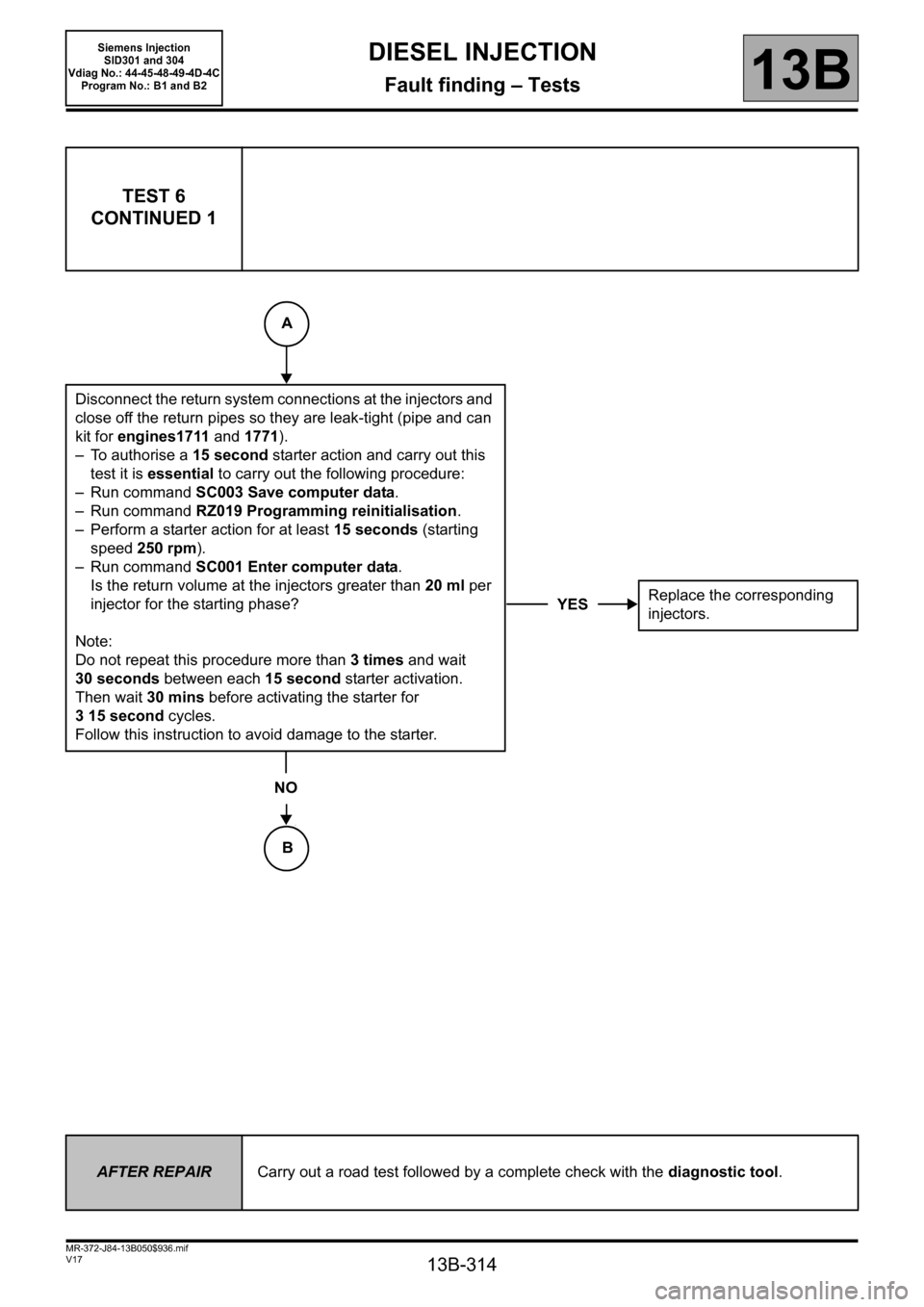

TEST 6

CONTINUED 1

Disconnect the return system connections at the injectors and

close off the return pipes so they are leak-tight (pipe and can

kit for engines1711 and 1771).

– To authorise a 15 second starter action and carry out this

test it is essential to carry out the following procedure:

– Run command SC003 Save computer data.

– Run command RZ019 Programming reinitialisation.

– Perform a starter action for at least 15 seconds (starting

speed 250 rpm).

– Run command SC001 Enter computer data.

Is the return volume at the injectors greater than 20 ml per

injector for the starting phase?

Note:

Do not repeat this procedure more than 3times and wait

30 seconds between each 15 second starter activation.

Then wait 30 mins before activating the starter for

315second cycles.

Follow this instruction to avoid damage to the starter.

NO

YESReplace the corresponding

injectors.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

B

A

Page 316 of 329

13B-316

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests13B

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

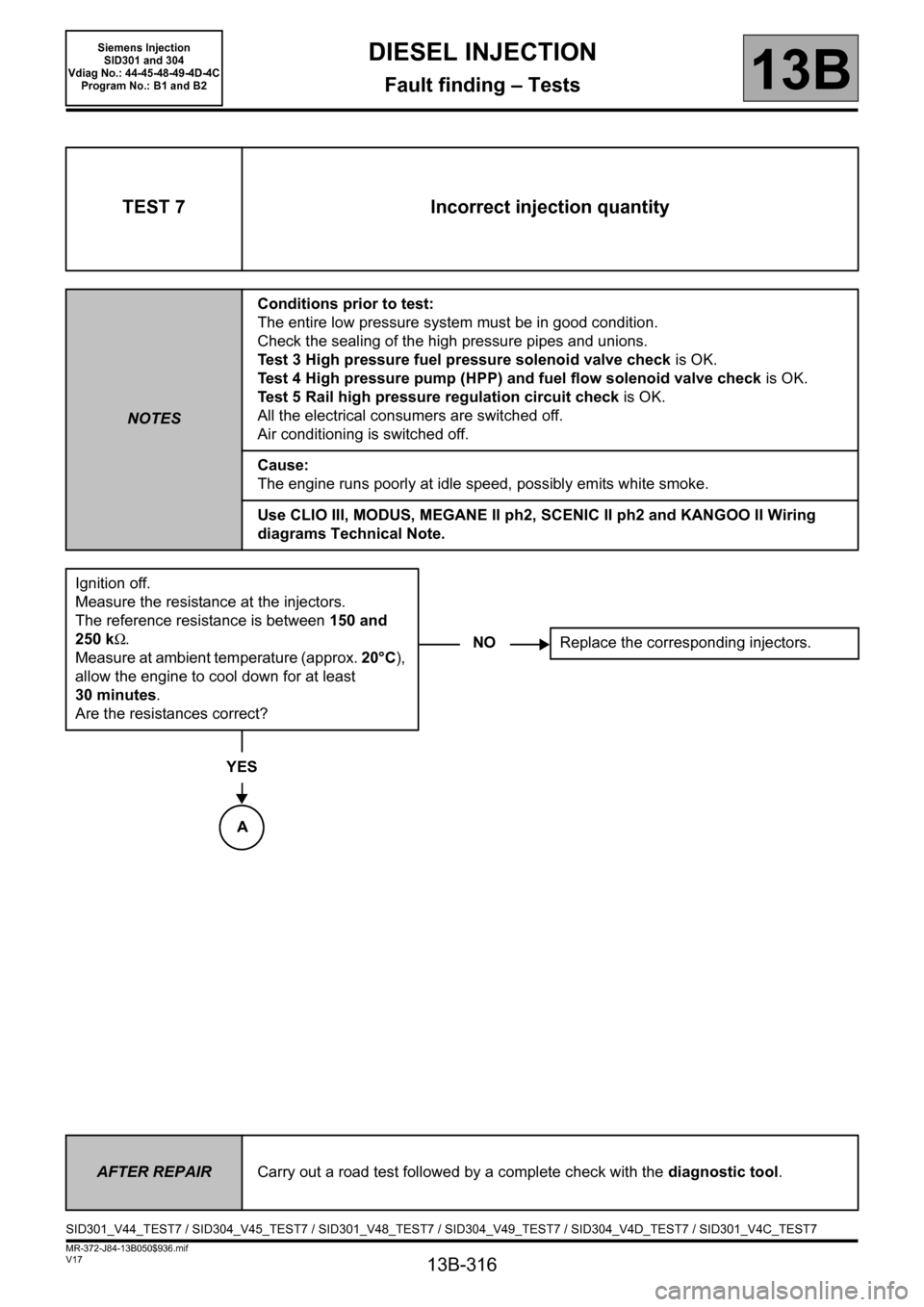

TEST 7 Incorrect injection quantity

NOTESConditions prior to test:

The entire low pressure system must be in good condition.

Check the sealing of the high pressure pipes and unions.

Te s t 3 High pressure fuel pressure solenoid valve check is OK.

Test 4 High pressure pump (HPP) and fuel flow solenoid valve check is OK.

Te s t 5 Rail high pressure regulation circuit check is OK.

All the electrical consumers are switched off.

Air conditioning is switched off.

Cause:

The engine runs poorly at idle speed, possibly emits white smoke.

Use CLIO III, MODUS, MEGANE II ph2, SCENIC II ph2 and KANGOO II Wiring

diagrams Technical Note.

Ignition off.

Measure the resistance at the injectors.

The reference resistance is between 150 and

250 kΩ.

Measure at ambient temperature (approx. 20°C),

allow the engine to cool down for at least

30 minutes.

Are the resistances correct?

YES

NOReplace the corresponding injectors.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

SID301_V44_TEST7 / SID304_V45_TEST7 / SID301_V48_TEST7 / SID304_V49_TEST7 / SID304_V4D_TEST7 / SID301_V4C_TEST7

A

Page 317 of 329

13B-317

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests13B

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

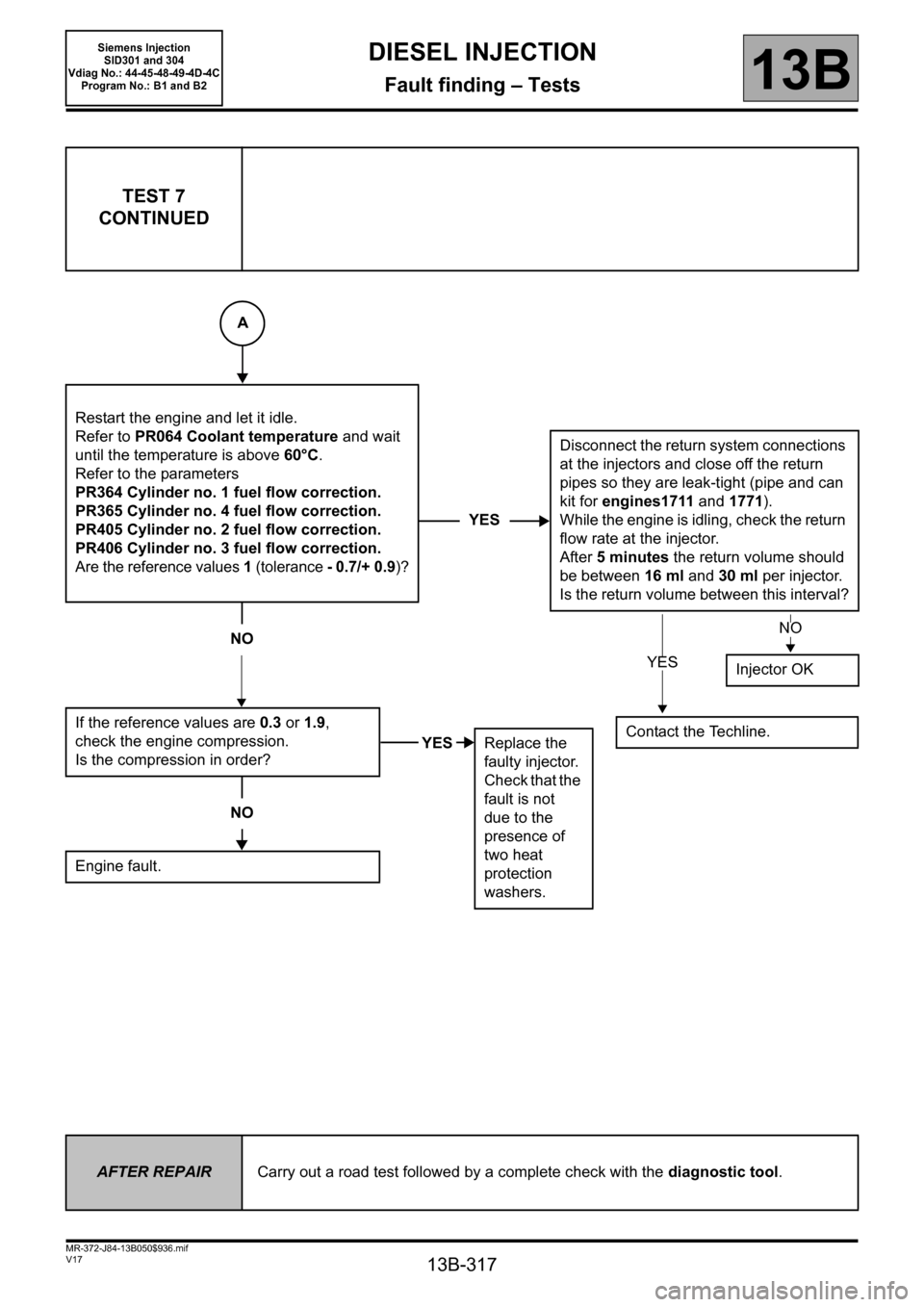

TEST 7

CONTINUED

Restart the engine and let it idle.

Refer to PR064 Coolant temperature and wait

until the temperature is above 60°C.

Refer to the parameters

PR364 Cylinder no. 1 fuel flow correction.

PR365 Cylinder no. 4 fuel flow correction.

PR405 Cylinder no. 2 fuel flow correction.

PR406 Cylinder no. 3 fuel flow correction.

Are the reference values 1 (tolerance - 0.7/+ 0.9)?

NO

If the reference values are 0.3 or 1.9,

check the engine compression.

Is the compression in order?

NO

Engine fault.

YESDisconnect the return system connections

at the injectors and close off the return

pipes so they are leak-tight (pipe and can

kit for engines1711 and 1771).

While the engine is idling, check the return

flow rate at the injector.

After 5minutes the return volume should

be between 16 ml and 30 ml per injector.

Is the return volume between this interval?

Injector OK

Contact the Techline.

NO

YES

YESReplace the

faulty injector.

Check that the

fault is not

due to the

presence of

two heat

protection

washers.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

A