wheel bolts RENAULT TWINGO RS 2009 2.G Chasiss Service Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 281

Page 142 of 281

35A-2

WHEELS AND TYRES

Wheel: Removal - Refitting

35A

If this procedure does not work:

aStrike the inner surface of the wheel (2) using a mal-

let and a wooden block to detach it.

aRemove:

-the wheel bolts,

-the wheel.

REFITTING

I - REFITTING PREPARATION OPERATION

aClean the hub carrier using a wire brush.

aCheck the condition of the tyre.

aDo not move or remove the balance weights.

II - REFITTING OPERATION FOR PART

CONCERNED

aClean the mating surfaces between the wheel and

the hub carrier using a wire brush.aCoat the wheel-mating face (3) with COPPER ANTI-

SEIZE AGENT (see Vehicle: Parts and consum-

ables for the repair) (04B, Consumables - Prod-

ucts).

aAlign the mark on the wheel with the mark made on

the hub when it was removed.

aFit the wheel to the vehicle, positioning the valve at

the top.

aInsert the wheel bolts.

aTighten the wheel bolts to bring all the bolt heads

into contact with the wheel.

106089

Note:

Do not strike the surface of the wheel using

excessive force as this may damage it.

Note:

there are two types of wheel bolts for alloy and

steel wheel rims; do not swap them.

124750

113180

Page 143 of 281

35A-3

WHEELS AND TYRES

Wheel: Removal - Refitting

35A

aPretighten the wheel bolts to 30 N.m, with the wheel

suspended, starting with the bolts at the bottom.

aRotate the wheel through 180˚ to bring the valve into

the bottom position.

aPosition the vehicle on its wheels.

aTorque tighten the wheel bolts in order (see 30A,

General information, Front axle system: Tighten-

ing torque, page 30A-27) (30A, General informa-

tion).

aRefit the trim piece.Note:

Use sockets with protective sheaths in order to

avoid scratching the alloy wheel rims.

Page 151 of 281

35A-11

WHEELS AND TYRES

Wheel rim: Identification

35A

IDENTIFICATION

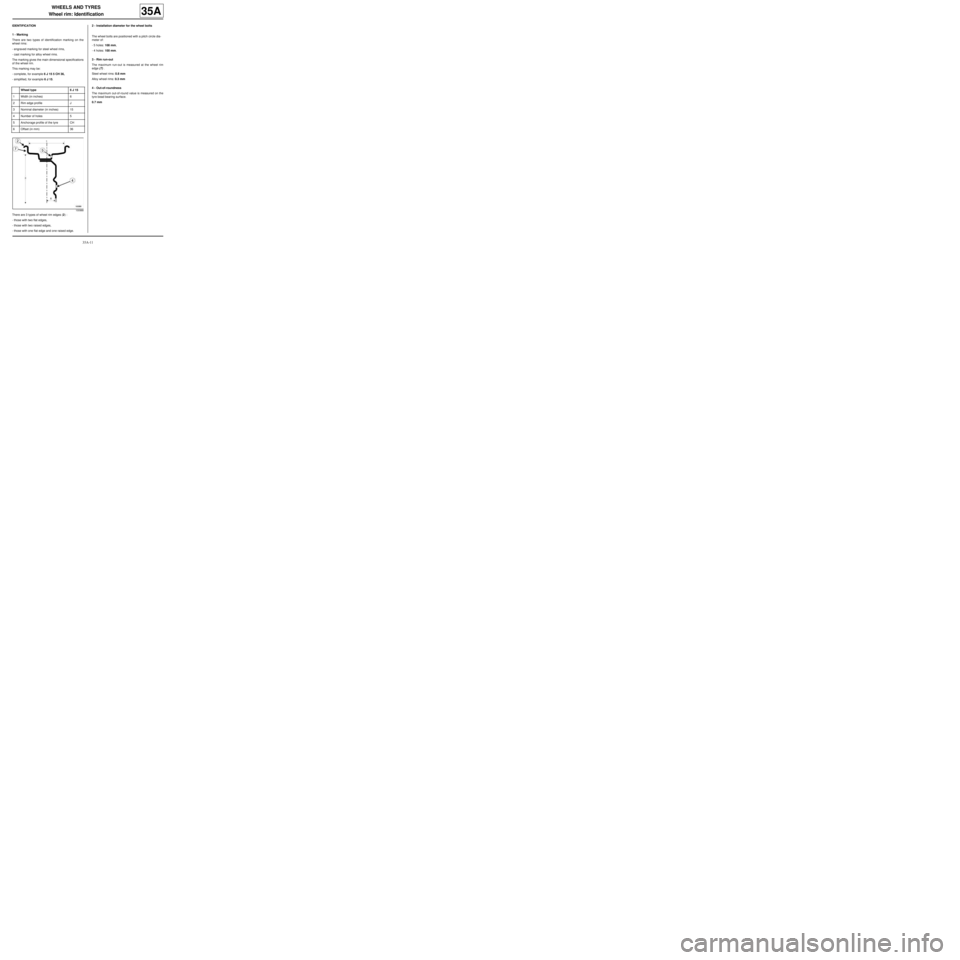

1 - Marking

There are two types of identification marking on the

wheel rims:

-engraved marking for steel wheel rims,

-cast marking for alloy wheel rims.

The marking gives the main dimensional specifications

of the wheel rim.

This marking may be:

-complete, for example 6 J 15 5 CH 36,

-simplified, for example 6 J 15.

There are 3 types of wheel rim edges (2) :

-those with two flat edges,

-those with two raised edges,

-those with one flat edge and one raised edge.2 - Installation diameter for the wheel bolts

The wheel bolts are positioned with a pitch circle dia-

meter of:

-5 holes: 108 mm,

-4 holes: 100 mm.

3 - Rim run-out

The maximum run-out is measured at the wheel rim

edge (7) .

Steel wheel rims: 0.8 mm

Alloy wheel rims: 0.3 mm

4 - Out-of-roundness

The maximum out-of-round value is measured on the

tyre bead bearing surface.

0.7 mm Wheel type 6 J 15

1Width (in inches) 6

2Rim edge profile J

3Nominal diameter (in inches) 15

4Number of holes 5

5Anchorage profile of the tyre CH

6Offset (in mm) 36

100988

Page 152 of 281

36A-1

STEERING ASSEMBLY

Steering box: Removal - Refitting

36A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift ( (see Vehicle:

Towing and lifting) ).

aRemove:

-the front wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the « subframe - front driveshaft lower arm - power-

assisted steering box - front anti-roll bar » assem-

bly (see 31A, Front axle components, Front axle

subframe: Removal - Refitting, page 31A-43) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the power-assisted steering box bolts (1) ,

-the power-assisted steering box.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the power-assisted steering box,

-the power-assisted steering box bolts.

aTorque tighten the power-assisted steering box

bolts (105 Nm).

II - FINAL OPERATION.

aRefit:

-the « subframe - front driveshaft lower arm - power-

assisted steering box - front anti-roll bar » assem-

bly (see 31A, Front axle components, Front axle

subframe: Removal - Refitting, page 31A-43) ,

-the wheel arch liners (see Front wheel arch liner:

Removal - Refitting) (55A, Exterior protection),

-the front wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

aCheck the axle geometry (see 30A, General infor-

mation, Axle assemblies: Check, page 30A-23) .

aIf necessary, adjust the axle assemblies' geometry

(see 30A, General information, Front axle sys-

tem: Adjustment, page 30A-36) . Tightening torquesm

power-assisted steering

box bolts105 Nm

119405

Page 158 of 281

36A-7

STEERING ASSEMBLY

Steering column: Removal - Refitting

LEFT-HAND DRIVE

36A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aUnlock the steering column.

aLock the airbag computer using the Diagnostic tool

(see Fault finding - Replacement of components)

(MR 413, 88C, Airbags - Pretensioners).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (MR 411, 80A, Battery).

aSet the wheels straight ahead.

aRemove:

-the driver's front airbag (see Driver's frontal air-

bag: Removal - Refitting) (MR 411, 88C, Airbags

- Pretensioners),

-the steering wheel (see 36A, Steering assembly,

Steering wheel: Removal - Refitting, page 36A-

23) ,-the steering column switch assembly (see Steer-

ing column switch assembly: Removal - Refit-

ting) (MR 411, 84A, Steering column switch

assembly),

-the immobiliser antenna/transponder ring (see

Transponder ring: Removal - Refitting) (MR

411, 82A, Immobiliser),

-the ignition switch if the steering column is replaced

(see Ignition switch: Removal - Refitting) (MR

411, 82A, Immobiliser).

II - REMOVAL OPERATION FOR PART

CONCERNED

aRemove the cover from the universal joint (1) (do not

keep).

aRemove:

-the universal joint bolt (2) (do not keep),

-the universal joint nut (do not keep). Equipment required

Diagnostic tool

Tightening torquesm

bolt connecting the

steering column to the

inter mediate shaft30 Nm

steer ing column bolts21 Nm

universal joint bolt24 Nm

IMPORTANT

To avoid any risk of triggering when working on

or near a pyrotechnic component (airbags or pre-

tensioners), lock the airbag computer using the

diagnostic tool.

When this function is activated, all the trigger

lines are inhibited and the airbag warning light on

the instrument panel lights up continuously (igni-

tion on).

IMPORTANT

Never handle the pyrotechnic systems (preten-

sioners or airbags) near to a source of heat or

naked flame - they may be triggered.

119544

Page 159 of 281

36A-8

STEERING ASSEMBLY

Steering column: Removal - Refitting

LEFT-HAND DRIVE

36A

aDisconnect the power-assisted steering computer

connectors (3) .

aRemove:

-the steering column bolts (4) ,

-the steering column with the intermediate shaft,

-the bolt connecting the steering column to the inter-

mediate shaft,-the steering column intermediate shaft.

aRemove:

-the steering column bolts (5) ,

-the steering column with the intermediate shaft,

REFITTING

I - REFITTING PREPARATIONS OPERATION

aAlways replace:

-the steering wheel bolt after each removal,

-the universal joint bolt and cam nut after each re-

moval. POWER ASSISTED STEERING

119858

119883

MANUAL STEERING

119647

Page 162 of 281

36A-11

STEERING ASSEMBLY

Steering column: Removal - Refitting

RIGHT-HAND DRIVE

36A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aUnlock the steering column.

a

Lock the airbag computer using the Diagnostic tool

(see Fault finding - Replacement of components)

(MR 413, 88C, Airbags and seat belt pretensioners).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (MR 411, 80A, Battery).

aRemove:

-the driver's front airbag (see Driver's frontal air-

bag: Removal - Refitting) (MR 411, 88C, Airbags

and pretensioners),

-the steering wheel (see 36A, Steering assembly,

Steering wheel: Removal - Refitting, page 36A-

23) .aRemove the rev counter (see Rev counter: Remov-

al - Refitting) (MR 411, 83A, Instrument panel).

aRemove:

-the dashboard lower cover (1) ,

-the bolts (2) from the steering wheel lower cover,

-the steering wheel lower cover (3) ,

-the steering wheel upper cover (4) ,

-the steering column switch assembly (see Steer-

ing column switch assembly: Removal - Refit-

ting) (MR 411, 84A, Control - Signals),

-the antenna/transponder ring (see Transponder

ring: Removal - Refitting) (MR 411, 82A, Immobi-

liser),

-the ignition switch if the steering column is replaced

(see Ignition switch: Removal - Refitting) (MR

411, 82A, Immobiliser). Equipment required

Diagnostic tool

Tightening torquesm

bolt connecting the

steer ing column and the

inter mediate shaft30 Nm

steer ing column bolts21 Nm

universal joint bolt24 Nm

IMPORTANT

To avoid any risk of triggering when working on

or near a pyrotechnic component (airbags or pre-

tensioners), lock the airbag computer using the

diagnostic tool.

When this function is activated, all the trigger

lines are inhibited and the airbag warning light on

the instrument panel lights up continuously (igni-

tion on).

IMPORTANT

Never handle the pyrotechnic systems (preten-

sioners or airbags) near to a source of heat or

naked flame - they may be triggered.

ENGINE REV COUNTER

123870

Page 163 of 281

36A-12

STEERING ASSEMBLY

Steering column: Removal - Refitting

RIGHT-HAND DRIVE

36A

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the universal joint cover (5) (do not keep).

aSet the wheels straight ahead.

aRemove:

-the universal joint bolt (6) (do not keep),

-the universal joint nut (7) (do not keep).aDisconnect the power-assisted steering computer

connectors (8) .

aRemove:

-the steering column bolts (9) ,

-the steering column with the intermediate shaft,

116021

123861

POWER ASSISTED STEERING

123858

123857

Page 164 of 281

36A-13

STEERING ASSEMBLY

Steering column: Removal - Refitting

RIGHT-HAND DRIVE

36A

-the bolt connecting the steering column and the in-

termediate shaft,

-the steering column intermediate shaft.

aRemove:

-the steering column bolts (10) ,

-the steering column with the intermediate shaft,

REFITTING

I - REMOVAL PREPARATION OPERATION

aAlways replace:

-the steering wheel bolt,

-the universal joint cam nut and bolt.II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the intermediate shaft of the steering column,

-the bolt connecting the steering column and the in-

termediate shaft.

aTorque tighten the bolt connecting the steering

column and the intermediate shaft (30 Nm).

aRefit:

-the steering column with the intermediate shaft on

the cross member using the retainer (11) ,

-the bolts on the steering column.

aTorque tighten the steering column bolts (21 Nm).

aConnect the power-assisted steering computer con-

nectors. MANUAL STEERING

119647

POWER ASSISTED STEERING

119859

POWER ASSISTED STEERING

Page 166 of 281

36A-15

STEERING ASSEMBLY

Steering column: Removal - Refitting

RIGHT-HAND DRIVE

36A

-the steering wheel lower cover,

-the steering wheel lower cover bolts,

-the dashboard lower cover.

aRefit the rev counter (see Rev counter: Removal -

Refitting) (MR 411, 83A, Instrument panel).

aRefit:

-the steering wheel (see 36A, Steering assembly,

Steering wheel: Removal - Refitting, page 36A-

23) ,

-the driver's front airbag (see Driver's frontal air-

bag: Removal - Refitting) (MR 411, 88C, Airbags

and pretensioners).

aConnect the battery (see Battery: Removal - Refit-

ting) (MR 411, 80A, Battery).

a

Unlock the airbag computer using the Diagnostic

tool (see Fault finding - Replacement of compo-

nents) (MR 413, 88C, Airbags and pretensioners). ENGINE REV COUNTER

IMPORTANT

To avoid a fault with or even triggering of pyro-

technic components (airbags or pretensioners),

check the airbag computer using the diagnostic

tool.