RENAULT TWINGO RS 2009 2.G Panelwork Repair Manual

TWINGO RS 2009 2.G

RENAULT

RENAULT

https://www.carmanualsonline.info/img/7/1724/w960_1724-0.png

RENAULT TWINGO RS 2009 2.G Panelwork Repair Manual

Trending: dashboard warning lights, headlight, warning light, headlights, brake, spare wheel, engine

Page 51 of 209

41A-12

FRONT LOWER STRUCTURE

Front side member closure panel, front section: General description41A

Line (3) on the drawing shows a butt weld by conti-

nuous EGW welding.

110554

Page 52 of 209

41A-13

FRONT LOWER STRUCTURE

Front side member closure panel, front section: Description41A

The options for replacing this part are as follows:

-partial replacement,

-complete replacement.

I - COMPOSITION OF THE SPARE PARTII - PART FITTED

1 - Partial replacement

Left-hand side

Right-hand side

2 - Complete replacement

Left-hand side

120638

No. Description Type Thic-

kness

(mm)

(1) Front section of

front side mem-

ber closure panelHLE1.4

120641

120639

120642

Page 53 of 209

41A-14

FRONT LOWER STRUCTURE

Front side member closure panel, front section: Description41A

Right-hand side

III - POSITIONING OF LOCAL ELECTRICAL

EARTHS

120640

IMPORTANT

If the mating faces of the parts to be welded are not

accessible, make EGW plug welds to replace the

original resistance welds (see MR 400).

121245

WARNING

To avoid damaging the vehicles electric and electro-

nic components, the earths of any wiring harness

near the weld area must be disconnected.

Position the earth of the welding machine as closely

as possible to the weld area (see MR 400).

Page 54 of 209

41A-15

FRONT LOWER STRUCTURE

Front side member, rear section: Description

41A

To replace this part, also order the centre floor reinfor-

cement (1) .

There is only one way of replacing this part:

-complete replacement.

I - COMPOSITION OF THE SPARE PARTII - PART FITTED

120635

IMPORTANT

The straightening bench must be used.

120636

No. Description Type Thic-

kness

(mm)

(2) Front subframe

rear mounting

stiffenerMild

steel2

(3) Front side mem-

ber rear partHLE2

(4) Front subframe

rear mountingMild

steel2.5

(5) Centre floor front

side cross mem-

berMild

steel1

120637

WARNING

If the spot welds cannot be made as they were ori-

ginally using an electrical spot welding machine,

they should be replaced with plug welds after holes

have been drilled in the first panel.

Page 55 of 209

41A-16

FRONT LOWER STRUCTURE

Front side member, rear section: Description

41A

III - POSITIONING OF LOCAL ELECTRICAL

EARTHS

121246

IMPORTANT

To avoid damaging the vehicle's electric and elec-

tronic components, the battery and the earths of

any wiring harness near the weld area must be dis-

connected.

The earth of the welding machine must be placed

as close as possible to the weld area.

Page 56 of 209

41A-17

FRONT LOWER STRUCTURE

Front subframe front mounting: General description

41A

DESIGN OF THE STRUCTURAL COMPONENT

This part comprises two components:

-front subframe front mounting support unit (1) ,

-front subframe front mounting component (2) . IMPORTANT

Use a repair bench to ensure the positioning of the

points and the geometr y of the axle assemblies.

Note:

The information contained in the following descri-

bes the general repair procedure for all vehicles

having the same design for this part.

Before reading the following general information,

make sure that there are no special notes associa-

ted with the vehicle. These special notes are speci-

fied if necessary in other par ts of the sub-section

dealing with the component.

Note:

For a detailed description of a particular connec-

tion, see MR 400.

109560

Page 57 of 209

41A-18

FRONT LOWER STRUCTURE

Front subframe front mounting: Description

41A

There is only one way of replacing this part:

-complete replacement.

I - COMPOSITION OF THE SPARE PARTII - PART FITTED

120632

IMPORTANT

The straightening bench must be used.

120634

No. Description Type Thic-

kness

(mm)

(1) Front mounting of

subframe, outer

sectionHLE1.2

(2) Front mounting of

subframe, inner

sectionHLE1.2

120633

WARNING

If the spot welds cannot be made as they were ori-

ginally using an electrical spot welding machine,

they should be replaced with plug welds after holes

have been drilled in the first panel.

Page 58 of 209

41A-19

FRONT LOWER STRUCTURE

Front subframe front mounting: Description

41A

III - POSITIONING OF LOCAL ELECTRICAL

EARTHS

121245

IMPORTANT

To avoid damaging the vehicle's electric and elec-

tronic components, the battery and the earths of

any wiring harness near the weld area must be dis-

connected.

The earth of the welding machine must be placed

as close as possible to the weld area.

Page 59 of 209

41A-20

FRONT LOWER STRUCTURE

Engine stand: General description

41A

DESIGN OF THE STRUCTURAL COMPONENT

This is a basic part; it only functions as an engine

mounting.IMPORTANT

Use a repair bench to ensure the positioning of the

points and the geometr y of the axle assemblies.

Note:

The information contained in the following descri-

bes the general repair procedure for all vehicles

having the same design for this part.

Before reading this general information, check that

there are no special notes associated with this vehi-

cle. These special notes will be specified if applica-

ble in other parts of this subsection dealing with the

par t.

Note:

For a detailed description of a particular connec-

tion, see MR 400.

110557

Page 60 of 209

41A-21

FRONT LOWER STRUCTURE

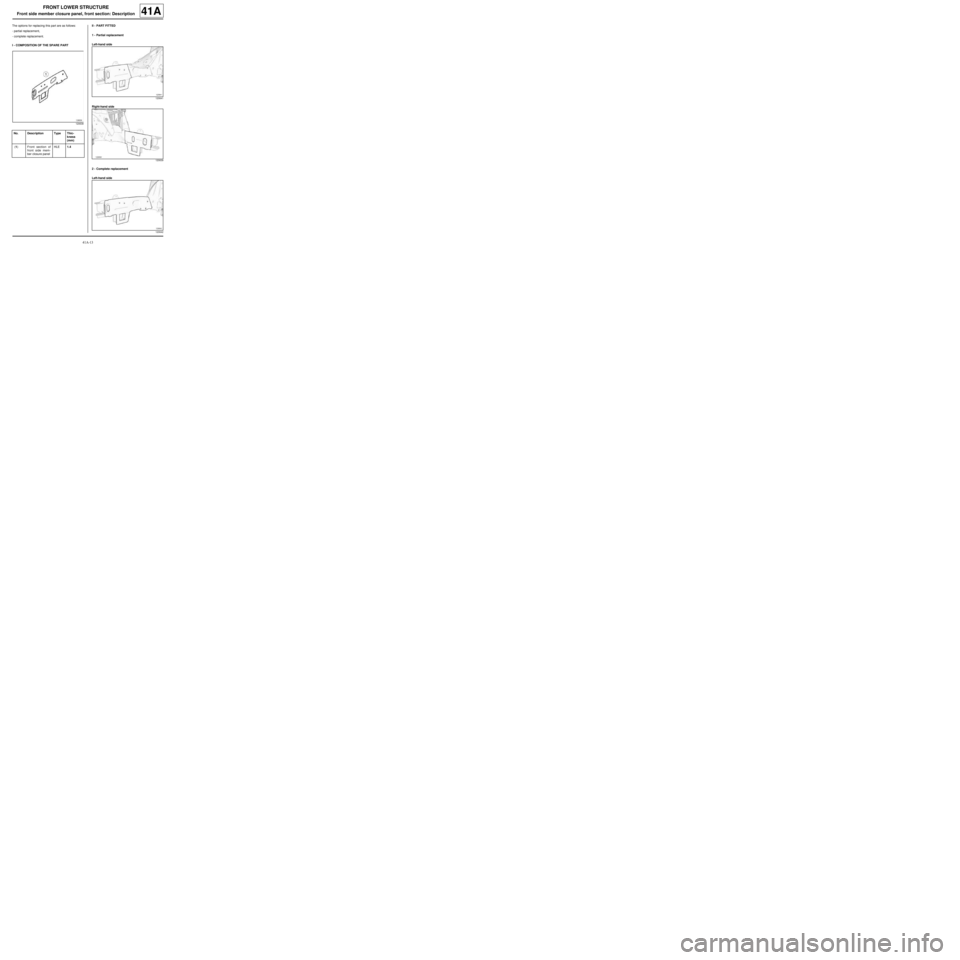

Engine stand: Description

41A

There is only one way of replacing this part:

-complete replacement.

I - COMPOSITION OF THE SPARE PARTII - PART FITTED

120626

IMPORTANT

The straightening bench must be used.

120627

No. Description Type Thic-

kness

(mm)

(1) E ngine support

plateMild

steel2

(2) Engine mounting

height adjusterMild

steel1.8

(3) Engine height

adjuster stiffenerHLE2

120628

WARNING

If the spot welds cannot be made as they were ori-

ginally using an electrical spot welding machine,

they should be replaced with plug welds after holes

have been drilled in the first panel.

Trending: door lock, sunroof, wiring, fuel, coolant, open bonnet, gas type