Seat Ibiza ST 2016 Manual Online

Manufacturer: SEAT, Model Year: 2016, Model line: Ibiza ST, Model: Seat Ibiza ST 2016Pages: 252, PDF Size: 5.56 MB

Page 81 of 252

Self-help

Check the condition of the wiper blades regu-

l arly

. If

the wipers scrape across the glass ,

they should be changed if they are damaged,

or cleaned if they are dirty ››› .

If thi

s doe

s not produce the desired results,

the setting angle of the windscreen wiper

arms might be incorrect. They should be

checked by a specialised workshop and cor-

rected if necessary. WARNING

Do not drive unless you have good visibility

through al l

windows!

● Clean the windscreen wiper blades and all

windows

regularly.

● The wiper blades should be changed once

or twice a y

ear. CAUTION

● Damaged or dir ty

windscreen wipers could

scratch the glass.

● Never use fuel, nail varnish remover, paint

thinner or similar pr

oducts to clean the win-

dows. This could damage the windscreen

wiper blades.

● Never move any windscreen wiper by hand.

This cou

ld cause damage.

● To prevent damage to the bonnet and the

windsc

reen wiper arms, the latter should only

be lifted off the windscreen when in service

position. Note

● The winds c

reen wiper arms can be moved

to the service position only when the bonnet

is properly closed.

● You can also use the service position, for

exampl

e, if you want to fix a cover over the

windscreen in the winter to keep it clear of

ice. Towing or tow-starting

Notes Read the additional information carefully

› ›

›

p

age 51

Please observe the following points if you

use a tow rope:

Notes for the driver of the towing vehicle

– Move the vehicle slowly until the cable is

taut. Then ac

celerate gradually.

– Begin and change gears cautiously. If you

are driving an aut

omatic vehicle, accelerate

gently.

– Remember that the brake servo and power

steering ar

e not working in the vehicle you

are towing. Brake sooner than normal and

pressing the pedal gently. Notes for the driver of the towed vehicle

– Ensure that the tow rope remains taut at all

times when to

wing.

Towing vehicles with an automatic gearbox

● Put the selector lever into position “N”.

● Do not drive faster than 50 km/h (31 mph).

● Do not tow further than 50 km.

● If a breakdown vehicle is used, the vehicle

must be t

owed with the front wheels raised. WARNING

If the vehicle has no electrical power, the

brake light s, t

urn signals and all other lights

will no longer function. Do not have the vehi-

cle towed away. Failure to follow this instruc-

tion could result in an accident. WARNING

Vehicle handling and braking capacity

chan g

e considerably during towing. Please

observe the following instructions to mini-

mise the risk of serious accidents and injury:

● As the driver of the vehicle being towed:

– You should depr

ess the brake much hard-

er as the brake servo does not operate.

Pay the utmost attention to avoid crash-

ing into the towing vehicle.

– More strength is required at the steering

wheel as the power steering does not op-

erate when the engine is switched off. » 79

Technical data

Advice

Operation

Emergencies

Safety

Page 82 of 252

Emergencies

●

As the driver of the t

owing vehicle:

– Accelerate with particular care and cau-

tion.

– Avoid sudden braking and manoeuvres.

– Brake earlier than usual and more

smoothly. CAUTION

When tow-starting, fuel could enter the cata-

lytic conv

erter and damage it. Note

● Obser v

e legal requirements when towing or

tow-starting.

● Switch on the hazard warning lights of both

vehicle

s. However, observe any regulations

to the contrary.

● For technical reasons, vehicles with an au-

tomatic g

earbox must not be tow-started.

● If there is no lubricant in the gearbox as the

resu

lt of a fault, you must raise the driven

wheels while the vehicle is being towed.

● If the vehicle has to be towed more than

50 km (30 miles), the fr

ont wheels should be

raised during towing, and towing should be

carried out by a qualified person.

● The steering wheel is locked when the vehi-

cle ha

s no electrical power. The vehicle must

then be towed with the front wheels raised.

Towing should be carried out by a qualified

person. ●

The towline anc hor

age should always be

kept in the vehicle. Towline anchorages

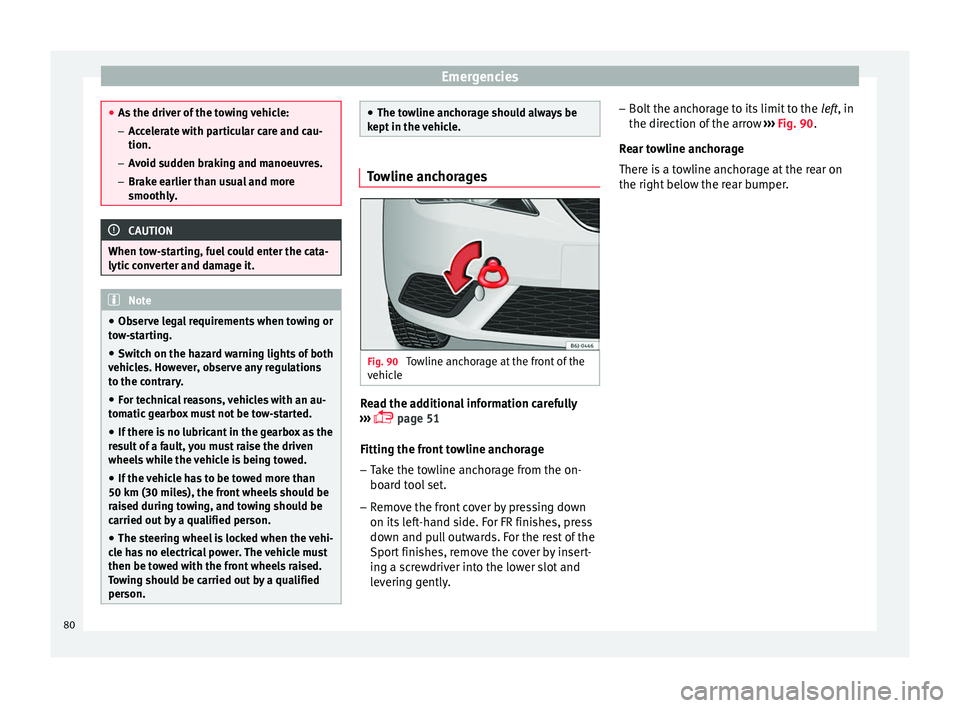

Fig. 90

Towline anchorage at the front of the

v ehic

le Read the additional information carefully

› ›

›

p

age 51

Fitting the front towline anchorage

– Take the towline anchorage from the on-

board too

l set.

– Remove the front cover by pressing down

on its left

-hand side. For FR finishes, press

down and pull outwards. For the rest of the

Sport finishes, remove the cover by insert-

ing a screwdriver into the lower slot and

levering gently. –

Bolt the anchor

age to its limit to the left, in

the direction of the arrow ››› Fig. 90.

Rear towline anchorage

There is a towline anchorage at the rear on

the right below the rear bumper. 80

Page 83 of 252

Fuses and bulbs

Fuses and bulbs F u

se s

Intr

oduction Due to the constant updating of vehicles,

fuse a

s

signments based on equipment and

the use of the same fuse for various electrical

components, it is not possible to provide an

up-to-date summary of the fuse positions for

the electrical components at the time this

manual was printed. For detailed information

about the fuse positions, please consult a

technical service.

In general, a fuse can be assigned to various

electrical components. Likewise, an electrical

component can be protected by several

fuses.

Only replace fuses when the cause of the

problem has been solved. If a newly inserted

fuse blows after a short time, you must have

the electrical system checked by a special-

ised workshop as soon as possible. WARNING

The high voltages in the electrical system can

give serious el

ectrical shocks, causing burns

and even death!

● Never touch the electrical wiring of the igni-

tion system. ●

Take c ar

e not to cause short circuits in the

electrical system. WARNING

Using unsuitable fuses, repairing fuses or

bridgin g a curr ent

circuit without fuses can

cause a fire and serious injury.

● Never use a fuse with a higher value. Only

replac

e fuses with a fuse of the same amper-

age (same colour and markings) and size.

● Never repair a fuse.

● Never replace a fuse by a metal strip, staple

or similar

. CAUTION

● To prev ent

damage to the vehicle's electric

system, before replacing a fuse always turn

off the ignition, the lights and all electrical

elements and remove the key from the igni-

tion.

● If you replace a fuse with higher-rating

fuse, y

ou could cause damage to another part

of the electrical system.

● Protect the fuse boxes when open to pre-

vent the entry

of dust or humidity as they can

damage the electrical system.

● Always carefully remove the fuse box cov-

ers and refit

them correctly to avoid problems

with your vehicle. Note

● One component m a

y have more than one

fuse.

● Several components may run on a single

fuse.

● In the v

ehicle, there are more fuses than

those indicated in thi

s chapter. These should

only be changed by a specialised workshop.

● Positions not containing a fuse do not ap-

pear in the fol

lowing tables.

● Some of the equipment listed in the tables

below pertain on

ly to certain versions of the

model or are optional extras.

● Please note that the above lists, while cor-

rect at the time of

printing, are subject to

change. Fuses to the left of the instrument

p

anel Read the additional information carefully

› ›

›

p

age 44

Only replace fuses with a fuse of the same

amperage (same colour and markings) and

size.

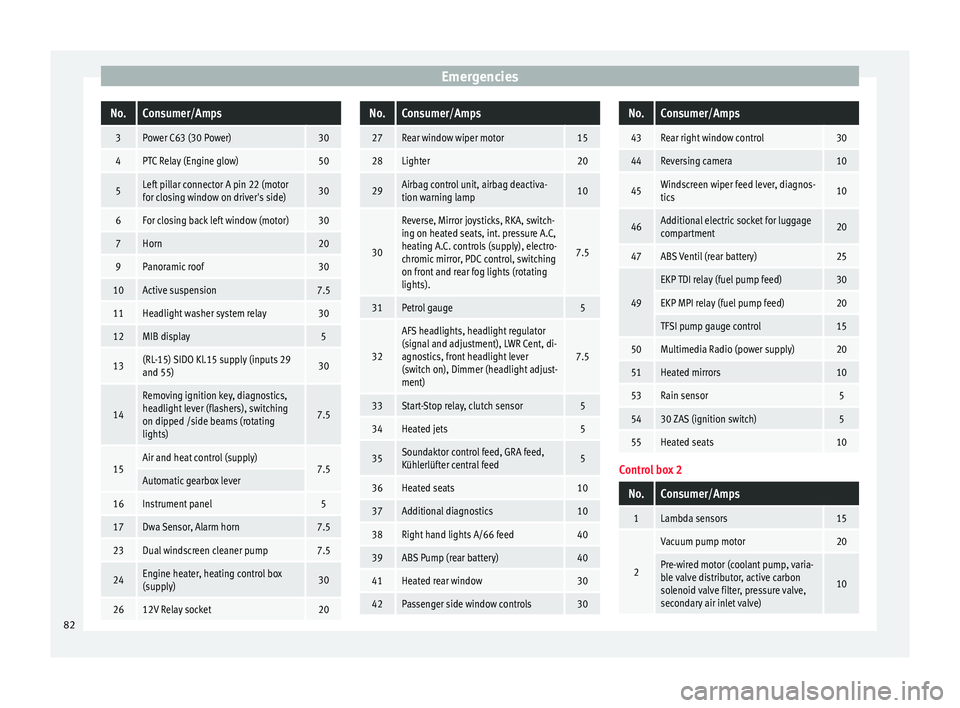

Control box 1

No.Consumer/Amps

1Left lights40

2Central locking40» 81

Technical data

Advice

Operation

Emergencies

Safety

Page 84 of 252

EmergenciesNo.Consumer/Amps

3Power C63 (30 Power)30

4PTC Relay (Engine glow)50

5Left pillar connector A pin 22 (motor

for closing window on driver's side)30

6For closing back left window (motor)30

7Horn20

9Panoramic roof30

10Active suspension7.5

11Headlight washer system relay30

12MIB display5

13(RL-15) SIDO Kl.15 supply (inputs 29

and 55)30

14

Removing ignition key, diagnostics,

headlight lever (flashers), switching

on dipped /side beams (rotating

lights)

7.5

15Air and heat control (supply)7.5Automatic gearbox lever

16Instrument panel5

17Dwa Sensor, Alarm horn7.5

23Dual windscreen cleaner pump7.5

24Engine heater, heating control box

(supply)30

2612V Relay socket20

No.Consumer/Amps

27Rear window wiper motor15

28Lighter20

29Airbag control unit, airbag deactiva-

tion warning lamp10

30

Reverse, Mirror joysticks, RKA, switch-

ing on heated seats, int. pressure A.C,

heating A.C. controls (supply), electro-

chromic mirror, PDC control, switching

on front and rear fog lights (rotating

lights).

7.5

31Petrol gauge5

32

AFS headlights, headlight regulator

(signal and adjustment), LWR Cent, di-

agnostics, front headlight lever

(switch on), Dimmer (headlight adjust-

ment)

7.5

33Start-Stop relay, clutch sensor5

34Heated jets5

35Soundaktor control feed, GRA feed,

Kühlerlüfter central feed5

36Heated seats10

37Additional diagnostics10

38Right hand lights A/66 feed40

39ABS Pump (rear battery)40

41Heated rear window30

42Passenger side window controls30

No.Consumer/Amps

43Rear right window control30

44Reversing camera10

45Windscreen wiper feed lever, diagnos-

tics10

46Additional electric socket for luggage

compartment20

47ABS Ventil (rear battery)25

49

EKP TDI relay (fuel pump feed)30

EKP MPI relay (fuel pump feed)20

TFSI pump gauge control15

50Multimedia Radio (power supply)20

51Heated mirrors10

53Rain sensor5

5430 ZAS (ignition switch)5

55Heated seats10

Control box 2

No.Consumer/Amps

1Lambda sensors15

2

Vacuum pump motor20

Pre-wired motor (coolant pump, varia-

ble valve distributor, active carbon

solenoid valve filter, pressure valve,

secondary air inlet valve)

10

82

Page 85 of 252

Fuses and bulbs

Fuse arrangement in engine compart-

ment Read the additional information carefully

›››

p

age 44

Only replace fuses with a fuse of the same

amperage (same colour and markings) and

size.

No.Consumer/Amps

1Fan, condenser40

TK8 fan, condenser50

2Glow plugs50

3ABS Pump40

EMBOX2-13 (TA8)20

4PTC glow phase 250

5PTC glow phase 350

6BDM, 30 ReF5

7MSG (KL30)7.5

8Windscreen wipers30

9Automatic gear box control, AQ 160

Control box30

10ABS Ventil25

EMBOX2-11 (TA8)5

No.Consumer/Amps

12

Injectors

10TDI fuel metering adjuster, TA8 ex-

haust temperature sensor

13Servo sensor5

14coolant pump high/low temperature,

gauge (relay EKP)10

1550 controls motor diag5

16Starter motor30

17Controls motor (MSG KL87)20

18PTC Relays, TOG sensor, engine

valves, PWM fan10

19Interior AUX Fuses30

20Glow plug relay, Heizrohr5

Ignition coil20 Changing bulbs

Gener al

not

es Read the additional information carefully

› ›

›

p

age 45

Before changing any bulb, first turn off the

failed device. Do not touch the glass part of the bulb with

your bare h

ands. The fingerprints left on the

glass will vaporise as a result of the heat gen-

erated by the bulb, reducing bulb life and

causing condensation on the reflector sur-

face, thus reducing effectiveness.

A bulb must only be replaced by one of the

same type. The type is indicated on the bulb,

either on the glass part or on the base.

Xenon headlights

With this type of headlight, the user can re-

place the turn signal bulb. Replacement of

the dipped/main beam bulb must be done by

Technical Services, given that complex ele-

ments must be removed from the vehicle and

the automatic control system that incorpo-

rates it must be reset.

The Xenon bulbs discharge 2.5 times the

light flux and have an average lifespan of 5

times more than that of halogen bulbs, this

means that, except due to unusual circum-

stances, there is no need to change the bulbs

for the whole life of the vehicle. WARNING

● Take p ar

ticular care when working on com-

ponents in the engine compartment if the en-

gine is warm, there is a risk of burns.

● Bulbs are highly sensitive to pressure. The

glass

can break when you touch the bulb,

causing injury. » 83

Technical data

Advice

Operation

Emergencies

Safety

Page 86 of 252

Emergencies

●

The high vo lt

age element of gas discharge

bulbs* (xenon light) must be handled correct-

ly. Otherwise, there is a risk of death.

● When changing bulbs, please take care not

to injure y

ourself on sharp parts in the head-

light housing. CAUTION

● Remov e the ignition k

ey before working on

the electric system. Otherwise, a short circuit

could occur.

● Switch off the lights or parking lights be-

fore y

ou change a bulb. For the sake of the environment

Please ask your specialist retailer how to dis-

pose of u sed b

ulbs in the proper manner. Note

● Depending on w e

ather conditions (cold or

wet), the front lights, the fog lights, the tail

lights and the turn signals may be temporari-

ly misted. This has no influence on the useful

life of the lighting system. By switching on

the lights, the area through which the beam

of light is projected will quickly be demisted.

However, the edges may continue to be mis-

ted.

● Please check at regular intervals that all

lighting (espec

ially the exterior lighting) on

your vehicle is functioning properly. This is not only in the interest of your own safety,

but a

l

so that of all other road users.

● Before changing a bulb, make sure you

have the corr

ect new bulb.

● Do not touch the glass part of the bulb with

your bare h

ands, use a cloth or paper towel

instead. The residue left by the fingerprints

would vaporise as a result of the heat gener-

ated by the bulb, they will be deposited on

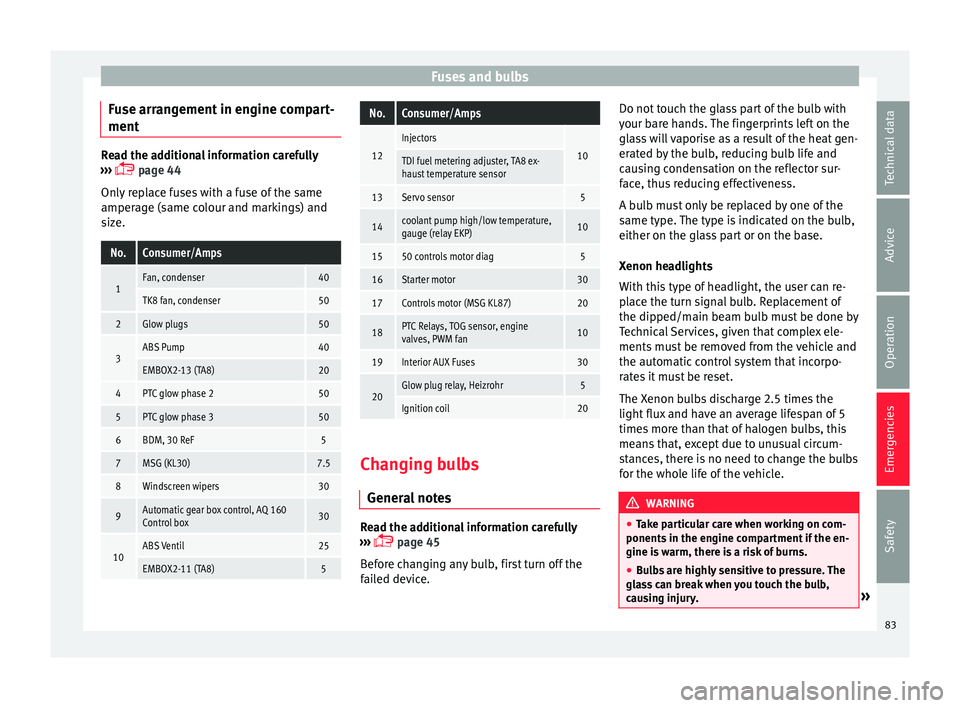

the reflector and will impair its surface. Single headlight bulb change

P o

sition of

the bulbs Fig. 91

Single headlight. Side lights - Dipped beam/main beam.

T

urn s

ignal

light.

DRL (day light)

A B

C Turn signal and DRL (day light) light

Fig. 92

Single headlight DRL light (day light). Fig. 93

Single turn signal lamp. –

Raise the bonnet.

– Turn the bulb holder ››

›

Fig. 92

1 or

› ›

›

Fig. 93

2 to the left and pull.

– Remove the bulb by pressing on the bulb

ho l

der and t urnin

g it anti-clockwise at the

same time.

84

Page 87 of 252

Fuses and bulbs

– Ins

tal

lation involves all of the above steps

in reverse sequence.

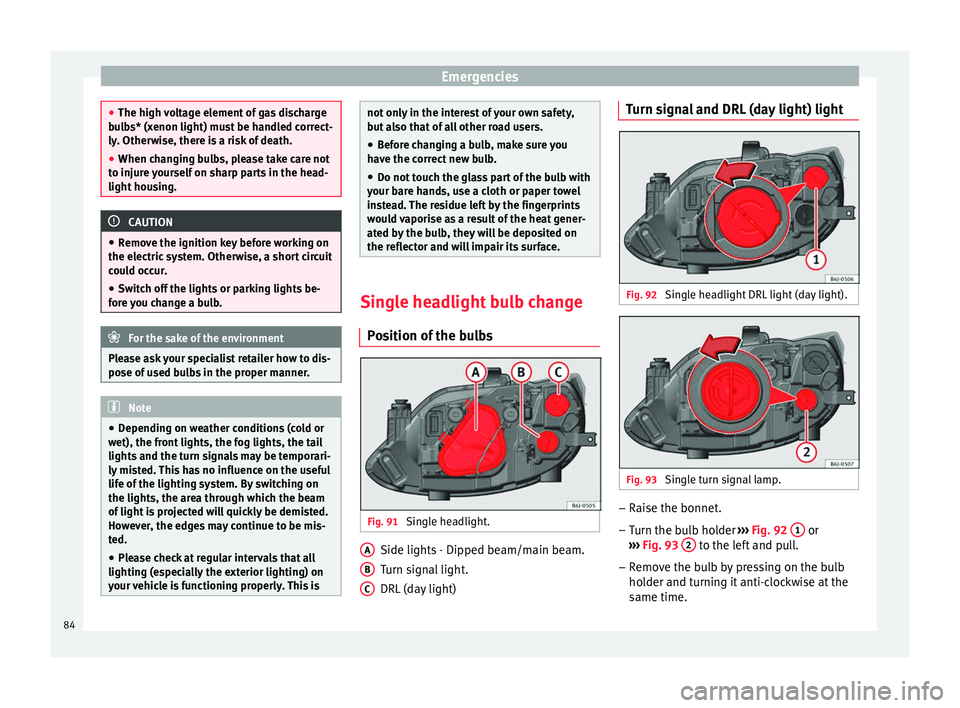

Dipped/main beam headlights and

side light Fig. 94

Single headlight. Fig. 95

Dipped beam/main beam and side

light of

the s in

gle headlight. Remove the cover

– Raise the bonnet.

– Move the loop ›

››

Fig. 94

1 in the direction

of the arr

ow and r

emove the cover.

Changing the dipped/main beam headlight – Remove connector ››› Fig. 95

3 from the

b u

lb

.

– Unclip the retainer spring ››› Fig. 95

2 pressing inwards to the right.

– Extract the bulb and fit the replacement so

th at

the lug on the b a

se fits into the recess

on the reflector.

– Fit the connector.

– Fit the cover and close the strap. Make sure

that the ga

sket sits well on the casing cover

during the operation.

– Check whether the new bulb is working.

Changing the s

ide light

– Extract the bulb holder ››› Fig. 95

4 out-

w ar

ds.

– R

emove the bulb by pulling it out and fit-

ting the new one.

– Inst

allation involves all of the above steps

in reverse sequenc

e.

– Fit the cover and close the strap. Make sure

that the ga

sket sits well on the casing cover

during the operation. –

Check whether the new bu

lb is working.

Double headlight bulb change Position of

the bulbs Fig. 96

Double headlight. Side lights

M

ain be

am hea

dlights

Dipped beam headlights

Turn signal

DRL (LED day light)

A B

C

D

E

85

Technical data

Advice

Operation

Emergencies

Safety

Page 88 of 252

Emergencies

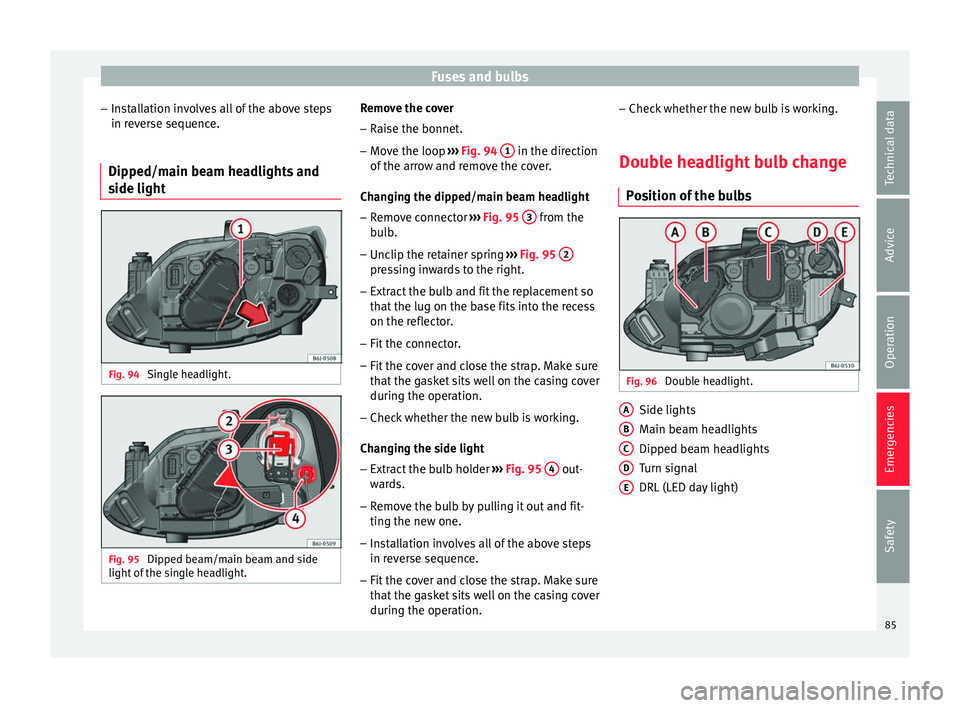

Side light and main beam Fig. 97

Double headlight. Fig. 98

Side light and main beam headlights. Remove the cover

– Raise the bonnet.

– Move the loop 1 in the direction of the ar-

r o

w and r emo

ve the cover ››› Fig. 97. Changing the side light

– Remove connector ››› Fig. 98

2 by pulling

outw ar

d.

– Remo

ve the bulb by pulling it out and fit-

ting the new one.

– Inst

allation involves all of the above steps

in reverse sequenc

e.

– Fit the cover and close the strap. Make sure

that the ga

sket sits well on the casing cover

during the operation.

– Check whether the new bulb is working.

Changing the m

ain beam bulb

– Remove connector ››› Fig. 98

3 by pulling

outw ar

d.

– Extr act

the bulb and fit the replacement so

that it s

its correctly into the cut-out on the

reflector.

– Installation involves all of the above steps

in reverse sequenc

e.

– Fit the cover and close the strap. Make sure

that the ga

sket sits well on the casing cover

during the operation.

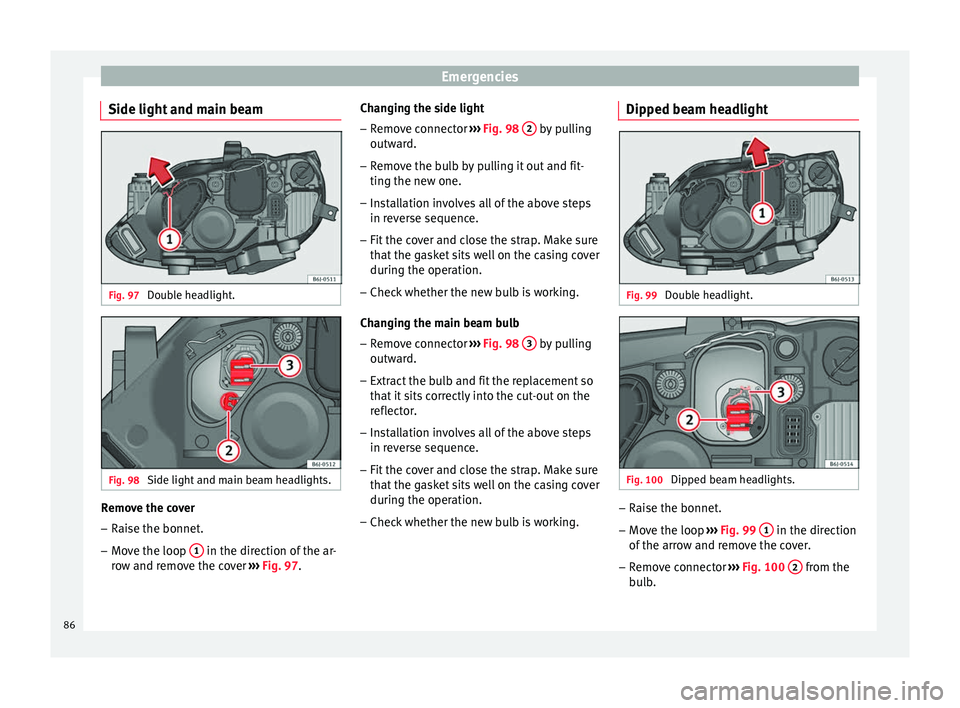

– Check whether the new bulb is working. Dipped beam headlight

Fig. 99

Double headlight. Fig. 100

Dipped beam headlights. –

Raise the bonnet.

– Move the loop ››

›

Fig. 99

1 in the direction

of the arr

ow and r

emove the cover.

– Remove connector ››› Fig. 100

2 from the

b u

lb

.

86

Page 89 of 252

Fuses and bulbs

– Unc lip the r

etainer s

pring ››› Fig. 100 3 pressing inwards to the right.

– Extract the bulb and fit the replacement so

th at

the lug on the b a

se fits into the recess

on the reflector.

– Fit the connector.

– Fit the cover and close the strap. Make sure

that the ga

sket sits well on the casing cover

during the operation.

– Check whether the new bulb is working.

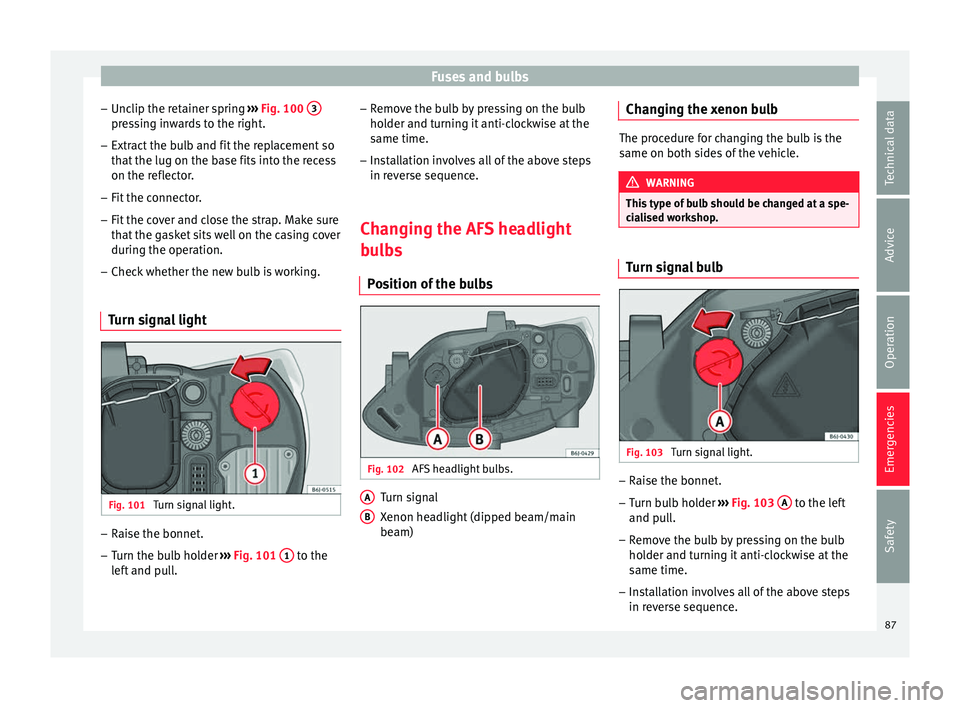

Turn signal light Fig. 101

Turn signal light. –

Raise the bonnet.

– Turn the bulb holder ››

›

Fig. 101

1 to the

l ef t

and p

ull. –

Remove the b

ulb by pressing on the bulb

holder and turning it anti-clockwise at the

same time.

– Installation involves all of the above steps

in reverse sequenc

e.

Changing the AFS headlight

bulb

s

Position of the bulbs Fig. 102

AFS headlight bulbs. Turn signal

X

enon he

adlight

(dipped beam/main

beam)

A B Changing the xenon bulb

The procedure for changing the bulb is the

same on both side

s

of the vehicle. WARNING

This type of bulb should be changed at a spe-

cia li

sed workshop. Turn signal bulb

Fig. 103

Turn signal light. –

Raise the bonnet.

– Turn bulb holder ››

›

Fig. 103

A to the left

and p u

ll

.

– Remove the bulb by pressing on the bulb

holder and turnin

g it anti-clockwise at the

same time.

– Installation involves all of the above steps

in reverse sequenc

e.

87

Technical data

Advice

Operation

Emergencies

Safety

Page 90 of 252

Emergencies

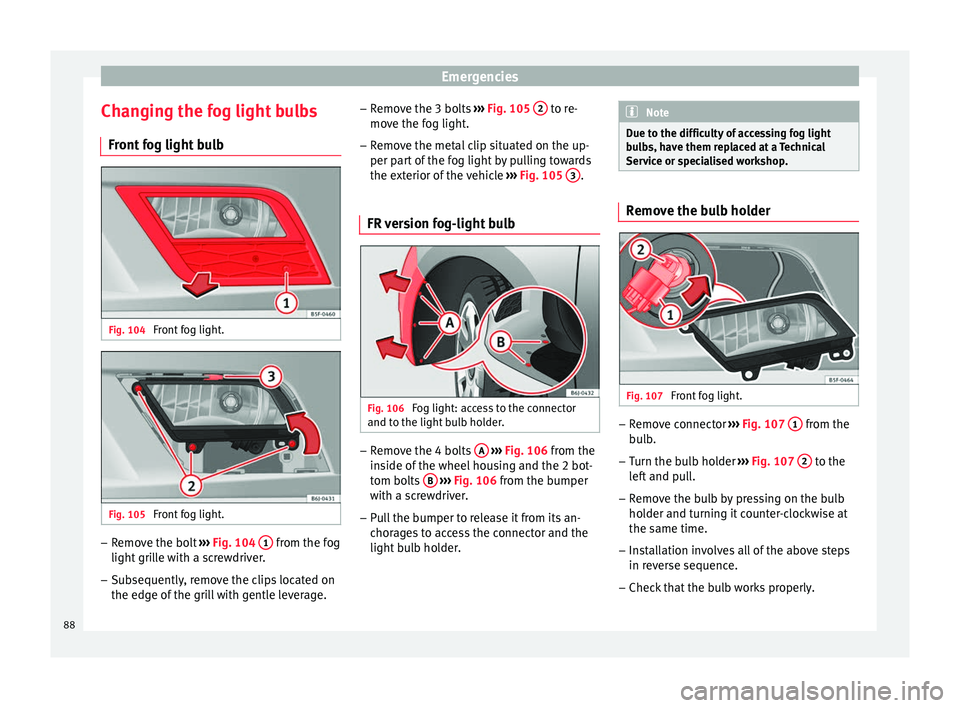

Changing the fog light bulbs Fr ont

fog light

bulbFig. 104

Front fog light. Fig. 105

Front fog light. –

Remove the bolt ››

›

Fig. 104

1 from the fog

light gri

ll

e with a screwdriver.

– Subsequently, remove the clips located on

the edge of the gril

l with gentle leverage. –

Remove the 3 bo

lts ››› Fig. 105 2 to re-

mo v

e the f og light

.

– Remove the metal clip situated on the up-

per part of

the fog light by pulling towards

the exterior of the vehicle ››› Fig. 105 3 .

FR version fog-light bulb Fig. 106

Fog light: access to the connector

and t o the light

bu

lb holder. –

Remove the 4 bolts A

› ›

› Fig. 106 fr

om the

inside of the wheel housing and the 2 bot-

tom bolts B

› ›

› Fig. 106 fr

om the bumper

with a screwdriver.

– Pull the bumper to release it from its an-

chorage

s to access the connector and the

light bulb holder. Note

Due to the difficulty of accessing fog light

bul b

s, have them replaced at a Technical

Service or specialised workshop. Remove the bulb holder

Fig. 107

Front fog light. –

Remove connector ››

›

Fig. 107

1 from the

b u

lb

.

– Turn the bulb holder ››› Fig. 107

2 to the

l ef

t and p

ull.

– Remove the bulb by pressing on the bulb

holder and turnin

g it counter-clockwise at

the same time.

– Installation involves all of the above steps

in reverse sequenc

e.

– Check that the bulb works properly.

88