wheel bolts RENAULT TWINGO RS 2009 2.G Chasiss User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 281

Page 66 of 281

31A-23

FRONT AXLE COMPONENTS

Front driveshaft hub carrier: Removal - Refitting

31A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aRemove:

-the front wheel on the side in question (see 35A,

Wheels and tyres, Wheel: Removal - Refitting,

page 35A-1) ,

-the front brake pads of the side in question (see

31A, Front axle components, Front brake pads:

Removal - Refitting, page 31A-1) ,

aRemove:

-the front brake calliper mounting (see 31A, Front

axle components, Front brake calliper mount-

ing: Removal - Refitting, page 31A-14) ,

-the front brake disc (see 31A, Front axle compo-

nents, Front brake disc: Removal - Refitting,

page 31A-19) ,

-the front wheel speed sensor on the hub carrier

(see 38C, Anti-lock braking system, Front wheel

speed sensor: Removal - Refitting, page 38C-

15) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aPosition the (Rou. 604-01).

aRemove the hub nut (1) .

aRemove:

-the nut (2) from the track rod end,

-the bolt (3) from the lower ball joint. Special tooling required

Rou. 604-01Hub locking tool.

Tav. 476Ball joint extractor.

Tav. 1420-01Screw jack for tools Tav.

1420, Tav.1050-04 , Tar.

1454, Tar. 1850.

Tightening torquesm

shock absorber lower

bolts105 Nm

front driveshaft lower

arm ball joint bolt105 Nm

ABS wiring bracket bolt8 Nm

track rod end nut37 N.m

hub nut280 Nm

guide pin upper bolt29 Nm

119543

119222

Page 72 of 281

31A-29

FRONT AXLE COMPONENTS

Front shock absorber and spring: Removal - Refitting31A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see ) (80A, Battery).

aRemove the front wheels (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDetach the wiring (1) from the wheel speed sensor.

aRemove:

-the bolt (2) of the wheel speed sensor wiring brack-

et,

-the wheel speed sensor wiring bracket,

-the shock absorber base nuts (3) ,

-the shock absorber base bolts.

aHang the hub carrier on the body using a safety

strap(s).

aRemove:

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) ,

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the shock absorber nut cover. Equipment required

safety strap(s)

spanner for shock absorber rod nut

Tightening torquesm

new shock absorber rod

nut62 N.m

new shock absorber

base nuts105 N.m

wheel speed sensor wir-

ing bracket bolt8 N.m

119221

Page 74 of 281

31A-31

FRONT AXLE COMPONENTS

Front shock absorber and spring: Removal - Refitting31A

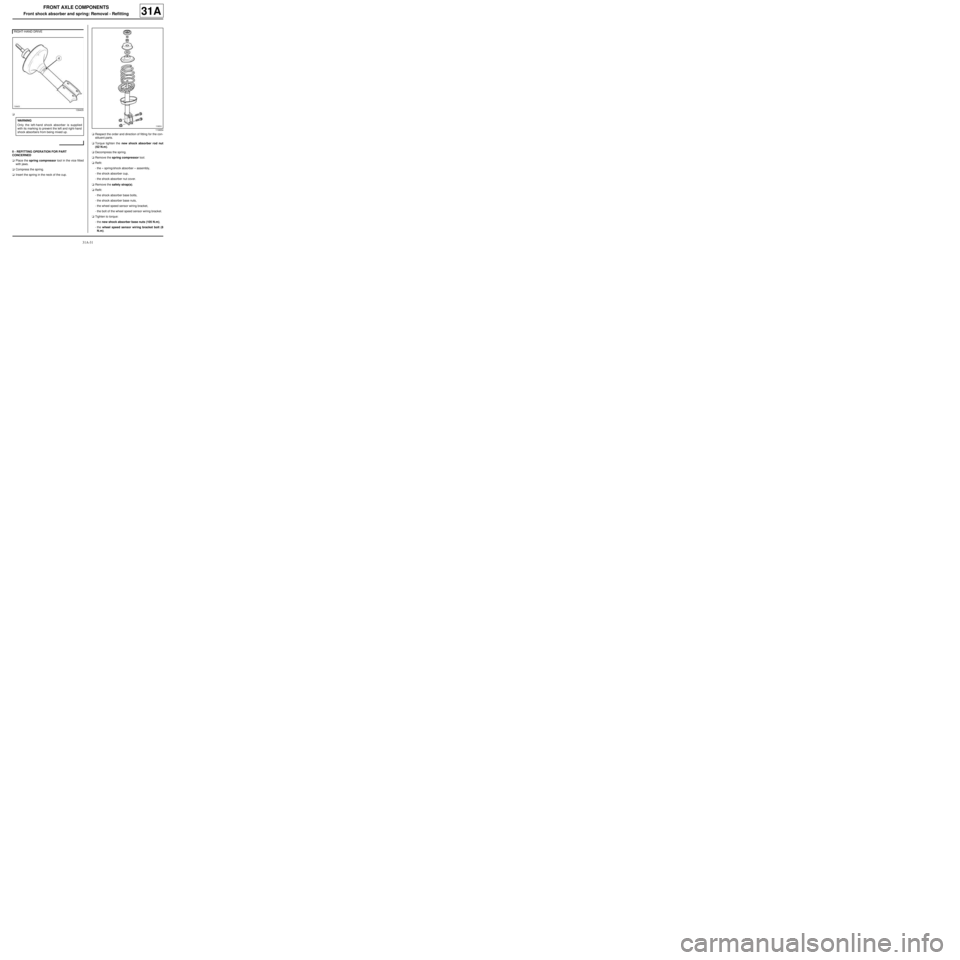

a

II - REFITTING OPERATION FOR PART

CONCERNED

aPlace the spring compressor tool in the vice fitted

with jaws.

aCompress the spring.

aInsert the spring in the neck of the cup.aRespect the order and direction of fitting for the con-

stituent parts.

aTorque tighten the new shock absorber rod nut

(62 N.m).

aDecompress the spring.

aRemove the spring compressor tool.

aRefit:

-the « spring/shock absorber » assembly,

-the shock absorber cup,

-the shock absorber nut cover.

aRemove the safety strap(s).

aRefit:

-the shock absorber base bolts,

-the shock absorber base nuts,

-the wheel speed sensor wiring bracket,

-the bolt of the wheel speed sensor wiring bracket.

aTighten to torque:

-the new shock absorber base nuts (105 N.m),

-the wheel speed sensor wiring bracket bolt (8

N.m). RIGHT-HAND DRIVE

139405

WARNING

Only the left-hand shock absorber is supplied

with its marking to prevent the left and right-hand

shock absorbers from being mixed up.

119654

Page 76 of 281

31A-33

FRONT AXLE COMPONENTS

Front driveshaft lower arm: Removal - Refitting

EQ UIPMENT LEVEL EA0 or EQUIPMENT LEVEL EA1 or EQUIPMENT LEVEL EA3 or EQUIPMENT LEVEL EA5

or EQUIPMENT LEVEL EAG or EQUIPMENT LEVEL EZ2 or EQUIPMENT LEVEL EZ4

31A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the front wheel on the side concerned (see

35A, Wheels and tyres, Wheel: Removal - Refit-

ting, page 35A-1) .aCompress the anti-roll bar rubber mounting bush on

the wheel side using the (Sus. 1413) (1) .

aRemove:

-the bolt (2) from the anti-roll bar on the wheel side,

-the rubber mounting bush from the anti-roll bar on

the wheel side. Special tooling required

Sus. 1413Rubber mounting compres-

sor for fitting the anti-roll bar.

(wheel end).

Tightening torquesm

front driveshaft lower

arm bolts105 Nm

lower ball joint bolt105 Nm

acoustic tie-rod nut62 Nm

acoustic tie-rod bolt21 Nm

anti-roll bar bolt on the

wheel side14 Nm

119346

Page 80 of 281

31A-37

FRONT AXLE COMPONENTS

Front driveshaft lower arm: Removal - Refitting

EQ UIPMENT LEVEL SPORT

31A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the front wheel (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .

aDetach the wheel arch liner (1) .aRemove:

-the bolt (2) from the acoustic tie-rod,

-the nut (3) from the acoustic tie-rod,

-the acoustic tie-rod. Tightening torquesm

front driveshaft lower

arm bolts105 N.m

lower ball joint nut62 N.m

acoustic tie-rod nut62 N.m

acoustic tie-rod bolt21 N.m

119209

119210

Page 82 of 281

31A-39

FRONT AXLE COMPONENTS

Front driveshaft lower arm: Removal - Refitting

EQ UIPMENT LEVEL SPORT

31A

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit the front driveshaft lower arm.

aFit the lower ball joint on the front driveshaft hub car-

rier.

aTorque tighten the front driveshaft lower arm

bolts (105 N.m ).

aTorque tighten the lower ball joint nut (62 N.m).

II - FINAL OPERATION

aRefit the acoustic tie-rod.

aTorque tighten:

-the acoustic tie-rod nut (62 N.m),

-the acoustic tie-rod bolt (21 N.m).

aRefit the front wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

aCheck the front axle geometry (see 30A, General

information, Front axle assembly: Adjustment

values, page 30A-31) .

119344

Note:

Ensure that direction of fitting for the front drive-

shaft lower arm bolts is correct.

Page 86 of 281

31A-43

FRONT AXLE COMPONENTS

Front axle subframe: Removal - Refitting

31A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the front wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion).II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the universal joint cover (1) (do not keep).

aSet the wheels straight ahead.

aFit a flywheel immobiliser.

aRemove the bolt (2) from the universal joint (do not

keep).

aTilt the universal joint on the steering box to detach it

from the pinion. Special tooling required

Tav. 476Ball joint extractor.

Mot. 1390Suppor t for removal - refitting

of engine - gearbox assembly

Equipment required

flywheel immobiliser

Tightening torquesm

rear subframe bolts105 Nm

front subframe bolts62 Nm

front end cross member

bolts21 Nm

acoustic tie-rod bolts21 Nm

acoustic tie-rod bolts90 Nm

subframe tie-rod bolts21 Nm

subframe tie-rod nuts62 Nm

gear lever arm nut28 Nm

nuts of the lower arm

ball joints62 N.m

bolts of the lower ball

joints62 N.m

nuts of the track rod

ends37 N.m

universal joint bolt24 Nm

119544

Note:

Do not pull the intermediate shaft out.

Page 92 of 281

31A-49

FRONT AXLE COMPONENTS

Front axle subframe: Removal - Refitting

31A

aCheck that the bush (25) is correctly positioned on

the lower arm ball joint.

aRefit:

-the lower arm ball joints,

-the track rod ends.

aRefit the anti-roll bar tie-rods to the shock absorbers.

aTorque tighten the nuts of the lower arm ball

joints (62 N.m).

aTorque tighten the bolts of the lower ball joints (62

N.m).

aTorque tighten the nuts of the track rod ends (37

N.m).

aObserve the direction of fitting for the universal joint

cam nut and bolt.

afit the universal joint to the steering box.aRefit the universal joint cam nut and a new bolt.

aPosition the universal joint cam nut and bolt.

aImmobilise the cam nut in its housing (on the univer-

sal joint).

aPretighten the universal joint cam nut and bolt.

aCheck that the universal joint is in the correct posi-

tion.

aTorque tighten the universal joint bolt (24 Nm).

aRemove the flywheel immobiliser.

III - FINAL OPERATION.

aRefit:

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

119223

EQ UIPMENT LEVEL SPORT

EQUIPMENT LEVEL EA0 or EQUIPMENT LEVEL

EA1 or EQUIPMENT LEVEL EA3 or EQUIPMENT

LEVEL EA5 or EQUIPMENT LEVEL EAG

116021

116022

Page 95 of 281

31A-52

FRONT AXLE COMPONENTS

Front anti-roll bar: Removal - Refitting

EQ UIPMENT LEVEL EA0 or EQUIPMENT LEVEL EA1 or EQUIPMENT LEVEL EA3 or EQUIPMENT LEVEL EA5

or EQUIPMENT LEVEL EAG or EQUIPMENT LEVEL EZ2 or EQUIPMENT LEVEL EZ4

31A

Anti-roll bar specifications:

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the front axle subframe (see 31A, Front

axle components, Front axle subframe: Removal

- Refitting, page 31A-43) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aCompress the anti-roll bar rubber mounting bush on

the wheel side using the (Sus. 1413).

aRemove:

-the bolt (1) from the anti-roll bar on the wheel side,

-the rubber mounting bush from the anti-roll bar,

-the anti-roll bar bearing bolts (2) ,

-the anti-roll bar bearings,

-the anti-roll bar,

-the rubber mounting bush from the anti-roll bar

bearing.

REFITTING

REFITTING OPERATION FOR PART CONCERNED

aRefit:

-the anti-roll bar bearing rubber mounting bush,

-the anti-roll bar.

aFit the anti-roll bar bearings into the subframe neck. Special tooling required

Sus. 1413Rubber mounting compres-

sor for fitting the anti-roll bar.

(wheel end).

Sus. 1824Fork for fitting the anti-roll bar

centre bearings.

Tightening torquesm

anti-roll bar bearing

bolts on the subframe35 Nm

anti-roll bar bolt on the

wheel side14 Nm

Engine Ø of the strut in

mm

D7F 25

D4F, K9K 26

119406

Page 96 of 281

31A-53

FRONT AXLE COMPONENTS

Front anti-roll bar: Removal - Refitting

EQ UIPMENT LEVEL EA0 or EQUIPMENT LEVEL EA1 or EQUIPMENT LEVEL EA3 or EQUIPMENT LEVEL EA5

or EQUIPMENT LEVEL EAG or EQUIPMENT LEVEL EZ2 or EQUIPMENT LEVEL EZ4

31A

aFit the (Sus. 1824) (3) on the anti-roll bar.

aLift the (Sus. 1824).

aRefit the anti-roll bar bearing bolts (4) .

aTorque tighten the anti-roll bar bearing bolts on

the subframe (35 Nm).

aRefit:

-the anti-roll bar rubber mounting bush on the wheel

side,

-the anti-roll bar bolt on the wheel side.aRefit the front axle subframe (see 31A, Front axle

components, Front axle subframe: Removal -

Refitting, page 31A-43) .

aCompress the anti-roll bar rubber mounting bush on

the wheel side using the (Sus. 1413) (5) .

aRefit the anti-roll bar nut (6) on the wheel side.

aTorque tighten the anti-roll bar bolt on the wheel

side ( 14 Nm).

119403

119404

12992