Seat Ibiza 2020 Directive 2014/53/EU Bluetooth

Manufacturer: SEAT, Model Year: 2020, Model line: Ibiza, Model: Seat Ibiza 2020Pages: 406, PDF Size: 9.22 MB

Page 121 of 406

Page 11 of 89 Report No. : 60404488 001

TR F No. IEC62368_1 C

OVERVIEW OF ENERGY SOURCES AND SAFEG UARDS

Clause Possible Hazard

5 Electrically - caused injury

Class and Energy Source

(e.g. ES3: Primary circuit) Body Part

(e.g. Ordinary) Safeguards

B S R

ES1: All parts Ordinary N/A N/A N/A

6 Electrically - caused fire

Class and Energy Source

(e.g. P S2: 100 Watt circuit) Material part

(e.g. Printed board ) Safeguards

B 1 st

S 2 nd

S

PS3: > 100 Watt circuit PCB and combustible

materials within the metallic

enclosure and

mains parts See clause

6.3.1 Control fire

spread,

Min V - 1,

PCB ,

connector

V - 1 See clause

6.4.1

Fire

enclosure is

provided

PS2: > PS1, ≤ 100 W att circuit PCB and combustible

materials i n monitor ,

Keyboard circuits See clause

6.3.1 See clause

6.4.5.2 N/A

7 Injury caused by hazardous substances

Class and Energy Source

(e.g. Ozone) Body Part

(e.g., Skilled) Safeguards

B S R

N/A N/A N/A N/A N/A

8 Mechanically - caused injury

Class and Energy Source

(e.g. MS3: Plastic fan blades) Body Part

(e.g. Ordinary) Safeguards

B S R

MS1: Sharp edges and corners Ordinary N/A N/A N/A

MS1: Equipment mass Ordinary N/A N/A N/A

9 Thermal burn

Class and Energy Source

(e.g. TS1: Keyboard caps) Body Part

(e.g., Ordinary) Safeguards

B S R

TS1:Monitor enclosure Ordinary N/A N/A N/A

TS1:Screen surface Ordinary N/A N/A N/A

TS1:Keyboard enclos ure Ordinary N/A N/A N/A

Page 122 of 406

Page 12 of 89 Report No. : 60404488 001

TR F No. IEC62368_1 C

10 Radiation

Class and Energy Source

(e.g. RS1: PMP sound output) Body Part

(e.g., Ordinary) Safeguards

B S R

RS1:Indicating lights Ordinary N/A N/A N/A

Supplementary Information:

“B” – Basic Safeguard; “S” – Supplementar y Safeguard; “R” – Reinforced Safeguard

Page 123 of 406

Page 13 of 89 Report No. : 60404488 001

TR F No. IEC62368_1 C

ENERGY SOURCE DIAGRAM

Optional . Manufacturers are to provide the energy sources diagram identify declared energy sources and

identifying the demarcations are between power sources. Recommend diagram be provided included in

power supply and multipart systems.

Insert diagram below. Example diagram designs are; Block diagrams; image(s) with layered data; mechanical

drawings

■ ES ■ PS ■ MS ■ TS ■ RS

ES Classification:

ES1: All parts .

PS Classification:

PS3: Head unit .

PS2: LCD module and Keyboard circuits .

MS classification:

MS1 : There are no sharp edges or corners . Equipment mass is under 7 kg .

TS classification:

TS1: All accessible parts including monitor enclosure, screen surface and keyboard enclosure .

RS classification:

RS1: Indicating lights and low power devices.

Page 124 of 406

Page 14 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

4 GENERAL REQUIREMENTS

P

4.1.1 Acceptance of materials, components and

subassemblies (See appended table 4.1.2) P

4.1.2 Use of components

The equipment is so de signed

and constructed that, under

normal operating conditions

(see Clause B.2), abnormal

operating conditions (see

Clause B.3), and single fault

conditions (see Clause B.4),

safeguards are provided to

reduce the likelihood of injury

or, in the case of fi re, property

damage P

4.1.3 Equipment design and construction

P

4.1.4 Specified ambient temperature for outdoor use ( o

C)

................................ ................................ .................... : Not intended for outdoor use N/A

4.1.5 Constructions and components not specifically

covered N/A

4.1.8 Liquids and liquid fille d components (LFC) N/A

4.1.15 Markings and instructions (See Annex F) P

4.4.3 Safeguard robustness P

4.4.3.1 General P

4.4.3.2 Steady force tests Building - in equipment N/A

4.4.3.3 Drop tests Building - in equipment N/A

4.4.3.4 Impact tests P

4.4. 3.5 Internal accessible safeguard tests No Internal accessible

safeguard is used N/A

4.4.3.6 Glass impact tests No glass in the equipment N/A

4.4.3.7 Glass fixation tests No laminated glass used N/A

Glass impact test (1J) N/A

Push/pull test (10 N) N/A

4.4.3.8 Thermoplastic material tests P

4.4.3.9 Air comprising a safeguard N/A

4.4.3.10 Accessibility, glass, safeguard effectiveness P

4.4.4 Displacement of a safeguard by an insulating liquid No insulating liquid used N/A

4.4.5 Safety interlo cks No Safety interlocks N/A

Page 125 of 406

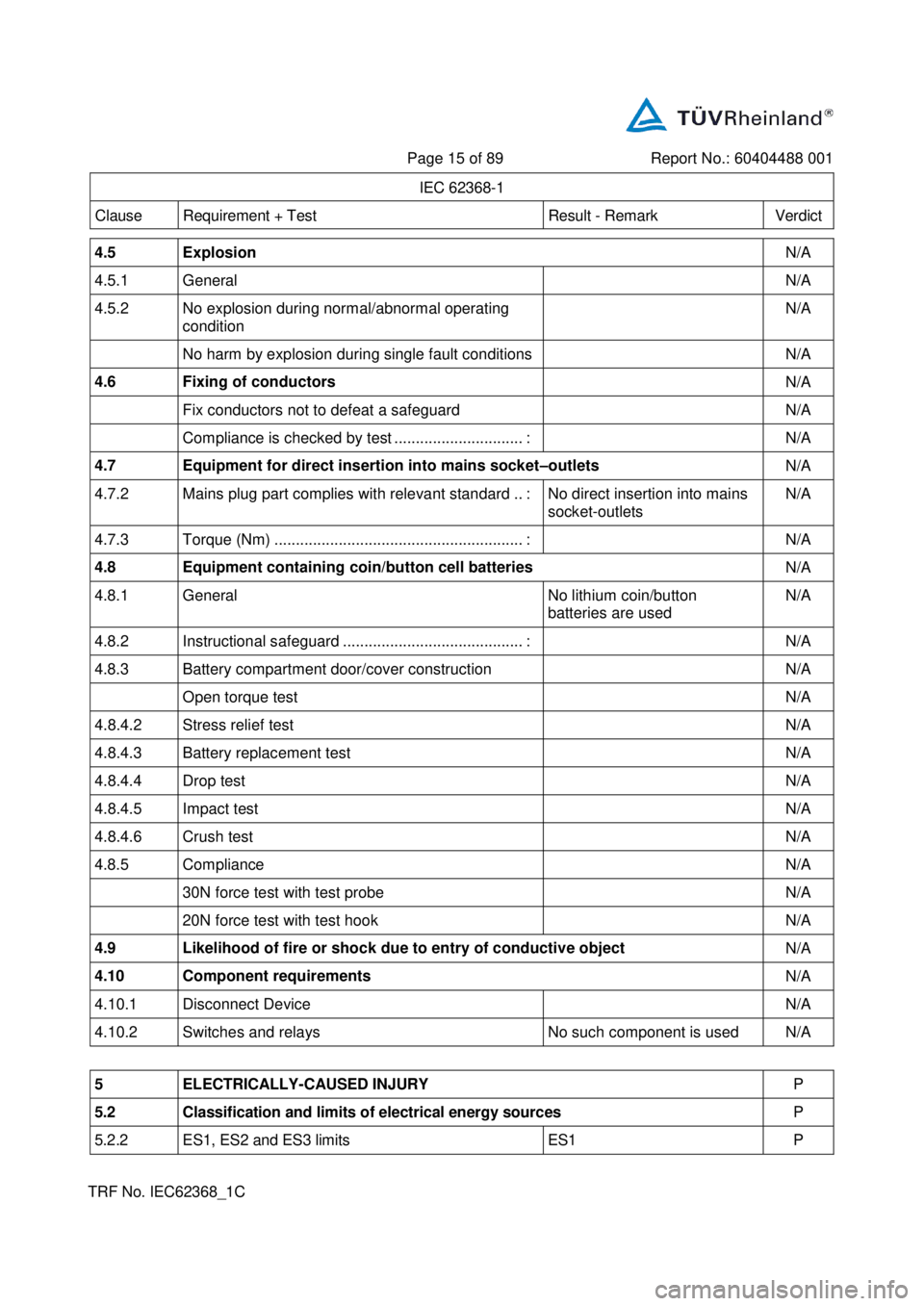

Page 15 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

4.5 Explosion

N/A

4.5.1 General N/A

4.5.2 No explosion during normal/abnormal operating

condition N/A

No harm by explosion during single fault conditions N/A

4.6 Fixing of conductors

N/A

Fix conductors not to defeat a safeguard N/A

Compliance is checked by test .............................. : N/A

4.7 Equipment for direct insertion into mains socket – outlets

N/A

4.7.2 Mains plug part complies with relevant standard .. : No direct insertion into mains

socket - outlets N/A

4.7.3 Torque (Nm) ................................ .......................... : N/A

4.8 Equipment containing coin/button cell batteries

N/A

4.8.1 General No lithium coin/button

batteries are used N/A

4.8.2 Instructional safeguard ................................ .......... : N/A

4.8.3 Battery compartment door/cover construction N/A

Open torque test N/A

4.8.4.2 Stress reli ef test N/A

4.8.4.3 Battery replacement test N/A

4.8.4.4 Drop test N/A

4.8.4.5 Impact test N/A

4.8.4.6 Crush test N/A

4.8.5 Compliance N/A

30N force test with test probe N/A

20N force test with test hook N/A

4.9 Likelihood of fire or shoc k due to entry of conductive object

N/A

4.10 Component requirements

N/A

4.10.1 Disconnect Device N/A

4.10.2 Switches and relays No such component is used N/A

5 ELECTRICALLY - CAUSED INJURY

P

5.2 Classification and limits of electrical energy sources

P

5.2.2 ES1, ES2 and ES3 limits ES1 P

Page 126 of 406

Page 16 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

5.2.2.2 Steady - state voltage and current limits .................... : (See appended table 5.2) P

5.2.2.3 Capacitance limits ................................ ..................... : N/A

5.2.2.4 Single pulse limits ................................ ..................... : No such single pulse with the

e quipment N/A

5.2.2.5 Limits for repetitiv e pulses ................................ ........ : No such repetitive pulses with

the e quipment N/A

5.2.2.6 Ringing signals No Ringing signals N/A

5.2.2.7 Audio signals P

5.3 Protection against electrical energy sources

N/A

5.3.1 General Requirements for accessible parts to

ordinary, inst ructed and skilled persons Only ES1 N/A

5.3.1 a) Accessible ES1/ES2 derived from ES2/ES3 circuits N/A

5.3.1 b) Skilled persons not unintentional contact ES3 bare

conductors N/A

5.3.2.1 Accessibility to electrical energy sources and

safeguards N/A

Accessibility to outdoor equipment bare parts N/A

5.3.2.2 Contact requirements N/A

Test with test probe from Annex V -

5.3.2.2 a) Air gap – electric strength test potential (V) ............. : N/A

5.3.2.2 b) Air gap – distance (mm) ................................ ........... : N/A

5.3.2.3 Compliance N/A

5.3.2.4 Terminals for connecting stripped wire N/A

5.4 Insulation materials and requirements

N/A

5.4.1.2 Properties of insulating material N/A

5.4.1.3 Material is non - hygroscopic N/A

5.4.1.4 Maximum operating temperature for insulating

materi als ................................ ................................ .... : N/A

5.4.1.5 Pollution degrees ................................ ...................... : N/A

5.4.1.5.2 Test for pollution degree 1 environment and for an

insulating compound N/A

5.4.1.5.3 Thermal cycling test N/A

5.4.1.6 Insulation in transformers with varying dimensions N/A

5.4.1.7 Insulation in circuits generating starting pulses N/A

5.4.1.8 Determination of working voltage ............................. : N/A

Page 127 of 406

Page 17 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

5.4.1.9 Insulating surfaces N/A

5.4.1.10 Thermoplastic parts on which conductive metallic

parts are directly mounted N/A

5.4.1.10.2 Vicat test ................................ ................................ .... : N/A

5.4.1.10. 3 Ball pressure test ................................ ...................... : N/A

5.4.2 Clearances N/A

5.4.2.1 General requirements N/A

Clearances in circuits connected to AC Mains,

Alternative method N/A

5.4.2.2 Procedure 1 for determining clearance N/A

Temporary overvoltage ................................ ............ :

5.4.2.3 Procedu re 2 for determining clearance N/A

5.4.2.3.2.2 a.c. mains transient voltage ................................ ...... :

5.4.2.3.2.3 d.c. mains transient voltage ................................ ..... :

5.4.2.3.2.4 External circuit transient voltage ............................... :

5.4.2.3.2.5 Transient voltage determined by measurement ...... :

5.4.2.4 Determining the adequacy of a clearance using an

electric strength test ................................ ................. : N/A

5.4.2.5 Multiplication factors for clearances and test voltages

................................ ................................ ................... : N/A

5.4.2.6 Clearance measurement ................................ .......... : N/A

5.4.3 Creepage distances N/A

5.4.3.1 General N/A

5.4.3.3 Mate rial group ................................ ........................... :

5.4.3.4 Creepage distances measurement .......................... : N/A

5.4.4 Solid insulation N/A

5.4.4.1 General requirements N/A

5.4.4.2 Minimum distance through insulation ...................... : N/A

5.4.4.3 Insulating compound forming solid insulation N/A

5.4.4.4 Solid insulation in semiconductor devices N/A

5.4.4.5 Insulating compound forming cemented joints N/A

5.4.4.6 Thin sheet material N/A

5.4.4.6.1 General requirements N/A

5.4.4.6.2 Separable thin sheet material N/A

Page 128 of 406

Page 18 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

Number of layers (pcs) ................................ ............ : N/A

5.4 .4.6.3 Non - separable thin sheet material N/A

Number of layers (pcs) ................................ ......... : N/A

5.4.4.6.4 Standard test procedure for non - separable thin

sheet material ................................ ........................ : N/A

5.4.4.6.5 Mandrel test N/A

5.4.4.7 Solid i nsulation in wound components N/A

5.4.4.9 Solid i nsulation at frequencies >30 kHz, E

P , K

R , d ,

V

PW (V) ................................ ................................ ... : N/A

Alternative by electric strength test, tested voltage

(V), K

R ................................ ................................ .... : N/A

5.4.5 Antenna terminal insulation No a ntenna terminal N/A

5.4.5.1 General N/A

5.4.5.2 Voltage surge test N/A

5.4.5.3

In sulation resistance (M ) ................................ ..... : N/A

Electric strength test ................................ ................. : N/A

5.4.6 Insulation of internal wire as part of supplementary

safeguard N/A

5.4.7 Tests for semiconductor components and for

cemented joints N/A

5.4.8 Humidity conditioning N/A

Relative h umidity (%), temperature (°C), duration

(h) ................................ ................................ .......... :

5.4.9 Electric strength test Class III equipment N/A

5.4.9.1 Test procedure for type test of solid insulation ....... : N/A

5.4.9.2 Test procedure for routine test N/A

5.4.10 Safeguards against transient volta ges from external

circuits N/A

5.4.10.1 Parts and circuits separated from external circuits N/A

5.4.10.2 Test methods N/A

5.4.10.2.1 General N/A

5.4.10.2.2 Impulse test ................................ ........................... : N/A

5.4.10.2.3 Steady - state test ................................ .................... : N/A

5.4.10.3 Verification for insulati on breakdown for impulse

test ................................ ................................ ......... : N/A

5.4.11 Separation between external circuits and earth N/A

Page 129 of 406

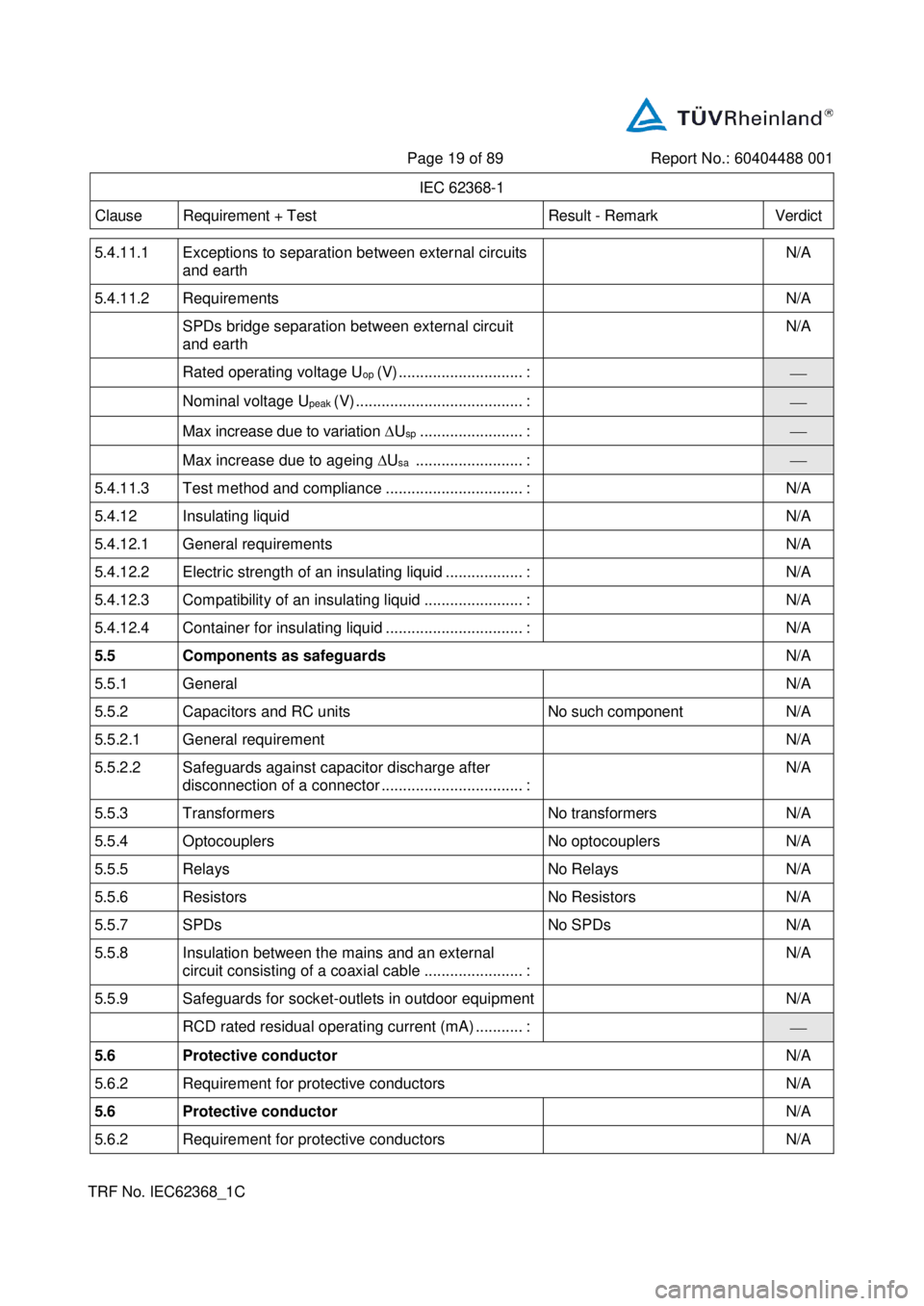

Page 19 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

5.4.11.1 Exceptions to separation between external circuits

and earth N/A

5.4.11.2 Requirements N/A

SPDs bridge separation between external circuit

and earth N/A

Rated operating voltage U

op (V) ............................. :

Nominal voltage U

peak (V) ................................ ....... :

Max increase due to variation U

sp ........................ :

Max increase due to ageing U

sa ......................... :

5.4.11.3 Test method and compliance ................................ : N/A

5.4.12 Insulating liquid N/A

5.4.12.1 Gener al requirements N/A

5.4.12.2 Electric strength of an insulating liquid .................. : N/A

5.4.12.3 Compatibility of an insulating liquid ....................... : N/A

5.4.12.4 Container for insulating liquid ................................ : N/A

5.5 Components as safeguards

N/A

5.5.1 General N/A

5.5.2 Capacitors and RC units No such component N/A

5.5.2.1 General requirement N/A

5.5.2.2 Safeguards against capacitor discharge after

disconnection of a connector ................................ . : N/A

5.5.3 Transformers No transformers N/A

5.5.4 Optocouplers No o ptocouplers N/A

5.5.5 Relays No Relays N/A

5.5.6 Resistors No Resistors N/A

5.5.7 SPDs No SPDs N/A

5.5.8 Insulation between the mains and an external

circuit consisting of a coaxial cable ....................... : N/A

5.5.9 Safeguards for socket - outlets in outdoor equipment N/A

RCD rated residual operat ing current (mA) ........... :

5.6 Protective conductor

N/A

5.6.2 Requirement for protective conductors N/A

5.6 Protective conductor

N/A

5.6.2 Requirement for protective conductors N/A

Page 130 of 406

Page 20 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

5.6.2.1 General requirements N/A

5.6.2.2 Colour of insulation N/A

5.6 .3 Requirement for protective earthing conductors N/A

Protective earthing conductor size (mm 2

) .............. :

Protective earthing conductor serving as a

reinforced safeguard N/A

Protective earthing conductor serving as a double

safeguard N/A

5.6.4 Require ments for protective bonding conductors N/A

5.6.4.1 Protective bonding conductors N/A

Protective bonding conductor size (mm 2

). .............. :

5.6.4.2 Protective current rating (A) ................................ .... : N/A

5.6.5 Terminals for protective conductors N/A

5.6.5.1 Terminal size fo r connecting protective earthing

conductors (mm) ................................ .................... : N/A

Terminal size for connecting protective bonding

conductors (mm) ................................ ....................... : N/A

5.6.5.2 Corrosion N/A

5.6.6 Resistance of the protective bonding system N/A

5.6.6.1 Requirements N/A

5.6.6.2 Test Method ................................ ........................... : N/A

5.6.6.3

R esistance ( ) or voltage drop .............................. : N/A

5.6.7 Reliable connection of a protective earthing

conductor N/A

5.6.8 Functional earthing N/A

Conductor size (mm 2

) ................................ ............. : N/A

Class II with functional earthing marking .............. : N/A

Appliance inlet cl & cr (mm) ................................ ... : N/A

5.7 Prospective touch voltage, touch current and protective conductor current

N/A

5.7.2 Measuring devices and networks N/A

5.7.2.1 Measurement of touch current N/A

5.7.2.2 Measurement of voltage N/A

5.7.3 Equipment set - up, supply c onnections and earth

connections N/A

5.7.4 Unearthed accessible parts ................................ ... : N/A