wheel bolts RENAULT TWINGO RS 2009 2.G Chasiss Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 281

Page 97 of 281

31A-54

FRONT AXLE COMPONENTS

Front anti-roll bar: Removal - Refitting

EQ UIPMENT LEVEL SPORT

31A

Anti-roll bar specifications:

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the front wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the wheel arch liners (see Front wheel arch liner:

Removal - Refitting) (55A, Exterior protection),

-the front axle subframe (see 31A, Front axle com-

ponents, Front axle subframe: Removal - Refit-

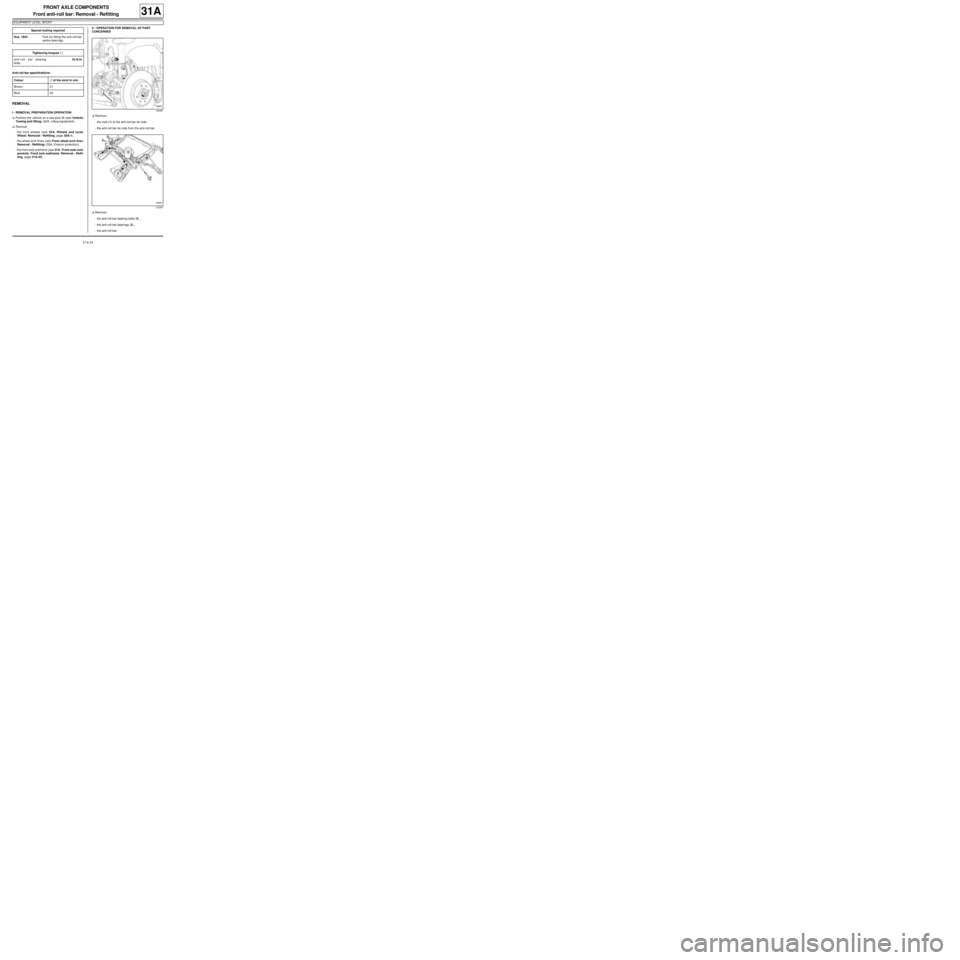

ting, page 31A-43) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the nuts (1) of the anti-roll bar tie rods,

-the anti-roll bar tie rods from the anti-roll bar.

aRemove:

-the anti-roll bar bearing bolts (2) ,

-the anti-roll bar bearings (3) ,

-the anti-roll bar, Special tooling required

Sus. 1824Fork for fitting the anti-roll bar

centre bearings.

Tightening torquesm

anti-roll bar bearing

bolts35 N.m

Colour∅ of the strut in mm

Brown 21

Blue 20132461

132457

Page 98 of 281

31A-55

FRONT AXLE COMPONENTS

Front anti-roll bar: Removal - Refitting

EQ UIPMENT LEVEL SPORT

31A

-the rubber mounting bushes of the anti-roll bar

bearings.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

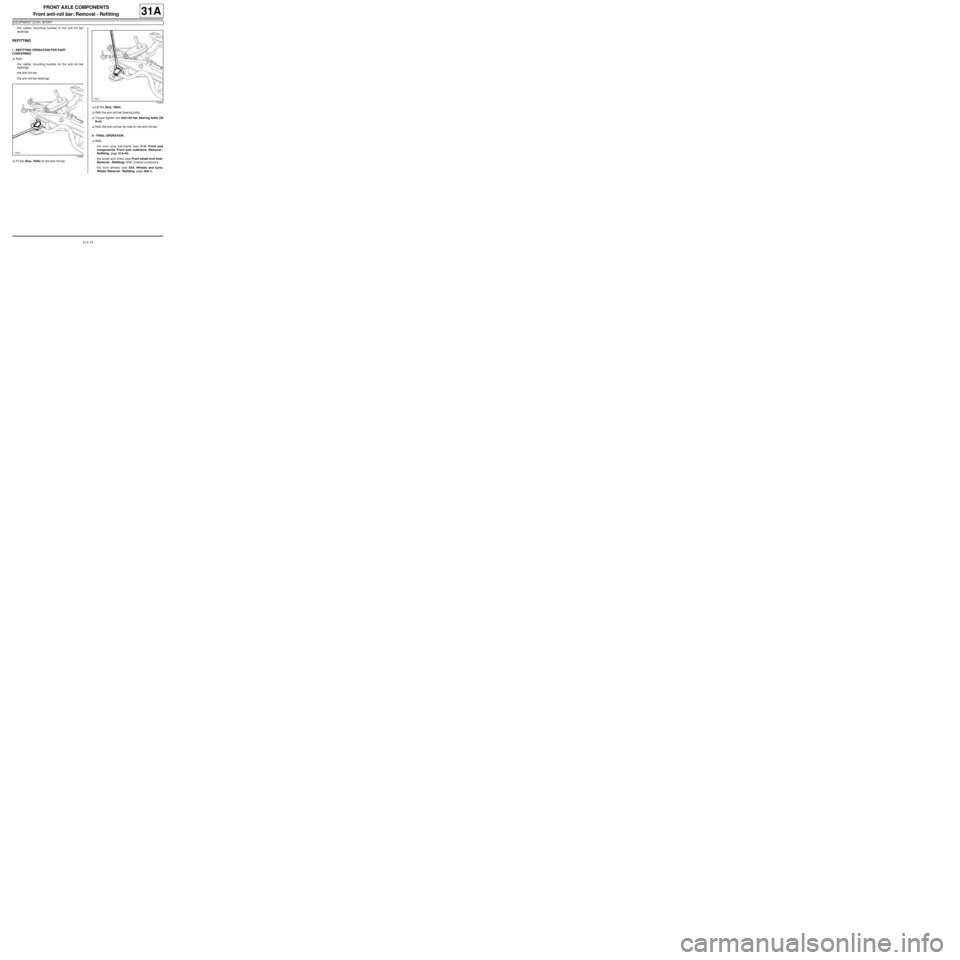

aRefit:

-the rubber mounting bushes on the anti-roll bar

bearings,

-the anti-roll bar,

-the anti-roll bar bearings.

aFit the (Sus. 1824) on the anti-roll bar.aLift the (Sus. 1824).

aRefit the anti-roll bar bearing bolts.

aTorque tighten the anti-roll bar bearing bolts (35

N.m).

aRefit the anti-roll bar tie rods on the anti-roll bar.

II - FINAL OPERATION.

aRefit:

-the front axle sub-frame (see 31A, Front axle

components, Front axle subframe: Removal -

Refitting, page 31A-43) ,

-the wheel arch liners (see Front wheel arch liner:

Removal - Refitting) (55A, Exterior protection),

-the front wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

119403

119404

Page 99 of 281

33A-1

REAR AXLE COMPONENTS

Rear brake pads: Removal - Refitting

EQ UIPMENT LEVEL SPORT

33A

When replacing brake pads, be sure to replace the

pads on the opposite side.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRelease the parking brake.

aRemove the rear wheels (see 35A, Wheels and ty-

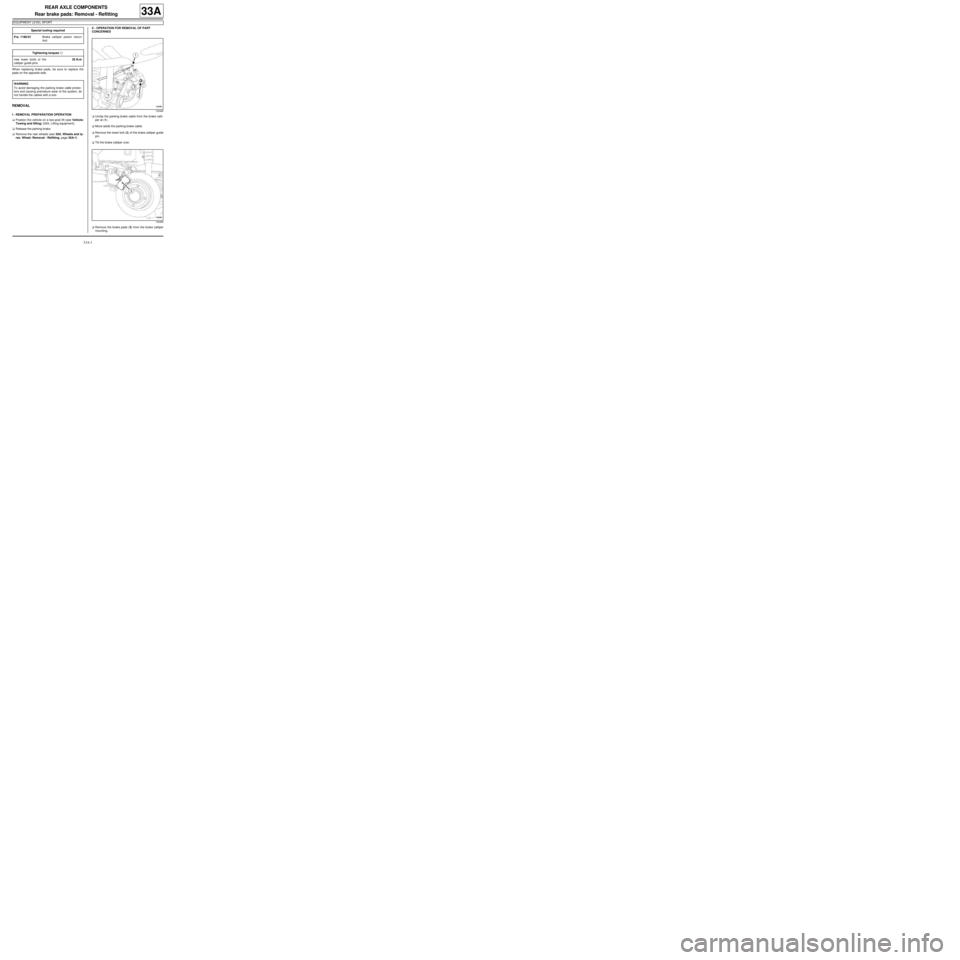

res, Wheel: Removal - Refitting, page 35A-1) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

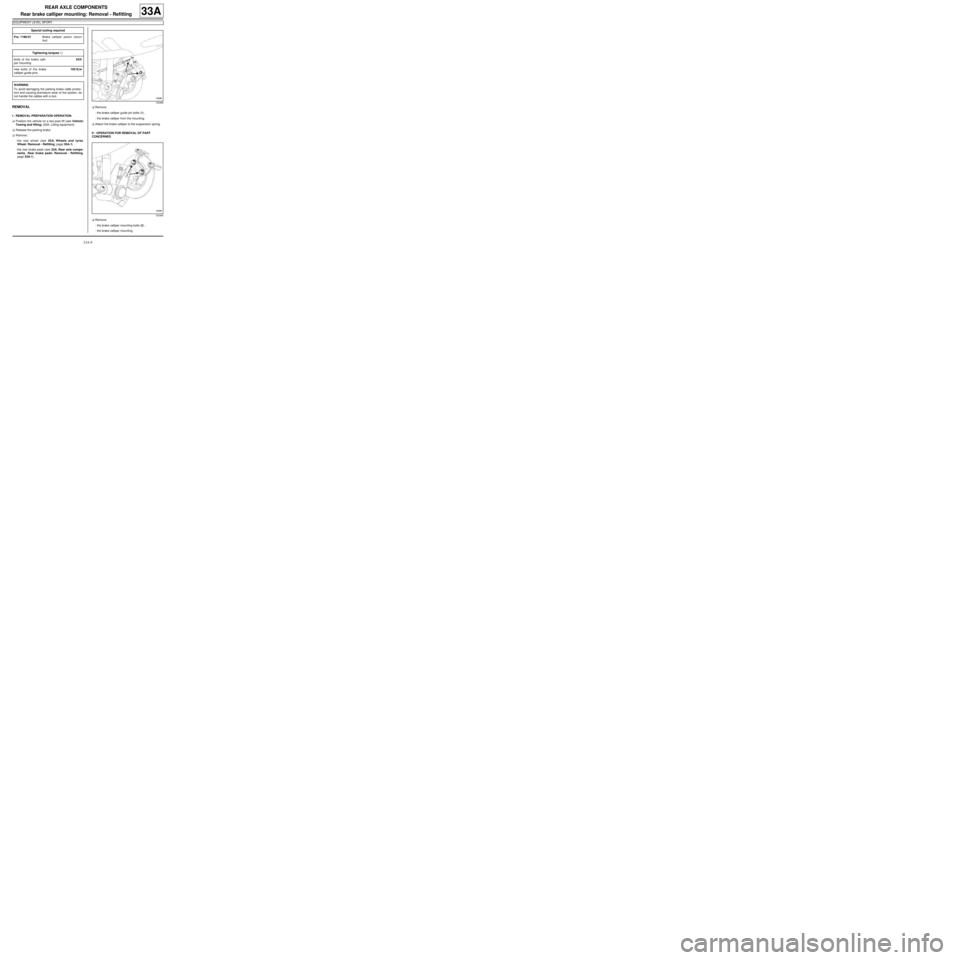

aUnclip the parking brake cable from the brake calli-

per at (1) .

aMove aside the parking brake cable.

aRemove the lower bolt (2) of the brake calliper guide

pin.

aTilt the brake calliper over.

aRemove the brake pads (3) from the brake calliper

mounting. Special tooling required

Fre. 1190-01Brake calliper piston return

tool.

Tightening torquesm

new lower bolts of the

calliper guide pins35 N.m

WARNING

To avoid damaging the parking brake cable protec-

tors and causing premature wear of the system, do

not handle the cables with a tool.

132468

132466

Page 101 of 281

33A-3

REAR AXLE COMPONENTS

Rear brake pads: Removal - Refitting

EQ UIPMENT LEVEL SPORT

33A

aFit:

-the brake callipers,

-the parking brake cables.

aTorque tighten the new lower bolts of the calliper

guide pins (35 N.m).

aClip on the handbrake cables.

III - FINAL OPERATION

aRefit the rear wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

IMPORTANT

To avoid any accident, bring the pistons, brake

pads and brake discs into contact by depressing

the brake pad several times.

Page 105 of 281

33A-7

REAR AXLE COMPONENTS

Rear brake calliper: Removal - Refitting

EQ UIPMENT LEVEL SPORT

33A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRelease the parking brake.

aPosition a pedal press on the brake pedal to limit

the outflow of brake fluid.

aRemove the rear wheel (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

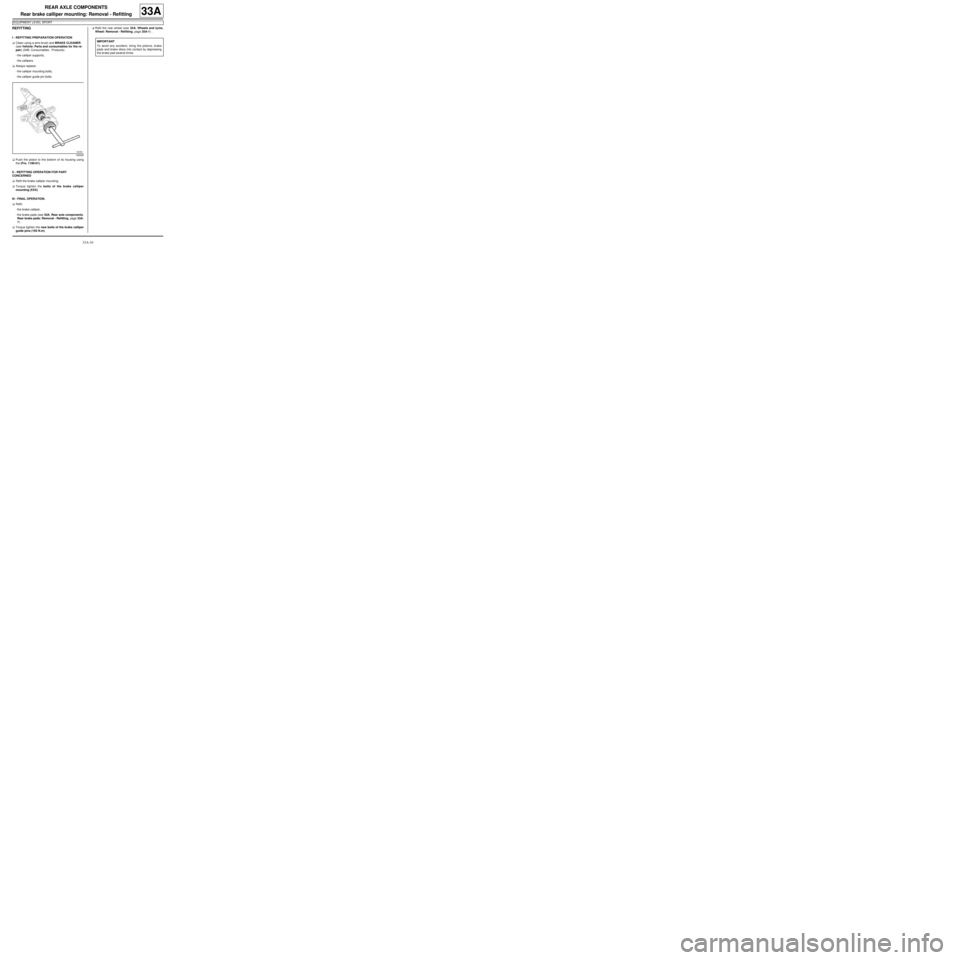

aUnclip the parking brake cable from the brake calli-

per at (1) .

aMove aside the parking brake cable.

aLoosen the calliper brake pipe union (2) .

aRemove:

-the brake calliper guide pin bolts (3) ,

-the brake calliper from the mounting,

-the union between the brake pipe and the calliper,

-the brake calliper.

REFITTING

I - REFITTING PREPARATION OPERATION

aClean using a wire brush and BRAKE CLEANER

(see Vehicle: Parts and consumables for the re-

pair) (04B, Consumables - Products):

-the calliper supports,

-the callipers.

aAlways replace the brake calliper guide pin bolts. Special tooling required

Fre. 1190-01Brake calliper piston return

tool.

Equipment required

pedal press

Tightening torquesm

new bolts on the brake

calliper guide pins35 N.m

brake pipe union on the

calliper13 N.m

WARNING

To avoid damaging the parking brake cable protec-

tors and causing premature wear of the system, do

not handle the cables with a tool.

132468

Page 106 of 281

33A-8

REAR AXLE COMPONENTS

Rear brake calliper: Removal - Refitting

EQ UIPMENT LEVEL SPORT

33A

aPush the piston to the bottom of its housing using

the (Fre. 1190-01).

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the brake calliper on the calliper mounting.

aTorque tighten:

-the new bolts on the brake calliper guide pins

(35 N.m),

-the brake pipe union on the calliper (13 N.m).

aFit the parking brake cable.

aClip the handbrake on the brake calliper.

III - FINAL OPERATION

aRefit the rear wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

aRemove the pedal press from the brake pedal.

aBleed the brake circuit (see 30A, General informa-

tion, Braking circuit: Bleed, page 30A-4) .

106309

IMPORTANT

To avoid any accident, bring the pistons, brake

pads and brake discs into contact by depressing

the brake pad several times.

Page 107 of 281

33A-9

REAR AXLE COMPONENTS

Rear brake calliper mounting: Removal - Refitting

EQ UIPMENT LEVEL SPORT

33A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRelease the parking brake.

aRemove:

-the rear wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the rear brake pads (see 33A, Rear axle compo-

nents, Rear brake pads: Removal - Refitting,

page 33A-1) .aRemove:

-the brake calliper guide pin bolts (1) ,

-the brake calliper from the mounting.

aAttach the brake calliper to the suspension spring.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the brake calliper mounting bolts (2) ,

-the brake calliper mounting. Special tooling required

Fre. 1190-01Brake calliper piston return

tool.

Tightening torquesm

bolts of the brake calli-

per mountingXXX

new bolts of the brake

calliper guide pins105 N.m

WARNING

To avoid damaging the parking brake cable protec-

tors and causing premature wear of the system, do

not handle the cables with a tool.

132468

132465

Page 108 of 281

33A-10

REAR AXLE COMPONENTS

Rear brake calliper mounting: Removal - Refitting

EQ UIPMENT LEVEL SPORT

33A

REFITTING

I - REFITTING PREPARATION OPERATION

aClean using a wire brush and BRAKE CLEANER

(see Vehicle: Parts and consumables for the re-

pair) (04B, Consumables - Products):

-the calliper supports,

-the callipers.

aAlways replace:

-the calliper mounting bolts,

-the calliper guide pin bolts.

aPush the piston to the bottom of its housing using

the (Fre. 1190-01).

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the brake calliper mounting.

aTorque tighten the bolts of the brake calliper

mounting (XXX).

III - FINAL OPERATION.

aRefit:

-the brake calliper,

-the brake pads (see 33A, Rear axle components,

Rear brake pads: Removal - Refitting, page 33A-

1) .

aTorque tighten the new bolts of the brake calliper

guide pins (105 N.m).aRefit the rear wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

106309

IMPORTANT

To avoid any accident, bring the pistons, brake

pads and brake discs into contact by depressing

the brake pad several times.

Page 109 of 281

33A-11

REAR AXLE COMPONENTS

Rear brake disc: Removal - Refitting

EQ UIPMENT LEVEL SPORT

33A

Brake discs cannot be reground. If there is excessive

scoring or wear, they will need to be replaced (see

30A, General information, Brake: Specifications,

page 30A-19) .

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the rear wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the rear brake pads (see 33A, Rear axle compo-

nents, Rear brake pads: Removal - Refitting,

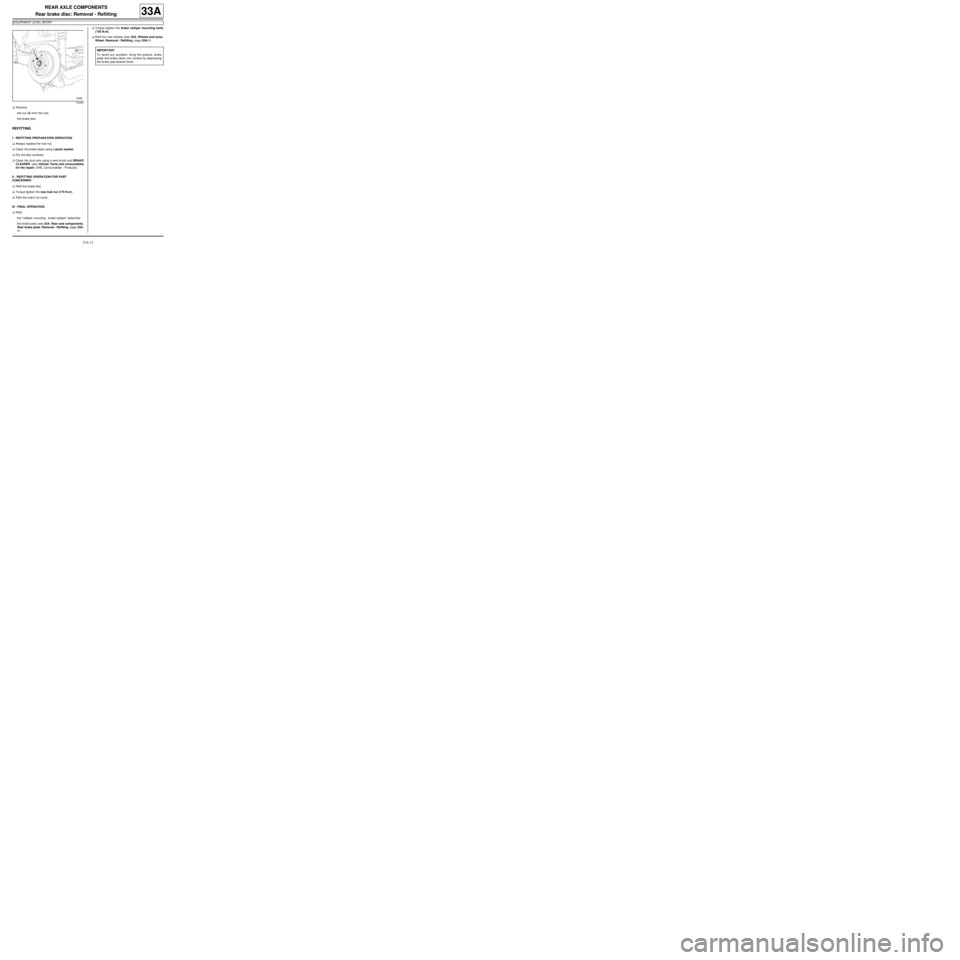

page 33A-1) .aRemove:

-the brake calliper mounting bolts (1) ,

-the "brake calliper mounting - brake calliper" as-

sembly.

aAttach the "calliper mounting - brake calliper" to the

shock absorber spring.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the hub's nut cover (2) . Equipment required

par ts washer

Tightening torquesm

new hub nut175 N.m

brake calliper mounting

bolts105 N.m

WARNING

To avoid damaging the parking brake cable protec-

tors and causing premature wear of the system, do

not handle the cables with a tool.

132467

132456

Page 110 of 281

33A-12

REAR AXLE COMPONENTS

Rear brake disc: Removal - Refitting

EQ UIPMENT LEVEL SPORT

33A

aRemove:

-the nut (3) from the hub,

-the brake disc.

REFITTING

I - REFITTING PREPARATION OPERATION

aAlways replace the hub nut.

aClean the brake discs using a parts washer.

aDry the disc surfaces.

aClean the stub axle using a wire brush and BRAKE

CLEANER (see Vehicle: Parts and consumables

for the repair) (04B, Consumables - Products).

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the brake disc.

aTorque tighten the new hub nut (175 N.m ).

aRefit the hub's nut cover.

III - FINAL OPERATION.

aRefit:

-the "calliper mounting - brake calliper" assembly,

-the brake pads (see 33A, Rear axle components,

Rear brake pads: Removal - Refitting, page 33A-

1) .aTorque tighten the brake calliper mounting bolts

(105 N.m).

aRefit the rear wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

132455

IMPORTANT

To avoid any accident, bring the pistons, brake

pads and brake discs into contact by depressing

the brake pad several times.