SSANGYONG KORANDO 1997 Service Repair Manual

KORANDO 1997

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57502/w960_57502-0.png

SSANGYONG KORANDO 1997 Service Repair Manual

Trending: Idle control, overheating, child lock, OBD port, high beam, key, checking oil

Page 991 of 2053

SSANGYONG MY2002

4F-8 ABS AND TCS

1 Master Cylinder

2 Hydraulic Modulator

3 Damper

4 Pump

5 Pump Motor

HYDRAULIC CIRCUIT

ABS 5.3

Pressure Increased

KAA4F040

6 Accumulator

7 Inlet Valve for Each Wheel

8 Outlet Valve for Each Wheel

9 Front Wheel

10 Rear Wheel

Page 992 of 2053

ABS AND TCS 4F-9

SSANGYONG MY2002

Pressure Maintained

1 Master Cylinder

2 Hydraulic Modulator

3 Damper

4 Pump

5 Pump Motor

KAA4F050

6 Accumulator

7 Inlet Valve for Each Wheel

8 Outlet Valve for Each Wheel

9 Front Wheel

10 Rear Wheel

Page 993 of 2053

SSANGYONG MY2002

4F-10 ABS AND TCS

Pressure Maintained

1 Master Cylinder

2 Hydraulic Modulator

3 Damper

4 Pump

5 Pump Motor

KAA4F060

6 Accumulator

7 Inlet Valve for Each Wheel

8 Outlet Valve for Each Wheel

9 Front Wheel

10 Rear Wheel

Page 994 of 2053

ABS AND TCS 4F-11

SSANGYONG MY2002

1 Master Cylinder

2 Hydraulic Modulator

3 Damper

4 Pump

5 Pump Motor

6 Accumulator

7 Inlet Valve for Each Wheel

ABS/TCS 5.3

Pressure Increased

KAA4F070

8 Outlet Valve for Each Wheel

9 Wheel

10 Prime Valve

11 Pilot Valve

12 Check Valve

13 ISD (Integrated Suction Damper)

Page 995 of 2053

SSANGYONG MY2002

4F-12 ABS AND TCS

Pressure Maintained

1 Master Cylinder

2 Hydraulic Modulator

3 Damper

4 Pump

5 Pump Motor

6 Accumulator

7 Inlet Valve for Each Wheel

KAA4F080

8 Outlet Valve for Each Wheel

9 Wheel

10 Prime Valve

11 Pilot Valve

12 Check Valve

13 ISD (Integrated Suction Damper)

Page 996 of 2053

ABS AND TCS 4F-13

SSANGYONG MY2002

Pressure Decreased

1 Master Cylinder

2 Hydraulic Modulator

3 Damper

4 Pump

5 Pump Motor

6 Accumulator

7 Inlet Valve for Each Wheel

KAA4F090

8 Outlet Valve for Each Wheel

9 Wheel

10 Prime Valve

11 Pilot Valve

12 Check Valve

13 ISD (Integrated Suction Damper)

Page 997 of 2053

SSANGYONG MY2002

4F-14 ABS AND TCS

COMPONENT LOCATOR

ABS, ABS/TCS 5.3

1 ABS/TCS Hydraulic Unit

(with EBCM in case of ABS only)

2 ABS/TCS EBCM Unit (in case of TCS)

3 Rear Wheel Speed Sensor

KAA4F100

4 ABS Warning Indicator Light

5 Diagnosis Connector

6 Front Wheel Speed Sensor

7 Acceleration Sensor

Page 998 of 2053

ABS AND TCS 4F-15

SSANGYONG MY2002

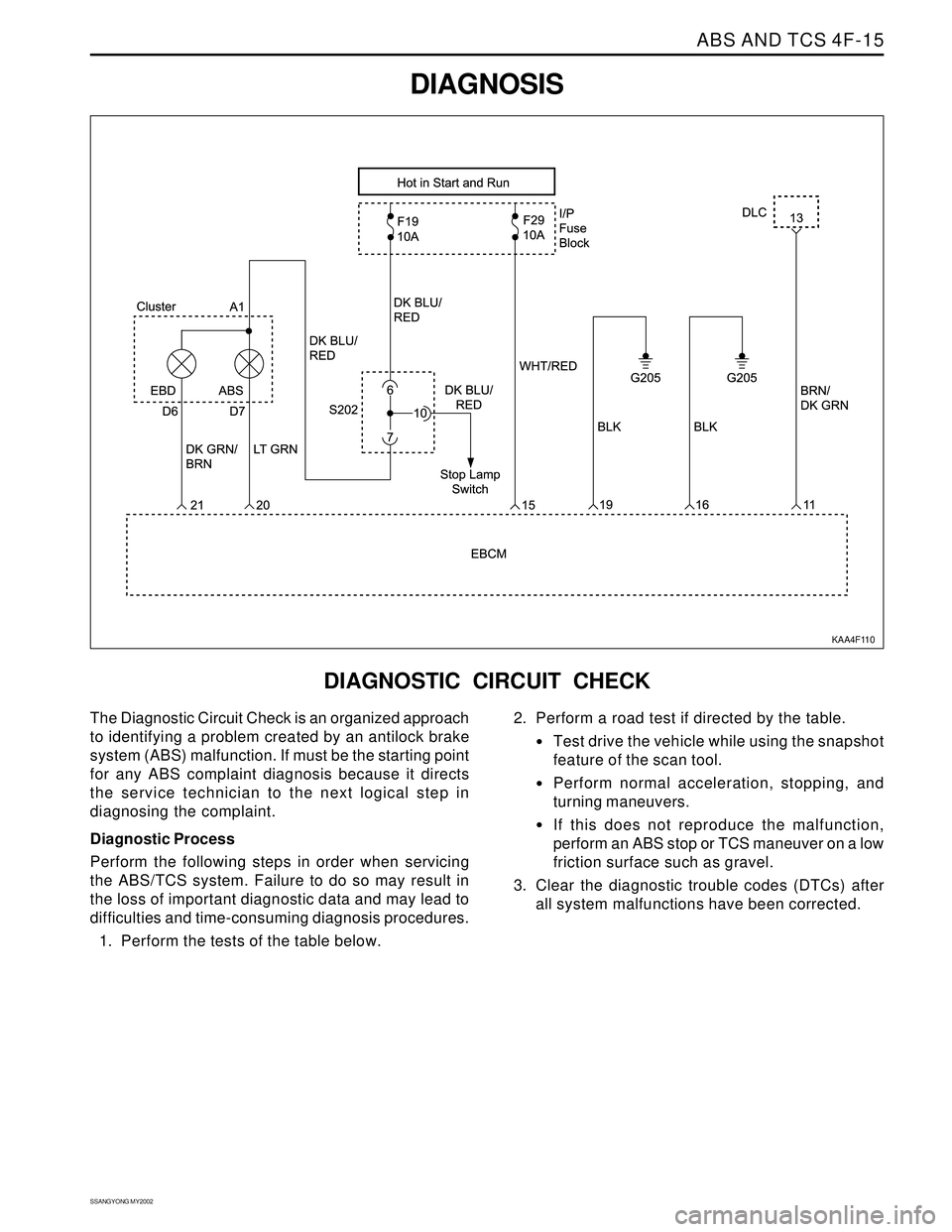

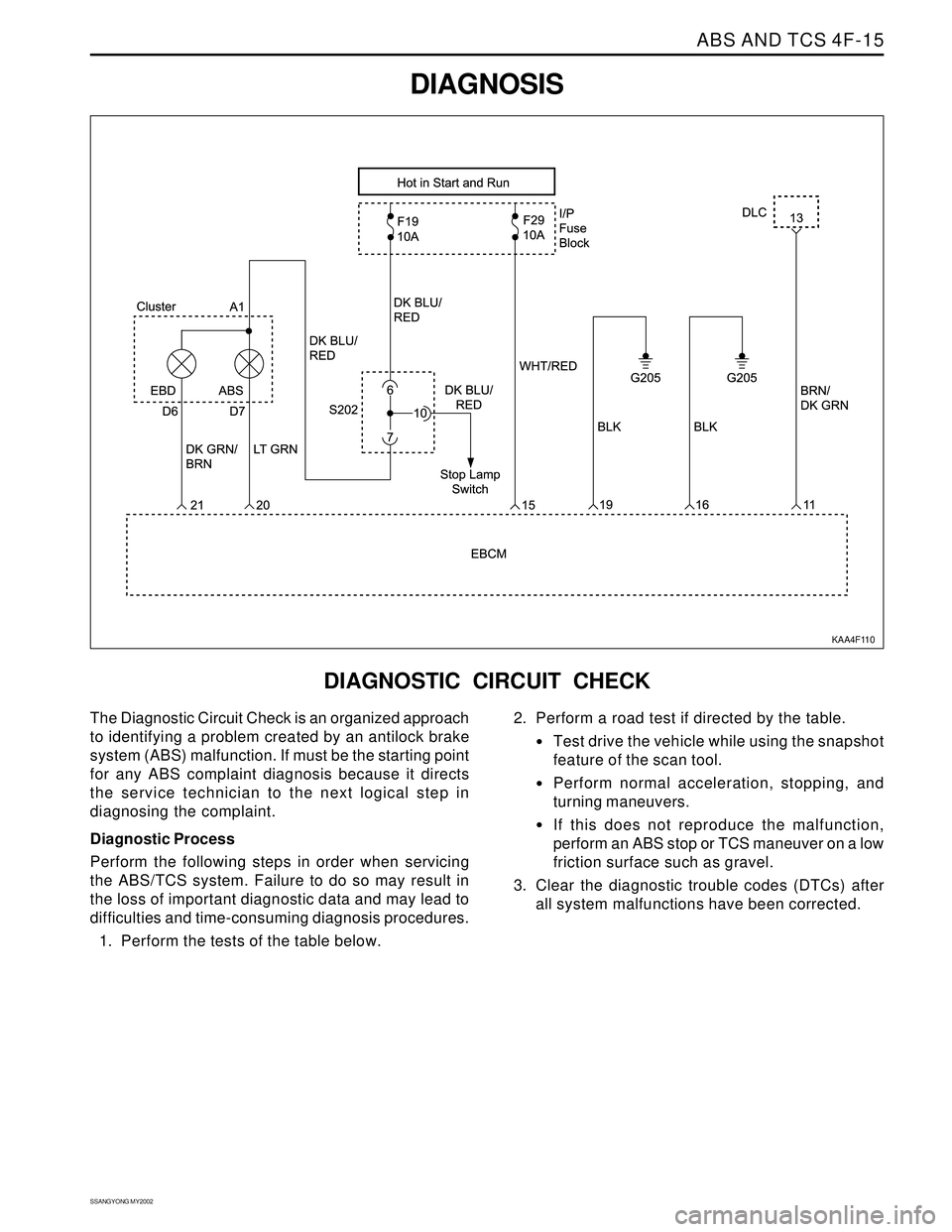

DIAGNOSIS

KAA4F110

DIAGNOSTIC CIRCUIT CHECK

The Diagnostic Circuit Check is an organized approach

to identifying a problem created by an antilock brake

system (ABS) malfunction. If must be the starting point

for any ABS complaint diagnosis because it directs

the service technician to the next logical step in

diagnosing the complaint.

Diagnostic Process

Perform the following steps in order when servicing

the ABS/TCS system. Failure to do so may result in

the loss of important diagnostic data and may lead to

difficulties and time-consuming diagnosis procedures.

1. Perform the tests of the table below.2. Perform a road test if directed by the table.

Test drive the vehicle while using the snapshot

feature of the scan tool.

Perform normal acceleration, stopping, and

turning maneuvers.

If this does not reproduce the malfunction,

perform an ABS stop or TCS maneuver on a low

friction surface such as gravel.

3. Clear the diagnostic trouble codes (DTCs) after

all system malfunctions have been corrected.

Page 999 of 2053

SSANGYONG MY2002

4F-16 ABS AND TCS

1. Install the scan tool.

2. Turn ignition switch to ON.

3. Select the Data List mode.

Is the scan tool receiving data from the electronic

brake control module (EBCM)?

Check the display.

Are there any current DTCs displayed?

1. Turn the ignition to LOCK for 10 seconds.

2. Turn the ignition to ON and observe the ABS

indicator.

Does the indicator light for 2 seconds and then go off?

Check the ABS indicator.

Did the ABS indicator turn on and stay on?

Check whether the vehicle is equipped with traction

control.

Is the vehicle equipped with traction control?

1. Turn the ignition to LOCK for 10 seconds.

2. Turn the ignition to ON and observe the TCS

indicator.

Does the indicator light for 2 seconds and then go off?

1. Turn the ignition to LOCK.

2. Disconnect the EBCM harness connector.

3. Turn the ignition to ON.

4. Use a digital voltmeter (DVM) to measure the

voltage from ground to terminal 1 and 50 of the

EBCM harness connector.

Is the voltage equal to the specified value?

1. Turn the ignition to LOCK.

2. Use a DVM to measure the resistance from the EBCM

harness connector, terminals 28 and 29 to ground.

Is the resistance equal to the specified value?

Repair the open in the circuit that failed.

Is the repair complete?

Use a DVM to measure the resistance between

terminal 46 of the EBCM harness connector and

terminal 8 of the data link connector (DLC).

Is the resistance below the specified value?

Replace the ABS unit.

Is the repair complete?

Repair the open or high resistance in circuit BrG

between terminal 11 of the EBCM harness connector

and terminal 13 of the DLC.

Is the repair complete?

Perform the road test described above.

Are any DTCs set? Step

1

2

3

4

5

6

7

8

9

10

11

12

13

Diagnostic Circuit Check

Action Yes

Go to Step 2

Refer to the

applicable DTC

table

Go to Step 5

Go to “ABS

Indicator Lamp

Illuminated

Constantly”

Go to Step 6

Go to Step 13

Go to Step 8

Go to Step 10

System OK

Go to Step 11

System OK

Go to Step 1

Go to the table

for the DTCNo

Go to Step 7

Go to Step 3

Go to Step 4

Go to

“ABS Indicator

Lamp Inopera-

tive

Go to Step 13

Go to “Traction

Control System

Indicator Lamp

Inoperative”

Go to “Power

Supply to

Control Mod-

ule, No DTCs

Stored

Go to Step 9

-

Go to Step 12

-

-

System OK Value(s)

-

-

-

-

-

-

11 - 14 v

≈ 0 Ω

-

2 Ω

-

-

-

Page 1000 of 2053

ABS AND TCS 4F-17

SSANGYONG MY2002

BLANK

Trending: water pump, high beam, overheating, engine oil capacity, maintenance, warning lights, refrigerant type