SSANGYONG KORANDO 1997 Service Repair Manual

Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 981 of 2053

REAR BRAKES 4E-21

SSANGYONG MY2002

7. Connect the brake pipe to the wheel cylinder.

Installation Notice

Tightening Torque15 - 19 Nm

(11 - 14 lb-ft)

8. Bleed the brake system and verify the parking

brake operation.

Install the tire.

YAD4C450

Page 982 of 2053

SSANGYONG MY2002

4E-22 REAR BRAKES

UNIT REPAIR

WHEEL CYLINDER

Disassembly Procedure

1. Remove the upper brake return spring and remove

the wheel cylinder with pulling the upper lining

outside.

2. Disassembly the wheel cylinder assembly.

Remove the dust boot and do not reuse them

(1).

Remove the piston (2).

Remove the piston cup and do not reuse it (3).

Remove the spring assembly (4).

Remove the bleeder screw (5).

3. Clean all the parts with the denatured alcohol. Dry

the parts with unlubricated compressed air.

Bleeder Screw7 - 10 Nm

(62 - 89 lb-in)

8 - 12 Nm

(71 - 106 lb-in)

Wheel Cylinder

Mounting Bolt

Notice: Lubricate the new seals, the piston, the

piston cup and the wheel cylinder bore with clean

brake fluid before assembly. 4. Installation should follow the removal procedure

in the reverse order.

5. Tighten the bleeder screw and wheel cylinder as

specified torque.

YAD4C460

YAD4C470

YAD4C480

Page 983 of 2053

REAR BRAKES 4E-23

SSANGYONG MY2002

2. Pull out the lever pin (arrow) and Disconnect the

the parking brake lever and the adjuster lever.

3. Installation should follow the removal procedure

in the reverse order.

YAD4C500

PARKING BRAKE LEVER

1. Disconnect the parking brake lever and the

adjuster lever from the lining.

YAD4C490

Page 984 of 2053

SSANGYONG MY2002

4E-24 REAR BRAKES

14

20

70

- Brake Hose Bolt

Caliper Guide Bolt

Caliper Mounting Bolts

Splash Shield-to-Knuckle BoltsN•m Application

Lb-In

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

Lb-Ft

19

27

95

6-

-

-

53

Page 985 of 2053

SECTION 4F

ANTILOCK BRAKE SYSTEM AND

TRACTION CONTROL SYSTEM

TABLE OF CONTENTS

General Description and System Opertion..........4F-3

Basic Knowledge Required...................................4F-3

ABS System Components...................................4F-3

Traction Control System (TCS) Description...........4F-3

EBD System........................................................4F-5

EBD Failure Matrix...............................................4F-6

Tires and ABS/TCS..............................................4F-7

Hydraulic Circuit...................................................4F-8

ABS 5.3...............................................................4F-8

ABS/TCS 5.3.....................................................4F-11

Component Locator...........................................4F-14

ABS, ABS/TCS 5.3............................................4F-14

Diagnosis............................................................4F-15

Diagnostic Circuit Check....................................4F-15

ABS Indicator Lamp Inoperative.........................4F-18

Traction Control System (TCS) Indicator Lamp

Inoperative.....................................................4F-22

EBD Indicator Lamp Inoperative.........................4F-26

Power Supply to Control Module,

No DTCs Stored..............................................4F-30

ABS Indicator Lamp Illuminated Continuously,

No DTCs Stored..............................................4F-34

Self-Diagnostics................................................4F-36

Displaying DTCs................................................4F-36

Clearing DTCs...................................................4F-36

Intermittents and Poor Connections....................4F-36

DTC 03 - Left Front Wheel Speed Sensor Fault ...4F-38

DTC 07 - Left Front Wheel Speed Sensor

Continuity Fault...............................................4F-40

DTC 04 - Right Front Wheel Speed Sensor

Fault...............................................................4F-42DTC 08 - Right Front Wheel Speed Sensor

Continuity Fault...............................................4F-44

DTC 05 - Left Rear Wheel Speed Sensor Fault....4F-46

DTC 09 - Left Rear Wheel Speed Sensor

Continuity Fault...............................................4F-48

DTC 06 - Right Rear Wheel Speed Sensor Fault .4F-50

DTC 10 - Right Rear Wheel Speed Sensor

Continuity Fault...............................................4F-52

DTC 11 - Wheel Speed Sensor Frequency Error ..4F-54

DTC 42 - Acceleration Sensor Fault....................4F-58

DTC 43 - Acceleration Sensor Continuity Fault.....4F-60

DTC 13/14 - Left Front Inlet and Outlet Valve

Solenoid Fault.................................................4F-62

DTC 15/16 - Right Front Inlet and Outlet Valve

Solenoid Fault.................................................4F-64

DTC 17/18 - Left Rear Inlet and Outlet Valve

Solenoid Fault.................................................4F-66

DTC 19/20 - Right Rear Inlet and Outlet Valve

Solenoid Fault.................................................4F-68

DTC 21/22 - Left Rear Prime Line and Traction

Control System (TCS) Pilot Valve Fault............4F-70

DTC 23/24 - Right Rear Prime Line and Traction

Control System (TCS) Pilot Valve Fault............4F-72

DTC 12 - Valve Relay Circuit Fault......................4F-74

DTC 24 - Pump Motor or Pump Motor

Relay Fault.....................................................4E-76

DTC 27 - Stoplamp Switch Fault.........................4E-80

DTC 28 - Low Voltage Fault................................4E-84

DTC 02 - ABS Control Module Internal Fault........4E-88

Scheatic and Routing Diagrams........................4E-90

ABS Circuit (Without TCS): Gasoline...................4E-90

ABS/TCS Circuit: Gasoline.................................4E-91

ABS/ABD (Automatic Brake

Differential Lock): Diesel.................................4E-93

Page 986 of 2053

EBCM Connection Fact View.............................4E-95

EBCM Connector...............................................4E-95

Hydraulic Modulator Connector..........................4E-96

Repair Instructions..............................................4E-99

On-Vehicle Service...............................................4E-99

Service Precautions...........................................4E-99

ABS 5.3 Assembly..........................................4E-100

ABS/TCS Unit..................................................4E-100

Front Wheel Speed Sensor..............................4E-101Rear Wheel Speed Sensor...............................4E-101

Acceleration Sensor .........................................4E-102

System Fuse...................................................4E-102

Indicators........................................................4E-102

Unit Repair........................................................4E-103

ABS Front Tooth Wheel....................................4E-103

Special Tools and Equipment..........................4E-104

Special Tools Table..........................................4E-104

Page 987 of 2053

ABS AND TCS 4F-3

SSANGYONG MY2002

GENERAL DESCRIPTION AND SYSTEM OPERATION

BASIC KNOWLEDGE REQUIRED

Before using this section, it is important that you have

a basic knowledge of the following items. Without this

knowledge, it will be difficult to use the diagnostic

procedures contained in this section.

•Basic Electrical Circuits - You should understand

the basic theory of electricity and know the meaning

of voltage, current (amps), and resistance (ohms).

You should understand what happens in a circuit

with an open or shorted wire. You should be able to

read and understand a wiring diagram.

Use of Circuit Testing Tools - You should know

how to use a test light and how to bypass

components to test circuits using fused jumper

wires. You should be familiar with a digital

multimeter. You should be able to measure voltage,

resistance, and current, and be familiar with the

controls and how to use them correctly.

ABS SYSTEM COMPONENTS

The ABS 5.3 Antilock Braking System (ABS) consists

of a conventional hydraulic brake system plus antilock

components. The conventional brake system includes

a vacuum booster, master cylinder, front disc brakes,

rear disc brakes, interconnecting hydraulic brake pipes

and hoses, brake fluid level switch and the BRAKE

indicator.

The ABS components include a hydraulic unit, an elec-

tronic brake control module (EBCM), two system fuses,

four wheel speed sensors (one at each wheel), intercon-

necting wiring, the ABS indicator, the EBD indicator

and the TCS indicator. See “ABS Component Locator”

in this section for the general layout of this system.

The hydraulic unit with the attached EBCM is located

between the surge tank and the bulkhead on the left

side of the vehicle.

The basic hydraulic unit configuration consists of hy-

draulic check valves, two solenoid valves for each

wheel, a hydraulic pump, and two accumulators. The

hydraulic unit controls hydraulic pressure to the front

calipers and rear calipers by modulating hydraulic

pressure to prevent wheel lockup.

Units equipped with TCS add two more valves for each

drive wheel for the purpose of applying the brake to a

wheel that is slipping. This is done with pressure from

the hydraulic pump in the unit. There is also a TCS

indicator lamp on the instrument panel to alert the driver

to the fact that the TCS system is active. The

components identified in the drawing are those added

to the basic ABS 5.3 system to provide traction control.

Nothing in the hydraulic unit or the EBCM is serviceable.

In the event of any failure, the entire ABS unit withattached EBCM must be replaced. For more

information, refer to “Base Braking Mode” and

“Antilock Braking Mode” in this section.

TRACTION CONTROL SYSTEM

(TCS) DESCRIPTION

General Information

The traction control system (TCS) is a traction system

by means of brake intervention only, available in a low

speed range (< 60kph).

It workes on µ - split roads with sidewise different friction

coefficients.

The spinning driven wheel is braked and the drive

torque can be transferred to the wheel on the high-µ

side. During TCS active, the TCS information lamp is

blinking.

The temperature of the brakes is calculated by a mathe-

matical model and TCS is switched passive if the calcu-

lated temperature is greater than a threshold value (500

°C).

TCS is permitted again, when the calculated tempera-

ture is less than 350 °C.

Control Algorithm

The input signals for the control algorithm are the

filtered wheel speed signals from the ABS speed

processing.

With the speed difference of the driven wheels, the

control deviation is calculated.

If the control deviation exceeds a certain threshold

value, the wheel with the greater slip is braked actively.

The threshold value depends on the vehicle speed:

It is reduced with increasing vehicle speed down to a

constant value.

KAA4F010

Page 988 of 2053

SSANGYONG MY2002

4F-4 ABS AND TCS

Pressure Modulation

Depending on the control deviation and the wheel accel-

eration of the spinning wheel, pressure increase, hold

and decrease are made.

The pressure modulation is done with the conventional

control with the valves. Prime valve, pilot valve, inlet

valve and outlet valve according to the following table:

Speed Range

TCS is available in the speed range ≤ 60 kph.

Above 60 kph vehicle speed, TCS is passive.

It is possible to initiate TCS operation up to a vehicle

speed of 55 kph.

Prime Valve

Pilot Valve

Inlet Valve

Outlet Valve

Increase

Open

Closed

Open

ClosedHold

Open

Closed

Closed

ClosedDecrease

Open

Closed

Closed

Open

System Failure (EBD,

ABS or TCS are Not

Distinguished)

ABS Warning

LampIgnition ONABS

OperationTCS

OperationTCS Passive Due to

Temperature Model

2 second on

for lamp

checkOFF OFF ON OFF

TCS Info

Lamp2 second on

for lamp

checkOFFBlinking

(FLASHING)OFF ON

EBD Warning

Lamp2 second on

for lamp

checkEBD

operation/OFFOFF ON OFF

Temperature Model

TCS operation is a high thermal load for the brakes.

To avoid any damages at the brakes, the disk tempera-

ture is calculated with a mathematical model for each

driven wheel separately. After ignition on, the

calculation starts with 30°C and then three different

phases are evaluated separately and added:

TCS operation, braking and coling phase.

If the temperature is highter than 500°C, TCS is dis-

abled for this wheel.

It is permitted again, if the model has calculated down

the 350°C.

Lamp Concepts

The system is equipped with an TCS information lamp,

which is blinking during TCS operation.

The activation of the EBD, TCS warning lamp and the

TCS info lamp issummarized in thefollowing table:

Page 989 of 2053

ABS AND TCS 4F-5

SSANGYONG MY2002

EBD (ELECTRONIC BRAKE

FORCE DISTRIBUTION) SYSTEM

System Description

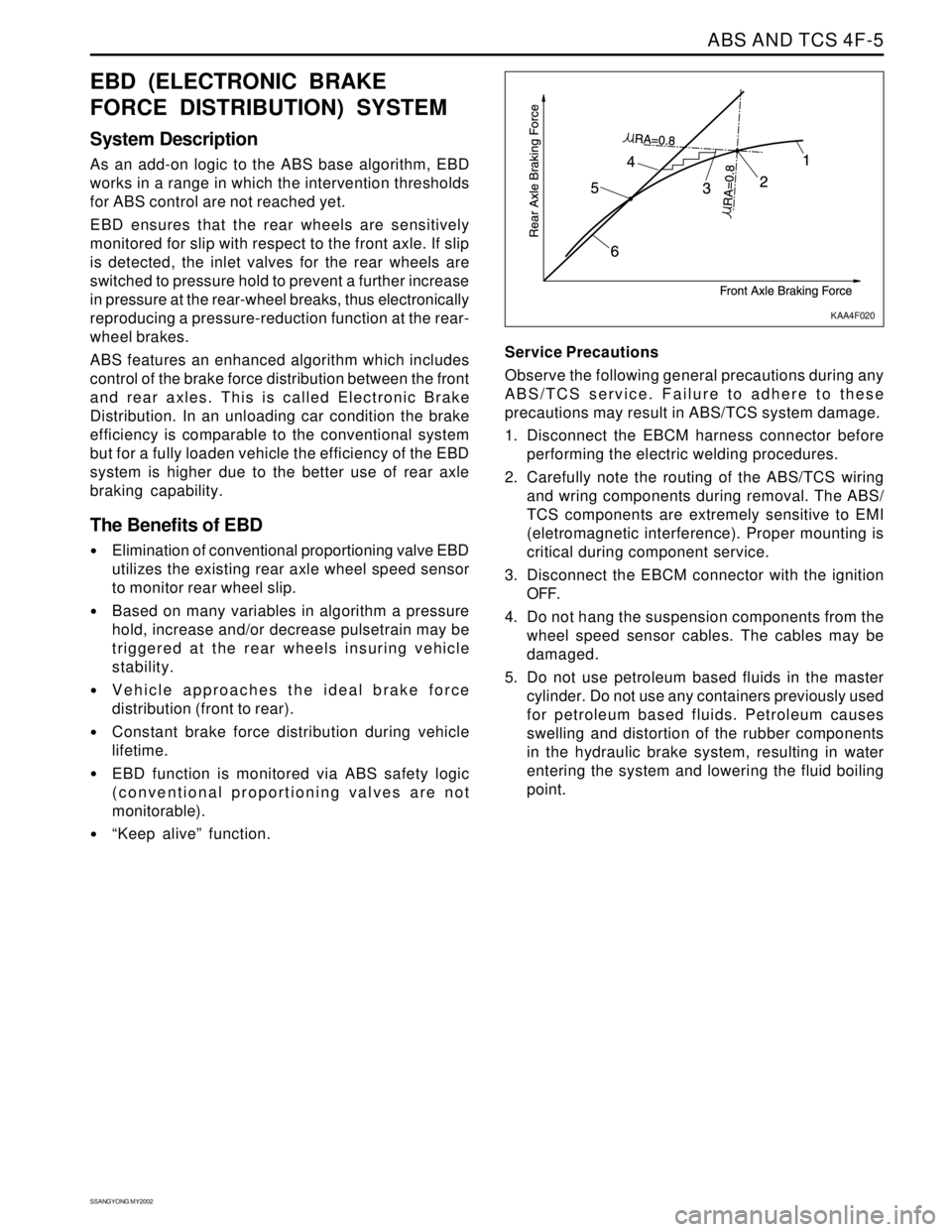

As an add-on logic to the ABS base algorithm, EBD

works in a range in which the intervention thresholds

for ABS control are not reached yet.

EBD ensures that the rear wheels are sensitively

monitored for slip with respect to the front axle. If slip

is detected, the inlet valves for the rear wheels are

switched to pressure hold to prevent a further increase

in pressure at the rear-wheel breaks, thus electronically

reproducing a pressure-reduction function at the rear-

wheel brakes.

ABS features an enhanced algorithm which includes

control of the brake force distribution between the front

and rear axles. This is called Electronic Brake

Distribution. In an unloading car condition the brake

efficiency is comparable to the conventional system

but for a fully loaden vehicle the efficiency of the EBD

system is higher due to the better use of rear axle

braking capability.

The Benefits of EBD

Elimination of conventional proportioning valve EBD

utilizes the existing rear axle wheel speed sensor

to monitor rear wheel slip.

Based on many variables in algorithm a pressure

hold, increase and/or decrease pulsetrain may be

triggered at the rear wheels insuring vehicle

stability.

Vehicle approaches the ideal brake force

distribution (front to rear).

Constant brake force distribution during vehicle

lifetime.

EBD function is monitored via ABS safety logic

(conventional proportioning valves are not

monitorable).

“Keep alive” function.Service Precautions

Observe the following general precautions during any

ABS/TCS service. Failure to adhere to these

precautions may result in ABS/TCS system damage.

1. Disconnect the EBCM harness connector before

performing the electric welding procedures.

2. Carefully note the routing of the ABS/TCS wiring

and wring components during removal. The ABS/

TCS components are extremely sensitive to EMI

(eletromagnetic interference). Proper mounting is

critical during component service.

3. Disconnect the EBCM connector with the ignition

OFF.

4. Do not hang the suspension components from the

wheel speed sensor cables. The cables may be

damaged.

5. Do not use petroleum based fluids in the master

cylinder. Do not use any containers previously used

for petroleum based fluids. Petroleum causes

swelling and distortion of the rubber components

in the hydraulic brake system, resulting in water

entering the system and lowering the fluid boiling

point.

KAA4F020

Page 990 of 2053

SSANGYONG MY2002

4F-6 ABS AND TCS

EBD (Electronic Brake-Force Distribution) FAILURE MATRIX

KAA4F030