air RENAULT TWINGO 2009 2.G Chasiss Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 281

Page 1 of 281

© Renault s.a.s 2007 "The repair procedures given by the manufacturer in this document are based on the

technical specifications current when it was prepared.

The procedures may be modified as a result of changes introduced by the manufacturer in

the production of the various component units and accessories from which the vehicles are

constructed".All rights reserved by Renault.

Copying or translating, in part or in full, of this document or use of the service part reference

numbering system is forbidden without the prior written authority of Renault.

NOVEMBER 2009 EDITION ANGLAISE

X44

3Chassis

30AGENERAL INFORMATION

31AFRONT AXLE COMPONENTS

33AREAR AXLE COMPONENTS

35AWHEELS AND TYRES

36ASTEERING ASSEMBLY

36BPOWER ASSISTED STEERING

37AMECHANICAL COMPONENT CONTROLS

38CANTI-LOCK BRAKING SYSTEM

Page 2 of 281

TWINGO - Chapitre 3

Contents

Pages

TWINGO - Chapitre 3ContentsPages

30A GENERAL INFORMATION

Brake circuit: Operating

diagram 30A-1

Brake circuit: Precautions for

the repair 30A-2

Braking circuit: Bleed 30A-4

Brake circuit: Tightening

torque 30A-6

Rigid brake pipe: Repair 30A-13

Brake fluid: Specifications 30A-18

Brake: Specifications 30A-19

Steering: Tightening torque 30A-20

Axle assemblies: Check 30A-23

Underbody heights:

Adjustment value 30A-24

Front axle system:

Tightening torque 30A-27

Front axle assembly:

Adjustment values 30A-31

Front axle system:

Adjustment 30A-36

Rear axle system: Tightening

torque 30A-37

Rear axle assembly:

Adjustment values 30A-3831A FRONT AXLE COMPONENTS

Front brake pads: Removal -

Refitting 31A-1

Front brake hose: Removal -

Refitting 31A-6

Front brake calliper: Removal

- Refitting 31A-8

Front brake calliper: Repair 31A-12

Front brake calliper

mounting: Removal -

Refitting 31A-14

Front brake disc protector:

Removal - Refitting 31A-18

Front brake disc: Removal -

Refitting 31A-19

Front brake disc: Description 31A-22

Front driveshaft hub carrier:

Removal - Refitting 31A-23

Front hub carrier bearing:

Removal - Refitting 31A-26

Front shock absorber and

spring: Removal - Refitting 31A-29

Front driveshaft lower arm:

Removal - Refitting 31A-33

Front driveshaft lower arm

ball joint: Removal - Refitting 31A-40

Front axle subframe:

Removal - Refitting 31A-43

Page 6 of 281

30A-2

GENERAL INFORMATION

Brake circuit: Precautions for the repair

30A

I - SAFETY

1 - Advice to be followed before any operation

For an operation requiring the use of a lift, follow the

safety advice (see Vehicle: Towing and lifting) (02A,

Lifting equipment).

The brake regulation circuit must be free of all hydrau-

lic and electrical faults.

In case of incorrect handling, the brake fluid can cause

serious injury and damage. Follow the manufacturer's

instructions for brake fluid.

To prevent dust from entering the master cylinder res-

ervoir and the brake circuit, the plug must be removed

just before filling and closed immediately afterwards,

2 - Instructions to be followed during the operation

Do not press on the brake pedal during work on the

brake system.

If, during work on the brake system, any damage on

any part is observed, it must be repaired before driving

the vehicle again.

Brake fluid is highly corrosive. Ensure any brake fluid

spilt on parts of the vehicle is cleaned off.

Use brake fluids that comply with the Renault standard

(see Vehicle: Parts and consumables for the repair)

.

Check the brake fluid levels in the braking circuit and

the bleeding device.

Check that the pressure of the bleeding device is be-

tween 1.5 bar and 2 bar.

II - CLEANLINESS

1 - Advice to be followed before any operation

Protect any bodywork components that risk being dam-

aged by brake fluid with a cover.

2 - Instructions to be followed during the operation

Fit blanking plugs recommended for the Siemens K9K

injection system at the end of each pipe and in all the

openings of the disconnected components of the brake

circuit.

Clean around the braking system with BRAKE

CLEANER (see Vehicle: Parts and consumables

for the repair) (04B, Consumables - Products).Do not allow friction materials to come into contact with

grease, oil or other lubricants and cleaning products

which are mineral oil based.

III - GENERAL RECOMMENDATIONS

When replacing brake pads, always replace the pads

on the other side as well.

When replacing a disc, always replace the disc on the

opposite side.

When replacing brake discs, you must replace the

brake pads.

Always replace the rigid brake pipe clips.

Reminder:

-The pipes between the master cylinder, callipers and

the hydraulic assembly are connected using threaded

unions with a metric thread.

-Therefore, only parts specified in the Parts Catalogue

for this vehicle should be used. WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

WARNING

In order not to damage the brake hose:

-do not tension the hose,

-do not twist the hose,

-check that there is no contact with the surrounding

components, regardless of the position of the

wheels.

IMPORTANT

To avoid any accident, br ing the pistons, brake pads

and brake discs into contact by depressing the

brake pad several times.

Page 7 of 281

30A-3

GENERAL INFORMATION

Brake circuit: Precautions for the repair

30A

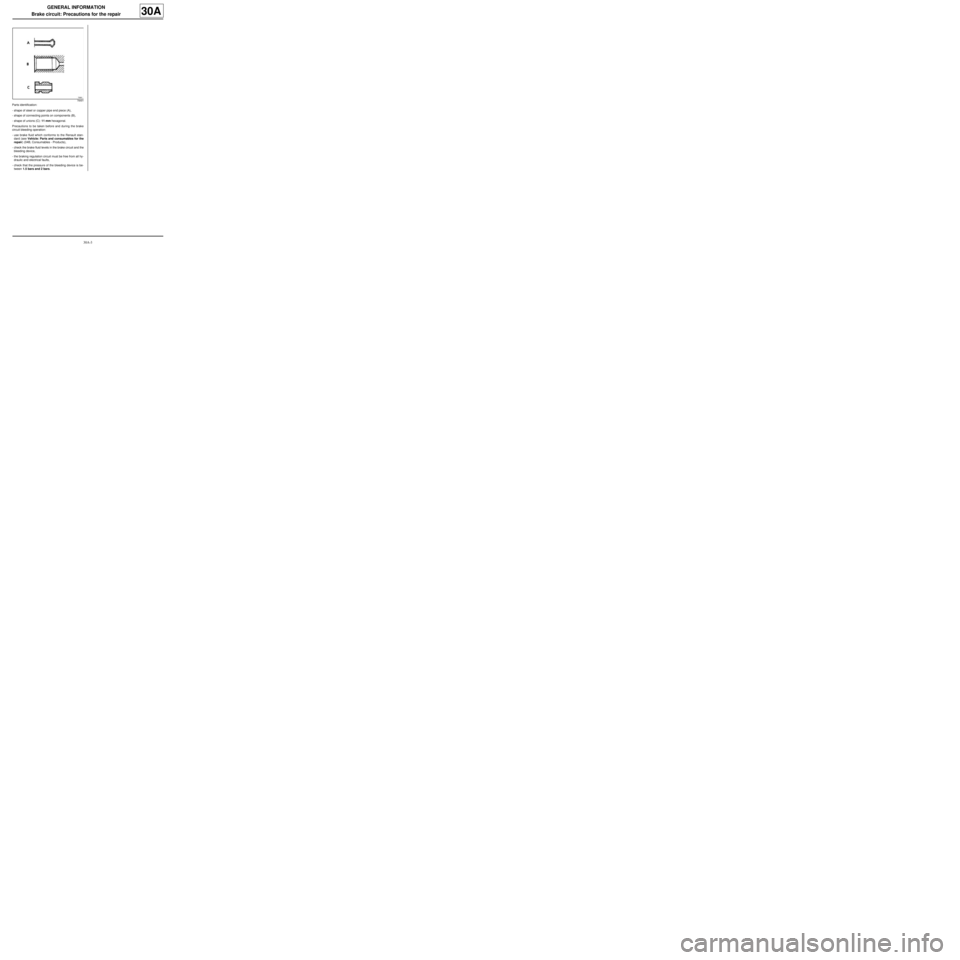

Parts identification:

-shape of steel or copper pipe end piece (A),

-shape of connecting points on components (B),

-shape of unions (C): 11 mm hexagonal.

Precautions to be taken before and during the brake

circuit bleeding operation:

-use brake fluid which conforms to the Renault stan-

dard (see Vehicle: Parts and consumables for the

repair) (04B, Consumables - Products),

-check the brake fluid levels in the brake circuit and the

bleeding device,

-the braking regulation circuit must be free from all hy-

draulic and electrical faults,

-check that the pressure of the bleeding device is be-

tween 1.5 bars and 2 bars.

78491

Page 8 of 281

30A-4

GENERAL INFORMATION

Braking circuit: Bleed

30A

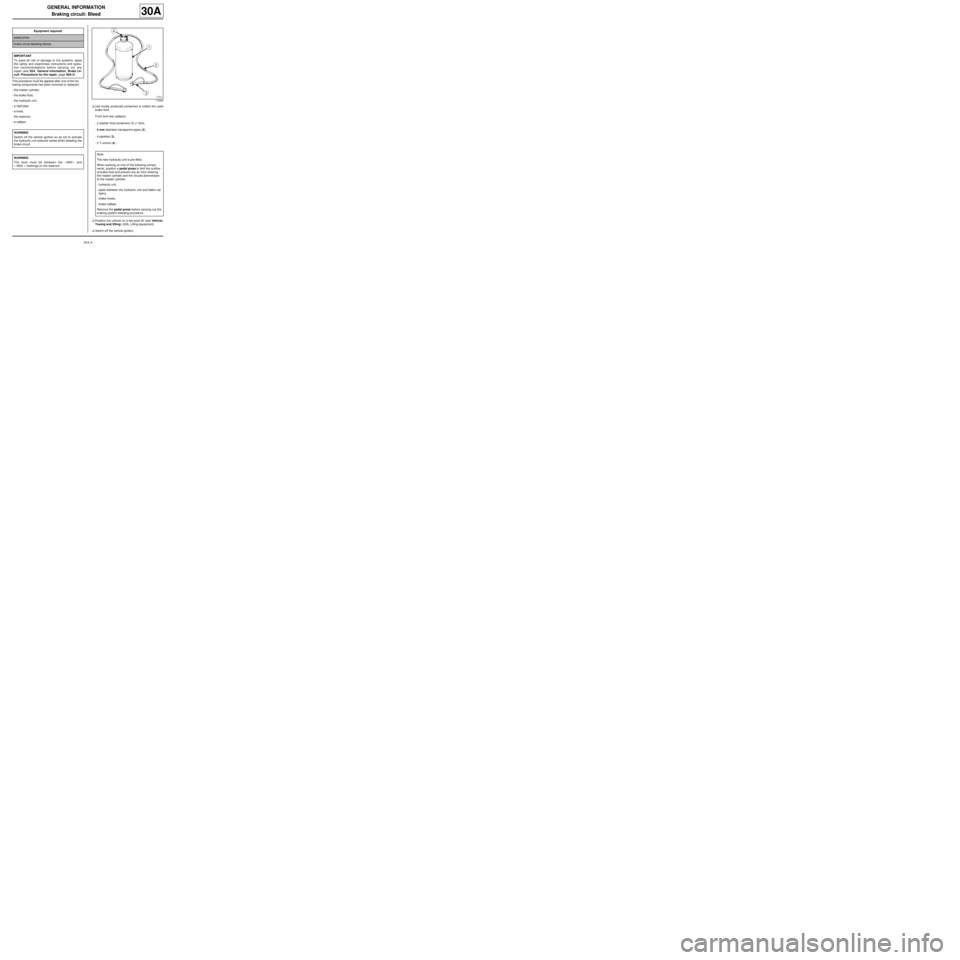

This procedure must be applied after one of the fol-

lowing components has been removed or replaced:

-the master cylinder,

-the brake fluid,

-the hydraulic unit,

-a rigid pipe,

-a hose,

-the reservoir,

-a calliper.aUse locally produced containers to collect the used

brake fluid.

Front and rear callipers:

-2 washer fluid containers (1) (1 litre),

-4 mm diameter transparent pipes (2) ,

-4 pipettes (3) ,

-2 T-unions (4) .

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aSwitch off the vehicle ignition. Equipment required

pedal press

brake circuit bleeding device

IMPORTANT

To avoid all risk of damage to the systems, apply

the safety and cleanliness instructions and opera-

tion recommendations before carrying out any

repair (see 30A, General information, Brake cir-

cuit: Precautions for the repair, page 30A-2) .

WARNING

Switch off the vehicle ignition so as not to activate

the hydraulic unit solenoid valves when bleeding the

brake circuit.

WARNING

The level must be between the « MIN » and

« MAX » markings on the reservoir.

115993

Note:

The new hydraulic unit is pre-filled.

When working on one of the following compo-

nents , position a pedal press to limit the outflow

of brake fluid and prevent any air from entering

the master cylinder and the circuits downstream

of the master cylinder:

-hydraulic unit,

-pipes between the hydraulic unit and brake cal-

lipers,

-brake hoses,

-brake calliper.

Remove the pedal press before carrying out the

braking system bleeding procedure.

Page 9 of 281

30A-5

GENERAL INFORMATION

Braking circuit: Bleed

30A

aConnect the brake circuit bleeding device (after

having received Renault approval) to the master cyl-

inder reservoir (see the instructions for the equip-

ment).

aPressurise the brake circuit.

aAdjust the pressure to between 1.5 bar < P < 2 bar

for 3 minutes to stabilise it in the braking circuit.

aClose the circuit between the bleed screw and brake

fluid reservoir without dumping the pressure.

aFit the bleed containers to the four bleed screws of

the callipers.

aUndo the calliper bleed screws:

-front left-hand,

-front right-hand,

-rear left-hand,

-rear right-hand.

aOpen the circuit between the bleed screw and brake

fluid reservoir and allow the liquid to run until all the

air bubbles have been released.

aTighten the bleed screws in the following order:

-front left-hand,

-front right-hand,

-rear left-hand,

-rear right-hand.

aUndo the calliper bleed screw:

-front left-hand,

-allow the fluid to run until all the air bubbles have

been released,

-tighten the bleed screw on the calliper.

aCarry out the previous operation on the callipers:

-front right-hand,

-rear left-hand,

-rear right-hand.

aClose the bleed screw to dump the pressure in the

brake circuit.aRemove the brake circuit bleeding device from

the master cylinder reservoir.

aCheck pedal travel and resistance. If it is not correct,

finish bleeding the brake circuit with the help of a se-

cond operator. Start the bleed operation by bleeding

the calliper that is the furthest away from the master

cylinder:

-hold down the brake pedal,

-open the circuit bleed screw to release the air from

the brake circuit,

-close the circuit bleed screw,

-release the brake pedal.

aTop up the brake fluid level in the reservoir, if neces-

sary. Check the sealing of the front and rear bleed

screws and ensure that the sealing covers are in

place (see 30A, General information, Brake cir-

cuit: Tightening torque, page 30A-6) .

aDuring a road test, trigger braking regulation to con-

firm that the brake pedal travel is correct.

aClean off any traces of brake fluid on the vehicle us-

ing BRAKE CLEANING PRODUCT (see Vehicle:

Parts and consumables for the repair) Note:

The circuit between the bleed screw and brake

fluid reservoir is closed in different ways depen-

ding on the type of equipment used:

-valve,

-switch.

Page 17 of 281

30A-13

GENERAL INFORMATION

Rigid brake pipe: Repair

30A

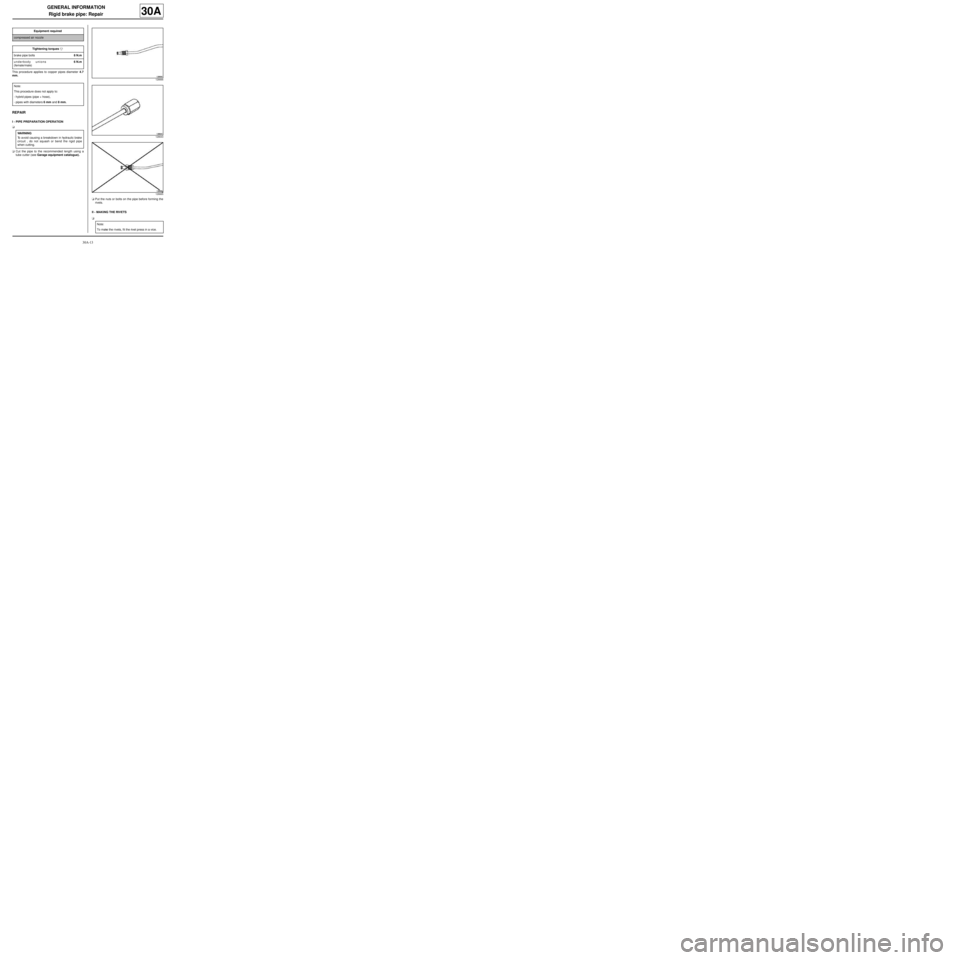

This procedure applies to copper pipes diameter 4.7

mm.

REPAIR

I - PIPE PREPARATION OPERATION

a

aCut the pipe to the recommended length using a

tube cutter (see Garage equipment catalogue).

aPut the nuts or bolts on the pipe before forming the

rivets.

II - MAKING THE RIVETS

a Equipment required

compressed air nozzle

Tightening torquesm

brake pipe bolts8 N.m

underbody unions

(female/male)6 N.m

Note:

This procedure does not apply to:

-hybrid pipes (pipe + hose),

-pipes with diameters 6 mm and 8 mm.

WARNING

To avoid causing a breakdown in hydraulic brake

circuit , do not squash or bend the rigid pipe

when cutting.

128666

128643

128665

Note:

To make the r ivets, fit the rivet press in a vice.

Page 18 of 281

30A-14

GENERAL INFORMATION

Rigid brake pipe: Repair

30A

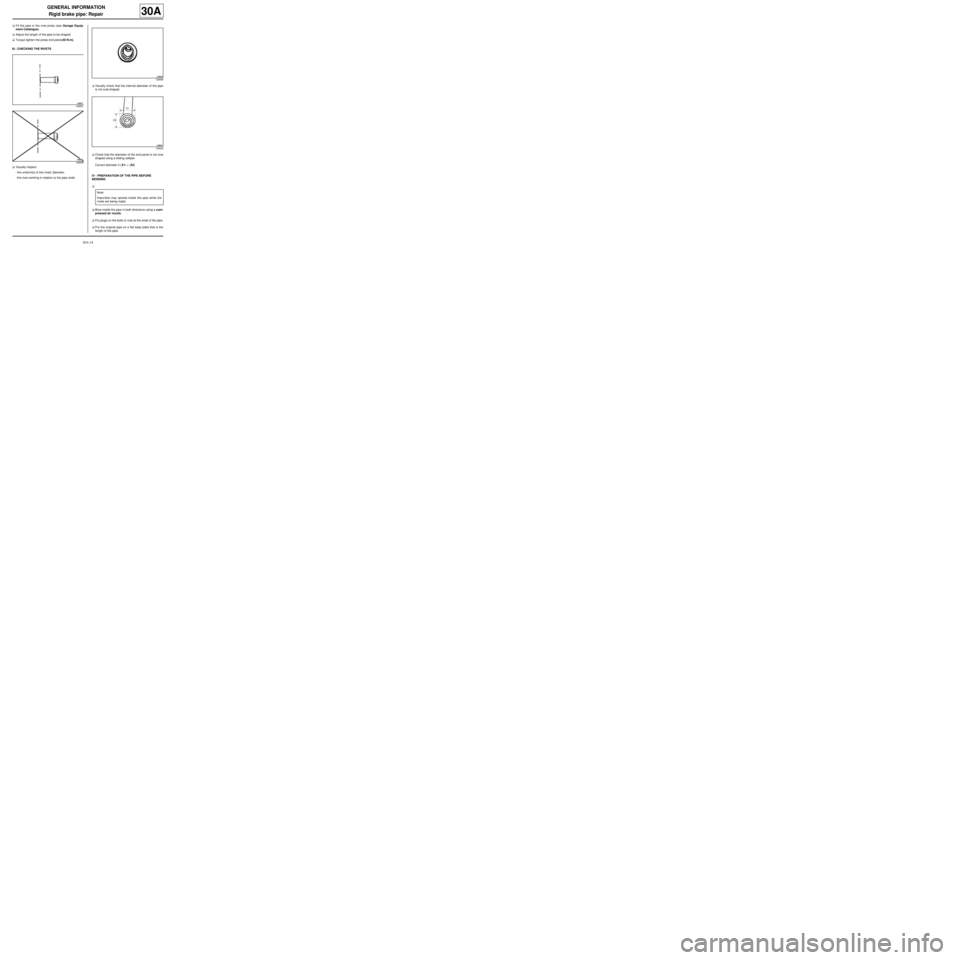

aFit the pipe in the rivet press (see Garage Equip-

ment Catalogue).

aAdjust the length of the pipe to be shaped.

aTorque tighten the press end piece(40 N.m).

III - CHECKING THE RIVETS

aVisually inspect:

-the uniformity of the rivets' diameter,

-the rivet centring in relation to the pipe shaft.aVisually check that the internal diameter of the pipe

is not oval-shaped.

aCheck that the diameter of the end panel is not oval

shaped using a sliding calliper.

Correct diameter if (X1) = (X2)

IV - PREPARATION OF THE PIPE BEFORE

BENDING

a

aBlow inside the pipe in both directions using a com-

pressed air nozzle.

aPut plugs on the bolts or nuts at the ends of the pipe.

aPut the original pipe on a flat base plate that is the

length of the pipe.

128667

128669

128668

128645

Note:

Impurities may spread inside the pipe while the

rivets are being made.

Page 19 of 281

30A-15

GENERAL INFORMATION

Rigid brake pipe: Repair

30A

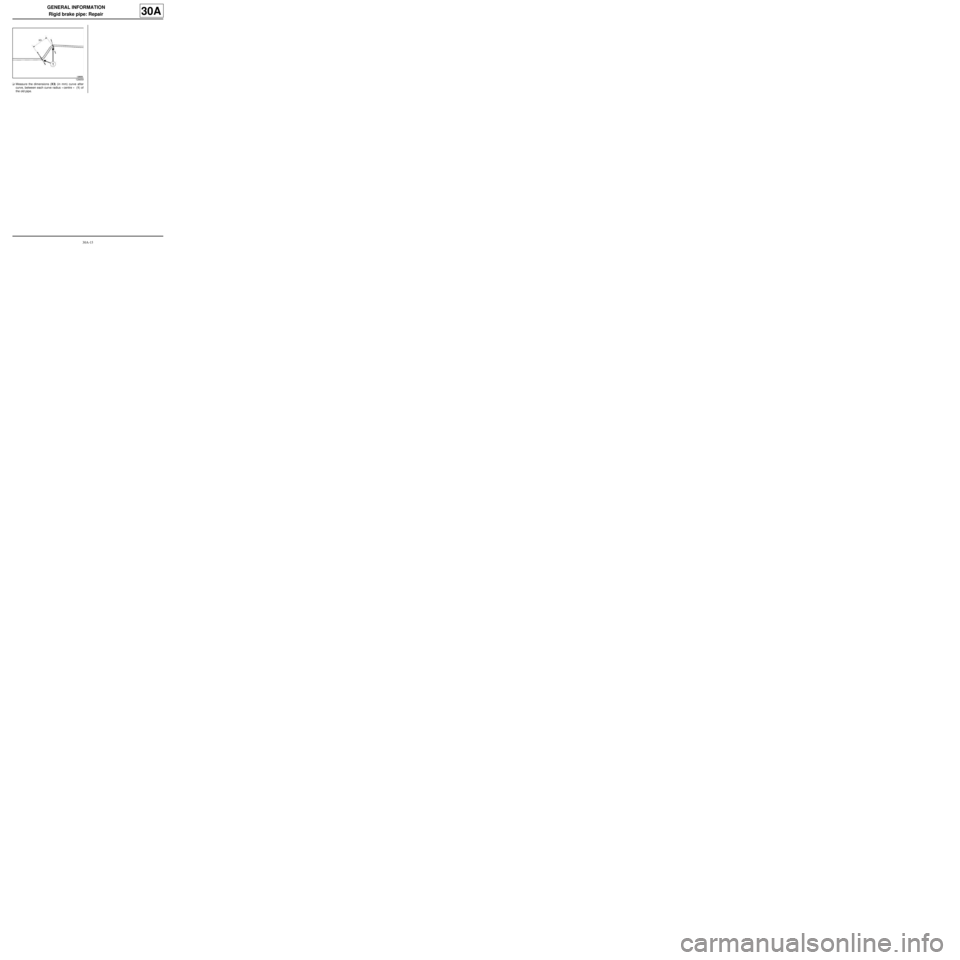

aMeasure the dimensions (X3) (in mm) curve after

curve, between each curve radius « centre » (1) of

the old pipe.

128659

Page 20 of 281

30A-16

GENERAL INFORMATION

Rigid brake pipe: Repair

30A

a

aShape the pipe using a bender, curve after curve,

while respecting the original shape of the pipe.

128814

WARNING

To avoid weakening the pipe, either bend once or

bend progressively by increasing the bend (that

is, by continually decreasing the curve radius).

Do not install a rigid pipe on a vehicle that may

have been bended and then unbended alterna-

tively to reach the correct curve radius.

Note:

During the bending operation, the required angle

should be passed slightly in order to compensate

for material elasticity.