RENAULT TWINGO RS 2009 2.G Panelwork Repair Manual

TWINGO RS 2009 2.G

RENAULT

RENAULT

https://www.carmanualsonline.info/img/7/1724/w960_1724-0.png

RENAULT TWINGO RS 2009 2.G Panelwork Repair Manual

Trending: headlight, instrument panel, air condition, fuel tank removal, open bonnet, battery replacement, tire type

Page 61 of 209

41A-22

FRONT LOWER STRUCTURE

Engine stand: Description

41A

III - POSITIONING OF LOCAL ELECTRICAL

EARTHS

121247

121246

IMPORTANT

To avoid damaging the vehicle's electric and elec-

tronic components, the battery and the earths of

any wiring harness near the weld area must be dis-

connected.

The earth of the welding machine must be placed

as close as possible to the weld area.

Page 62 of 209

41A-23

FRONT LOWER STRUCTURE

Front half unit: General description

41A

DESIGN OF THE STRUCTURAL COMPONENT

The special feature of this type of part is that it combi-

nes the functions of front side member, front wheel

arch, centre floor front side cross member and front

end side cross member, and is made up of several pa-

nels of different types and thicknesses.IMPORTANT

Use a repair bench to ensure the positioning of the

points and the geometr y of the axle assemblies.

Note:

The information contained in the following descri-

bes the general repair procedure for all vehicles

having the same design for this part.

Before reading the following general information,

make sure that there are no special notes associa-

ted with the vehicle. These special notes are speci-

fied if necessary in other par ts of the sub-section

dealing with the component.

Note:

For a detailed description of a particular connec-

tion, see MR 400.

109546

Page 63 of 209

41A-24

FRONT LOWER STRUCTURE

Front half unit: Description

C44

41A

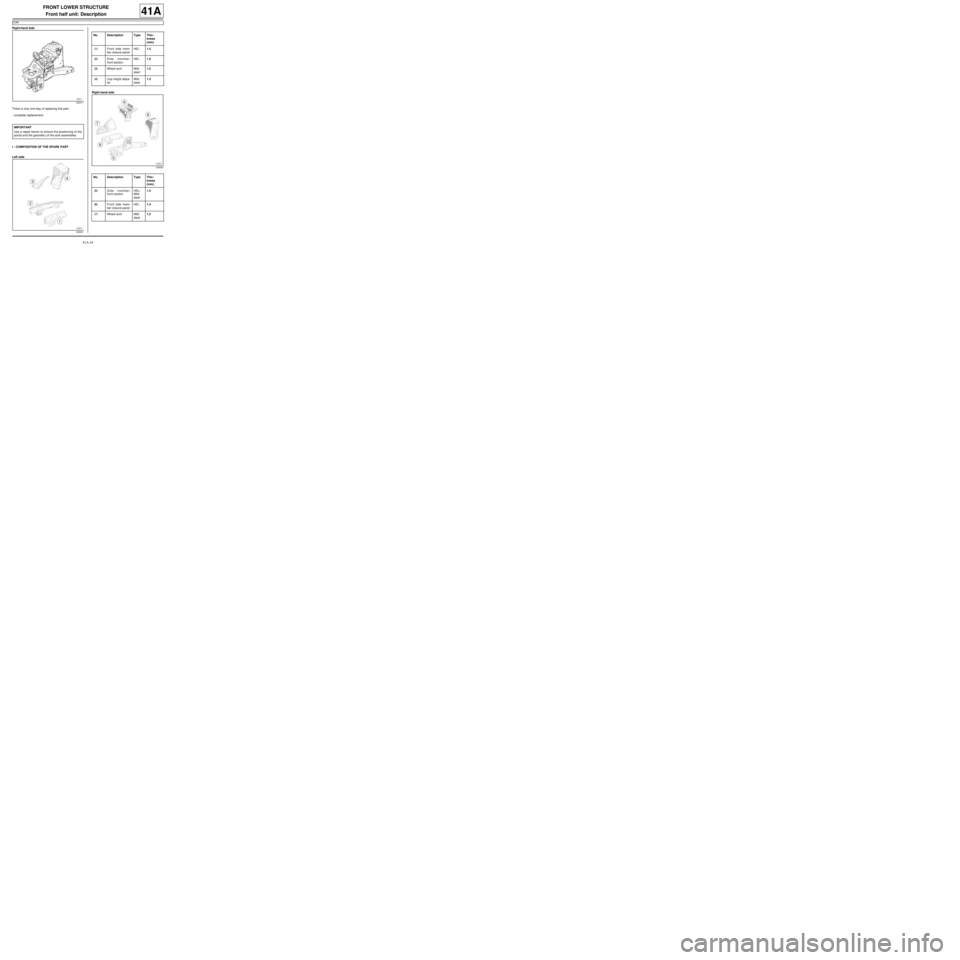

Right-hand side

There is only one way of replacing this part:

-complete replacement.

I - COMPOSITION OF THE SPARE PART

Left sideRight-hand side

125411

IMPORTANT

Use a repair bench to ensure the positioning of the

points and the geometr y of the axle assemblies.

120631

No. Description Type Thic-

kness

(mm)

(1) Front side mem-

ber closure panelHEL1.4

(2) S ide member,

front sectionHEL1.5

(3) Wheel arch Mild

steel1.2

(4) Cup height adjus-

terMild

steel1.3

120630

No. Description Type Thic-

kness

(mm)

(5) S ide member,

front sectionHEL/

Mild

steel1.5

(6) Front side mem-

ber closure panelHEL1.4

(7) Wheel arch Mild

steel1.2

Page 64 of 209

41A-25

FRONT LOWER STRUCTURE

Front half unit: Description

C44

41A

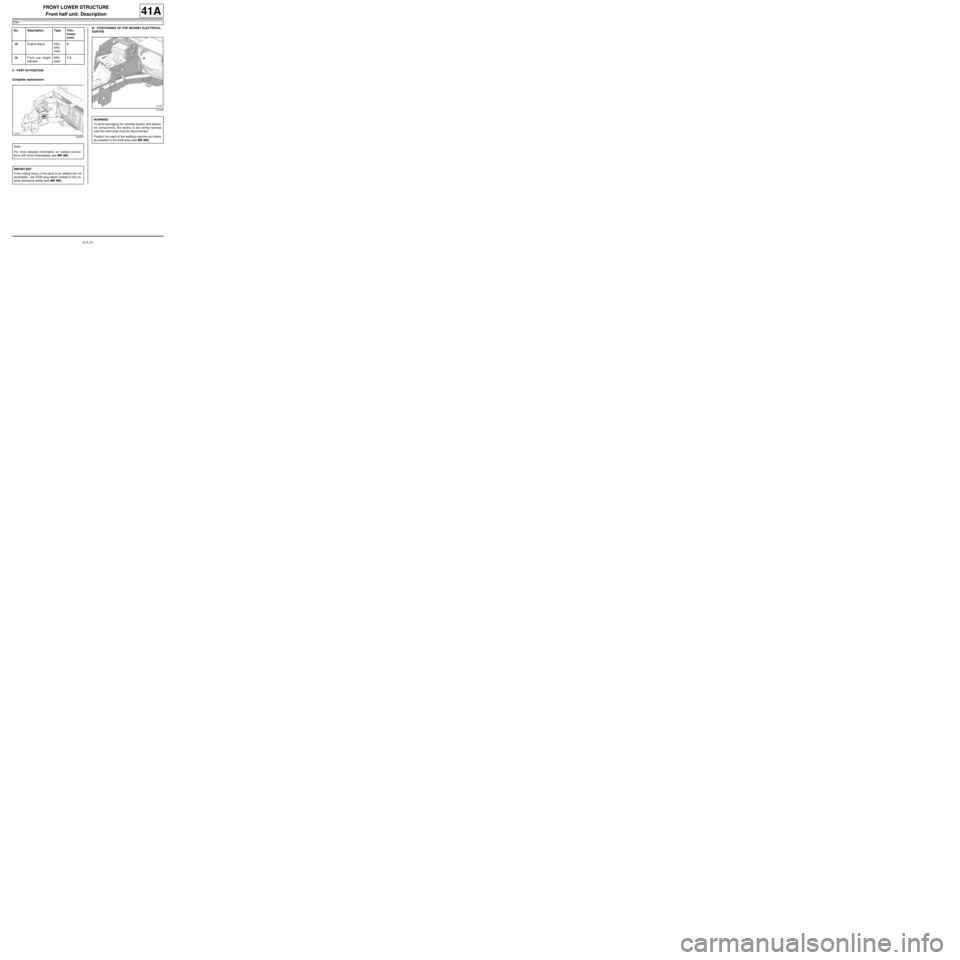

II - PART IN POSITION

Complete replacementIII - POSITIONING OF THE NEARBY ELECTRICAL

EARTHS

(8) Engine stand HEL/

Mild

steel2

(9) Front cup height

adjusterMild

steel1.3

120629

Note:

For more detailed information on welded connec-

tions with three thicknesses, see MR 400.

IMPORTANT

If the mating faces of the parts to be welded are not

accessible, use EGW plug welds instead of the ori-

ginal resistance welds (see MR 400) No. Description Type Thic-

kness

(mm)

121246

WARNING

To avoid damaging the vehicles electric and electro-

nic components, the earths of any wiring harness

near the weld area must be disconnected.

Position the earth of the welding machine as closely

as possible to the weld area (see MR 400).

Page 65 of 209

41B-1

CENTRE LOWER STRUCTURE

Centre floor, side section: General description

41B

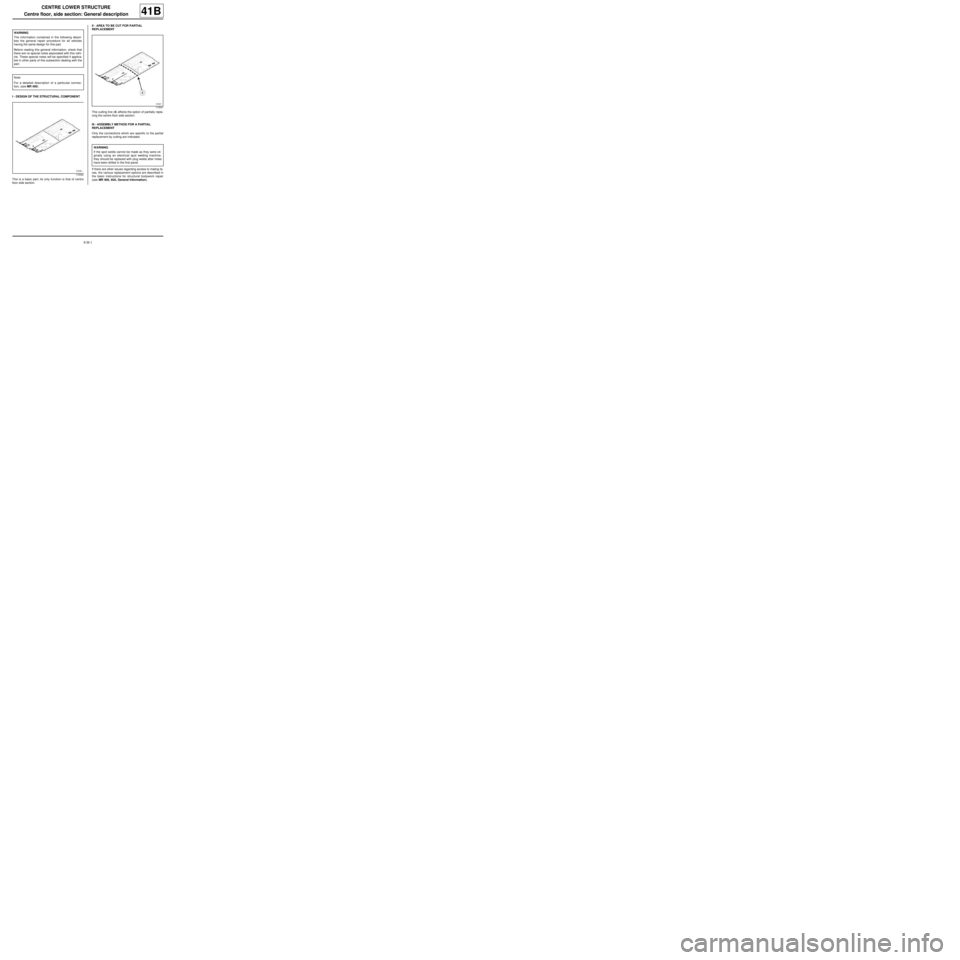

I - DESIGN OF THE STRUCTURAL COMPONENT

This is a basic part; its only function is that of centre

floor side section.II - AREA TO BE CUT FOR PARTIAL

REPLACEMENT

This cutting line (4) affects the option of partially repla-

cing the centre floor side section.

III - ASSEMBLY METHOD FOR A PARTIAL

REPLACEMENT

Only the connections which are specific to the partial

replacement by cutting are indicated.

If there are other issues regarding access to mating fa-

ces, the various replacement options are described in

the basic instructions for structural bodywork repair

(see MR 400, 40A, General Information). WARNING

The information contained in the following descri-

bes the general repair procedure for all vehicles

having the same design for this part.

Before reading this general information, check that

there are no special notes associated with this vehi-

cle. These special notes will be specified if applica-

ble in other parts of this subsection dealing with the

par t.

Note:

For a detailed description of a particular connec-

tion, (see MR 400).

110540

110541

WARNING

If the spot welds cannot be made as they were ori-

ginally using an electrical spot welding machine,

they should be replaced with plug welds after holes

have been drilled in the first panel.

Page 66 of 209

41B-2

CENTRE LOWER STRUCTURE

Centre floor, side section: General description

41B

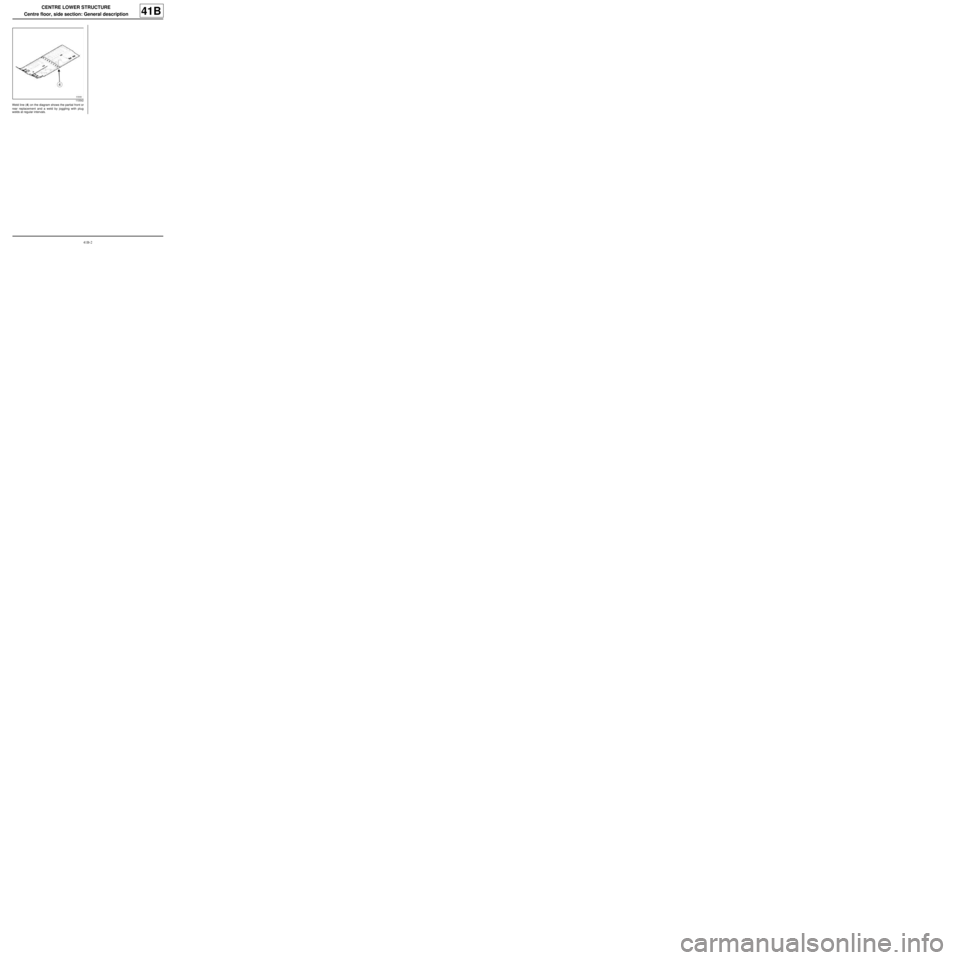

Weld line (4) on the diagram shows the partial front or

rear replacement and a weld by joggling with plug

welds at regular intervals.

110542

Page 67 of 209

41B-3

CENTRE LOWER STRUCTURE

Centre floor, side section: Description

41B

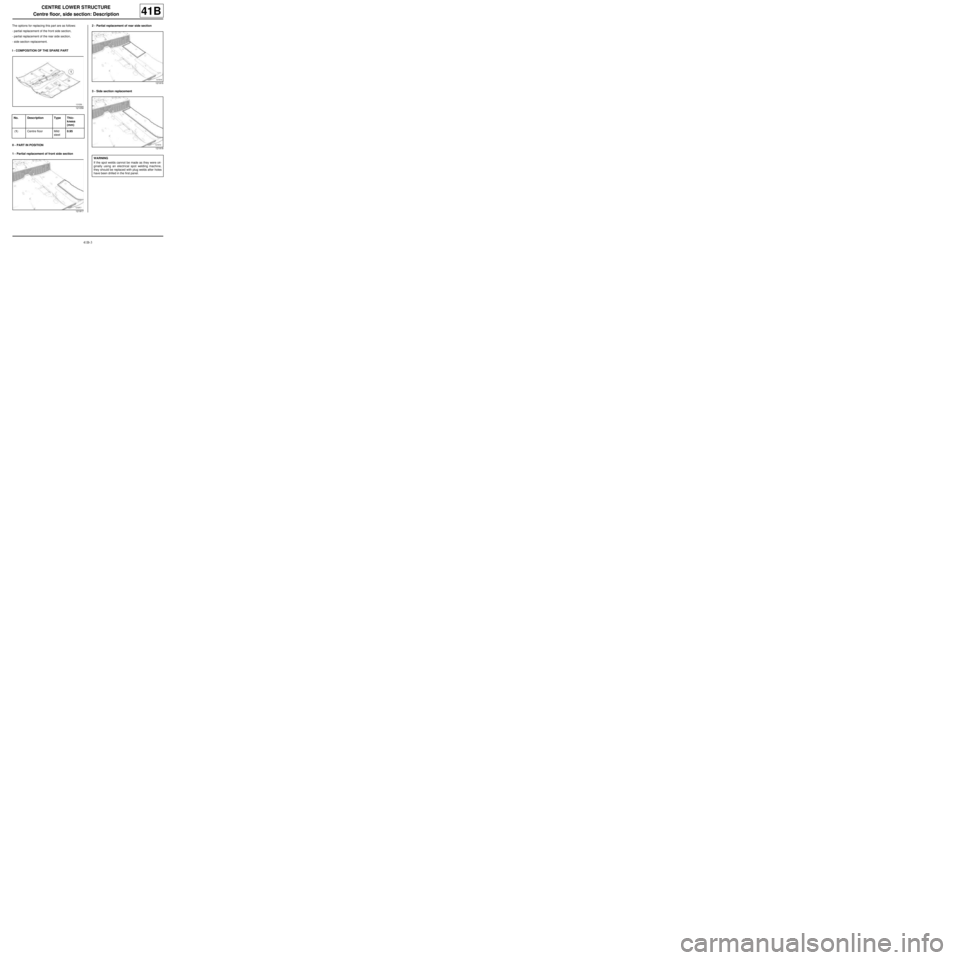

The options for replacing this part are as follows:

-partial replacement of the front side section,

-partial replacement of the rear side section,

-side section replacement.

I - COMPOSITION OF THE SPARE PART

II - PART IN POSITION

1 - Partial replacement of front side section2 - Partial replacement of rear side section

3 - Side section replacement

121058

No. Description Type Thic-

kness

(mm)

(1) Centre floor Mild

steel0.95

121917

121916

121918

WARNING

If the spot welds cannot be made as they were ori-

ginally using an electrical spot welding machine,

they should be replaced with plug welds after holes

have been drilled in the first panel.

Page 68 of 209

41B-4

CENTRE LOWER STRUCTURE

Centre floor, side section: Description

41B

III - POSITIONING OF LOCAL ELECTRICAL

EARTHS

121246

121250

IMPORTANT

To avoid damaging the vehicle's electric and elec-

tronic components, the battery and the earths of

any wiring harness near the weld area must be dis-

connected.

The earth of the welding machine must be placed

as close as possible to the weld area.

Page 69 of 209

41B-5

CENTRE LOWER STRUCTURE

Centre floor front side cross member: General description41B

I - DESIGN OF THE STRUCTURAL COMPONENT

This is a basic part; it only fulfils the function of a centre

floor front side cross member.This is a basic part; it only fulfils the function of a centre

floor front side cross member.

There is no partial replacement for this part, the repair

bench is not required.

II - AREA TO BE CUT FOR PARTIAL

REPLACEMENT

The line (1) in the drawing shows the area in which it is

possible to carry out a partial replacement.

III - ASSEMBLY METHOD FOR A PARTIAL

REPLACEMENT

Only the connections which are specific to the partial

replacement by cutting are indicated. IMPORTANT

Use a repair bench to ensure the positioning of the

points and the geometr y of the axle assemblies.

Note:

The information contained in the following descri-

bes the general repair procedure for all vehicles

having the same design for this part.

Before reading this general information, check that

there are no special notes associated with this vehi-

cle. These special notes will be specified if applica-

ble in other parts of this subsection dealing with the

par t.

Note:

For a detailed description of a particular connec-

tion, see MR 400.

110598

120936

110599

Page 70 of 209

41B-6

CENTRE LOWER STRUCTURE

Centre floor front side cross member: General description41B

If there are other issues regarding access to mating fa-

ces, the various replacement options are described in

the basic instructions for structural bodywork repair

(see MR 400).

Line (3) on the drawing shows a butt weld by conti-

nuous EGW welding.WARNING

If the mating faces of the parts to be welded are not

accessible, make EGW plug welds to replace the

original resistance welds (see MR 400).

110600

Trending: jacking, brake light, interior lights, wheel bolts, door lock, wheel, gas type