Seat Toledo 2012 Owner's manual

Manufacturer: SEAT, Model Year: 2012, Model line: Toledo, Model: Seat Toledo 2012Pages: 249, PDF Size: 3.6 MB

Page 191 of 249

190Wheels and tyres

The manufacturing date is also indicated on the tyre sidewall (possibly only

on the inner side of the wheel). DOT … 27 12…

means, for example, that the tyre was produced in the 27th week of 2012.

Follow the instructions ⇒ page 190 if you only have a temporary spare

wheel.

Tyres with directional tread pattern

The direction of rotation is indicated by the arrows on the tyre sidewall. The

direction of rotation indicated must be respected. This guarantees optimum

grip and helps avoid excessive noise, wear and aquaplaning.

In the event of a flat tyre, a spare wheel with an undetermined tread pattern

or an opposite tread pattern must be used and you must drive carefully, as

in these cases the tyres no longer offer maximum performance. Spare wheelFig. 126 Luggage com-

partment: spare wheel

The spare wheel is housed in a well under the floor panel in the luggage

compartment and is secured by a special bolt ⇒ Fig. 126.

Take out the tool box before removing the spare wheel.

The tyre pressure of the spare wheel must be checked (preferably whenever

the tyre pressure is checked – see sticker on fuel tank flap ⇒ page 188) to

ensure the spare wheel remains ready for use.

If the spare wheel is not the same size or design as the tyres that are moun-

ted on the car (for example if the car has winter tyres or tyres with direction

tread), only use the spare tyre for a short period of time in the event of

breakdown and drive with the corresponding care ⇒

.

It must be replaced as soon as possible for a wheel with a normal size and

finish.

Temporary spare wheel

If the vehicle is equipped with a temporary spare wheel, there will be a

warning sign on the rim of the wheel.

Page 192 of 249

191

Wheels and tyres

Follow the instructions below when driving with this wheel fitted.

● After fitting the wheel, the warning sign must not be covered.

● Do not drive faster than 80 km/h (50 mph) with a spare wheel and take

great care during the trip. Avoid heavy acceleration, hard braking and fast

cornering.

● The tyre pressure is the same as that of the standard tyres.

● Only use this spare wheel to reach the nearest Official Service, as it is

not designed for permanent use.

WARNING

● Under no circumstances must damaged spare wheels be used.

● If the spare wheel is different in size or design to the tyres currently

fitted, never drive faster than 80 km/h (50 mph). Avoid heavy accelera-

tion, hard braking and fast cornering.

CAUTION

Follow the instructions given on the temporary spare wheel label.

Note

The tyre pressure of the spare wheel must always correspond to the highest

pressure prescribed for the model of vehicle in question.

Wheel trim

Removing

– Place the hook from the vehicle tool kit on the reinforced edge

of the wheel trim. –

Insert the box spanner through the hook, supporting it on the

tyre and remove the wheel trim.

Fitting

– First press the wheel trim onto the wheel at the cut out de-

signed for the valve. Then press the wheel trim on both sides in

the direction of the valve so that it fits correctly in place around

all the perimeter.

CAUTION

● Press down by hand, do not hit the wheel trim! Knocking it sharply, par-

ticularly at points where the wheel trim has not yet been inserted, could re-

sult in damage to the wheel trim guiding and centring elements.

● Before fitting the trim on a steel alloy wheel attached with an anti-theft

wheel bolt, make sure the bolt is in the hole in the valve area ⇒ page 202,

Anti-theft wheel bolts.

● Where trim is fitted at a later date, ensure enough air inflow is guaran-

teed in order to cool the brake system.

Wheel bolt caps

Fig. 127 Pull off the

wheel bolt cap

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 193 of 249

192Wheels and tyres

Removing

–Insert the plastic clip into the cap until the inner retaining

notches on the clips touch the collar of the cap and then re-

move ⇒ Fig. 127.

Fitting

– Insert the caps as far as they will go over the wheel bolts.

The wheel bolt caps are stored in a box on the spare wheel or in the spare

wheel well.

Tyre pressure

Fig. 128 Tyre pressure

setting switch

The tyre pressure monitoring system uses ABS sensors to compare the revo-

lutions and the circumference of each wheel. Should the circumference of

any wheel change, the warning lamp in the general instrument panel

⇒ page 72 will light up and an audible warning will be heard.

Tyre circumference may change if:

● Tyre pressure is too low

● Tyre structure is damaged ●

Vehicle load not evenly distributed

● Wheels on one axle are subjected to greater load, (e.g. driving with trail-

er, uphill, downhill)

● Snow chains are fitted

● The temporary spare wheel is fitted

● One wheel on the axle has been changed

Basic system settings

Should the tyre pressure change or if one or more wheels are changed or

the position of the wheel on the vehicle is changed, e.g. changing round the

front and rear wheels, or where a warning lamp lights up when driving, the

system must be adjusted as follows:

● Inflate all tyres to the prescribed pressures ⇒ page 188.

● Switch the ignition on.

● Hold the

⇒ Fig. 128 button down for at least 2 seconds. The warn-

ing lamp will light up when the button is pressed. The system memory is

also deleted and a new calibration system will begin, which is indicated by

an audible warning before the warning lamp switches off .

● If the warning lamp remains lit and does not switch off, not even once

the basic setting process is complete, this indicates a fault in the system.

Contact an Official Service.

The warning lamp lights up

If the pressure on at least one tyre is significantly lower than the pressure

set by the driver, the warning lamp ⇒

will light up.

The warning lamp flashes

If the warning lamp flashes, there is a fault in the system. Contact a special-

ised service to have it fixed.

Page 194 of 249

193

Wheels and tyres

WARNING

● If the warning lamp lights up, slow down immediately and avoid

any severe braking or steering manoeuvres. Stop and check the tyres and

their pressure as soon as possible.

● Under certain conditions (e.g. sporty driving style, driving on loose

surfaces or in the winter) the warning lamp may take a while to light

up or may remain switched off.

● Despite the tyre pressure monitoring system, the driver remains re-

sponsible for maintaining the correct tyre pressure. You must therefore

check the tyre pressure often.

Note

● The tyre pressure monitoring system is not a replacement for regularly

checking the tyre pressure, as it is unable to recognise an even drop in pres-

sure.

● The tyre pressure monitoring system is unable to warn of a sudden drop

in tyre pressure, e.g. a puncture. In this case, try to stop the vehicle carefully

with no severe braking or steering manoeuvres.

● To ensure the tyre pressure monitoring system works correctly, the basic

setting must be performed every 10 000 km (6000 miles) or once a year.

Wheel bolts

The wheel bolts are matched to the rims. When installing different wheels,

e.g. to fit light alloy wheels or wheels with winter tyres, it is important to use

the correct wheel bolts with the right length and correctly shaped bolt

heads. The is essential for the secure fit of the wheels and for the proper

function of the brake system. Winter tyres

Winter tyres will significantly improve handling of the vehicle in winter road

conditions. The design of summer tyres (width, rubber compound, tread

pattern) gives less grip at temperatures below 7 °C (45 °F), on ice and snow.

This applies particularly to vehicles equipped with

wide section tyres or

high speed tyres (code letters H or V on the sidewall).

In order to preserve the performance of the vehicle as much as possible,

winter tyres must be fitted on all four wheels, the minimum depth of the

tread must be 4 mm and the maximum age must be 4 years.

You can use winter tyres of a lower speed rating if the maximum speed limit

of these tyres will not be exceeded, even if the maximum speed limit for the

vehicle is higher.

For the sake of the environment

Summer tyres should be fitted again in time, as they give better handling on

roads free of snow and ice and at temperatures over 7 °C (45 °F). Summer

tyres have a shorter braking distance, produce less rolling noise and do not

wear down as quickly. They also reduce fuel consumption.

Snow chains

Snow chains must only be used on the front wheels.

In winter road conditions, snow chains not only help to improve grip but al-

so improve the braking capacity.

For technical reasons snow chains may only be used on tyres with the fol-

lowing wheel rim/tyre combinations.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 195 of 249

194Wheels and tyres

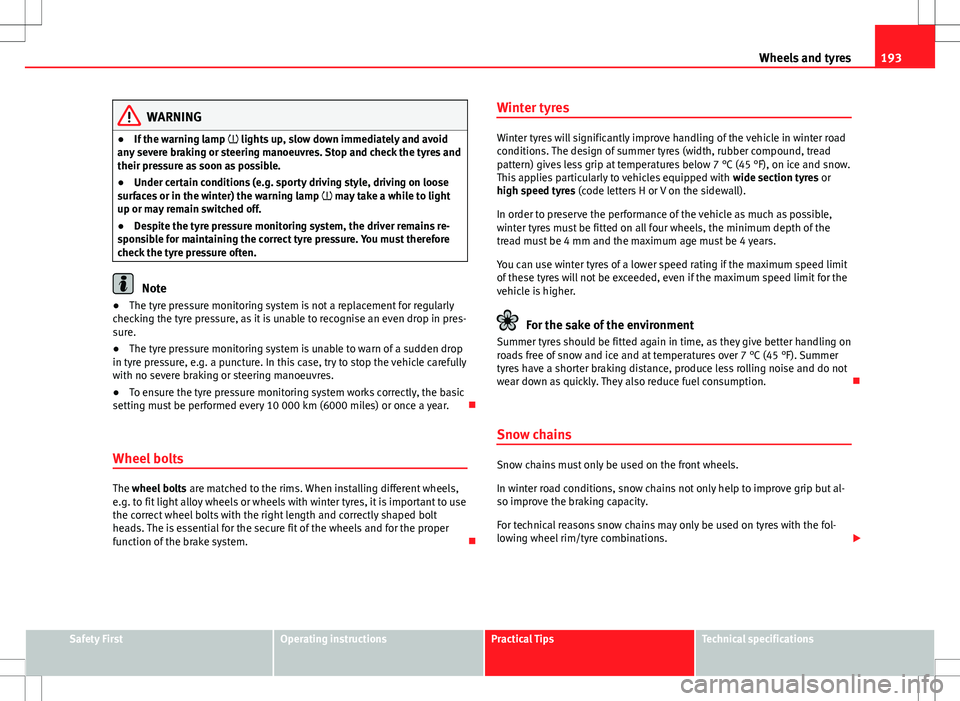

Rim sizeRim offsetTyre size5J x 14a)35 mm175/706J x 15b)38 mm185/606J x 15b)38 mm195/55a)

Only use snow chains with fine-pitch links and lock no greater than 9 mm.

b) Only use snow chains with fine-pitch links and lock no greater than 13 mm.

Remove the wheel trims before fitting snow chains.

CAUTION

Chains must be removed when roads are free of snow. Otherwise they will

impair handling, damage the tyres and wear out very quickly.

Page 196 of 249

195

Accessories, modifications and spare parts

Accessories, modifications and spare parts

General notes

If you wish to retrofit accessories in the vehicle, or if a part of the vehicle

has been replaced by a new part or technical modifications are required, the

following instructions must be taken into account.

● Before purchasing accessories or spare parts and before making techni-

cal modifications, always request advice from an Authorised SEAT dealer

⇒

.

● In the event that technical modifications are carried out on the vehicle,

the instructions and regulations specified by the company, SEAT, must be

observed.

No damage will be caused to the vehicle if the established procedures are

respected, which guarantees safe driving and operation. After the modifica-

tions are carried out, the vehicle will comply with the restrictions and regu-

lations of the highway code. More information can be obtained at an Au-

thorised SEAT dealer, where all jobs required can be carried out appropriate-

ly.

Vehicle improvements and refurbishment

The owner must store the technical documents regarding the modifications

carried out on the vehicle to be handed over to those responsible for the

processing of the end-of-life vehicle. This ensures end-of-life processing of

the vehicle, while protecting the environment.

Work done on the electrical components and software can cause disruption

in operations. Due to the interconnection of electronic components, this

disruption can also negatively influence systems that are not directly affec-

ted. This can adversely affect reliability of the vehicle, and can produce ex-

cessive wear of the parts.

Damage caused by technical modifications that are not made with the con-

sent of SEAT will be excluded from the warranty – see warranty certificate.

WARNING

● Jobs or modifications unduly carried out on your vehicle can cause

disruption to operations - Risk of accident!

● We recommend that you use only expressly authorised SEAT Original

Accessories and ® SEAT Original Spare Parts for your vehicle. The relia-

bility, safety and compatibility with your vehicle of SEAT Original Acces-

sories and ® SEAT Original Spare Parts has been checked.

● Despite the continuous observation of the market, we cannot judge

nor guarantee the suitability of other products for your vehicle, be they

authorised products or products approved by a state testing facility.

Note

SEAT Original Accessories and ® SEAT Original Spare Parts can be pur-

chased at authorised SEAT dealers where the purchased parts can also be

fitted.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 197 of 249

196Accessories, modifications and spare parts

Modifications and effects of the airbag

system

In the adjustment and modification, respect the SEAT directive.

Modifications and corrections of the front bumper, doors, front seats, roof

or bodywork must be carried out at authorised SEAT workshops. Compo-

nents of the airbag system can be found in these parts of the vehicle.

WARNING

● Airbag modules must never be repaired. They must be replaced.

● Never fit components of the airbag system removed from old vehicles

or those originating from a recycling process in the vehicle.

● The modification of the suspension of the vehicle wheels, including

the use of non-permitted combinations of tyres and rims can alter the op-

eration of the airbag system and increase the risk of serious or fatal inju-

ries in an accident.

● During all jobs on the airbag system, in addition to the removal and

fitting of parts of the system in the course of other repair jobs, parts of

the airbag system can be damaged. Therefore in the event of an accident,

this may cause the airbags to activate incorrectly or not activate al all.

Page 198 of 249

197

Self-help

Self-help

First-aid kit and warning triangle

Fig. 129 Location of

warning triangle

The warning triangle, measuring max. 436 x 45 x 32 mm, can be secured to

the lining on the rear of the luggage compartment with rubber straps

⇒ Fig. 129.

WARNING

The first-aid kit and fire extinguisher must be properly secured so that

they are not catapulted through the vehicle during driving and braking

manoeuvres or in the event of an accident. Risk of injury.

Note

● Observe the expiry date of the contents of the first aid kit.

● We recommend you use the first-aid kit and the warning triangle from

the SEAT Original Accessories programme available in authorised SEAT deal-

ers. Fire extinguisher

Read the instructions given on the fire extinguisher carefully.

The fire extinguisher must be checked once a year by an authorised person

(take the applicable legal regulations into account).

WARNING

The fire extinguisher must be properly secured so that it is not catapul-

ted through the vehicle, causing injuries, during driving and braking ma-

noeuvres or in the event of an accident.

Note

● The fire extinguisher must comply with local legal requirements.

● Observe the expiry date of the fire extinguisher. The fire extinguisher

may not work properly if used after the expiry date.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 199 of 249

198Self-help

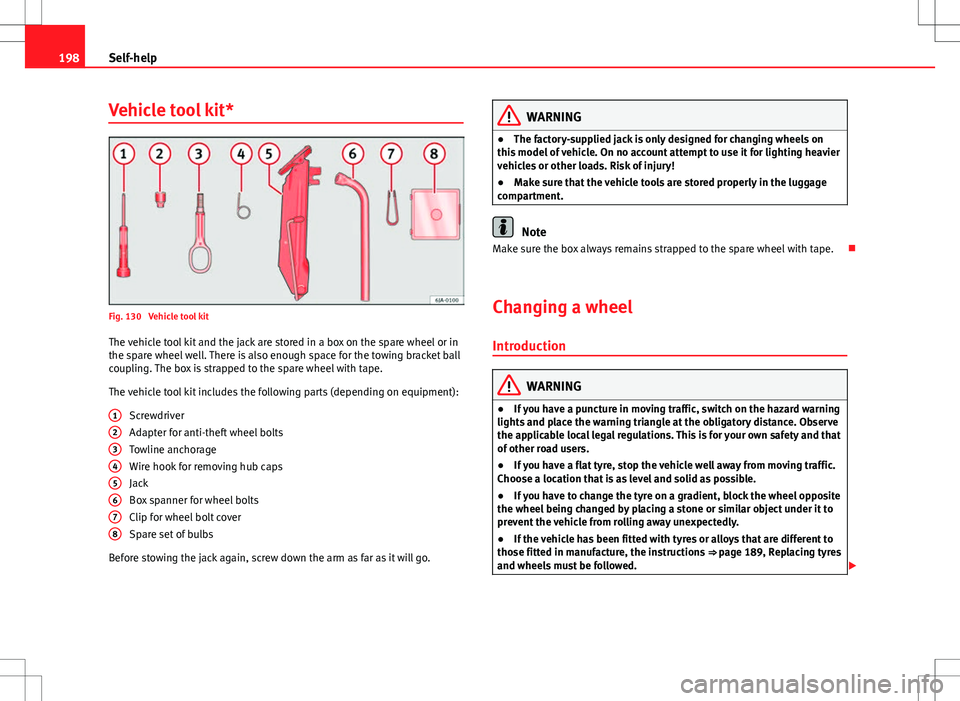

Vehicle tool kit*

Fig. 130 Vehicle tool kit

The vehicle tool kit and the jack are stored in a box on the spare wheel or in

the spare wheel well. There is also enough space for the towing bracket ball

coupling. The box is strapped to the spare wheel with tape.

The vehicle tool kit includes the following parts (depending on equipment):

Screwdriver

Adapter for anti-theft wheel bolts

Towline anchorage

Wire hook for removing hub caps

Jack

Box spanner for wheel bolts

Clip for wheel bolt cover

Spare set of bulbs

Before stowing the jack again, screw down the arm as far as it will go. 1

2345678

WARNING

● The factory-supplied jack is only designed for changing wheels on

this model of vehicle. On no account attempt to use it for lighting heavier

vehicles or other loads. Risk of injury!

● Make sure that the vehicle tools are stored properly in the luggage

compartment.

Note

Make sure the box always remains strapped to the spare wheel with tape.

Changing a wheel Introduction

WARNING

● If you have a puncture in moving traffic, switch on the hazard warning

lights and place the warning triangle at the obligatory distance. Observe

the applicable local legal regulations. This is for your own safety and that

of other road users.

● If you have a flat tyre, stop the vehicle well away from moving traffic.

Choose a location that is as level and solid as possible.

● If you have to change the tyre on a gradient, block the wheel opposite

the wheel being changed by placing a stone or similar object under it to

prevent the vehicle from rolling away unexpectedly.

● If the vehicle has been fitted with tyres or alloys that are different to

those fitted in manufacture, the instructions ⇒ page 189, Replacing tyres

and wheels must be followed.

Page 200 of 249

199

Self-help

WARNING (Continued)

● Always raise the vehicle with the doors closed.

● Never place parts of your body, e.g. arms and legs, underneath the

vehicle when supported only by the jack.

● Secure the base of the jack with suitable supports so that it cannot

slip. The jack could slide if the ground below it is soft and slippery and

the vehicle could slip off it. Therefore, place the jack on a firm surface or

use a large, stable base. On a slippery surface, e.g. tiles, use a non-slip

base such as a rubber mat.

● Never start the engine when the vehicle is raised. Risk of injury.

● The jack should only be used in the correct jacking points.

CAUTION

● The prescribed tightening torque for wheel bolts on steel and alloy

wheels is 120 Nm.

● If the anti-theft wheel bolt is overly tightened, this could damage the

bolt and the adapter

Note

● The set of anti-theft wheel bolts or the adapter are available from au-

thorised SEAT dealers.

● Please observe the relevant local legal regulations when changing the

wheel.

Preparation work

Some preparation is required before changing a wheel:

– If you have a flat tyre, stop the vehicle as far away as possible

from moving traffic. The surface must be horizontal.–

All vehicle occupants should leave the vehicle . Vehicle occu-

pants should waiting in a safe place, e.g. behind the roadside

crash barrier) while the wheel is being changed.

– Switch off the ignition and engage neutral or move the selector

lever on the automatic gearbox to position P.

– Apply the handbrake firmly.

– If towing a trailer, unhitch it.

– Take the vehicle tool kit ⇒ page 198 and the spare wheel

⇒ page 198 out of the luggage compartment.

Changing a wheel

If possible, change the wheel on a level surface.

– Pull off the hub cap ⇒ page 191 or the wheel bolt covers

⇒ page 191.

– First loosen the anti-theft wheel bolts and then the other wheel

bolts ⇒ page 200.

– Raise the vehicle until the wheel to be changed is no longer

touching the ground ⇒ page 201.

– Remove the wheel bolts and place them on a clean surface

(cloth, paper, etc.).

– Take off the wheel.

– Lift the spare wheel into position and tighten the wheel bolts

lightly.

Safety FirstOperating instructionsPractical TipsTechnical specifications