service Seat Toledo 2014 Owner's Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2014, Model line: Toledo, Model: Seat Toledo 2014Pages: 200, PDF Size: 4.37 MB

Page 108 of 200

Operation

●

Refuelling just once with leaded petrol dis-

ables the exhaust system! Economical and environmentally

friendly driving

Fuel consumption, environmental pollution

and wear to the engine, brakes and tyres de-

pends in large part on your driving style. By

adopting an economical driving style and an-

ticipating the traffic situation ahead, you can

easily reduce fuel consumption by 10-15%.

Some tips on how to help you reduce pollu-

tion while saving money are listed below.

Drive anticipating the traffic situation

A vehicle uses most fuel when accelerating.

When you anticipate situations, you have to

brake less often and, thus, accelerate less. If

it is possible, let the vehicle roll with a

gear

engaged , for example, if you see a red light

ahe a

d. The braking effect achieved in this

way helps to reduce the wear of brakes and

tyres; emissions and fuel consumption are

reduced to zero (disconnection due to iner-

tia).

Change gear early to save energy

An effective way of saving fuel is to change

up

quickly through the gears. Running the

engine at high rpm in the lower gears uses

an unnecessary amount of fuel. Manual gearbox:

shift up from first to second

gear as soon as possible. We recommend

that, whenever possible, you change to a

higher gear upon reaching 2000 rpm. Follow

the “recommended gear” indication that ap-

pears on the instrument panel ››› page 32,

Recommended gear display.

Avoid driving at high speed

We advise you not to drive at the top speed

permitted by the vehicle. Fuel consumption,

exhaust emissions and noise levels all in-

crease very rapidly at higher speeds. Driving

at moderate speeds will help to save fuel.

Avoid idling

It is worthwhile switching off the engine

when waiting in a traffic jam, at level cross-

ings or at traffic lights with a long red phase.

The fuel saved after only 30 - 40 seconds is

greater than the amount of fuel needed to re-

start the engine.

The engine takes a long time to warm up

when it is idling. Mechanical wear and pollu-

tant emissions are also especially high dur-

ing this initial warm-up phase. It is therefore

best to drive off immediately after starting

the engine. Avoid running the engine at high

speed. Periodic maintenance

Periodic maintenance work guarantees that,

before beginning a journey, you will not con-

sume more than the required amount of fuel.

A well-serviced engine gives you the benefit

of

improved fuel efficiency as well as maxi-

mum reliability and an enhanced resale val-

ue.

A badly serviced engine can consume up to

10% more fuel than necessary.

Avoid short journeys

To reduce the consumption and emission of

polluting exhaust gases, the engine and the

exhaust gas filtration systems should reach

the optimum operating temperature.

With the en

gine cold, fuel consumption is

proportionally higher. The engine does not

warm up and fuel consumption does not nor-

malise until having driven approximately four

kilometres (2.5 miles). This is why we recom-

mend avoiding short trips whenever possi-

ble.

Maintain the correct tyre pressures

Bear in mind that keeping the tyres at an ad-

equate pressure saves fuel. If the tyre pres-

sure is just one bar (14.5 psi/100 kPa) too

low, fuel consumption can increase by as

much as 5%. Due to the greater rolling resist-

ance, under-inflation also increases tyre wear

wear and impairs handling.

106

Page 110 of 200

Operation

CAUTION

● In the event of driving through water, parts

of the vehicle can be seriously damaged,

such as the engine, gearbox, catalytic con-

verter, suspension or the electrical system.

● Oncoming vehicles that drive through wa-

ter can cause waves that exceed your vehi-

cle's permitted level for driving through wa-

ter.

● There may be pot-holes mud or rocks under

the water that can hinder or prevent driving

through water.

● Do not drive through salt water. The salt

can cause rust. All components that are ex-

posed to salt water must be rinsed immedi-

ately with fresh water. Note

After driving through water we recommend

that you contact a specialised service for an

inspection. Preventing damage to the vehicle

In order to prevent damage to the vehicle,

take special care:

● on roads that are in poor condition,

● when mounting kerbs,

● when approaching very steep ramps, etc., ●

with the parts of the vehicle situated on the

lower part of the vehicle, i.e. the spoiler, the

exhaust pipe.

This applies especially to vehicles with a very

low suspension (sport) and when the vehicle

is fully loaded. Driver assistance systems

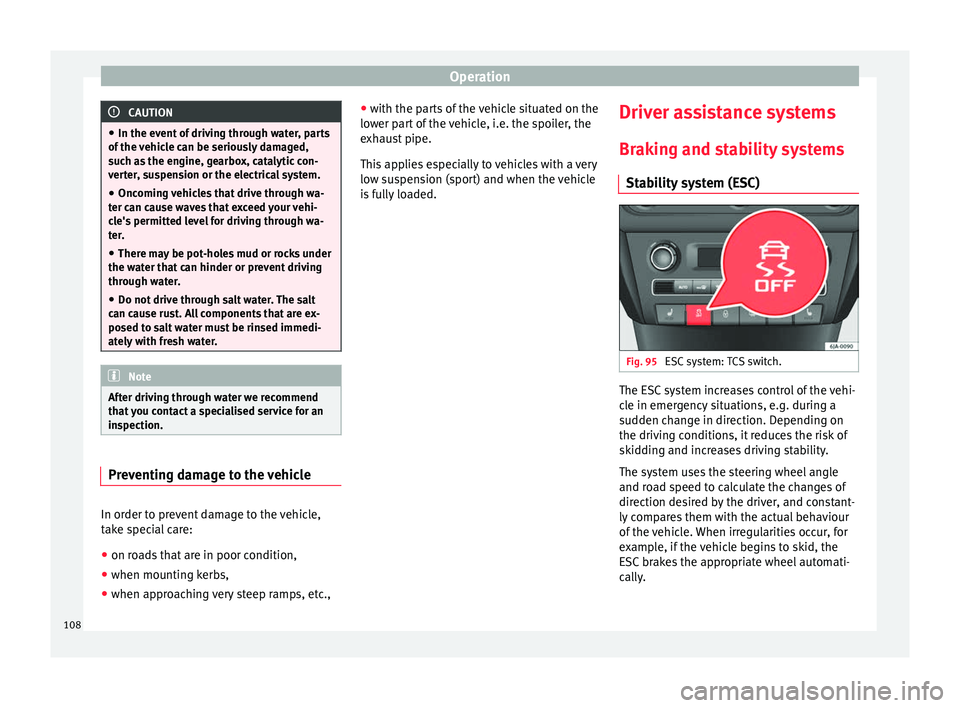

Braking and stability systems Stability system (ESC) Fig. 95

ESC system: TCS switch. The ESC system increases control of the vehi-

cle in emergency situations, e.g. during a

sudden change in direction. Depending on

the driving conditions, it reduces the risk of

skidding and increases driving stability.

The system uses the steering wheel angle

and road speed to calculate the changes of

direction desired by the driver, and constant-

ly compares them with the actual behaviour

of the vehicle. When irregularities occur, for

example, if the vehicle begins to skid, the

ESC brakes the appropriate wheel automati-

cally.

108

Page 112 of 200

Operation

Electronic differential lock If one of the wheels starts to skid, the EDL

brakes that wheel, transmitting the driving

force to the other wheels. This increases ve-

hicle stability and improves driving stability.

To prevent the disc brake of the braking

wheel from overheating, the EDL cuts out au-

tomatically if subjected to excessive loads.

The vehicle will continue to function normally

without EDL. The EDL will switch on again au-

tomatically when the brake has cooled down.

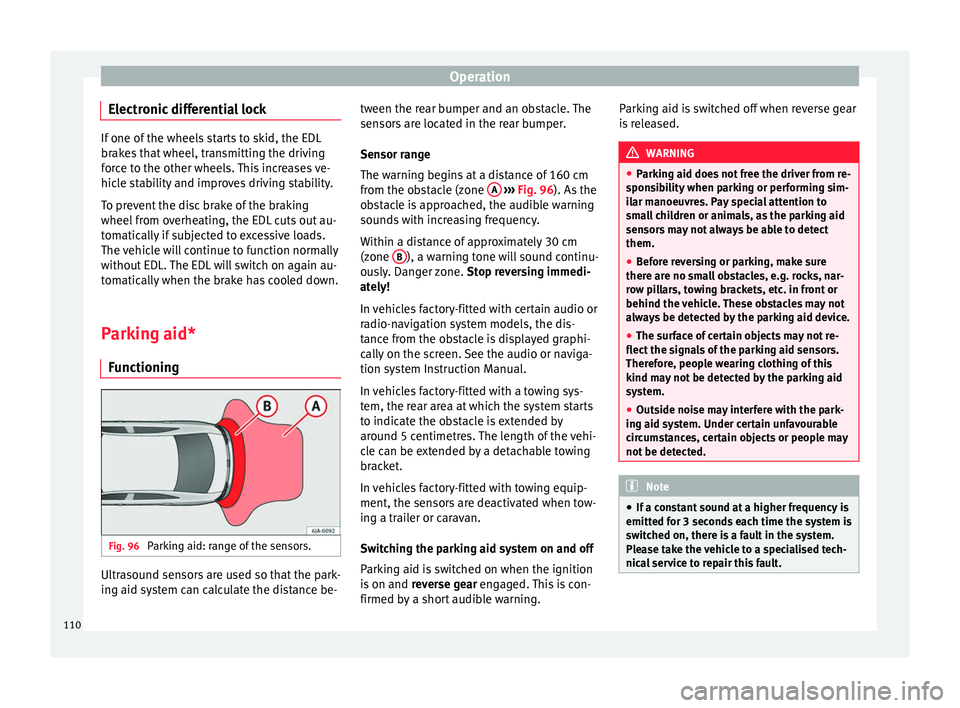

Parking aid* Functioning Fig. 96

Parking aid: range of the sensors. Ultrasound sensors are used so that the park-

ing aid system can calculate the distance be- tween the rear bumper and an obstacle. The

sensors are located in the rear bumper.

Sensor range

The warning begins at a distance of 160 cm

from the obstacle (zone

A

››› Fig. 96 ). As the

o b

stacle is approached, the audible warning

sounds with increasing frequency.

Within a distance of approximately 30 cm

(zone B ), a warning tone will sound continu-

ously. Danger zone. Stop reversing immedi-

ately!

In vehicles factory-fitted with certain audio or

radio-navigation system models, the dis-

tance from the obstacle is displayed graphi-

cally on the screen. See the audio or naviga-

tion system Instruction Manual.

In vehicles factory-fitted with a towing sys-

tem, the rear area at which the system starts

to indicate the obstacle is extended by

around 5 centimetres. The length of the vehi-

cle can be extended by a detachable towing

bracket.

In vehicles factory-fitted with towing equip-

ment, the sensors are deactivated when tow-

ing a trailer or caravan.

Switching the parking aid system on and off

Parking aid is switched on when the ignition

is on and reverse gear engaged. This is con-

firmed by a short audible warning. Parking aid is switched off when reverse gear

is released. WARNING

● Parking aid does not free the driver from re-

sponsibility when parking or performing sim-

ilar manoeuvres. Pay special attention to

small children or animals, as the parking aid

sensors may not always be able to detect

them.

● Before reversing or parking, make sure

there are no small obstacles, e.g. rocks, nar-

row pillars, towing brackets, etc. in front or

behind the vehicle. These obstacles may not

always be detected by the parking aid device.

● The surface of certain objects may not re-

flect the signals of the parking aid sensors.

Therefore, people wearing clothing of this

kind may not be detected by the parking aid

system.

● Outside noise may interfere with the park-

ing aid system. Under certain unfavourable

circumstances, certain objects or people may

not be detected. Note

● If a constant sound at a higher frequency is

emitted for 3 seconds each time the system is

switched on, there is a fault in the system.

Please take the vehicle to a specialised tech-

nical service to repair this fault. 110

Page 118 of 200

Operation

Please observe the following indications

››› page 35, Coolant level and temperature

.

The coolant temperature can be reduced by

switching on the heating. WARNING

● Adjust your speed to suit the road and traf-

fic conditions.

● An electrical installation that is connected

incorrectly or by non-specialised personnel

can prevent the connection of the current to

the trailer and cause faults in the operation of

the electrical system throughout the entire

vehicle, leading to accidents and serious in-

jury.

● All electrical work must be carried out only

by specialised services.

● Never directly connect the trailer electrical

device to the electrical sockets of the reverse

driving lights or other sources of electrical

current. CAUTION

● Avoid corners, and sudden and sharp brak-

ing.

● Once the trailing arm has been removed,

place the corresponding cover on the hole of

the fastening point. This prevents dirt from

entering the hole – see the trailer system as-

sembly manual. Note

● In the event of frequent journeys with a

trailer, we recommend also having the vehi-

cle inspected in between the service inter-

vals.

● When connecting and disconnecting the

trailer, the handbrake must be applied.

● For technical reasons, trailers with LED re-

verse lights cannot be incorporated into the

vehicle anti-theft alarm system. Towing bracket device

Introduction If the vehicle is equipped with a towing

bracket device from the factory or is a genu-

ine SEAT accessory, it meets all national tech-

nical and legal requirements for towing.

Your vehicle is fitted with a 13-pin power

socket for the electrical connection between

the trailer and the vehicle. If the towing

bracket is equipped with a

7-pin connector,

y ou c

an use the corresponding available

adaptor that is a genuine SEAT accessory.

The towing device has a maximum vertical

load of 50 kg

. WARNING

● Before driving with the ball-headed bar fit-

ted, verify its correct assembly and place-

ment in the clamping bush.

● Do not use the ball-headed bar if it is not

correctly placed and fixed in the clamping

bush.

● Do not use the towing device for towing if it

is damaged or has missing parts.

● Do not modify or adapt the towing device

connection.

● Never disengage the ball-headed bar with

the trailer still hitched. CAUTION

Be careful not to damage the paint on the

bumper when handling the ball-headed bar. 116

Page 119 of 200

Towing bracket device

Description Fig. 99

Towing bracket device support for

hitching/ball-headed bar. The ball-headed bar is detachable. It is loca-

ted in the spare wheel compartment or in the

spare wheel compartment in the boot

››› page 150, Vehicle tool kit*.

Key to ››› Fig. 99

13-pin socket

Safety flange

1 2 Clamping bush

Clamping bush cap

Ball head cover

Ball-headed bar

Locking balls

Centred

Red marking on the manual regulator

Manual regulator

Key

Key slot cover

Red marking on the manual regulator

White marking on the ball-headed bar

Note

Contact an Authorised Service Partner if you

lose your key. 3

4

5

6

7

8

9

10

11

12

13

14 Placing in service position

Fig. 100

Placing in service position.

» 117Technical specifications

Advice

Operation

Safety

Page 120 of 200

Operation

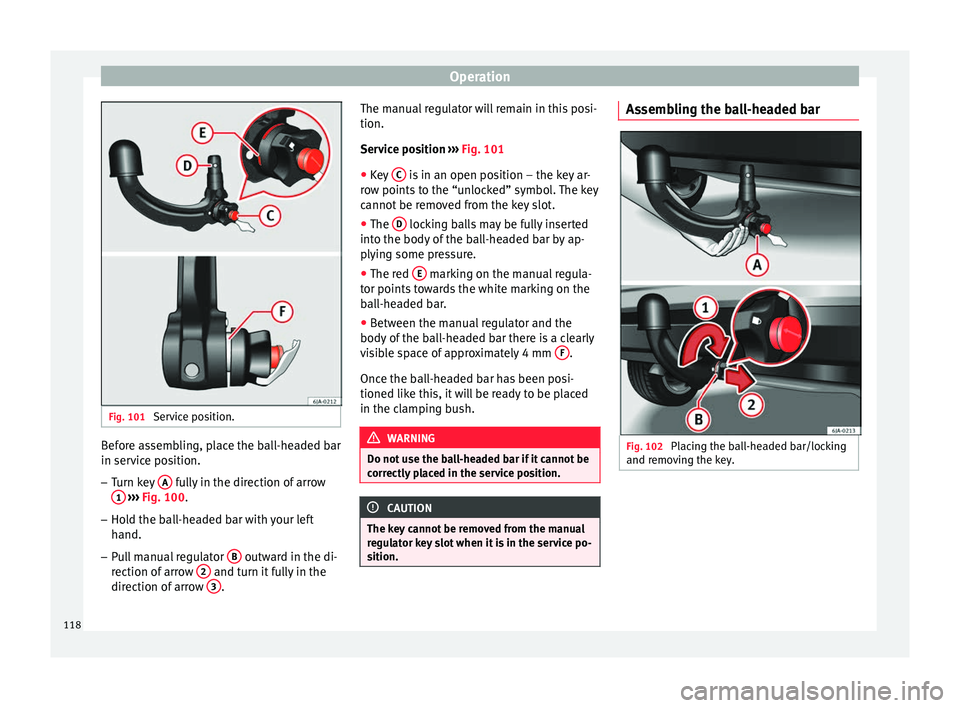

Fig. 101

Service position. Before assembling, place the ball-headed bar

in service position.

–

Turn key A fully in the direction of arrow

1

››› Fig. 100 .

– Ho l

d the ball-headed bar with your left

hand.

– Pull manual regulator B outward in the di-

rection of arrow 2 and turn it fully in the

direction of arrow 3 .The manual regulator will remain in this posi-

tion.

Service position

› ››

Fig. 101

● K

ey C is in an open position – the key ar-

row points to the “unlocked” symbol. The key

cannot be removed from the key slot.

● The D locking balls may be fully inserted

into the body of the ball-headed bar by ap-

plying some pressure.

● The red E marking on the manual regula-

tor points towards the white marking on the

ball-headed bar.

● Between the manual regulator and the

body of the ball-headed bar there is a clearly

visible space of approximately 4 mm F .

Once the ball-headed bar has been posi-

tioned like this, it will be ready to be placed

in the clamping bush. WARNING

Do not use the ball-headed bar if it cannot be

correctly placed in the service position. CAUTION

The key cannot be removed from the manual

regulator key slot when it is in the service po-

sition. Assembling the ball-headed bar

Fig. 102

Placing the ball-headed bar/locking

and removing the key. 118

Page 121 of 200

Towing bracket device

Fig. 103

Placing the key slot cover. –

Remove the cap from the clamping bush 4›››

Fig. 99 by pulling downwards.

– Plac

e the ball-headed bar in the service po-

sition ››› page 117.

– Hol

d the ball-headed bar from underneath

››› Fig. 102

and push it into the clamping

bush as far as possible until you hear it

click into place ››› .

The manual regulator A

automatically turns

in the op po

site direction, adjusting to the

ball-headed bar ››› .

– Switch off the manual regulator lock with

key B by turning the key fully to the right

in the direction of arrow 1 – the arrow in

the key displays the “locked” symbol.

– Remove the key in the direction of arrow

2 .

– Place cover C over the manual regulator

lock in the direction of arrow 3

››› Fig. 103 .–

Verif

y the correct placement of the ball-

headed bar ››› page 119. WARNING

● Do not hold the manual regulator with your

hand when fitting the ball-headed bar since

you could sustain injuries to your fingers.

● When mounting the ball-headed bar, al-

ways lock it with a key and remove the key

from the slot.

● The ball-headed bar must not be in the

service position with the key in the key slot.

● If the ball-headed bar is not placed in the

service position you will not be able to place

it in the clamping bush. CAUTION

When removing the key, always place the

cover over the key slot of the manual regula-

tor to prevent dirt from entering. Note

Once removed, place the clamping bush cap

in an appropriate location in the boot. Verification of correct placement

Fig. 104

Correct placement of the ball-head-

ed bar. Before using the ball-headed bar, ensure it is

correctly fitted.

Ensure that:

● The ball-headed bar does not come out of

the clamping bush in a “jerky” manner.

● The red mark A

››› Fig. 104 on the manual

r e

gulator signals toward the white mark on

the ball-headed bar.

● The manual regulator is adjusted to the

ball-headed bar, leaving no space between

them.

● The regulator is locked and the key has

been removed.

● Cover B has been placed over the manual

regulator lock. »

119

Technical specifications

Advice

Operation

Safety

Page 122 of 200

Operation

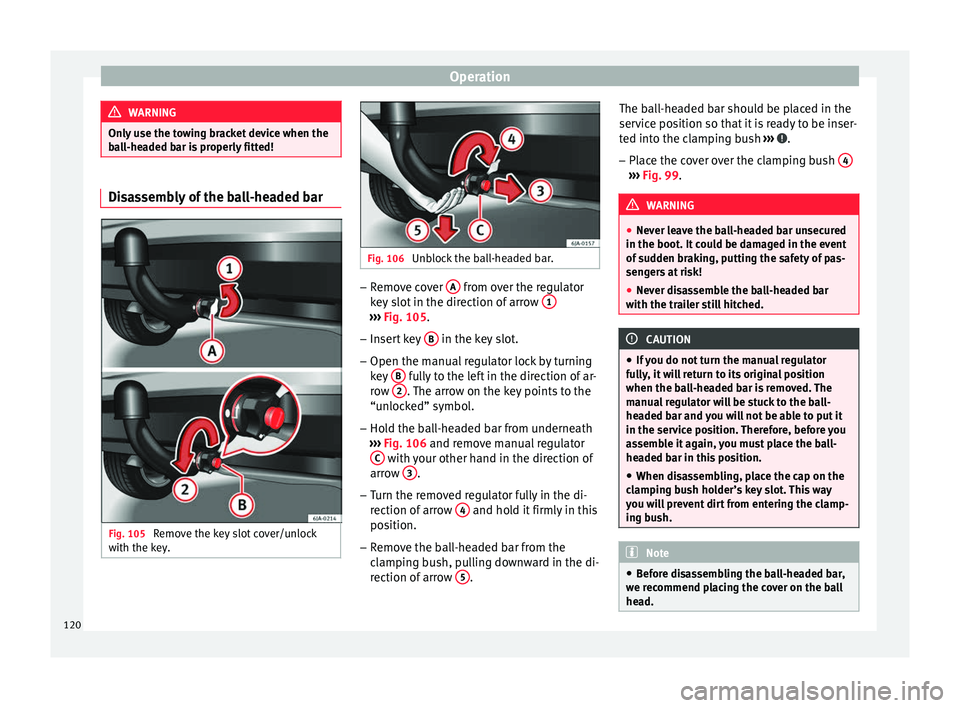

WARNING

Only use the towing bracket device when the

ball-headed bar is properly fitted! Disassembly of the ball-headed bar

Fig. 105

Remove the key slot cover/unlock

with the key. Fig. 106

Unblock the ball-headed bar. –

Remove cover A from over the regulator

key slot in the direction of arrow 1 ›››

Fig. 105 .

– Inser

t key B in the key slot.

– Open the manual regulator lock by turning

key B fully to the left in the direction of ar-

row 2 . The arrow on the key points to the

“unlocked” symbol.

– Hold the ball-headed bar from underneath

››› Fig. 106 and remove manual regulator

C with your other hand in the direction of

arrow 3 .

– Turn the removed regulator fully in the di-

rection of arrow 4 and hold it firmly in this

position.

– Remove the ball-headed bar from the

clamping bush, pulling downward in the di-

rection of arrow 5 .The ball-headed bar should be placed in the

service position so that it is ready to be inser-

ted into the clamping bush

››› .

– Place the cover over the clamping bush 4 ›››

Fig. 99 . WARNING

● Never leave the ball-headed bar unsecured

in the boot. It could be damaged in the event

of sudden braking, putting the safety of pas-

sengers at risk!

● Never disassemble the ball-headed bar

with the trailer still hitched. CAUTION

● If you do not turn the manual regulator

fully, it will return to its original position

when the ball-headed bar is removed. The

manual regulator will be stuck to the ball-

headed bar and you will not be able to put it

in the service position. Therefore, before you

assemble it again, you must place the ball-

headed bar in this position.

● When disassembling, place the cap on the

clamping bush holder’s key slot. This way

you will prevent dirt from entering the clamp-

ing bush. Note

● Before disassembling the ball-headed bar,

we recommend placing the cover on the ball

head. 120

Page 127 of 200

Care and maintenance

Waxing and polishing of the vehicle

paintwork Care

To a great extent, good waxing protects the

vehicle surface from the harmful effects of

the environment.

The vehicle must be treated with a high qual-

ity, hard wax when water no longer forms

droplets on clean paintwork.

A new coat of high quality, hard wax can be

applied to the clean, painted surface only

when it has fully dried. Even if a wax solution

is used regularly in the car wash, it is advisa-

ble to protect the paint with a coat of wax at

least twice a year.

Polishing

Polishing is only necessary if the paint has

lost its shine, and the gloss cannot be

brought back by applying wax.

The vehicle must be waxed after polishing if

the polish used does not contain wax com-

pounds to seal the paint.

CAUTION

● Never wax the windows.

● Do not use polishes and hard wax on pain-

ted parts with a matt finish or on plastic

parts. ●

Do not polish your vehicle in a sandy or

dusty environment. Cleaning chrome

Clean the chrome first with a clean cloth and

then buff up with a soft, dry cloth. If this does

not clean the chrome properly, use a special

chrome cleaner.

CAUTION

Do not polish the chrome in a dusty environ-

ment or it could be scratched. Paint damage

Minor damage to the paint, such as scratches

or stone chips, should be touched up without

delay using paint.

Suitable

touch-up brushes or sprays for the

c o

lour of your vehicle can be purchased from

authorised SEAT dealers. Note

We recommend you leave paint damage re-

pairs to a SEAT Authorised Service. Plastic parts

Exterior plastic parts will come clean using a

damp cloth. If this is not sufficient, plastic

parts can also be treated with special sol-

vent-free plastic cleaning detergents

.

Do not u

se paint cleaners, polishes or wax on

plastic parts.

Windows and exterior mirrors Remove snow and ice from windows and rear

vision mirrors with a plastic scraper only. To

avoid damaging the surface of the glass, the

scraper should only be pushed in one direc-

tion and not moved to and fro.

The windows should also be cleaned on the

inside at regular intervals.

Use a separate cloth or chamois to dry the

windows and rear vision mirrors.

Do not use the chamois used to polish the

bodywork to dry the windows. Waxing and

polishing residues could cause smears on

the glass and hinder visibility.

CAUTION

● Never use hot or boiling water to remove

snow and ice from the windows. Risk of crack-

ing glass! » 125

Technical specifications

Advice

Operation

Safety

Page 128 of 200

Advice

●

Make sure you do not damage the paint-

work on the vehicle on removing snow and

ice from the windows and rear vision mirrors.

● Do not remove the snow or ice dirty with

thick particles, e.g. gravel, sand or road salt,

from windows and mirrors. Risk of damage to

the glass and mirror surfaces. Radio reception and aerial

In vehicles factory-fitted with an audio or

navigation system, the aerial may be instal-

led in different places:

● inside the rear window next to the heating

elements,

● on the roof of the vehicle.

Headlights Use soap and clean, hot water to clean the

front headlights.

CAUTION

● Never rub the headlights to dry them and

do not use sharp objects to clean the plastic

glass material. These could damage the pro-

tective paint and cause the headlights to

crack. ●

Do not use aggressive cleaning products or

chemical solvents to clean the glass. This

could damage the headlights. Care of rubber seals

The weatherstrips on doors and windows will

remain pliable and last longer if they are oc-

casionally treated with a suitable rubber care

product. This will prevent premature ageing

and leaks. If they are properly cared for, the

seals will be less likely to freeze up in the

winter.

Door lock cylinder Special products must be used to defrost

lock cylinders.

Note

● Make sure, when washing the vehicle, that

the least amount of water possible enters the

lock cylinders.

● We recommend the use of products from

the selection of SEAT Original Accessories to

care for the door lock cylinder. Wheels

Wheel trims

If you wash the vehicle regularly, you should

also thoroughly wash the wheel trim. Regu-

larly remove any brake dust and road salt

from the wheels, otherwise the wheel materi-

al could be damaged. Repair any damage to

the wheel paintwork immediately.

Alloy wheels

After thorough washing, treat the wheels

with a protective product for alloy wheels. Do

not use abrasive products to care for the

wheels.

WARNING

Moisture, ice and road salt may affect braking

efficiency. Risk of accident! CAUTION

Heavy dirt on the wheels could lead to their

misalignment. This could result in vibrations

being transmitted to the steering wheel that

under certain conditions may cause prema-

ture steering wear. This dirt must be re-

moved. Note

We recommend you leave paint damage re-

pairs to a SEAT Authorised Service. 126