Seat Ibiza 2020 Directive 2014/53/EU Bluetooth

Manufacturer: SEAT, Model Year: 2020, Model line: Ibiza, Model: Seat Ibiza 2020Pages: 406, PDF Size: 9.22 MB

Page 141 of 406

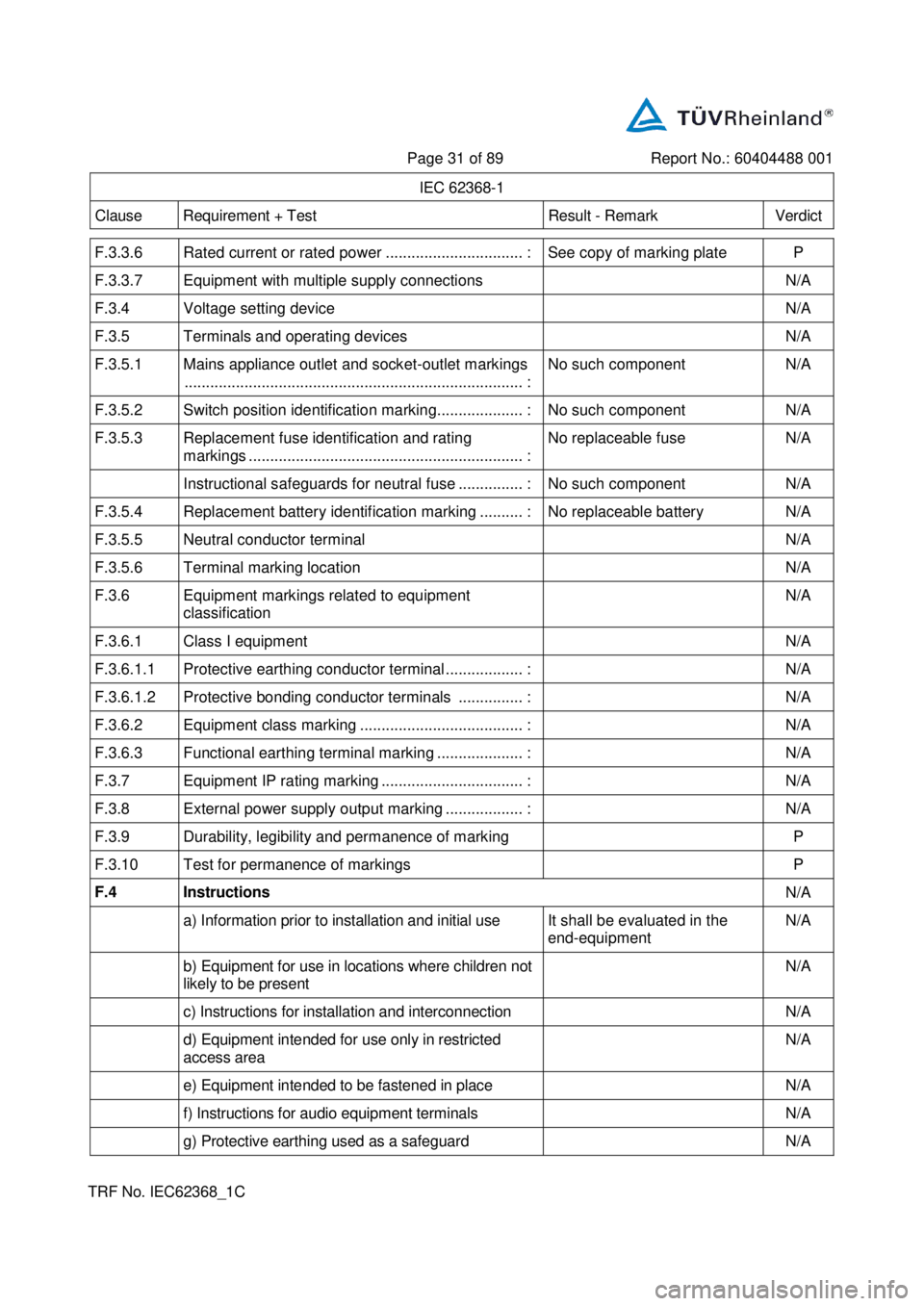

Page 31 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

F.3.3.6 Rated current or rate d power ................................ : See copy of marking plate P

F.3.3.7 Equipment with multiple supply connections N/A

F.3.4 Voltage setting device N/A

F.3.5 Terminals and operating devices N/A

F.3.5.1 Mains appliance outlet and socket - outlet markings

................................ ................................ ............... : No such component N/A

F.3.5.2 Switch position identification marking .................... : No such component N/A

F.3.5.3 Replacement fuse identification and rating

markings ................................ ................................ : No replaceable fuse N/A

Instructional safeguards for neutral fuse ............... : No such component N/A

F.3.5.4 Replacement batter y identification marking .......... : No replaceable battery N/A

F.3.5.5 Neutral conductor terminal N/A

F.3.5.6 Terminal marking location N/A

F.3.6 Equipment markings related to equipment

classification N/A

F.3.6.1 Class I equipment N/A

F.3.6.1.1 Protective earthing conductor terminal .................. : N/A

F.3.6.1.2 Protective bonding conductor terminals ............... : N/A

F.3.6.2 Equipment class marking ................................ ...... : N/A

F.3.6.3 Functional earthing terminal marking .................... : N/A

F.3.7 Equipment IP rating marking ................................ . : N/A

F.3.8 External power supply output marking .................. : N/A

F.3.9 Durability, legibility and permanence of marking P

F.3.10 Test for permanence of markings P

F.4 Instructions

N/A

a) Information prior to installation and initial use It shall be evaluated in the

end - equipment N/A

b) Eq uipment for use in locations where children not

likely to be present N/A

c) Instructions for installation and interconnection N/A

d) Equipment intended for use only in restricted

access area N/A

e) Equipment intended to be fastened in place N/A

f) Instructions for audio equipment terminals N/A

g) Protective earthing used as a safeguard N/A

Page 142 of 406

Page 32 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

h) Protective conductor current exceeding ES2 limits N/A

i) Graphic symbols used on equipment N/A

j) Permanently connected equipment not provid ed

with all - pole mains switch N/A

k) Replaceable components or modules providing

safeguard function N/A

l) Equipment containing insulating liquid N/A

m ) Installation instructions for outdoor equipment N/A

F.5

Instructional safeguards N/A

G COMP ONENTS

N/A

G.1 Switches

N/A

G.1.1 General No such switches are used as

disconnect devices N/A

G.1.2 Ratings, endurance, spacing, maximum load N/A

G.1.3 Test method and compliance N/A

G.2 Relays

N/A

G.2.1 Requirements No such relays are used as

dis connect devices N/A

G.2.2 Overload test N/A

G.2.3 Relay controlling connectors supplying power to

other equipment N/A

G.2.4 Test method and compliance N/A

G.3 Protective devices

N/A

G.3.1 Thermal cut - offs No thermal cut - offs N/A

Thermal cut - outs separately approved according to

IEC 60730 with conditions indicated in a) & b) N/A

Thermal cut - outs tested as part of the equipment as

indicated in c) N/A

G.3.1.2 Test method and compliance N/A

G.3.2 Thermal links No thermal links N/A

G.3.2.1 a) Thermal links tested separately according to IEC

60691 with specifics N/A

b) Thermal links tested as part of the equipment N/A

G.3.2.2 Test method and compliance N/A

G.3.3 PTC thermistors No PTC thermistors N/A

G.3.4 Overcurrent protection device s N/A

Page 143 of 406

Page 33 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

G.3.5 Safeguards components not mentioned in G.3.1 to

G.3.4 No such components N/A

G.3.5.1 Non - resettable devices suitably rated and marking

provided N/A

G.3.5.2 Single faults conditions ................................ .......... : N/A

G.4 Connectors

N/A

G.4.1 Spacings N/A

G.4.2 Mai ns connector configuration .............................. : N/A

G.4.3 Plug is shaped that insertion into mains socket -

outlets or appliance coupler is unlikely N/A

G.5 Wound components

N/A

G.5.1 Wire insulation in wound components N/A

G.5.1.2 Protection against mechanical stress N/A

G.5.2 Endurance test N/A

G.5.2.1 General test requirements N/A

G.5.2.2 Heat run test N/A

Test time (days per cycle) ................................ ..... :

Test temperature ( C) ................................ ............ :

G.5.2.3 Wound components supplied from the mains N/A

G.5.2.4 No insulation breakdown N/A

G.5.3 Transformers No transformers is used N/A

G.5.3.1 Compliance method ................................ ............... : N/A

Position ................................ ................................ .. : N/A

Method of protection ................................ .............. : N/A

G.5.3.2 Insulation N/A

Protection from displacement of windings ............. :

G.5.3.3 Transformer overload tests N/A

G.5.3.3.1 T est conditions N/A

G.5.3.3.2 Winding temperatures N/A

G.5.3.3.3 Winding temperatures - alternative test method N/A

G.5.3.4 Transformers using FIW N/A

G.5.3.4.1 General N/A

FIW wire nominal diameter ................................ .... :

G.5.3.4.2 Transformers with basic insulat ion only N/A

Page 144 of 406

Page 34 of 8 9 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

G.5.3.4.3 Transformers with double insulation or reinforced

insulation ................................ ............................... : N/A

G.5.3.4.4 Transformers with FIW wound on metal or ferrite

core N/A

G.5.3.4.5 Thermal cycling test and compliance N/A

G.5.3.4.6 Partial discharge test N/A

G. 5.3.4.7 Routine test N/A

G.5.4 Motors (See appended table 4.1.2) N/A

G.5.4.1 General requirements N/A

G.5.4.2 Motor overload test conditions N/A

G.5.4.3 Running overload test N/A

G.5.4.4.2 Locked - rotor overload test N/A

Test duration (days) ................................ .............. :

G.5.4.5 Running overload test for DC motors N/A

G.5.4.5.2 Tested in the unit N/A

G.5.4.5.3 Alternative method N/A

G.5.4.6 Locked - rotor overload test for DC motors N/A

G.5.4.6.2 Tested in the unit N/A

Maximum Temperature ................................ ........ : (See ap pended table B.3, B.4) N/A

G.5.4.6.3 Alternative method N/A

G.5.4.7 Motors with capacitors N/A

G.5.4.8 Three - phase motors N/A

G.5.4.9 Series motors N/A

Operating voltage ................................ ................. :

G.6 Wire Insulation

N/A

G.6.1 General N/A

G.6.2 Enamel led winding wire insulation N/A

G.7 Mains supply cords

N/A

G.7.1 General requirements N/A

Type ................................ ................................ ....... :

G.7.2 Cross sectional area (mm 2

or AWG) ..................... : N/A

G.7.3 Cord anchorages and strain relief for non -

detachable power supply cords N/A

G.7.3.2 Cord stra in relief N/A

Page 145 of 406

Page 35 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

G.7.3.2.1 Requirements N/A

Strain relief test force (N) ................................ ...... : N/A

G.7.3.2.2 Strain relief mechanism failure N/A

G.7.3.2.3 Cord sheath or jacket position, distance (mm) ...... : N/A

G.7.3.2.4 Strain relief and cord anchorage material N /A

G.7.4 Cord Entry N/A

G.7.5 Non - detachable cord bend protection N/A

G.7.5.1 Requirements N/A

G.7.5.2 Test method and compliance N/A

Overall diameter or minor overall dimension, D

(mm) ................................ ................................ ...... :

Radius of curvature after test (mm) ....................... :

G.7.6 Sup ply wiring space N/A

G.7.6.1 General requirements N/A

G.7.6.2 Stranded wire N/A

G.7.6.2.1 Requirements N/A

G.7.6.2.2 Test with 8 mm strand N/A

G.8 Varistors

N/A

G.8.1 General requirements N/A

G.8.2 Safeguards against fire N/A

G.8.2.1 General N/A

G.8.2.2 Varistor overload test N/A

G.8.2.3 Temporary overvoltage test N/A

G.9 Integrated circuit (IC) current limiters

N/A

G.9.1 Requirements N/A

IC limiter output current (max. 5A) ........................ :

Manufacturers’ defined drift ................................ .. :

G.9.2 Test Progr am N/A

G.9.3 Compliance N/A

G.10 Resistors

N/A

G.10.1 General N/A

G.10.2 Conditioning N/A

G.10.3 Resistor test N/A

Page 146 of 406

Page 36 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

G.10.4 Voltage surge test N/A

G.10.5 Impulse test N/A

G.10.6 Overload test N/A

G.11 Capacitors and RC units

N/A

G.11.1 Gen eral requirements N/A

G.11.2 Conditioning of capacitors and RC units N/A

G.11.3 Rules for selecting capacitors N/A

G.12 Optocouplers

N/A

Optocouplers comply with IEC 60747 - 5 - 5 with

specifics N/A

Type test voltage V

ini,a ................................ ........... :

Routine test vo ltage, V

ini, b ................................ ..... :

G.13 Printed boards

N/A

G.13.1 General requirements N/A

G.13.2 Uncoated printed boards N/A

G.13.3 Coated printed boards N/A

G.13.4 Insulation between conductors on the same inner

surface N/A

G.13.5 Insulation between conducto rs on different surfaces N/A

Distance through insulation ................................ ... : N/A

Number of insulation layers (pcs) ......................... :

G.13.6 Tests on coated printed boards N/A

G.13.6.1 Sample preparation and preliminary inspection N/A

G.13.6.2 Test method and compliance N/A

G.14 Coating on components terminals

N/A

G.14.1 Requirements ................................ ....................... : N/A

G.15 Pressurized liquid filled components

N/A

G.15.1 Requirements N/A

G.15.2 Test methods and compliance N/A

G.15.2.1 Hydrostatic pressure test N/A

G.15.2.2 Creep resistance te st N/A

G.15.2.3 Tubing and fittings compatibility test N/A

G.15.2.4 Vibration test N/A

Page 147 of 406

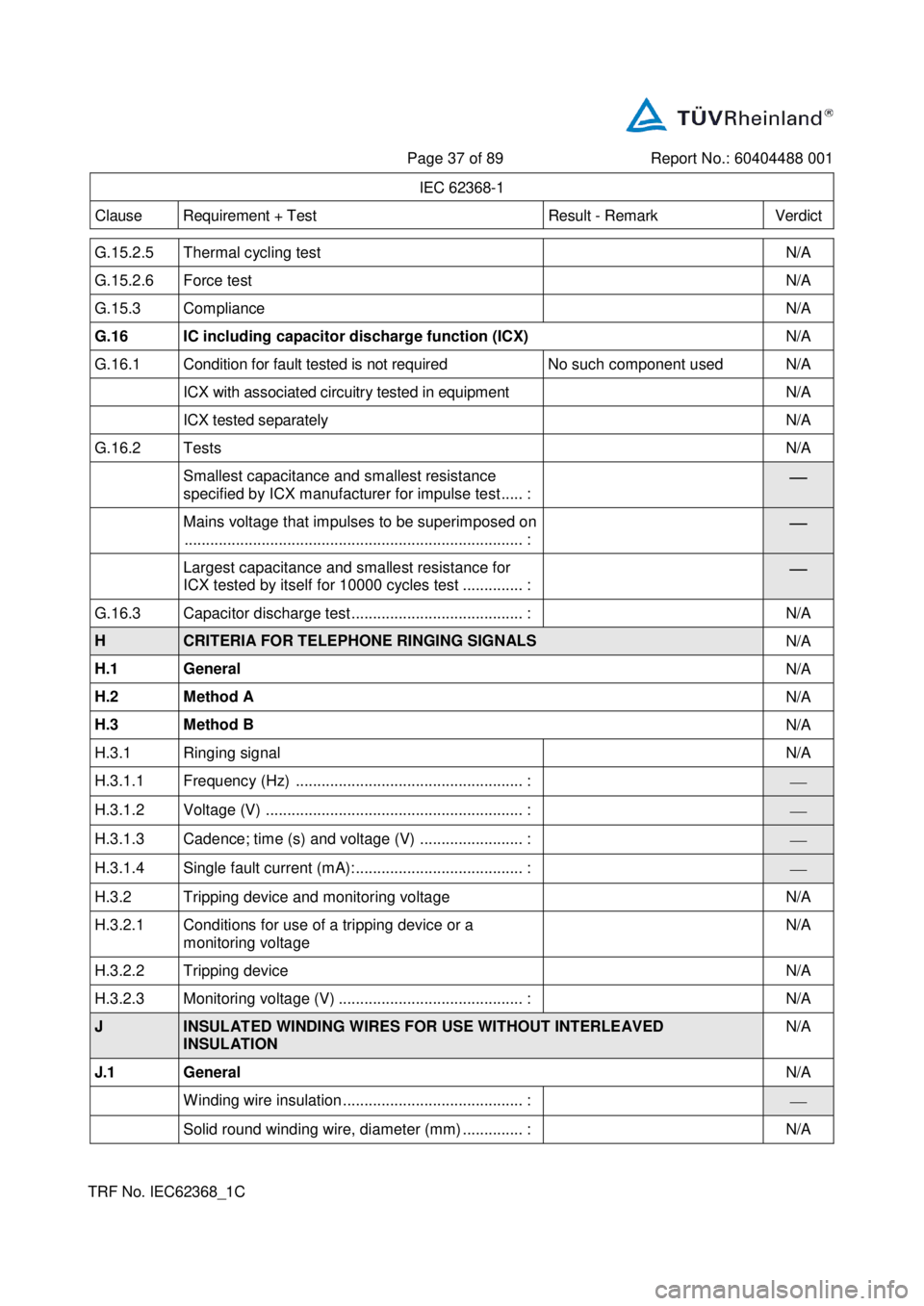

Page 37 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

G.15.2.5 Thermal cycling test N/A

G.15.2.6 Force test N/A

G.15.3 Compliance N/A

G.16 IC including capacitor discharge function (ICX)

N/A

G.16.1 Condition f or fault tested is not required N o such component used N/A

ICX with associated circuitry tested in equipment N/A

ICX tested separately N/A

G.16.2 Tests N/A

Smallest capacitance and smallest resistance

specified by ICX manufacturer for impulse te st ..... :

Mains voltage that impulses to be superimposed on

................................ ................................ ............... :

Largest capacitance and smallest resistance for

ICX tested by itself for 10000 cycles test .............. :

G.16.3 Capacitor discharge test ................................ ........ : N/A

H CRITERIA FOR TELEPHONE RINGING SIGNALS

N/A

H.1 G eneral

N/A

H.2 Method A

N/A

H.3 Method B

N/A

H.3.1 Ringing signal N/A

H.3.1.1 Frequency (Hz) ................................ ..................... :

H.3.1.2 Voltage (V) ................................ ............................ :

H.3.1.3 Cadence; time (s) and voltage (V) ........................ :

H.3.1.4 Single fault current (mA): ................................ ....... :

H.3.2 Tripping device and monitor ing voltage N/A

H.3.2.1 Conditions for use of a tripping device or a

monitoring voltage N/A

H.3.2.2 Tripping device N/A

H.3.2.3 Monitoring voltage (V) ................................ ........... : N/A

J INSULATED WINDING WIRES FOR USE WITHOUT INTERLEAVED

INSULATION N/A

J.1 General

N/A

W inding wire insulation ................................ .......... :

Solid round winding wire, diameter (mm) .............. : N/A

Page 148 of 406

Page 38 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

Solid square and rectangular (flatwise bending)

winding wire, cross - sectional area (mm 2

) .............. : N/A

J.2/J.3

Tests and Manufacturing (See separate test report)

K SAFETY INTERLOCK S

N/A

K.1 General requirements

N/A

Instructional safeguard ................................ .......... : N/A

K.2 Components of safety interlock safeguard mechanism

N/A

K.3 Inadvertent change of operating mode

N/A

K.4 Interlock safeguard override

N/A

K.5 Fail - safe

N/A

K.5.1 Under single fa ult condition N/A

K.6 Mechanically operated safety interlocks

N/A

K.6.1 Endurance requirement N/A

K.6.2 Test method and compliance ................................ : N/A

K.7 Interlock circuit isolation

N/A

K.7.1 Separation distance for contact gaps & interlock

circuit elements N/A

In circuit connected to mains, separation distance

for contact gaps (mm) ................................ ............ : N/A

In circuit isolated from mains, separation distance

for contact gaps (mm) ................................ ............ : N/A

Electric strength test before and after the test of

K.7.2 ................................ ................................ ...... : N/A

K.7.2 Overload test , Current (A) ................................ ..... : N/A

K.7.3 Endurance test N/A

K.7.4 Electric strength test N/A

L DISCONNECT DEVICES

N/A

L.1 General requirements

N/A

L.2 Permanently connected equipment

N/A

L.3 Parts that remain energized

N/A

L.4 Single - phase equipment

N/ A

L.5 Three - phase equipment

N/A

L.6 Switches as disconnect devices

N/A

L.7 Plugs as disconnect devices

N/A

L.8 Multiple power sources

N/A

Page 149 of 406

Page 39 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

Instructional safeguard ................................ .......... : N/A

M EQUIPMENT CONTAINING BATTERIES AND THEIR PROTECTION CIRCUITS

N/A

M.1 General requirements

N/A

M.2 Safety of batteries and their cells

N/A

M.2.1 Batteries and their cells comply with relevant IEC

standards ................................ ............................... : Batteries is not provided N/A

M.3 Protection circuits for batteries provided within

the equipment N/A

M.3.1 Requi rements N/A

M.3.2 Test method N/A

Overcharging of a rechargeable battery N/A

Excessive discharging N/A

Unintentional charging of a non - rechargeable

battery N/A

Reverse charging of a rechargeable battery N/A

M.3.3 Compliance N/A

M.4 Addit ional safeguards for equipment containing a portable secondary lithium

battery N/A

M.4.1 General N/A

M.4.2 Charging safeguards N/A

M.4.2.1 Requirements N/A

M.4.2.2 Compliance ................................ ............................ : N/A

M.4.3 Fire enclosure ................................ ........................ : N/A

M.4.4 Drop test of equipment containi ng a secondary

lithium battery N/A

M.4.4.2 Preparation and procedure for the drop test N/A

M.4.4.3 Drop, Voltage on reference and dropped batteries

(V); voltage difference during 24 h period (%): .... : N/A

M.4.4.4 Check of the charge/discharge function N/A

M.4.4.5 Charge / discharge cycle test N/A

M.4.4.6 Compliance N/A

M.5 Risk of burn due to short - circuit during carrying

N/A

M.5.1 Requirement N/A

M.5.2 Test method and compliance N/A

M.6 Safeguards against short - circuits

N/A

Page 150 of 406

Page 40 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

M.6.1 External a nd internal faults N/A

M.6.2 Compliance N/A

M.7 Risk of explosion from lead acid and NiCd batteries

N/A

M.7.1 Ventilation preventing explosive gas concentration N/A

Calculated hydrogen generation rate .................... : N/A

M.7.2 Test method and compliance N/A

Minimum air flow rate, Q (m 3

/h) ............................. :

N/A

M.7.3 Ventilation tests N/A

M.7.3.1 General N/A

M.7.3.2 Ventilation test – alternative 1 N/A

Hydrogen gas concentration (%) ........................... : N/A

M.7.3.3 Ventilation test – alternative 2 N/A

Obtained hydrogen generation rate ....................... : N/A

M.7.3.4 Ventilation test – alternative 3 N/A

Hydrogen gas concentration (%) ........................... : N/A

M.7.4 Marking ................................ ................................ .. : N/A

M.8 Protection against internal ignition from external spark sources of batteries

with aqueous electrolyte N/A

M.8.1 General N/A

M .8.2 Test method N/A

M.8.2.1 General N/A

M.8.2.2 Estimation of hypothetical volume V

Z (m 3

/s) ......... :

M.8.2.3 Correction factors ................................ .................. :

M.8.2.4 Calculation of distance d (mm) ............................. :

M.9 Preventing electrolyte spillage

N/A

M.9.1 Protection from electrolyte spillage N/A

M.9.2 Tray for preventing electrolyte spillage N/A

M.10

Instructions to prevent reasonably foreseeable

misuse N/A

Instructional safeguard ................................ .......... : N/A

N ELECTROCHEMICAL POTENTIALS

N/A

Material (s) used ................................ ..................... :