RENAULT TWINGO RS 2009 2.G Panelwork User Guide

TWINGO RS 2009 2.G

RENAULT

RENAULT

https://www.carmanualsonline.info/img/7/1724/w960_1724-0.png

RENAULT TWINGO RS 2009 2.G Panelwork User Guide

Trending: air condition, airbag, spare tire, open bonnet, brake light, headlight, door lock

Page 11 of 209

40A-6

GENERAL INFORMATION

Vehicle on repair bench: Description

C44

40A

III - TRIM-SETTING MAIN REAR REFERENCE

POINTS

1 - Rear mechanical components in place

The jig supports the underside of the rear axle fork and

is centred in the rear axle bolt tapped hole (B) .

Use this situation for a frontal impact or a light rear im-

pact.

2 - Rear mechanical components removed

The jig rests under the rear side member and is cen-

tred on tapped hole (B) .

Use this situation for a rear impact with removal of the

mechanical components.IV - SECONDARY REAR TRIM-SETTING

REFERENCE POINT

The jig rests under the rear side member and is positio-

ned in the hole (J) .

Use this situation to confirm the trim-setting following a

frontal impact (e.g.: to replace a complete front half

unit).

It is used to confirm the vehicle trim setting in case of

doubt about the deformation of a main front reference

point.

120609

121746

Note:

If it is suspected that one of these points may be

deformed, use two additional points located in an

area not affected by the impact in order to confirm

trim-setting.

121748

Page 12 of 209

40A-7

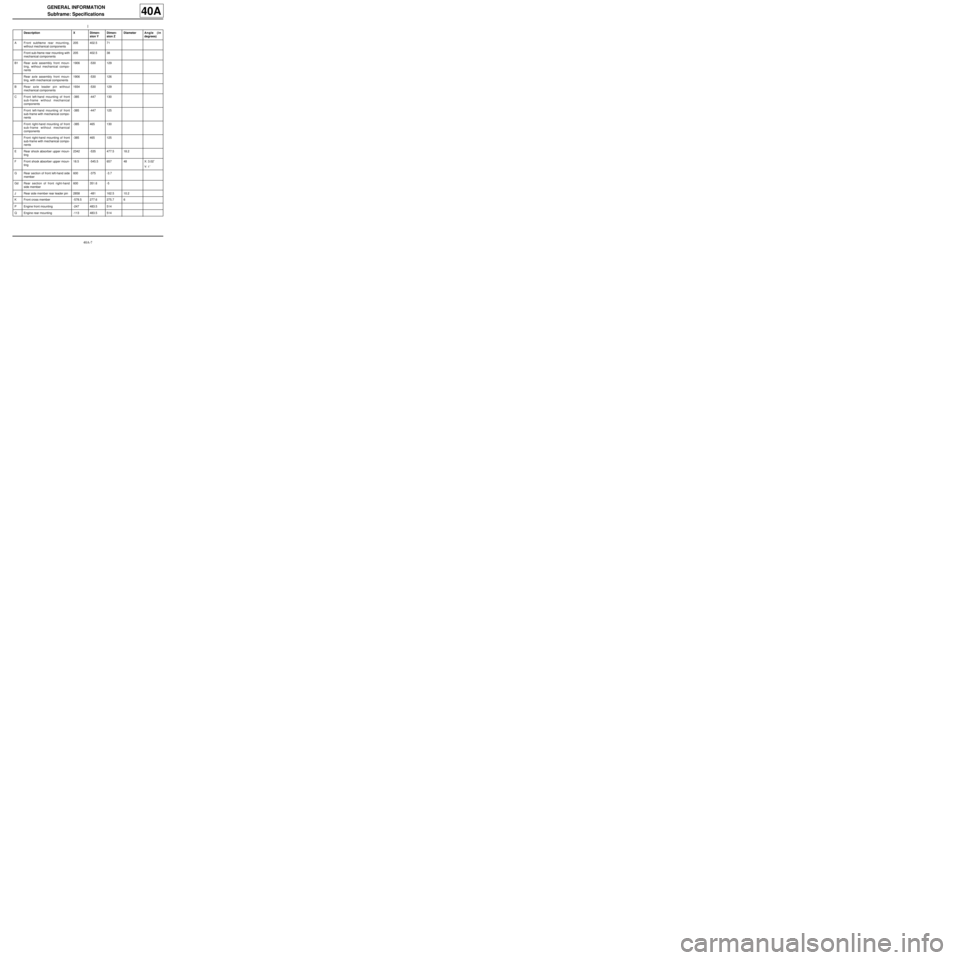

GENERAL INFORMATION

Subframe: Specifications

40A

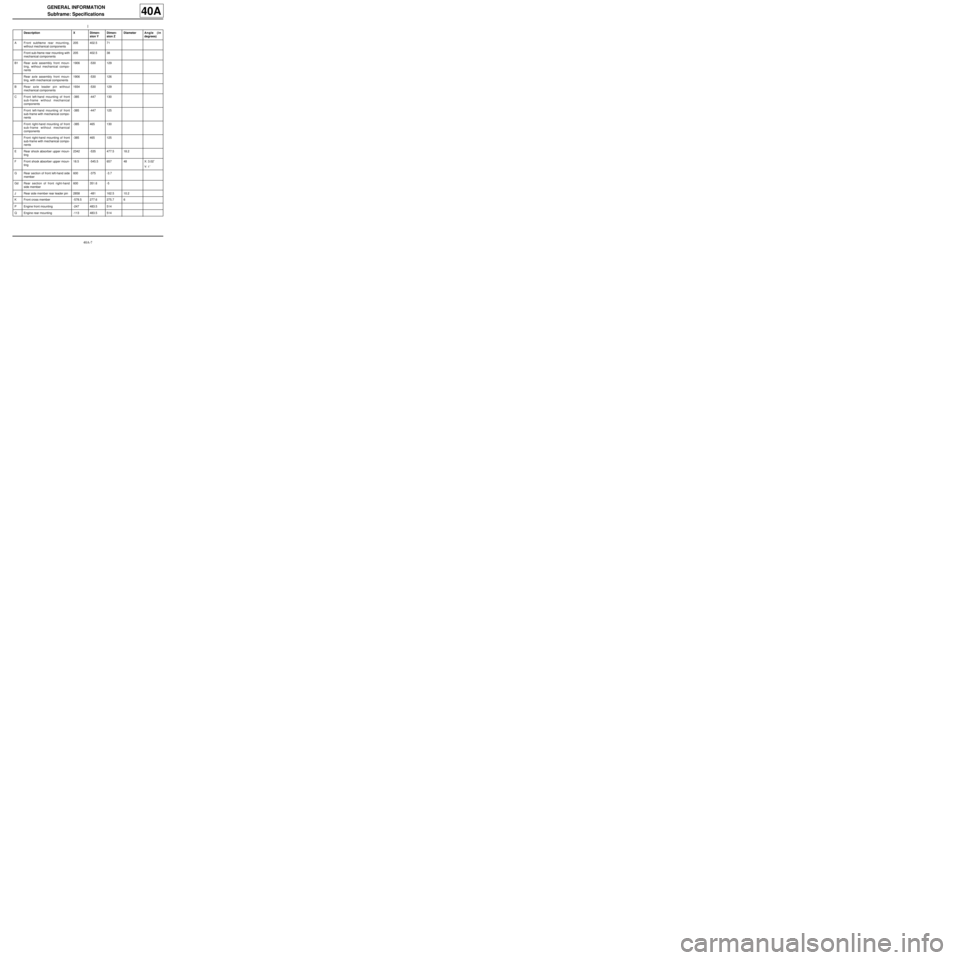

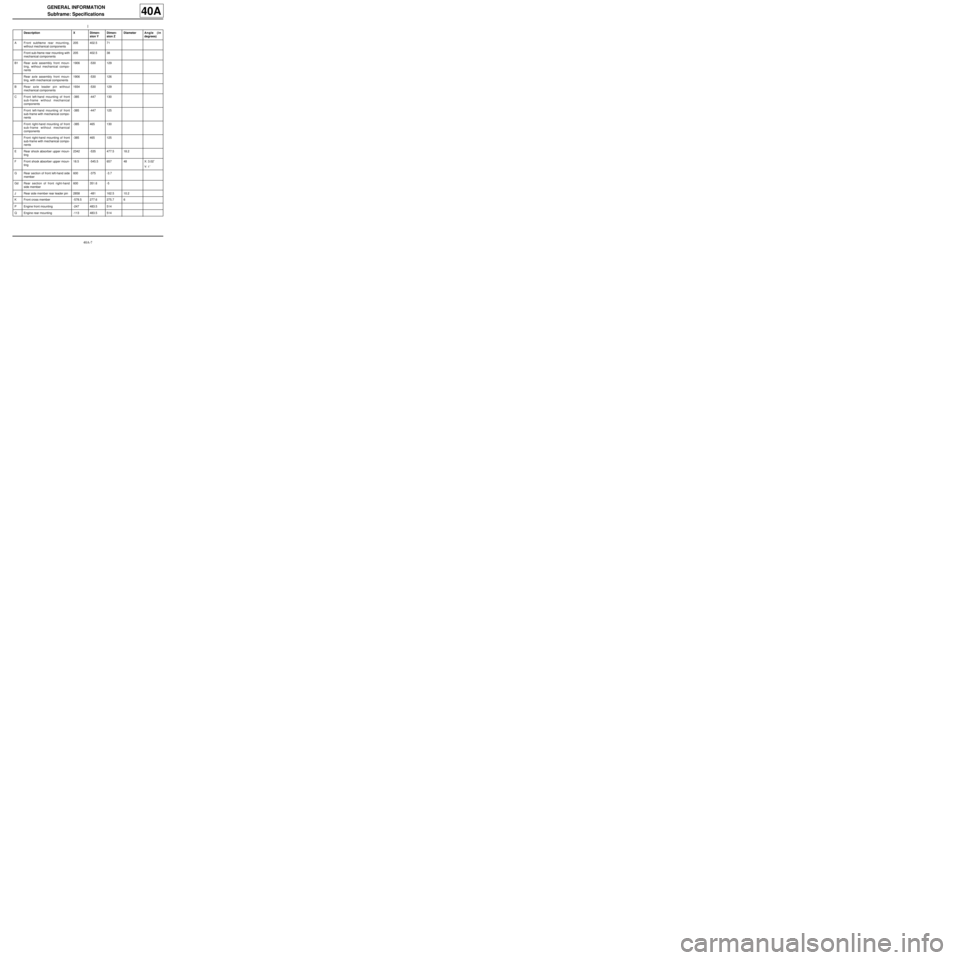

Description X Dimen-

sion YDimen-

sion ZDiameterAngle (in

degrees)

AFront subframe rear mounting,

without mechanical components205 402.5 71

Front sub-frame rear mounting with

mechanical components205 402.5 38

B1Rear axle assembly front moun-

ting, without mechanical compo-

nents1906 -530 129

Rear axle assembly front moun-

ting, with mechanical components1906 -530 126

BRear axle leader pin without

mechanical components1934 -530 129

CFront left-hand mounting of front

sub-frame without mechanical

components-385 -447 130

Front left-hand mounting of front

sub-frame with mechanical compo-

nents-385 -447 125

Front right-hand mounting of front

sub-frame without mechanical

components-385 465 130

Front right-hand mounting of front

sub-frame with mechanical compo-

nents-385 465 125

ERear shock absorber upper moun-

ting2342 -535 477.5 18.2

FFront shock absorber upper moun-

ting18.5 -545.5 657 48 X: 3.02˚

Y: 1˚

GRear section of front left-hand side

member600 -375 -3.7

GdRear section of front right-hand

side member600 351.6 -5

JRear side member rear leader pin 2858 -481 162.5 10.2

KFront cross member -578.5 277.6 275.7 6

PEngine front mounting -247 483.5 514

QEngine rear mounting -113 483.5 514

Page 13 of 209

40A-8

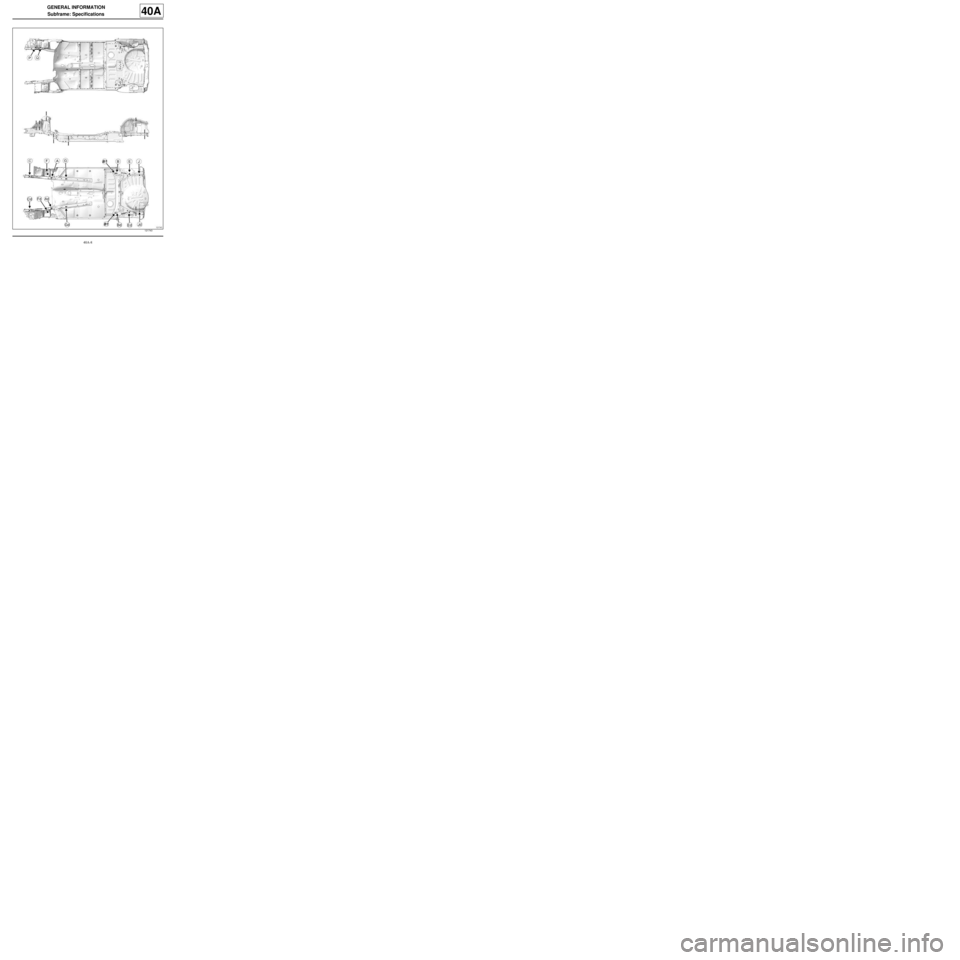

GENERAL INFORMATION

Subframe: Specifications

40A

121743

Page 14 of 209

40A-9

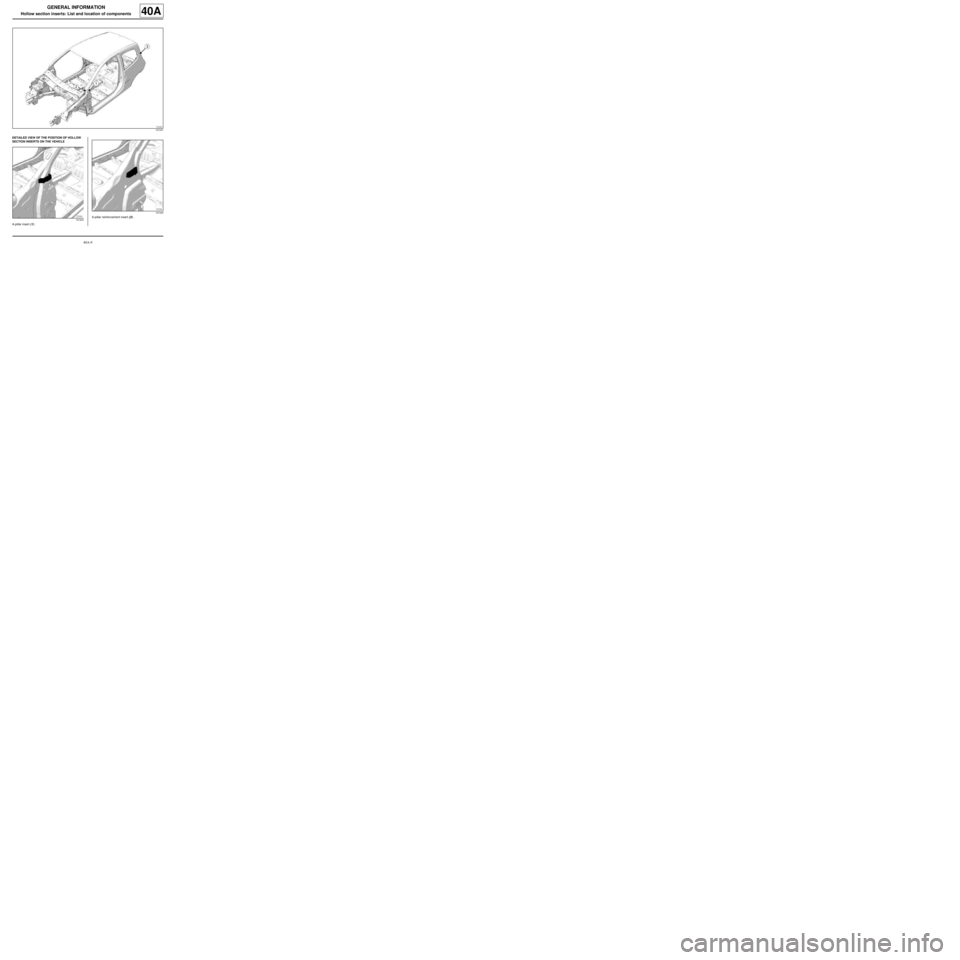

GENERAL INFORMATION

Hollow section inserts: List and location of components40A

DETAILED VIEW OF THE POSITION OF HOLLOW

SECTION INSERTS ON THE VEHICLE

A-pillar insert (1) .A-pillar reinforcement insert (2) .

121241

121243

121244

Page 15 of 209

40A-10

GENERAL INFORMATION

Hollow section inserts: List and location of components40A

Rear wing panel insert (3) .

121242

Page 16 of 209

40A-11

GENERAL INFORMATION

Hollow section inserts: Precautions for the repair

40A

The expanding inserts ensure that the vehicle cavities

are sealed and soundproofed. They react to the tempe-

rature when the bodywork is immersed in the catapho-

retic bath at the factory. These conditions cannot be

reproduced on the bodywork.

As inserts are not recoverable, always replace expan-

ding inserts.

The inserts supplied by the Parts Department are

identical to the original parts.

To obtain the same sealing and soundproofing proper-

ties, carry out the following operations:

-clean the bonding surfaces with heptane,

-if necessary, block the holes in the insert using pieces

cut from a soundproofing pad.

-apply a bead of preformed trim sealing mastic around

and inside the insert holes,

-fit the insert by compressing the mastic.

In some cases, it is possible to replace the accessible

part of the insert only, which must be cut out of the re-

placement part.WARNING

Do not refit the part after compressing the bead.

When EGW welding, protect the inserts from spat-

ter and heat dispersion.

For example, use a heat shield.

Page 17 of 209

40A-12

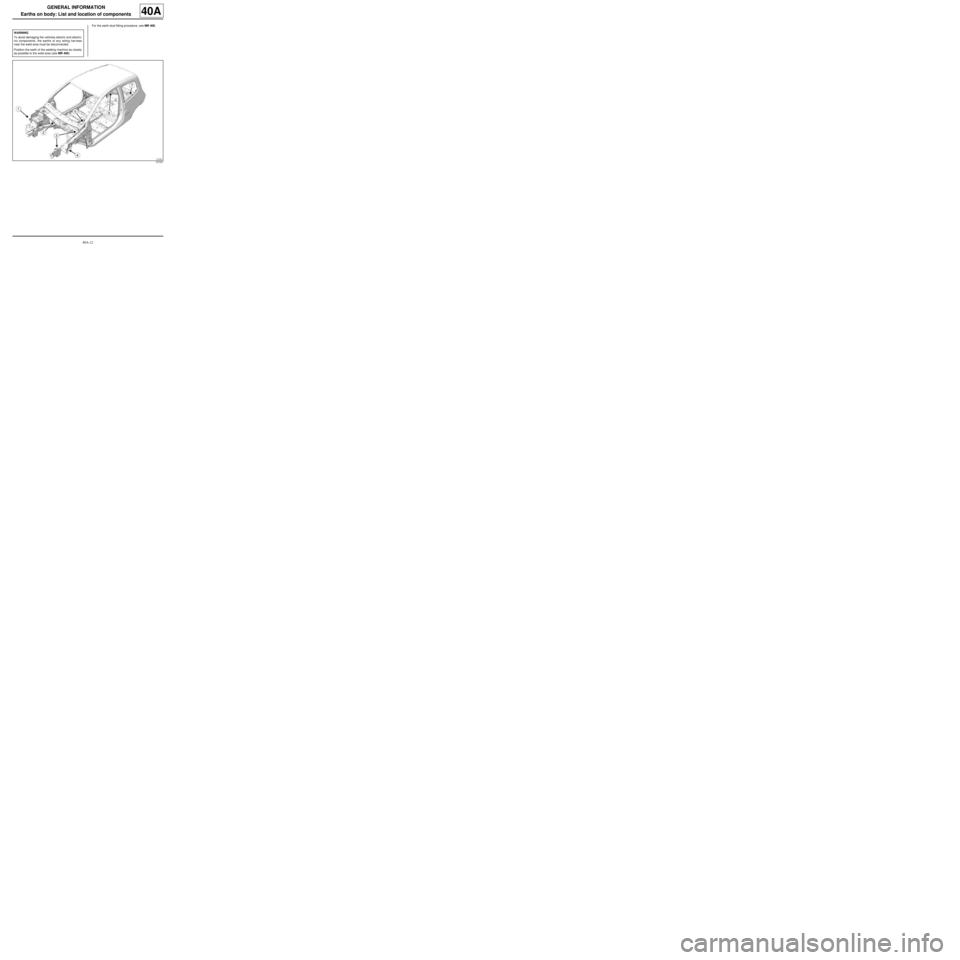

GENERAL INFORMATION

Earths on body: List and location of components

40A

For the earth stud fitting procedure, see MR 400.

WARNING

To avoid damaging the vehicles electric and electro-

nic components, the earths of any wiring harness

near the weld area must be disconnected.

Position the earth of the welding machine as closely

as possible to the weld area (see MR 400).

121241

Page 18 of 209

40A-13

GENERAL INFORMATION

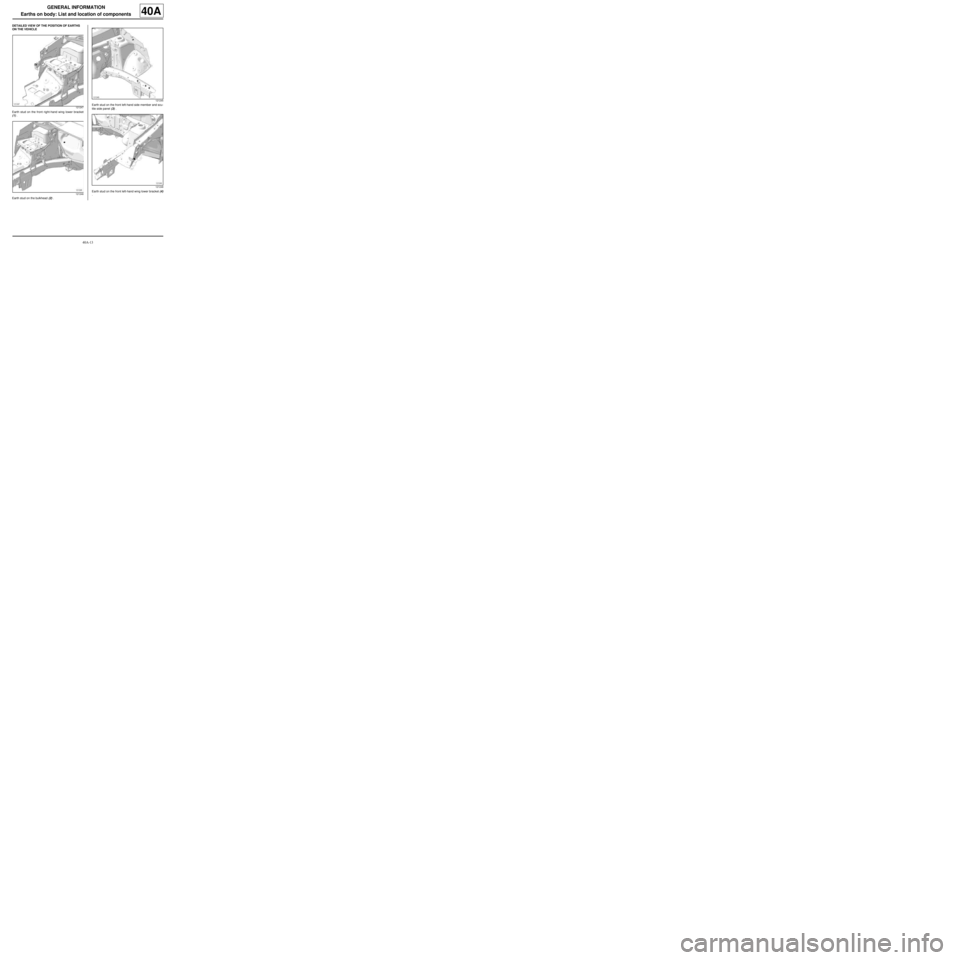

Earths on body: List and location of components

40A

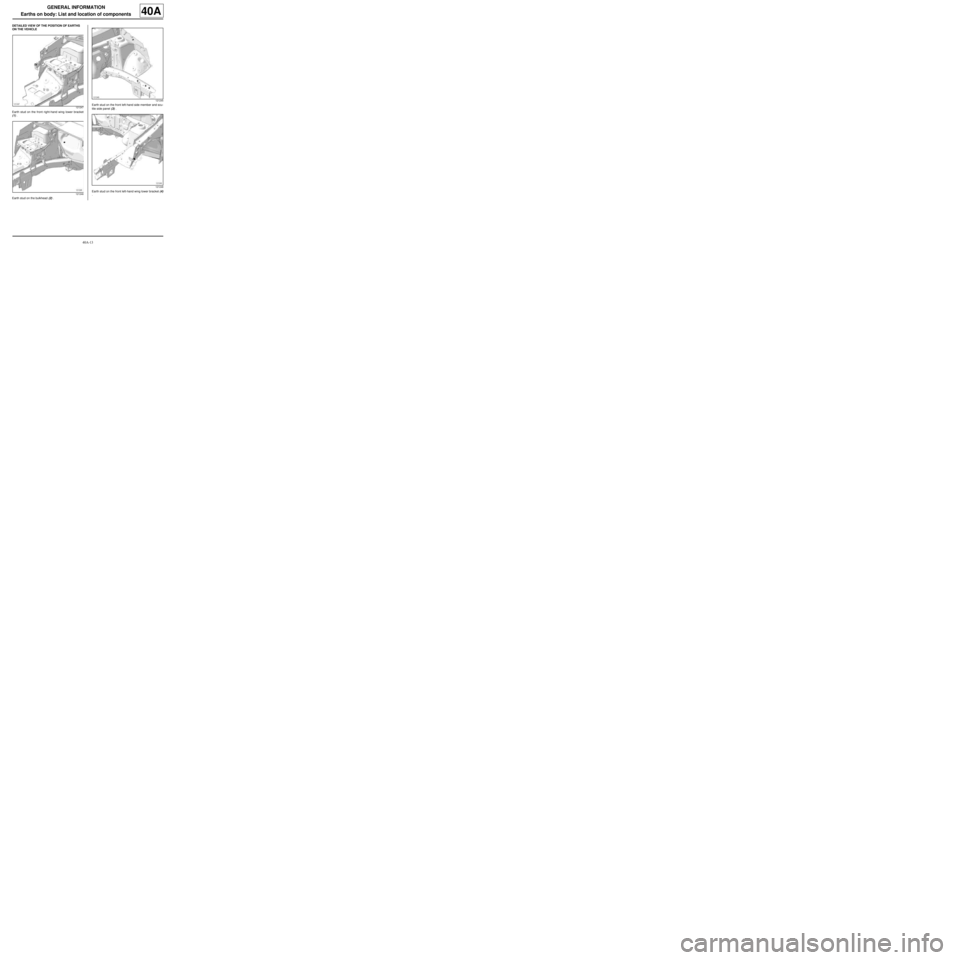

DETAILED VIEW OF THE POSITION OF EARTHS

ON THE VEHICLE

Earth stud on the front right-hand wing lower bracket

(1) .

Earth stud on the bulkhead (2) .Earth stud on the front left-hand side member and scu-

ttle side panel (3) .

Earth stud on the front left-hand wing lower bracket (4)

.

121247

121246

121245

121248

Page 19 of 209

40A-14

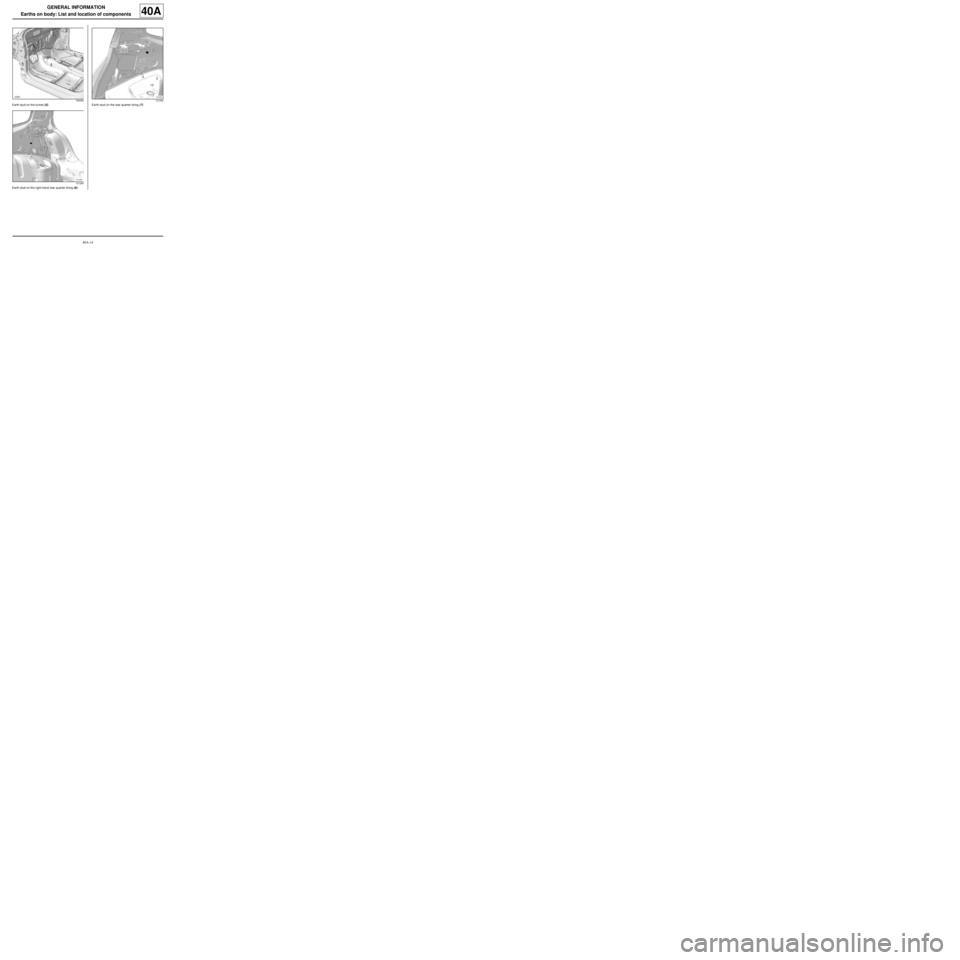

GENERAL INFORMATION

Earths on body: List and location of components

40A

Earth stud on the tunnel (5) .

Earth stud on the right-hand rear quarter lining (6) .Earth stud on the rear quarter lining (7) .

125408

121249121250

Page 20 of 209

40A-15

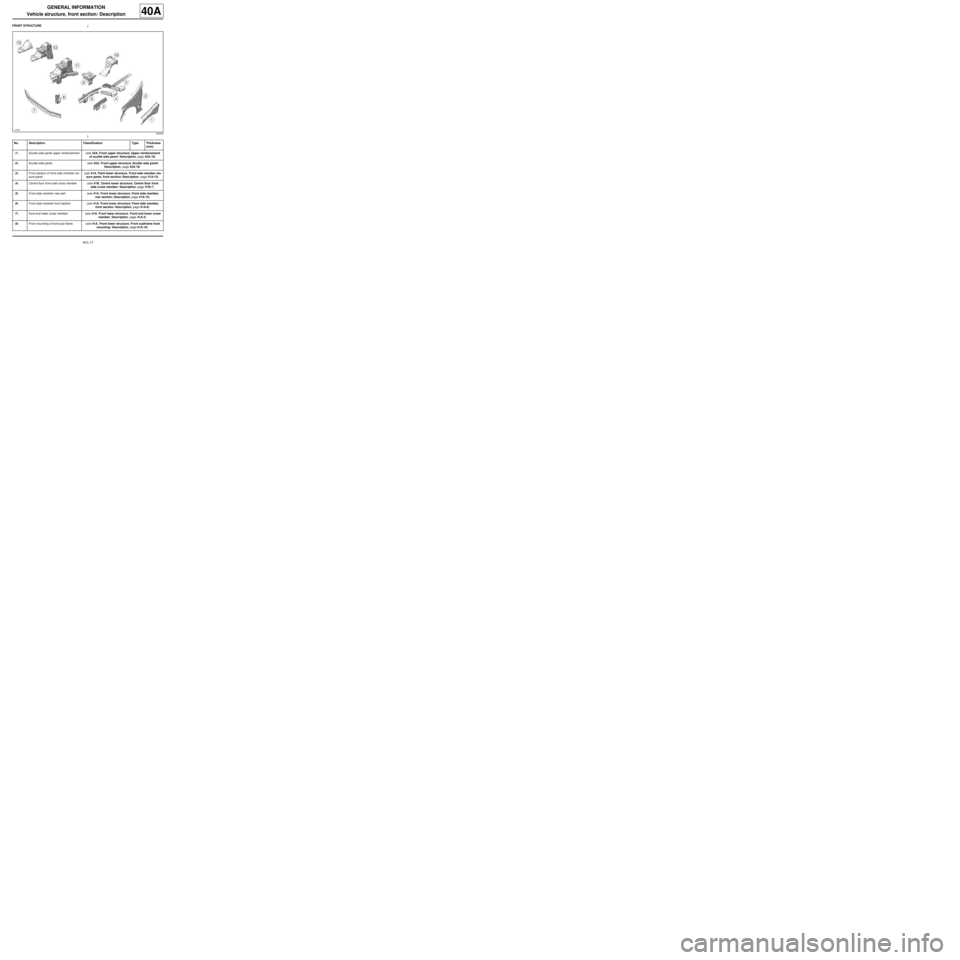

GENERAL INFORMATION

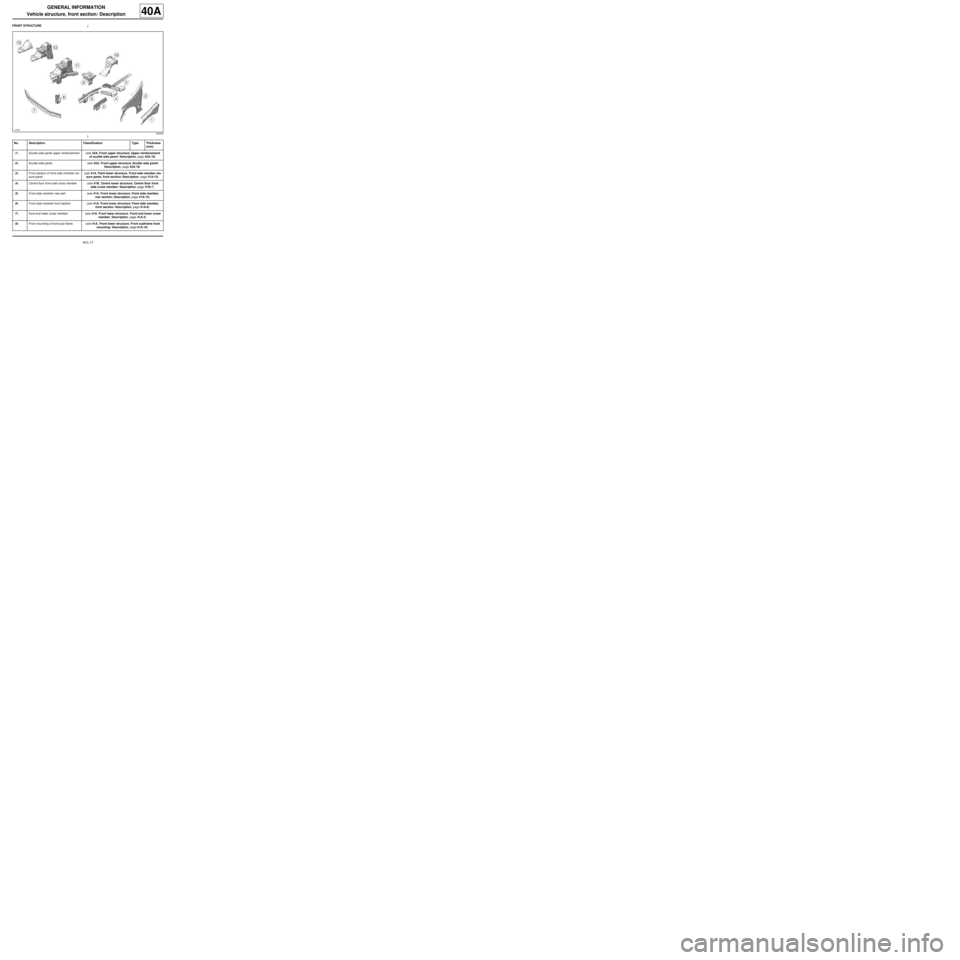

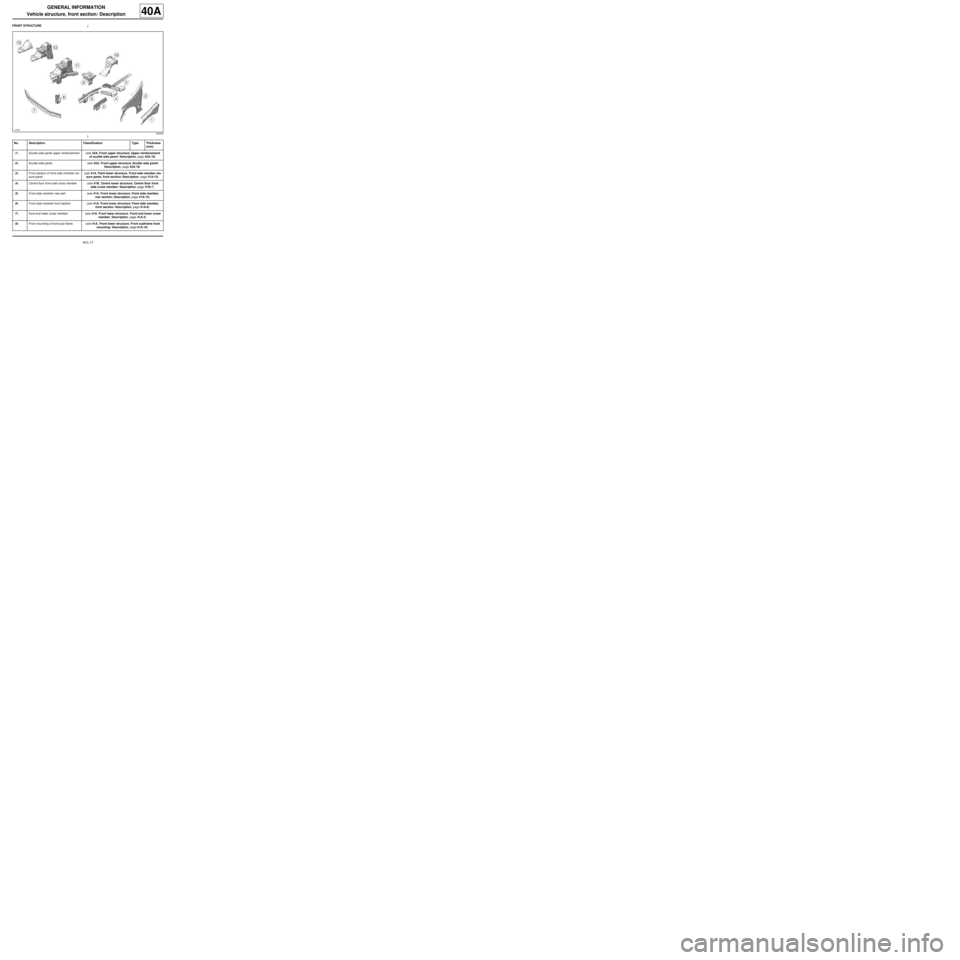

Vehicle structure, front section: Description

40A

FRONT STRUCTURE

125409

No. Description Classification Type Thickness

(mm)

(1) Scuttle side panel upper reinforcement (see 42A, Front upper structure, Upper reinforcement

of scuttle side panel: Description, page 42A-19)

(2) Scuttle side panel (see 42A, Front upper structure, Scuttle side panel:

Description, page 42A-16)

(3) Front section of front side member clo-

sure panel (see 41A, Front lower structure, Front side member clo-

sure panel, front section: Description, page 41A-13)

(4) Centre floor front side cross member (see 41B, Centre lower structure, Centre floor front

side cross member: Description, page 41B-7)

(5) Front side member rear part (see 41A, Front lower structure, Front side member,

rear section: Description, page 41A-15)

(6) Front side member front section (see 41A, Front lower structure, Front side member,

front section: Description, page 41A-8)

(7) front-end lower cross member (see 41A, Front lower structure, Front end lower cross

member: Description, page 41A-2)

(8) Front mounting of front sub-frame (see 41A, Front lower structure, Front subframe front

mounting: Description, page 41A-18)

Trending: instrument panel, brake, ESP, tailgate, gas type, warning, lock