check engine SSANGYONG KORANDO 1997 Service Owners Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 405 of 2053

1D2 -- 10 M161 ENGINE COOLING

D AEW OO M Y_2000

Tools Required

124589152100 Tester

Removal & Installation Procedure

1. Drain the coolant.

2. Disconnect the coolant hoses (8, 9, 10).

3. Take off the drive belt.

4. Unscrew the four bolts (6) from water pump pulley

and remove the pulley (7).

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

Notice:Hold the pulley with fan clutch holder 603 589

00 40 00 while removing the pulley.

5. Unscrew the bolts (1, 2, 3, 4) from water pump hous-

ing (5) and remove the water pump.

Installation Notice

Tightening

(1,2,3)9--11NSm

(80 -- 97 lb-in)

Tightening

Torque(4)22.5 -- 27.5 NSm

(16.6 -- 20.3 lb-ft)

6. Clean the sealing surface.

7. Replace the gasket with new one.

Notice:Apply the sealant when the sealing surface of

water pump housing and coolant mounting area is clean.

8. Installation should follow the removal procedure in

the reverse order.

9. Check for leaks by starting the engine.

Page 406 of 2053

M161 ENGINE COOLING 1D2 -- 11

D AEW OO M Y_2000

THERMOSTAT

1 Bolt (M6 X 25, 3 pieces)

9--11 NSm (80-- 97 lb-in) .....................

2 Thermostat Cover

3 De-- aeration Hose4 Coolant Outlet Hose

5 Thermostat

6O--ring

Removal & Installation Procedure

1. Drain the coolant from the radiator.

2. Loosen the hose mounting clip and remove the cool-

ant hose (3, 4).

3. Unscrew the three bolts (1) and remove the thermo-

stat cover assembly from thermostat housing.

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

Do not separate the thermostat cover and thermo-

stat.

4. Replace the O -- ring if necessary.

5. Check the leakage in the cooling system.

Page 408 of 2053

M161 ENGINE COOLING 1D2 -- 13

D AEW OO M Y_2000

Removal & Installation Procedure

1. Drain the coolant.

2. Remove the de-- aeration hose (4), coolant outlet

hose (5) and coolant bypass hose (6).

3. Disconnect the coolant temperature sensor connec-

tor.

4. Unscrew the bolt (1c) and pry off the tensioning de-

vice shock absorber (7).

Installation Notice

Tightening Torque

22.5 -- 27.5 NSm

(16.6 -- 20.3 lb-ft)

5. Unscrow the bolts (1a, 1b) and remove the engine

hanger bracket and thermostat housing.

Installation Notice

Tightening

(1a)9--11NSm

(80 -- 97 lb-in)

Tightening

Torque(1b)22.5 -- 27.5 NSm

(16.6 -- 20.3 lb-ft)

6. Replace the O -- ring with new one.

7. Installation should follow the removal procedure in

the reverse order.

8. Check for leaks in cooling system.

Page 411 of 2053

1D2 -- 16 M161 ENGINE COOLING

D AEW OO M Y_2000

Removal & Installation Procedure

1. Drain coolant from the radiator.

2. Remove the coolant thermo connector from the ra-

diator.

3. Remove the each coolant hoses.

4. Remove the automatic transmission fluid cooler

pipes from radiator.

Installation Notice

Tightening Torque

20 NSm (15 lb-ft)

5. Remove all the bolts (7) from the radiator bracket (9)

and remove the bracket (9) and insulator (8).

Installation Notice

Tightening Torque

3--7NSm (27 -- 62 lb-in)

6. Remove the radiator (10).

7. Check the radiator pin for crack, damage, leakage

and bending and replace it if necessary.

8. Installation is reverse order of removal.

9. Check for leakage in the cooling system.

Page 421 of 2053

1E 2 -- 10 M161 ENGINE ELECTRICAL

D AEW OO M Y_2000

DT1/2 : between No.71 and No.69

Notice:Check the ignition cable and the ECU if out of

the specified value.

3. Measure the secondary cable resistance between the

ignition coil 5a and 5b using a multimeter.

Specified Value

6--8.5kΩ

Page 422 of 2053

M161 ENGINE ELECTRICAL 1E 2 -- 11

D AEW OO M Y_2000

UNIT REPAIR

BATTERY

Inspection

Notice

DWhen charging the battery, do not leave the inflam-

mable objects around it.

DWhen checking the electrolyte of battery, put on an

eye protector and gloves.

1. Inspect the surface of the battery and replace if any

defects were found on it.

2. Check if the specific gravity of the electrolyte is within

the specified value.

Battery capacity(Ah)

90

Battery specific gravity≥1.24

Max. tolerance between cells≥0.04

Notice

DReplace the battery if the maximum tolerance of the

electrolyte between cells is out of the specified value.

DMeasure the specific gravity in the approx. 20°Cof

ambient temperature

3. Replenish the electrolyte if necessary.

Page 423 of 2053

D AEW OO M Y_2000

SECTION 1F2

ENGINE CONTROLS

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless other -

wise noted.

TABLE OF CONTENTS

Engine and ECM Problem Check Report 1F2 -- 2....

Specifications 1F2 -- 3............................

Engine Data Display Table 1F2 -- 3.................

Fastener Tightening Specifications 1F2 -- 4..........

Fuel System Specification 1F2 -- 5.................

Temperature vs Resistance 1F2 -- 5................

Special Tools and Equipment 1F2 -- 6..............

Special Tools Table 1F2 -- 6.......................

Schematic and Routing Diagrams 1F2 -- 7..........

ECM Wiring Diagram

(2.3L DOHC -- MSE 3.53S) 1F2 -- 7..............

Diagnosis 1F2 -- 14................................

Failure Code Diagnosis 1F2 -- 14.....................

Clearing Failure Codes 1F2 -- 14...................

Failure Codes Table 1F2 -- 14.....................

Ignition System 1F2 -- 18...........................

Ignition Coil 1F2 -- 20.............................

Crankshaft Position (CKP) Sensor 1F2 -- 22.........

Camshaft Position (CMP) Sensor 1F2 -- 26..........

Camshaft Actuator 1F2 -- 30......................

Knock Sensor (KS) 1F2 -- 32......................

Spark Plug 1F2 -- 34.............................

System Voltage 1F2 -- 38.........................

Ignition Switch 1F2 -- 39..........................

Fuel System 1F2 -- 40..............................

Fuel Pump 1F2 -- 42.............................

Fuel Injector 1F2 -- 46............................

Purge Control Valve 1F2 -- 50.....................

Fuel Rail 1F2 -- 52...............................

Fuel Pressure Regulator 1F2 -- 54.................

Induction System 1F2 -- 56..........................

Throttle Valve Actuator 1F2 -- 56...................

Hot Film Air Mass (HFM) Sensor 1F2 -- 60..........

Engine Coolant Temperature (ECT) Sensor 1F2 -- 64.

Accelerator Pedal Module 1F2 -- 68................Cooling Fan 1F2 -- 72............................

A/C Compressor Relay 1F2 -- 73...................

Cruise Control Switch 1F2 -- 74....................

Traction Control System (TCS) 1F2 -- 75............

Stop Lamp Switch 1F2 -- 76.......................

Engine RPM 1F2 -- 77............................

Exhaust System 1F2 -- 78...........................

Catalytic Converter 1F2 -- 78......................

Oxygen Sensor 1F2 -- 80.........................

Engine Control Module 1F2 -- 86.....................

Serial Data Communication 1F2--88...............

Internal Failure 1F2 -- 90..........................

Electronic Throttle Controller Safety

Malfunction 1F2 -- 92...........................

Immobilizer 1F2 -- 94.............................

Maintenance and Repair 1F2 -- 95..................

On -- Vehicle Service 1F2 -- 95........................

Discharging the Pressure in Fuel System 1F2 -- 95...

Fuel Pump 1F2 -- 95.............................

Fuel Filter 1F2 -- 96..............................

Fuel Tank 1F2 -- 97..............................

Fuel Pressure Regulator 1F2 -- 98.................

Fuel Rail and Injector 1F2 -- 99....................

Engine Coolant Temperature Sensor 1F2 -- 100......

Throttle Body (Integrated with the

Actuator) 1F2 -- 101............................

Hot Film Air Mass (HFM) Sensor 1F2 -- 102.........

Knock Sensor 1F2 -- 102..........................

Pedal Position Sensor 1F2 -- 103...................

Oxygen Sensor 1F2 -- 103........................

Purge Control Valve 1F2 -- 104....................

Canister 1F2 -- 104...............................

Camshaft Position Sensor 1F2 -- 104...............

Crankshaft Position Sensor 1F2 -- 105..............

Engine Control Module 1F2 -- 105..................

Page 424 of 2053

1F2 -- 2 M161 ENGINE CONTROLS

D AEW OO M Y_2000

ENGINE AND ECM PROBLEM CHECK REPORT

VEHICLE AND CUSTOMER INFORMATION

Date problem Occurred

Customer NameVehicle Model

Driver NameVIN

Purchase dateEngine Model

License No.MileageKm

miles

MIL INFORMATION

Condition of MILjRemains onjSometimes illuminatesjDoes not illuminate

DTC inspection

(if available)jNormaljMalfunction code(s) (code )

jFreezed frame data ( )

PROBLEM DESCRIPTION

jEngine Does Not StartjNo crankingjNo initial combustionjNo complete combustion

jHard to StartjSlow cranking

jOthers

jPoor IdlingjIncorrect first IdlejAbnormal idle rpmjHigh (rpm)jLow (rpm)

jIdling UnstablejOthers

jPoor DriveabilityjHesitationjBack firejMuffler explosion (after-burning)

jSurgingjKnockingjPoor performancejOther

jEngine StalljSoon after startingjAfter accelerator pedal depressed

jAfter accelerator pedal releasedjDuring A/C operation

jShifting from N to D or D to N

jAt full steeringjOthers

jOthers

CONDITION WHEN PROBLEM OCCURS

Problem FrequencyjConstantjIntermittent (times per day/month)jOnce onlyjOthers

WeatherjFinejCloudyjRainyjSnowyjVarious/Others

Ambient TemperaturejHotjWar mjCooljCold (approx.____°F/____°C)

PlacejHighwayjSuburbsjInner CityjUphilljDownhill

jRough RoadjOthers

Engine TemperaturejColdjWarming UpjBefore warming upjAfter warm-up

jAny temp.jOthers

Engine OperationjStartingjJust after starting (min.)jIdlingjRacingjDriving

jConstant speedjAccelerationjDeceleration

jA/C switch ON/OFFjOther

Page 436 of 2053

1F2 -- 14 M161 ENGINE CONTROLS

D AEW OO M Y_2000

DIAGNOSIS

FAILURE CODE DIAGNOSIS

CLEARING FAILURE CODES

Notice:To prevent Engine Control Module (ECM) damage, the key must be OFF when disconnecting or reconnecting

the power to the ECM (for example battery cable, ECM pigtail connector, ECM fuse, jumper cables, etc.)

Parameters listed in the table may not be exactly the same as your reading due to the type of instrument or other

factors. If a failure code is displayed during the “TROUBLE CODE” in scan tool check mode, check the circuit for the

code listed in the table below. For details of each code, turn to the page referred to under the “See Page” for the re-

spective “Failure Code” in the below table.

Failure codes should be cleared after repairs have been completed.

FAILURE CODES TABLE

Failure

codeSee

PageDescription

001F2 -- 66Engine coolant temperature sensor low voltage

011F2 -- 66Engine coolant temperature sensor high voltage

021F2 -- 66Engine coolant temperature sensor plausibility

031F2 -- 62Intake air temperature sensor low voltage

041F2 -- 62Intake air temperature sensor high voltage

051F2 -- 62Intake air temperature sensor plausibility

061F2 -- 66Engine coolant temperature insufficient for closed loop fuel control

081F2 -- 38System voltage too low

091F2 -- 62Mass air flow sensor plausibility

101F2 -- 62Mass air flow sensor low voltage

111F2 -- 62Mass air flow sensor high voltage

171F2 -- 23Crankshaft position sensor signal failure (no engine revolution signal)

181F2 -- 23Crankshaft position sensor signal failure (rpm > max. value)

191F2 -- 27Camshaft position senosr signal : No.1 cylinder recognition failure

201F2 -- 23Crankshaft position sensor signal failure (gap recognition failure)

211F2 -- 90Transmission coding failure

231F2 -- 88CAN communication failure : ASR/MSR

241F2 -- 88CAN communication failure : ABS

251F2 -- 94Communication with transponder missing

261F2 -- 88CAN communication failure : TCU (A/T only)

291F2 -- 89CAN communication failure : ID 200h not plausible

301F2 -- 89CAN communication failure : ID 208h not plausible

311F2 -- 89CAN communication failure : communication initialization failure

321F2 -- 77Engine rpm output circuit short circuit to battery

331F2 -- 77Engine rpm output circuit short circuit to ground or open

341F2 -- 43Fuel pump relay short circuit to battery

351F2 -- 43Fuel pump relay short circuit to ground or open

Page 444 of 2053

1F2 -- 24 M161 ENGINE CONTROLS

D AEW OO M Y_2000

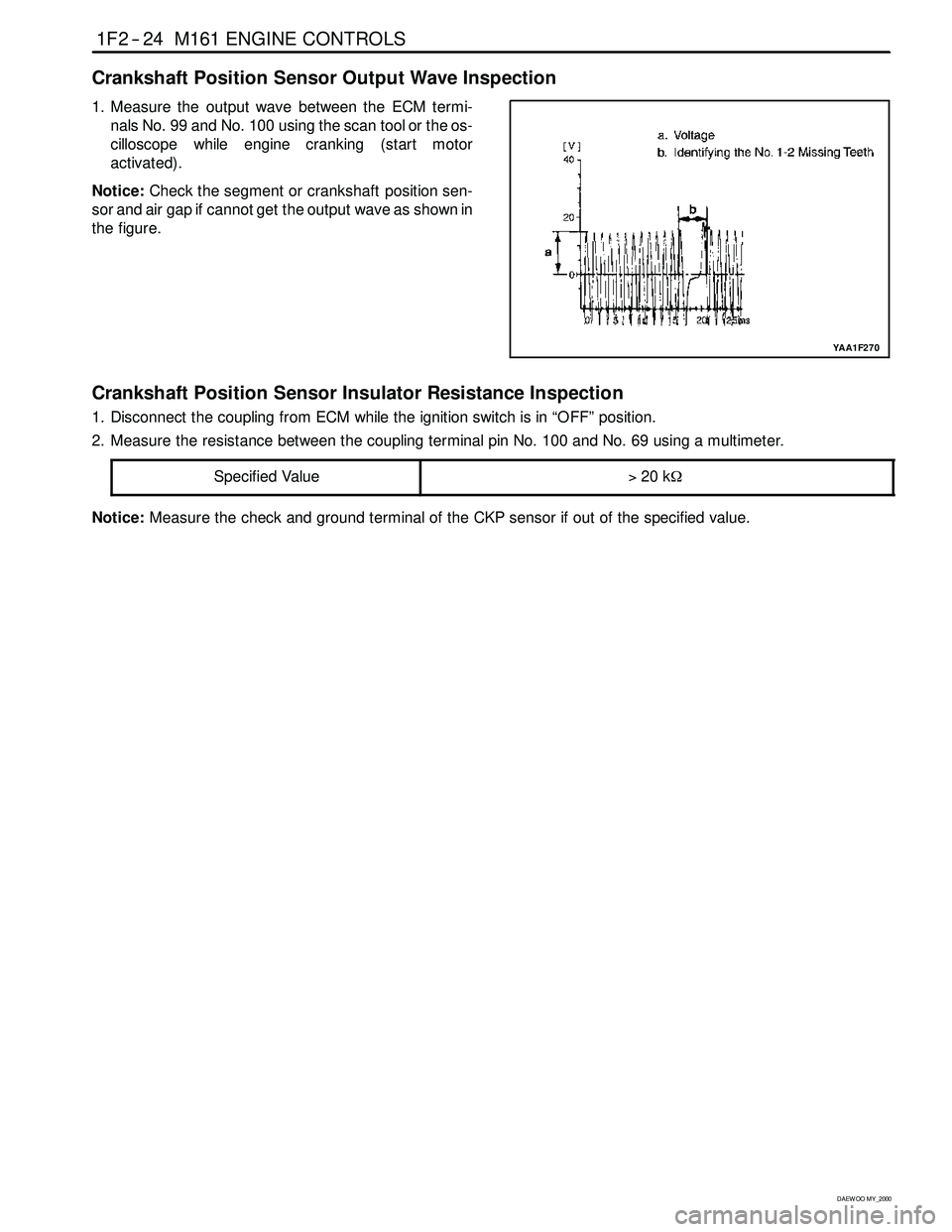

Crankshaft Position Sensor Output Wave Inspection

1. Measure the output wave between the ECM termi-

nals No. 99 and No. 100 using the scan tool or the os-

cilloscope whileengine cranking (start motor

activated).

Notice:Check the segment or crankshaft position sen-

sor and air gap if cannot get the output wave as shown in

the figure.

YAA1F270

Crankshaft Position Sensor Insulator Resistance Inspection

1. Disconnect the coupling from ECM while the ignition switch is in “OFF” position.

2. Measure the resistance between the coupling terminal pin No. 100 and No. 69 using a multimeter.

Specified Value

>20 kΩ

Notice:Measure the check and ground terminal of the CKP sensor if out of the specified value.